Professional Documents

Culture Documents

Mie Hse Jha 002 - Welding, Cutting, Fabrication Work

Uploaded by

Luqman OsmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mie Hse Jha 002 - Welding, Cutting, Fabrication Work

Uploaded by

Luqman OsmanCopyright:

Available Formats

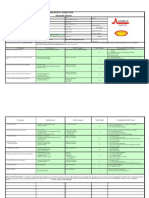

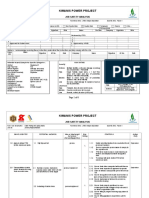

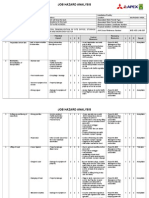

JOB HAZARD ANALYSIS

HOW TO USE THIS FORM :

1) Crew performing task reviews ALL generic JHA considerations.

2) Review previous JHA update(s) for useful information which will help this task.

3) Create new JHA update with generic form and ALL considerations for this task.

4) Carry out task as per plan. If any conditions change ---STOP & RE-ASSESS.

5) File JHA update for future reference.

Installation/Facility

Location

Associated Work Permit Type

Associated Work Permit Number

Electrical Isolation Certificate Number

Physical Isolation Certificate Number

WORK ACTIVITY

JHA Cross-Reference Number

Job

Step

Description of

Job Step

Preparation before task

Loading & unloading

equipment

- Mechanical lifting

WELDING, CUTTING, FABRICATION WORK

Potential

Hazards

Potential

Impact

Control

Measures

- Lack in communication - Wrong information

& information

- Emergency event

- Permit application and valid

prior to work

- Safety briefing during toolbox

meeting or before starting

work as necessary

- Proper planning prior to work

- Workers are observed Rules &

Regulation on site through

HSE Induction

- Falling object

- Physical injury

- Property damage

- Miscommunication

during activity

- Physical injury

- Property damage

- Sharp object

- Physical injury

Recovery

Measures

MIE-HSE-JHA-002

Result

- Report to MIE

Management Rep.

- Report incident to

consortium

Acceptable

- Cordon off working area with

barricade & proper signage

- Work leader to prevent

unauthorized entry during lifting

- Trained rigger and signalman

to give signal during activity

- Use enough manpower to

handle the task

- Follow safe work method

for lifting activity

- Report to MIE

Management Rep.

-Report incident to

consortium

-To contact nearest

first aider on site

- Trained rigger and signalman

to give signal during activity

- Secure/covered any sharp

object

- Wear proper PPE (safety

gloves)

- Report to MIE

Management Rep.

-Report incident to

consortium

-To contact nearest

first aider on site

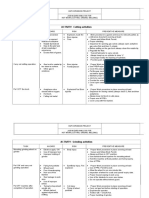

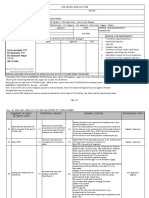

JOB HAZARD ANALYSIS

- Manual lifting

Cutting & grinding work

(grinder or high speed

cutter)

- Ergonomic

- Physical injury

- Potential for back, hand

and foot injury

- Briefing during toolbox /

before start work

- Proper body positioning

- Practice buddy system during

activity

- Use proper method to lift

material

- Report to MIE

Management Rep.

-Report incident to

consortium

-To contact nearest

first aider on site

- Sharp object

- Physical injury

- Secure/covered any sharp

object

- Wear proper PPE (safety

gloves)

- Report to MIE

Management Rep.

-Report incident to

consortium

-To contact nearest

first aider on site

- Rupture disk

- Physical injury

- Ensure the disc must have the

durability more than an

equipment

- Scrutiny by work leader

- Equipment must be inspected

- Ensure each rotating equipment

should equipped with guarding

- Proper PPE (Face shield, hand

glove)

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Tolerable

- Spark

- Property damage

- Personal injury

- Ensure that the working areas

are free from combustible and

flammable substance

- Use adequate fire blanket

- Fire extinguisher is always

available and fit to use

- Signage for hot work area

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Flying object / particles

- Eye Injury

- Proper PPE (face shield)

- Proper handling the tools

- Trained person to carry out

the task

Acceptable

- Exposure to excessive

noise

- Hearing impairment

- Wear hearing protection

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Sharp object

- Physical injury

- Eliminate/secure any sharp

object

Acceptable

- Hot Surface

- Hand Injury

- Wear proper PPE ( leather

glove)

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

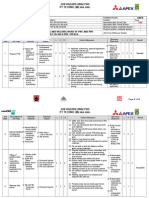

JOB HAZARD ANALYSIS

Drilling work

Welding work

- Cable management

- Electrical shock

- Make sure cable in good

condition

- Proper cable way

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Tolerable

- Poor maintenance of

the tools

- Personal injury

- Wear required PPE and use

approved tools

- Equipment must be inspected

by consortium

Acceptable

- Hot Surface

- Hand Injury

- Wear proper PPE ( leather

glove)

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Flying object / particles

- Eye Injury

- Proper handling the tools

- Trained manpower to carry

out the task

- Proper PPE

Acceptable

- Cable management

- Electrical shock

- make sure cable in good

condition

- Proper cable way

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Tolerable

- Welding spark

- Property damage

- Personal injury

- Ensure that the working areas

are free from combustible and

flammable substance

- Use fire blanket

- Fire extinguisher is always

available and fit to use

- Signage for hot work area

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Fumes

- Health

- Provide adequate fan

ventilation/blower

- Drink enough water

- Interval breaks to reduce

exposure to fumes

- Proper PPE (welding shield)

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Hot Surface

- Hand injury

- Wear proper PPE (leather

glove)

Acceptable

- Poor maintenance of

equipment

- Oil spillage / leakage

- Equipment must be inspected

by consortium

- Provide drip pan

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Cable management

- Electrical shock

- Make sure cable in good

condition

- Proper cable way

Tolerable

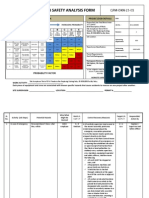

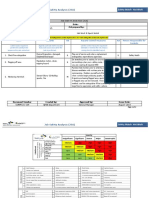

JOB HAZARD ANALYSIS

6

Touch-up paint

Daily job completion /

Housekeeping

- Improper handling

- Paint spillage

- Proper handling

- Attach cover underneath the

material

- Paint container shall be placed

at the drip pan

- Provide adequate ventilation

where necessary

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Fire

- Property damage

- Ensure working area free from

sources of heat/fire

Acceptable

- Inhalation

- Personal health

- Wear respiratory protection

Acceptable

- Paint splash

- Eye injury

- Wear proper PPE

- Provide eye wash station near

work area

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

-Walkway obstruction

- Slip and fall

- Tripping hazard

- Remove all material from

access way

- Ensure work area is kept clean

- Waste material should be

disposed at designated place

- Properly stacking and secure

the materials

- Report to MIE

Management Rep.

-Report incident to

consortium

-To contact nearest

first aider on site

Acceptable

- Ergonomics

- Physical injury

- Proper body positioning

- Practice buddy system during

activity

- Use safe method to lift material

Acceptable

- Sharp object

- Physical injury

- Eliminate/secure any sharp

object

- Wear proper PPE

- Report to MIE

Management Rep.

-Report incident to

consortium

-To contact nearest

first aider on site

Acceptable

L - LIKELIHOOD

CATEGORY

LOW

DEFINITION

1

CATEGORY

Remote

LOW

2

3

MEDIUM

Possible

MEDIU

M

HIGH

Probable

HIGH

IS THERE A SAFER WAY TO COMPLETE THE JOB?

ARE THERE ALTERNATIVES WITH LESS RISK?

RESULT

R - RATING

S - SEVERITY

DEFINITIONS

No Injury

No Damage

No Pollution

First Aid

Injury

Lost Time

Injury

Minor

Damage

Major

Damage

Minor

Pollution

Major

Pollution

6-9

UNACCEPTABLE

3-4

TOLERABLE

1-2

ACCEPTABLE

LIKELIHOOD

You might also like

- Mie Hse Jha 004 - Installation of TransformerDocument5 pagesMie Hse Jha 004 - Installation of TransformerLuqman Osman67% (6)

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

- Mie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationDocument6 pagesMie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationLuqman Osman100% (3)

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingQomarudin Comenk100% (2)

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- PTW JHA Installation of New Control Panel at WWTPDocument2 pagesPTW JHA Installation of New Control Panel at WWTPPHH9834100% (1)

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (4)

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- Aboveground Piping Installation Works 2016Document7 pagesAboveground Piping Installation Works 2016Aldrin75% (4)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan75% (4)

- JSA of Pipe Unloading.Document2 pagesJSA of Pipe Unloading.vijay kumar singh100% (1)

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseDocument5 pages3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- Jsa - Electrical WorksDocument2 pagesJsa - Electrical WorksaneshseNo ratings yet

- JSA Electrical WiringDocument10 pagesJSA Electrical WiringWeru Morris100% (1)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- JSA E&I 10.electrical Instrument Panels RemovalDocument3 pagesJSA E&I 10.electrical Instrument Panels RemovalAmyNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- JHA Manual HandlingDocument5 pagesJHA Manual HandlingFatin Zulkifli100% (1)

- JHA PaintingDocument9 pagesJHA Paintingperquino oasan100% (1)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- Pipe Fabrication and Erection JSADocument8 pagesPipe Fabrication and Erection JSAjithin shankarNo ratings yet

- Civil Works Construction Laydown AreaDocument4 pagesCivil Works Construction Laydown AreaMohammed MinhajNo ratings yet

- JSA for Above Ground Piping WorkDocument3 pagesJSA for Above Ground Piping WorkBhisamS SallehNo ratings yet

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility RelayDocument9 pagesJSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relayfrancis_e_tan100% (2)

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workdrmuhsin86% (7)

- DOCUMENT Loop Checking Activities JHADocument8 pagesDOCUMENT Loop Checking Activities JHAFrancis Enriquez Tan83% (6)

- JSA FORMAT For Materials LoadingDocument2 pagesJSA FORMAT For Materials LoadingVikky KumarNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- JSA Cable Pulling and Laying WorksDocument6 pagesJSA Cable Pulling and Laying Workskabir100% (1)

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- JSA for Scaffolding Erection, Dismantling and Other Construction WorksDocument9 pagesJSA for Scaffolding Erection, Dismantling and Other Construction Worksuttam mishra100% (1)

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocument4 pagesDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustNo ratings yet

- JHA For Electrical Works - Rev. 01.Document16 pagesJHA For Electrical Works - Rev. 01.SreekumarNo ratings yet

- JSA For Material ShiftingDocument3 pagesJSA For Material ShiftingMohammed Minhaj100% (1)

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Job Safety Analysis for Pipeline LoadingDocument8 pagesJob Safety Analysis for Pipeline LoadingMoaatazz NouisriNo ratings yet

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- JSA E&I 4.earthing Bonding InstallationDocument3 pagesJSA E&I 4.earthing Bonding InstallationAmyNo ratings yet

- JSA of Loading & Un Loading ActivitiesDocument3 pagesJSA of Loading & Un Loading ActivitiesMohammed Minhaj100% (1)

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Column Erection JSA AnalysisDocument6 pagesColumn Erection JSA AnalysisRaghava Richhu100% (2)

- Electrical Isolation JSA SheetDocument1 pageElectrical Isolation JSA SheetLal Dhwoj100% (2)

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- 1installation of Steel Structures JHA 1 (06!06!2015)Document33 pages1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- Mie-Hse-Jha-001 - Mobilization, Demobilization of Site Office, Storage Container and Workshop SetupDocument5 pagesMie-Hse-Jha-001 - Mobilization, Demobilization of Site Office, Storage Container and Workshop SetupLuqman Osman100% (4)

- JHA - General Electrical WorkDocument7 pagesJHA - General Electrical WorkEL Mer98% (48)

- Job Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteDocument3 pagesJob Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteganeshkanthNo ratings yet

- Jha Lin FillingDocument6 pagesJha Lin FillingLuqman OsmanNo ratings yet

- Sho AssignmentDocument10 pagesSho AssignmentnourNo ratings yet

- Your Electronic Ticket-EMD Receipt PDFDocument2 pagesYour Electronic Ticket-EMD Receipt PDFLuqman OsmanNo ratings yet

- GF-OGF4-X-PR-0522 - Hazardous Material Management Procedure - Rev A PDFDocument12 pagesGF-OGF4-X-PR-0522 - Hazardous Material Management Procedure - Rev A PDFLuqman OsmanNo ratings yet

- GF-OGF4-X-PR-0522 - Hazardous Material Management Procedure - Rev A PDFDocument12 pagesGF-OGF4-X-PR-0522 - Hazardous Material Management Procedure - Rev A PDFLuqman OsmanNo ratings yet

- Hse Consideration For LpiDocument2 pagesHse Consideration For LpiLuqman OsmanNo ratings yet

- PEP Suriname 2018 - 2DMTCSEM18 - Atlantic Guardian - V1.0 MSDocument51 pagesPEP Suriname 2018 - 2DMTCSEM18 - Atlantic Guardian - V1.0 MSLuqman OsmanNo ratings yet

- Shanghai Youlong LRDocument16 pagesShanghai Youlong LRLuqman Osman100% (1)

- MASwings Flight Receipt from Labuan to Kota KinabaluDocument2 pagesMASwings Flight Receipt from Labuan to Kota KinabaluLuqman OsmanNo ratings yet

- Management of Inert Confined Space EntryDocument4 pagesManagement of Inert Confined Space EntryLuqman OsmanNo ratings yet

- Overview CHRA 3rd Ed-Taklimat Pusat PengajarDocument31 pagesOverview CHRA 3rd Ed-Taklimat Pusat PengajarLuqman Osman100% (3)

- 6419RJ510-10006 Blinds Management ProcedureDocument14 pages6419RJ510-10006 Blinds Management ProcedureLuqman Osman100% (1)

- Hse Consideration For LpiDocument2 pagesHse Consideration For LpiLuqman Osman100% (1)

- 242 SDocument3 pages242 SLuqman OsmanNo ratings yet

- Hac BasicDocument3 pagesHac BasicLuqman OsmanNo ratings yet

- Management of Inert Confined Space EntryDocument4 pagesManagement of Inert Confined Space EntryLuqman OsmanNo ratings yet

- OSHE Membership FormDocument1 pageOSHE Membership FormLuqman OsmanNo ratings yet

- Risk Profile PrecommissioningDocument5 pagesRisk Profile PrecommissioningLuqman OsmanNo ratings yet

- Simplified LOTO ProcedureDocument8 pagesSimplified LOTO ProcedureLuqman OsmanNo ratings yet

- Hse Evaltuiaon Form Rev 1Document6 pagesHse Evaltuiaon Form Rev 1Luqman OsmanNo ratings yet

- V Paper 17Document12 pagesV Paper 17Luqman OsmanNo ratings yet

- Bow Tie Pneumatic 2nd TrialDocument1 pageBow Tie Pneumatic 2nd TrialLuqman OsmanNo ratings yet

- Case Study SogtDocument4 pagesCase Study SogtLuqman OsmanNo ratings yet

- Att III - Log Sheet MRTDocument1 pageAtt III - Log Sheet MRTLuqman OsmanNo ratings yet

- Attendance SheetDocument1 pageAttendance SheetLuqman OsmanNo ratings yet

- High Risk Behavior and Mental Problem Among AdolesenceDocument52 pagesHigh Risk Behavior and Mental Problem Among AdolesenceLuqman OsmanNo ratings yet

- Att I - Commissioning ChecklistDocument2 pagesAtt I - Commissioning ChecklistLuqman OsmanNo ratings yet

- Hazard Analysis TemplateDocument3 pagesHazard Analysis Templateizzat ezmanNo ratings yet

- Attendance Sheet:: Dr. MD Mizanur Rahman: Research Methodology: KOG 11603Document1 pageAttendance Sheet:: Dr. MD Mizanur Rahman: Research Methodology: KOG 11603Luqman OsmanNo ratings yet

- PRD Risk Register - Att 1Document1 pagePRD Risk Register - Att 1Luqman OsmanNo ratings yet

- Hse Close Out Report PresentationDocument31 pagesHse Close Out Report PresentationLuqman Osman100% (10)

- PULSE JET BAG FILTER DESIGNDocument2 pagesPULSE JET BAG FILTER DESIGNbasavaraju535No ratings yet

- REVIEWER Environmental ManagementDocument10 pagesREVIEWER Environmental ManagementAngelica May ClaritoNo ratings yet

- Ginés Morata: What S The Air?Document12 pagesGinés Morata: What S The Air?aliciaNo ratings yet

- R-MC MsdsDocument5 pagesR-MC MsdsSkySupplyUSANo ratings yet

- Disaster Risk Reduction Management Powerpoint 2Document28 pagesDisaster Risk Reduction Management Powerpoint 2Rodrigo Mesana IIINo ratings yet

- De Release - FinalDocument5 pagesDe Release - Finalapi-282139528No ratings yet

- Exxon MESQAC 2010Document55 pagesExxon MESQAC 2010G_ARVALIS8470100% (1)

- Global Dimming: An Answer For Global Warming?Document1 pageGlobal Dimming: An Answer For Global Warming?Yuraya PalasanNo ratings yet

- FARMAKOTOKSIKOLOGIDocument20 pagesFARMAKOTOKSIKOLOGIChanifia Izza MillataNo ratings yet

- Product Safety Information Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument9 pagesProduct Safety Information Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingmicNo ratings yet

- MSDS PDFDocument5 pagesMSDS PDFdang2172014No ratings yet

- Differences of Building Technologies and Built EnvironmentDocument2 pagesDifferences of Building Technologies and Built EnvironmentShobby ShobanaNo ratings yet

- Al Gore's An Inconvenient TruthDocument4 pagesAl Gore's An Inconvenient TruthMuskan BansalNo ratings yet

- Graftobian Translucent Powder MsdsDocument4 pagesGraftobian Translucent Powder MsdsMelissa V G RibeiroNo ratings yet

- SOPEP Manual Chapters for Oil Spill PreventionDocument3 pagesSOPEP Manual Chapters for Oil Spill Preventiontumi69No ratings yet

- Wedc An Engineer S Guide To Apron Slabs For Water Points 2012Document36 pagesWedc An Engineer S Guide To Apron Slabs For Water Points 2012Teodoro Quintana100% (1)

- Environmental Value Systems and PollutionDocument5 pagesEnvironmental Value Systems and PollutionSofia LaereNo ratings yet

- Week 1-SlidesDocument69 pagesWeek 1-SlidesYas MonazahNo ratings yet

- CH16 EditedDocument11 pagesCH16 EditedInmeNo ratings yet

- Disaster Risk Management Floods and EarthquakeDocument17 pagesDisaster Risk Management Floods and Earthquakebugaspearl0No ratings yet

- Philippine Mining Situation at A GlanceDocument3 pagesPhilippine Mining Situation at A GlancetimothymaderazoNo ratings yet

- Acidizare Curs SupervizoriDocument48 pagesAcidizare Curs SupervizoriCristian BarbuceanuNo ratings yet

- Best Indoor Plants for Air PurificationDocument8 pagesBest Indoor Plants for Air PurificationHarsan SinghNo ratings yet

- Case Study: ProblemDocument2 pagesCase Study: ProblemArashdeep SinghNo ratings yet

- Frog DissertationDocument171 pagesFrog Dissertationcreatingcreator100% (1)

- Project Report For Residential STPDocument107 pagesProject Report For Residential STPKhiara Claudine EspinosaNo ratings yet

- Ecological Dimension of Globalization Technology, Media, and Internet Dimension of GlobalizationDocument16 pagesEcological Dimension of Globalization Technology, Media, and Internet Dimension of GlobalizationHarry DecilloNo ratings yet

- SDS 0039Document14 pagesSDS 0039LeonGXPNo ratings yet

- Important Cases of Environmental LawDocument48 pagesImportant Cases of Environmental LawAbhishekGautamNo ratings yet

- CHAPTER 3 - StudentDocument63 pagesCHAPTER 3 - StudentNabilah AsrulNo ratings yet

- Environmental LawDocument46 pagesEnvironmental Lawjamilove20100% (2)