Professional Documents

Culture Documents

Design of Machine Elements - I - 2

Uploaded by

sai_raghava1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Machine Elements - I - 2

Uploaded by

sai_raghava1Copyright:

Available Formats

Seat No.

: _____

Enrolment No.______

GUJARAT TECHNOLOGICAL UNIVERSITY

B. E. Sem. - V - Examination June- 2011

Subject code: 152503

Subject Name: Design of Machine Elements - I

Date:24/06/2011

Time: 10:30 am 01:00 pm

Total Marks: 70

Instructions:

1. Attempt all questions.

2. Make suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

Q.1

(a) Define stress concentration. Sketch different methods of mitigation of

stress concentration.

07

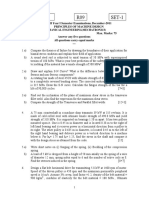

(b) A cantilever beam of 40C8 steel with ultimate tensile strength of 600

MPa as shown in Fig. 1 is subjected to a load varying from -50 N to

150N. Surface finish factor = 0.76, size factor = 0.85, reliability factor

= 0.879 and notch sensitivity is given as 0.9. Determine the

diameterd, considering the factor of safety as 1.5 and theoretical

stress concentration factor as 1.35.

07

Fig. 1

Q.2

(a) Explain the different causes of gear tooth failures and suggest

possible remedies to avoid such failures.

07

(b) A railway wagon of mass 20,000 Kg moving with a velocity of

2m/sec is brought to rest by two buffers of springs of mean diameter

300 mm. The maximum deflection of spring is 200 mm. Permissible

shear stress is 600 MPa. Modulus of rigidity as 80 KN/mm2. Find the

diameter of spring and number of turns.

07

OR

(b) A spring loaded safety valve is held against its seat by a close coiled

helical compression spring. The diameter of the valve is 75 mm.

Normal pressure on valve be 1 MPa and blow of pressure is 1.1 MPa.

The deflection of spring causing the opening of valve is 3.5 mm and

mean diameter of the coil is 100 mm. Find the diameter of spring bar

and the number of active coils, if permissible shear stress is 500 MPa

and modulus of rigidity is 80 KN/mm2.

07

Q.3

(a) Design a pair of spur pinion and gear made of cast steel and cast iron

respectively. The diameter of pinion is 140 mm and it transmits 30

Kw power at 1250 rpm. The gear ratio is 3:1 and teeth are 20o full

depth involute. Permissible static bending stress for pinion is 110

MPa and for gear is 55 MPa.

07

(b) Two precision cut forged steel helical gears have 20o full depth

involute teeth. For the given following parameters, find the

transmitted and wear load and state whether the design is safe or not.

07

The angle of helix is 23o.

Permissible static bending stress is 100 MPa.

Module is 3 mm and face width is 30 mm.

The speed of rotation of pinion is 600 rpm.

Gear ratio is 3:1.

Surface endurance strength is 630 MPa.

Q.3

Q.4

OR

(a) Find the power transmitted by a pair of bevel gears with 20o full

depth involute teeth. The material is steel with hardness 350 BHN.

Consider Module as 6.5 mm and face width 60 mm. Pinion rotates at

600 rpm. The shafts are perpendicular to each other. Take load stress

factor as 0.96 N/mm2. Deformation factor is 300 N/mm. The pinion

has 40 teeth and gear has 60 teeth. Safe static stress for the material is

105 MPa.

07

(b) For a hardened steel worm and gear the centre distance is 450 mm.

Transmission ratio is 20. Find the axial module and the lead angle.

07

(a) A clutch plate with maximum diameter 60 mm has maximum lining

pressure of 0.35 MPa. The power to be transmitted at 400 rpm is 135

Kw and coefficient of friction is 0.3. Find inside diameter and spring

force required to engage the clutch. If 6 springs are used with spring

index 6 and material as spring steel having safe shear stress 600 MPa,

find the wire diameter.

07

(b) For the internal expanding single shoe brake as shown in the Fig. 2,

maximum pressure between the lining and the drum is limited to 0.6

MPa. Coefficient of friction is 0.25 and width of the lining is 65 mm.

Find the torque about the point O and magnitude of force P.

07

Fig. 2

2

OR

Q.4

Q.5

Q.5

(a) Discuss the different types of belts. A leather belt of 125 mm wide

and 6 mm thick transmits power from a pulley of diameter 750 mm at

500 rpm. Angle of lap for smaller pulley is 150o, coefficient of

friction is 0.3, mass of the belt is 1000 Kg/m3 and the maximum

permissible stress is 2.75 MPa. Find the maximum power that can be

transmitted.

07

(b) Describe with the help of neat sketch, a centrifugal clutch and deduce

an expression for the total frictional torque transmitted. How the

shoes are designed for such a clutch?

07

(a) Cast Iron fly wheel used for a four stroke engine developing 150 Kw

power at 200 rpm. Calculate the diameter of the flywheel rim if the

hoop stress is not to exceed 4 MPa. Total fluctuation of speed is to be

4 % of the mean speed. Work done during the power stroke may be

assumed to be 1.5 times the average work done during the cycle.

Density of cast iron is 7200 kg/m3.

07

(b) What is the difference between column and strut? What are the

different types of end conditions based on Eulers column theory?

Define slenderness ratio.

OR

07

(a) Sketch the stress distribution of hoop and radial stress for a

compound cylinder subjected to internal pressure. Why compound

cylinder is better than single solid cylinder?

07

(b) Derive the expression to determine wrench torque required for bolt

tightening.

07

*************

You might also like

- QB Unit-3,4,5Document7 pagesQB Unit-3,4,5Agranshu BhardwajNo ratings yet

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- DME1Document3 pagesDME1Ganesh RamNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Internal Test 1Document3 pagesInternal Test 1Sathish KumarNo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- QB Unit-1,2Document5 pagesQB Unit-1,2Agranshu BhardwajNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Dme Lab Sheets Ii Iii IvDocument4 pagesDme Lab Sheets Ii Iii IvA58Vikas UbovejaNo ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- 15 151905 Machine Design IDocument3 pages15 151905 Machine Design IPeeka Prabhakara RaoNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Machine Members Design AssignmentDocument13 pagesMachine Members Design AssignmentHafiz Mahar28No ratings yet

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshNo ratings yet

- Assignment - 2Document4 pagesAssignment - 2vaijanath patilNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- Me 6503 Design of Machine Elements QBDocument3 pagesMe 6503 Design of Machine Elements QBDeepak SNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- Design of Machine Elements 2 Jan 2014Document2 pagesDesign of Machine Elements 2 Jan 2014Prasad C M100% (1)

- TE - 2019 - Design of Machine Elements PDFDocument4 pagesTE - 2019 - Design of Machine Elements PDFonkar nikamNo ratings yet

- Design of ShaftsDocument2 pagesDesign of ShaftsÖzgür AtaseverNo ratings yet

- Dme Home Assignment 2019-20Document4 pagesDme Home Assignment 2019-20VenkateshNo ratings yet

- Register Number NIT Mechanical Design Machine Elements ExamDocument2 pagesRegister Number NIT Mechanical Design Machine Elements ExamdharaniventhanNo ratings yet

- Assignment 2Document3 pagesAssignment 2sonawanepmsNo ratings yet

- Assignment QuestionDocument15 pagesAssignment QuestionPratik WalimbeNo ratings yet

- DME 1 Question BankDocument5 pagesDME 1 Question BankRahul YedduNo ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- Me1302 DmeDocument4 pagesMe1302 DmesumikannuNo ratings yet

- PART-B QUESTIONS STEADY STRESSES AND VARIABLE STRESSESDocument12 pagesPART-B QUESTIONS STEADY STRESSES AND VARIABLE STRESSESMadhu MithaNo ratings yet

- Design ProblemsDocument13 pagesDesign ProblemsAristotle RiveraNo ratings yet

- Fatigue Consideration in Design TutorialDocument2 pagesFatigue Consideration in Design Tutorialdjadja nakamayaNo ratings yet

- Dme Question BankDocument4 pagesDme Question BankRavi Patil100% (1)

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDocument5 pagesME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rNo ratings yet

- R09 B.Tech III Year I Semester Machine Elements ExamDocument1 pageR09 B.Tech III Year I Semester Machine Elements Examprasaad08No ratings yet

- Unit IDocument3 pagesUnit Imahendra babu mekalaNo ratings yet

- ME 1302 - MACHINE DESIGN (5th Mech)Document7 pagesME 1302 - MACHINE DESIGN (5th Mech)Madhu MithaNo ratings yet

- 353 35435 ME357 2011 4 2 1 Sheet MD2Document10 pages353 35435 ME357 2011 4 2 1 Sheet MD2adel nabhanNo ratings yet

- 16mu315 - Machine Design Question Bank: Ut Yt B TDocument3 pages16mu315 - Machine Design Question Bank: Ut Yt B THarishNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- TUTORIAL 3 Design of Shaft Key and CouplingDocument2 pagesTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- Assignment No-01 MEPC-301Document6 pagesAssignment No-01 MEPC-301SANDEEP BUDANIANo ratings yet

- Design ExercisesDocument13 pagesDesign ExercisesBookieeNo ratings yet

- Rr312404 Design of Machine ElementsDocument9 pagesRr312404 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Be 5 Sem Design of Machine Elements 2151907 Summer 2019Document2 pagesBe 5 Sem Design of Machine Elements 2151907 Summer 2019Yatharth DaveNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- DMM I Assignment - 4Document2 pagesDMM I Assignment - 4Konduru Vinay Kumar ReddyNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- MODEL QUESTION PAPER Mechanical VibrationsDocument3 pagesMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaNo ratings yet

- MDID Machine Design GTU PaperDocument3 pagesMDID Machine Design GTU PaperjaydeepNo ratings yet

- Design of Machine ElementsDocument10 pagesDesign of Machine ElementsMahalingam NanjappanNo ratings yet

- PPEDocument15 pagesPPEsai_raghava1No ratings yet

- Indg 244Document8 pagesIndg 244Mohamed IbrahimNo ratings yet

- Cane - Sugar - Manufacture - in - India Datos Sobre Producción de AzucarDocument525 pagesCane - Sugar - Manufacture - in - India Datos Sobre Producción de AzucarEnrique Lucero100% (1)

- Rankine CycleDocument17 pagesRankine CycleM.ThirunavukkarasuNo ratings yet

- Learn From The Examiner Writing e BookDocument36 pagesLearn From The Examiner Writing e Booksai_raghava1No ratings yet

- 11Document8 pages11sai_raghava1No ratings yet

- 171 0636Document3 pages171 0636sai_raghava1No ratings yet

- A Field Guide For Painting, Home Maintenance, and Renovation WorkDocument84 pagesA Field Guide For Painting, Home Maintenance, and Renovation Worksai_raghava1No ratings yet

- Maulana 2020Document11 pagesMaulana 2020Supun RanganaNo ratings yet

- Comparison of Structural Behaviour of Flat Plate and Flat Slab RC BuildingsDocument5 pagesComparison of Structural Behaviour of Flat Plate and Flat Slab RC BuildingsNan Shwe Kyi HtweNo ratings yet

- Sika Marine Application GuideDocument45 pagesSika Marine Application GuideLin LinNo ratings yet

- Ferrocement A Review IJERTV2IS100156Document5 pagesFerrocement A Review IJERTV2IS100156sudhirNo ratings yet

- To HQ 02 042 00 Philosophy Civil Works OnshoreDocument32 pagesTo HQ 02 042 00 Philosophy Civil Works Onshoremarin cristianNo ratings yet

- Mechanics of Materials: TorsionDocument30 pagesMechanics of Materials: TorsionMPRajNo ratings yet

- Rock properties affecting conical pick performance and comparison of experimental and theoretical cutting resultsDocument38 pagesRock properties affecting conical pick performance and comparison of experimental and theoretical cutting resultsFranceth Castellanos BallesterosNo ratings yet

- Seal Strength of Flexible Barrier Materials: Standard Test Method ForDocument11 pagesSeal Strength of Flexible Barrier Materials: Standard Test Method Forรอคนบนฟ้า ส่งใครมาให้ สักคน100% (1)

- TDS 10450010 en en Weicon-Hb-300 PDFDocument1 pageTDS 10450010 en en Weicon-Hb-300 PDFKJ SupplyNo ratings yet

- EMM3806 E1 Lab2Document8 pagesEMM3806 E1 Lab2KHAIRUL NASHRAN BIN ANUAR / UPMNo ratings yet

- Mechanical Properties of Material: Definition and Example (Notes & PDF)Document5 pagesMechanical Properties of Material: Definition and Example (Notes & PDF)Мария ЮжаковаNo ratings yet

- 9 Makä°ne Elemanlari English PDFDocument40 pages9 Makä°ne Elemanlari English PDFozmenNo ratings yet

- Effect of Cyclic LoadingDocument5 pagesEffect of Cyclic LoadingrashmiNo ratings yet

- Tension Members PDFDocument10 pagesTension Members PDFNIKHIL BANDWALNo ratings yet

- 12 PLAXIS BulletinDocument24 pages12 PLAXIS BulletinCarlos Augusto Sánchez RondónNo ratings yet

- ASTM E9 CompresionDocument9 pagesASTM E9 CompresionChris Matías YezNo ratings yet

- C780Document16 pagesC780Karlita Cisneros100% (2)

- PartB Vol2 2017Document192 pagesPartB Vol2 2017djodje1No ratings yet

- Design Recommendations For Steel Deck Floor SlabsDocument32 pagesDesign Recommendations For Steel Deck Floor Slabswayzane100% (1)

- Friction Coefficient of Steel On Concrete or GroutDocument7 pagesFriction Coefficient of Steel On Concrete or GroutLuis Ernesto Ramirez OsorioNo ratings yet

- Metallic Material Specification for 2.25 Cr-1 Mo Alloy with 85 KSI Yield StrengthDocument6 pagesMetallic Material Specification for 2.25 Cr-1 Mo Alloy with 85 KSI Yield StrengthReginaldo SantosNo ratings yet

- Fuekz.K DK Ks Esa Lajpukred Bekjrh Ydm+H Osq Fmtkbu JHFR LafgrkDocument29 pagesFuekz.K DK Ks Esa Lajpukred Bekjrh Ydm+H Osq Fmtkbu JHFR LafgrkAnuradhaPatraNo ratings yet

- High Temperature CorrosionDocument2 pagesHigh Temperature CorrosionIlhamChaniefNo ratings yet

- Astm F1948-15Document6 pagesAstm F1948-15hugoNo ratings yet

- Ghulam Ishaq Khan Institute of Engineering Sciences and Technology Sawabi, TopiDocument46 pagesGhulam Ishaq Khan Institute of Engineering Sciences and Technology Sawabi, TopiWajid AliNo ratings yet

- ME6503-Design of Machine Elements PDFDocument15 pagesME6503-Design of Machine Elements PDFkarthikNo ratings yet

- Kim2021 Article DesignAndManufactureOfAutomotiDocument13 pagesKim2021 Article DesignAndManufactureOfAutomotiHang ShenNo ratings yet

- Conducting Transverse and Concentrated Load Tests On Panels Used in Floor and Roof ConstructionDocument6 pagesConducting Transverse and Concentrated Load Tests On Panels Used in Floor and Roof ConstructionAdán Cogley Canto100% (1)

- Engineering Structures: Hadi Panahi, Aikaterini S. GenikomsouDocument20 pagesEngineering Structures: Hadi Panahi, Aikaterini S. GenikomsouBayuAgungGilangWibowo100% (1)

- Optimum Design of Castellated Beams Effect of Comp PDFDocument24 pagesOptimum Design of Castellated Beams Effect of Comp PDFAnika dixitNo ratings yet