Professional Documents

Culture Documents

Floating Flange Rubber Expansion Joints: Series 980

Uploaded by

Roland Bon IntudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Floating Flange Rubber Expansion Joints: Series 980

Uploaded by

Roland Bon IntudCopyright:

Available Formats

Series 980

1-800-285-1600 Quality Since 1935

Quality Value Service

Floating Flange

Rubber Expansion Joints

HOLZ SERIES 980

The HOLZ 980 line of expansion joints provides high quality, well engineered products suitable for most

applications, all at a reasonable cost. HOLZ 980 expansion joints are designed to allow for the

expansion, contraction, lateral and angular movement of a piping system. HOLZ 980 expansion joints

are especially suited for and used in the HVAC industry.

CONSTRUCTION

HOLZ 980 expansion joints are precision molded under high pressure to ensure joint integrity.

Quality materials and modern fabrication techniques deliver reliable performance.

REINFORCEMENT

The nylon tire cord reinforcement is bonded within the elastomer so that no reinforcement

material will be exposed to atmosphere or media.

COVER

The cover elastomer is either EPDM or Neoprene for excellent resistance to sunlight, ozone and

heat aging. The Neoprene cover is self-extinguishing for fire resistance.

TUBE

HOLZ 980 expansion joints are manufactured with a Neoprene tube elastomer as standard that

is oil resistant, or an EPDM tube elastomer for greater temperatures and is chemical resistant.

Contact HOLZ RUBBER for availability and pricing.

FLOATING FLANGES

HOLZ 980 expansion joints have floating metal flanges which allow for rotational misalignment

of the pipe. No cumbersome gaskets or separate retaining rings to lose or inventory.

ENGINEERING

All HOLZ 980 expansion joints are constructed with a spherical arch design for maximum

movement capability, minimum force to move and maximum pressure/full vacuum capability.

PRESSURE

The inherent design strength of the spherical arch allows for a high operating pressures and

burst pressures. The spherical arch design and the reinforcing material combine to provide for

full vacuum capability as noted by the Fluid Sealing Association.

MOVEMENTS

The wide spherical arch design of HOLZ 980 expansion joints, provides the maximum movement

capability in lateral deflection, angular misalignment, axial compression and extension. The high

pressure molding and tire cord reinforcing material of the HOLZ 980 expansion joint allows thin

wall construction for low forces to move. Compare our movement capability against competitive

products!

NOTE:

All HOLZ SERIES 980, STYLES 981 and 982, meet or exceed the Rubber Expansion Joint Division, Fluid Sealing

Association requirements for Standard Class 1, Series C.

AXIAL

compression

AXIAL

extension

LATERAL

shear or perpendicular to centerline

ANGULAR

bending of the centerline

HOLZ 980 expansion joints are ideal for use in the following applications:

SYSTEMS

INDUSTRIES

HVAC

Industrial Process

Marine

Construction

Power Plants

General Industrial

Page 2

Hot and Cold Water

Circulating Water

Refrigeration

Air Conditioning

Compressors

Pumps

REINFORCEMENT

METAL

FLANGE

HOLZ STYLE 981

COVER

TUBE

SINGLE ARCH

FLOATING FLANGE

EXPANSION JOINT

I.D.

FACE TO FACE

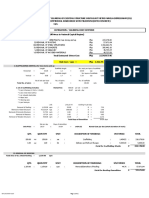

DESIGN CONDITIONS

MATERIALS OF CONSTRUCTION

14F - 275F

ELASTOMERS

GENERAL COMPATIBILITY

-10C to 135C

NEOPRENE

Moderate Chemicals and Acids, Ozone, Fats, Greases,

Many Oils and Solvents.

TEMP.

1 1/4" to 12" I.D.-225

PRESSURE

(PSI)

TUBE

ELASTOMERS

EPDM

14"I.D.-150

16" to 20" I.D.-125

REINFORCEMENT

26

COVER

ELASTOMERS

VACUUM

(In. of Hg.)

Pressure is based on 180F constant temperature. Contact

HOLZ RUBBER for pressures on higher operating temperatures.

METAL FLANGE

NOM. I.D.

Animal and Vegetable Oil, Ozone, Strong and

Oxidizing Chemicals.

NYLON TIRE CORD

NEOPRENE WITH NEOPRENE TUBE,

EPDM WITH EPDM TUBE.

125/150 lb. ANSI Standard of Drilling

(Refer to Page 6 for Specifications.)

GALVANIZED STEEL

STYLE 981

FACE TO FACE

MILLIMETERS

INCHES

INCHES

MILLIMETERS

1 1/4

32

1 1/2

40

MAXIMUM MOVEMENTS

COMP.

EXT.

LAT.

ANG.

150

1 3/16

3/8

1/2

15

150

1 3/16

3/8

1/2

15

50

150

1 3/16

3/8

1/2

15

2 1/2

65

150

1 3/16

3/8

1/2

15

80

150

1 3/16

3/8

1/2

15

100

150

1 3/16

1/2

1/2

15

125

150

1 3/16

1/2

1/2

15

150

150

1 3/16

1/2

1/2

15

200

150

1 3/16

1/2

1/2

15

10

250

203

1 3/16

3/4

3/4

15

12

300

203

1 3/16

3/4

3/4

15

14

350

203

1 3/16

3/4

3/4

15

16

400

203

1 3/16

3/4

3/4

15

18

450

203

1 3/16

3/4

3/4

15

20

500

203

1 3/16

3/4

3/4

15

NOTES:

1. Movements are non-concurrent. Contact HOLZ RUBBER for concurrent movement capabilities.

2. Media compatibility is general, refer to the HOLZ RUBBER Elastomer Specification Tables for specific resistance.

3. Movements are in inches unless otherwise stated.

4. For other sizes, elastomers/threading, contact HOLZ RUBBER.

Page 3

HOLZ STYLE 982

REINFORCEMENT

METAL

FLANGE

COVER

DOUBLE ARCH

FLOATING FLANGE

EXPANSION JOINT

TUBE

I.D.

FACE TO FACE

DESIGN CONDITIONS

MATERIALS OF CONSTRUCTION

14F to 275F

ELASTOMERS

GENERAL COMPATIBILITY

-10C to 135C

NEOPRENE

Moderate Chemicals and Acids, Ozone, Fats, Greases,

Many Oils and Solvents.

TEMP.

TUBE

ELASTOMERS

PRESSURE

(PSI)

EPDM

225

REINFORCEMENT

VACUUM

26

(In. of Hg.)

COVER

ELASTOMERS

Pressure is based on 180F constant temperature. Contact

HOLZ RUBBER for pressures on higher operating temperatures.

NOM. I.D.

IN.

MM

1 1/4

METAL FLANGE

NYLON TIRE CORD

NEOPRENE WITH NEOPRENE TUBE,

EPDM WITH EPDM TUBE.

GALVANIZED STEEL

125/150 lb. ANSI Standard of Drilling

(Refer to Page 6 for Specifications.)

STYLE 982

FACE TO FACE

MAXIMUM MOVEMENTS

IN.

MM

COMP.

EXT.

LAT.

ANG.

32

175

1 3/16

1 7/8

40

1 1/2

40

175

1 3/16

1 7/8

40

50

175

1 3/16

1 7/8

40

2 1/2

65

175

1 3/16

1 7/8

40

80

175

1 3/16

1 7/8

40

100

225

2 1/4

1 3/8

1 5/8

35

125

225

2 1/4

1 3/8

1 5/8

35

150

225

2 1/4

1 3/8

1 5/8

35

200

13

330

2 1/2

1 3/8

1 3/4

30

10

250

13

330

2 1/2

1 3/8

1 3/4

30

12

300

13

330

2 1/2

1 3/8

1 3/4

30

NOTES:

1. Movements are non-concurrent. Contact HOLZ RUBBER for

concurrent movement capabilities.

2. Media compatibility is general, refer to the HOLZ RUBBER Elastomer

Specification Tables for specific resistance.

3. Movements are in inches unless otherwise stated.

4. For other sizes, elastomers/drilling, contact HOLZ RUBBER.

Page 4

Animal and Vegetable Oil, Ozone, Strong and

Oxidizing Chemicals.

HOLZ 980

HYDROTEST

HOLZ STYLE 983

DOUBLE ARCH

THREADED UNION

EXPANSION JOINT

UNION

CONNECTOR

COVER

REINFORCEMENT

I.D.

TUBE

LENGTH

DESIGN CONDITIONS

MATERIALS OF CONSTRUCTION

14F to 275F

ELASTOMERS

GENERAL COMPATIBILITY

-10C to 135C

NEOPRENE

Moderate Chemicals and Acids, Ozone, Fats, Greases,

Many Oils and Solvents.

TEMP.

TUBE

ELASTOMERS

PRESSURE

(PSI)

EPDM

150

REINFORCEMENT

VACUUM

26

(In. of Hg.)

Pressure is based on 180F constant temperature. Contact

HOLZ RUBBER for pressures on higher operating temperatures.

Animal and Vegetable Oil, Ozone, Strong and

Oxidizing Chemicals.

NYLON TIRE CORD

COVER

ELASTOMERS

NEOPRENE WITH NEOPRENE TUBE, EPDM WITH EPDM TUBE.

UNION

CONNECTOR

FEMALE NPT THREADED (IPT) TO ANSI B-2.1 GALVANIZED STEEL

NOM. I.D.

STYLE 983

FACE TO FACE

MILLIMETERS

INCHES

INCHES

MILLIMETERS

3/4

20

25

1 1/4

MAXIMUM MOVEMENTS

COMP.

EXT.

LAT.

ANG.

203

7/8

1/4

7/8

35

203

7/8

1/4

7/8

25

32

203

7/8

1/4

7/8

25

1 1/2

40

203

7/8

1/4

7/8

20

50

203

7/8

1/4

7/8

15

2 1/2

65

203

7/8

1/4

7/8

15

80

203

7/8

1/4

7/8

15

NOTES:

1. Movements are non-concurrent. Contact HOLZ RUBBER for concurrent movement capabilities.

2. Media compatibility is general, refer to the HOLZ RUBBER Elastomer Specification Tables for specific resistance.

3. Movements are in inches unless otherwise stated.

4. For other sizes, elastomers, contact HOLZ RUBBER.

Page 5

HOLZ SERIES 980

DIMENSIONS

WEIGHTS

(INCHES)

STYLES 981 and 982

SEE NOTES

NOM I.D.

JOINT AND FLANGE OR

UNION (POUNDS)

STYLES

981

982

NOM I.D.

FLANGE

O.D.

FLANGE

THICKNESS

BOLT

CIRCLE

1 1/4

4 5/8

5/8

3 1/2

5/8

3/4

1.5

1 1/2

5/8

3 7/8

5/8

2.0

5/8

4 3/4

3/4

1 1/4

5.0

7.4

3.0

1 1/2

6.1

8.2

3.8

HOLE

NUMBER OF

DIAMETER

HOLES

2 1/2

11/16

5 1/2

3/4

7 1/2

11/16

3/4

11/16

7 1/2

3/4

10

13/16

8 1/2

7/8

11

7/8

9 1/2

13 1/2

7/8

11 3/4

10

16

15/16

14 1/4

983

8.9

9.0

5.4

2 1/2

12.3

13.3

7.8

14.0

14.3

11.3

18.3

20.3

7/8

22.8

24.5

7/8

26.8

29.5

12

40.6

43.8

10

56.6

64.1

12

83.0

95.0

14

115.0

12

19

15/16

17

12

14

21

1 1/32

18 3/4

12

1 1/8

16

23 1/2

1 3/32

21 1/4

16

1 1/8

16

165.0

18

25

1 3/16

22 3/4

16

1 1/4

18

168.0

20

27 1/2

1 3/16

25

20

1 1/4

20

170.0

NOTES:

1. Drilling meets 125/150 lb. standards of ANSI B16.1, B16.24, B16.5; AWWA C207 Class D & E.

2. Other drilling available. Contact HOLZ.

CONTROL RODS NUMBER OF UNITS REQUIRED FOR STYLES 981 and 982 ONLY

MAX. DESIGN OR TEST PRESSURE OF SYSTEM - PSIG

ROD

DIAMETER

(INCHES)

TWO UNITS

WEIGHT

FOUR UNITS

LBS./UNIT

1 1/4

7 3/4

5/8

830

6.5

1 1/2

8 1/8

5/8

510

6.5

9 3/4

5/8

661

6.5

2 1/2

10 3/4

5/8

529

7.5

11 1/4

5/8

441

8.0

12 11/16

5/8

311

467

622

8.0

13 11/16

5/8

235

353

470

8.0

14 11/16

5/8

186

278

371

10.0

17 7/16

163

244

326

13.0

10

20 1/2

163

244

325

16.0

12

23 11/16

160

240

320

16.0

14

25 13/16

112

167

223

20.0

16

29

1 1/4

113

170

227

20.0

18

30 1/2

1 1/4

94

141

187

21.0

20

33

1 1/4

79

118

158

21.0

NOTES:

1. Calculations are based on 65% of yield of the rod.

2. Weights are based on the standard length of the Series 981.

3. FSA Recommended minimum number of rods for indicated pipe size.

Page 6

CONTROL

ROD PLATE

RETAINING FLANGE

NOMINAL PIPE SIZE

JOINT I.D.

PLATE O.D.

(INCHES)

CONTROL ROD PLATE MAXIMUM O.D.

NOM I.D.

FLANGE

THICKNESS

OPTIONAL

COMPRESSION SLEEVE

BOLT

CIRCLE

EQUALLY

SPACED

BOLT HOLES

BOLT

HOLES

ER

DIAMET

Other HOLZ Expansion Joint Products

TRADITIONAL SPOOL TYPE

HOLZ RUBBER CO. has a complete

line of Arch and U-Type connectors

to meet your design requirements.

Engineered for vacuum, high

pressure, low pressure, vibration

elimination or unusual medias, you

can select the expansion joint best

suited for your application. HOLZ

RUBBER builds expansion joints to

meet U.S. Navy, Coast Guard and

ABS Specifications. Write/Call for

Brochure 15.12b/HOL for more

information.

U-TYPE

ARCH TYPE

REDUCERS OFFSETS

ECCENTRIC

CONCENTRIC

Eccentric or Concentric HOLZ

RUBBER CO. maintains a full variety

of materials to manufacture reducing

expansion joints to connect different

diameter pipe. All drilling will

straddle centerline unless otherwise

specified. HOLZ RUBBER CO. can

recommend the proper face to face

dimension to ensure proper flexure,

flow and construction. For

misaligned piping, HOLZ RUBBER

can engineer an expansion joint to

meet your requirements.

HOLZ SF-1000

EXPANSION JOINTS

The HOLZ SF-1000 expansion joint

line offers full face rubber flanges in

both the standard arch

configurations. Precision molded in

sizes to 12" ID. SF-1000 expansion

joints are engineered to perform.

STYLE SF-1000

FILLED ARCH

STYLE SF-1000

Send for our SF-1000 brochure for

complete information.

NON-METALLIC DUCTING

EXPANSION JOINTS

HOLZ RUBBER CO. manufactures a

full range of non-metallic expansion

joints for ducting systems. The 900

Series is designed for operating

temperatures to 400F in a variety of

elastomers. Also available is the

501HT Series designed for operating

temperatures to 2000F.

942

945

952

501HT

The HOLZ RUBBER CO. Flue Duct

Brochures provide you with design

information.

Page 7

HOLZ 980 (REV. 4/03)

Rubber

Expansion

Joints

SERIES 980

INHERENT ADVANTAGES OF

HOLZ 980 RUBBER

EXPANSION JOINTS

HOLZ 980 ADVANTAGES OVER

OTHER RUBBER

EXPANSION JOINTS

High Movement-to-Length Ratio

Higher Pressures

Low Deflection Forces

Greater Movement

Eliminates Electrolysis

Lower Spring Rates

Dampens Vibration

Oil Resistant Tube Standard

Corrosion Resistant

Immediate Availability

Sound Absorption

Floating Flanges

No Gaskets Required

Competitive Pricing

Distributed by:

1-800-285-1600 Quality Since 1935

1129 South Sacramento Street Call Box 241002

Lodi, CA 95240 USA

Local/Intl. Tel. 209-368-7171 Fax 209-368-3246

TOLL FREE (U.S. & Canada) 1-800-285-1600

TOLL FREE FAX (U.S. & Canada) 1-800-756-9998

http://www.holzrubber.com

E-mail: ejsales@holzrubber.com

Manufacturers of Engineered Expansion Joints

You might also like

- Redflex BrochureDocument24 pagesRedflex BrochuremecarrascogNo ratings yet

- Expension Joints Engineering AppliancesDocument30 pagesExpension Joints Engineering AppliancesAcid BurnsNo ratings yet

- GB Teguflex A4 2015Document8 pagesGB Teguflex A4 2015eliasx1No ratings yet

- Asme Sa-836 Specification For Forgings, Titaniumstabilized Carbon Steel, For Glass-Lined Piping and Pressure Vessel ServiceDocument5 pagesAsme Sa-836 Specification For Forgings, Titaniumstabilized Carbon Steel, For Glass-Lined Piping and Pressure Vessel Servicelucecita1902No ratings yet

- MeasurIT Red Valve Expansion Joints J1 0802Document3 pagesMeasurIT Red Valve Expansion Joints J1 0802cwiejkowskaNo ratings yet

- Compression Packing Selection Guide: Sealing Products For IndustryDocument13 pagesCompression Packing Selection Guide: Sealing Products For IndustryAdverNo ratings yet

- Round Industrial Duct Construction Standards: Sheet Metal and Air Conditioning Contractors' National Association, IncDocument19 pagesRound Industrial Duct Construction Standards: Sheet Metal and Air Conditioning Contractors' National Association, IncNathanNo ratings yet

- Titan Flow Control, IncDocument178 pagesTitan Flow Control, IncKemQueNo ratings yet

- Piston ValveDocument28 pagesPiston ValveDamien BouticourtNo ratings yet

- Catalog - Texas FlangesDocument76 pagesCatalog - Texas FlangesVicky GautamNo ratings yet

- BS 4504 Slip On Flanges PDFDocument7 pagesBS 4504 Slip On Flanges PDFMaclean ArthurNo ratings yet

- BS Bolt MaterialDocument1 pageBS Bolt MaterialKamlesh LuharNo ratings yet

- Astm A312Document2 pagesAstm A312faisi778No ratings yet

- FOAMGLAS Cellular Glass InsulationDocument18 pagesFOAMGLAS Cellular Glass InsulationermizeNo ratings yet

- Valvula Mariposa Danais 150Document15 pagesValvula Mariposa Danais 150Oscar CherroNo ratings yet

- Egg CrateDocument6 pagesEgg CrateZaw Moe KhineNo ratings yet

- Fluid Sealing Standards For NMEJ StandardsDocument9 pagesFluid Sealing Standards For NMEJ Standardsamol1321No ratings yet

- RubberCzech - Cataloque of Rubber Expansion JointsDocument62 pagesRubberCzech - Cataloque of Rubber Expansion JointsEngineering Hidromekanikal100% (1)

- NSF Standard 14Document3 pagesNSF Standard 14krisNo ratings yet

- Needle ValveDocument8 pagesNeedle ValveMuhammad Chilmi100% (1)

- Low Temperature and Cryogenic Ball ValvesDocument4 pagesLow Temperature and Cryogenic Ball Valves윤병택100% (1)

- P520A2-AMCA 24 Oct 17 (Latest) PDFDocument210 pagesP520A2-AMCA 24 Oct 17 (Latest) PDFออกแบบเครื่องแลกเปลี่ยนความร้อนNo ratings yet

- Foam ChamberDocument3 pagesFoam ChamberGonzalo CabreraNo ratings yet

- ASTM F1545 Plastic Lined Pipe 0803 PDFDocument6 pagesASTM F1545 Plastic Lined Pipe 0803 PDFdavi rodriguesNo ratings yet

- DME - Expansion Joint - Catalog PDFDocument19 pagesDME - Expansion Joint - Catalog PDFsammar_10No ratings yet

- Oil-X Evolution: High Efficiency Compressed Air FiltersDocument24 pagesOil-X Evolution: High Efficiency Compressed Air FiltersAdegallasNo ratings yet

- Screw Thread CalculationsDocument4 pagesScrew Thread CalculationsbagmassNo ratings yet

- Plastic-Lined Ferrous Metal Pipe, Fittings, and Flanges: Standard Specification ForDocument6 pagesPlastic-Lined Ferrous Metal Pipe, Fittings, and Flanges: Standard Specification ForMohammed TariqNo ratings yet

- Chibro Press Fit Piping Data SheetDocument5 pagesChibro Press Fit Piping Data SheetBoyd JohnstonNo ratings yet

- Hydroheater Auto Manual VersionDocument45 pagesHydroheater Auto Manual VersionVishal Nawalgaria100% (3)

- Astm A-351 GR CF8MDocument2 pagesAstm A-351 GR CF8MVictor Castellanos AlegriaNo ratings yet

- Dampers: Air Chem Systems, IncDocument12 pagesDampers: Air Chem Systems, Inchector.pineda7111No ratings yet

- Mechanical Operation Slurry TransportDocument113 pagesMechanical Operation Slurry TransportIsrarulHaqueNo ratings yet

- Kare Anemostat DamperliDocument4 pagesKare Anemostat Damperlidignified34No ratings yet

- Estimate of The Heat Gain or Loss and The Surface Temperatures of Insulated Flat, Cylindrical, and Spherical Systems by Use of Computer ProgramsDocument41 pagesEstimate of The Heat Gain or Loss and The Surface Temperatures of Insulated Flat, Cylindrical, and Spherical Systems by Use of Computer ProgramsMohan S100% (1)

- D10.4 R1986PVDocument7 pagesD10.4 R1986PVGabriela AxinteNo ratings yet

- Asme VIII Div1 2010-2011a PDFDocument86 pagesAsme VIII Div1 2010-2011a PDFJohan ConradieNo ratings yet

- Copper Tubes - ASTM B88MDocument7 pagesCopper Tubes - ASTM B88Myarzar17No ratings yet

- High-Rise Fan - Coil - EngineerDocument15 pagesHigh-Rise Fan - Coil - EngineerMIN GUINo ratings yet

- Allowable Nozzle LoadsDocument7 pagesAllowable Nozzle LoadsZulkarnain NasrullahNo ratings yet

- Hose&Braid Catalog FlexicraftDocument24 pagesHose&Braid Catalog Flexicraftkutts76No ratings yet

- Bolt/hex Nut Strength MarkingsDocument3 pagesBolt/hex Nut Strength Markings322399mk7086No ratings yet

- Egg Crate: Product InformationDocument5 pagesEgg Crate: Product Informationntt_121987No ratings yet

- F10ca004-Gb 0597Document8 pagesF10ca004-Gb 0597gabyorNo ratings yet

- Forbes Marshall Piston ValvesDocument8 pagesForbes Marshall Piston ValvesAnonymous 0CnvpxSNo ratings yet

- Astm F436.04 PDFDocument6 pagesAstm F436.04 PDFWelington Volpatto MoraisNo ratings yet

- RectangularDocument11 pagesRectangulararifzakirNo ratings yet

- Astm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)Document13 pagesAstm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)Vishal MistryNo ratings yet

- Knife Gate Valve - For Reference OnlyDocument16 pagesKnife Gate Valve - For Reference Onlysj_scribdNo ratings yet

- BS 5500 Appendix K and DDocument14 pagesBS 5500 Appendix K and DCRISTIAN SILVIU IANUCNo ratings yet

- Knife Gate Valve Testing Procedure Rev. 2Document2 pagesKnife Gate Valve Testing Procedure Rev. 2mehtahemalNo ratings yet

- Definition and Details of Flanges - Types of FlangesDocument11 pagesDefinition and Details of Flanges - Types of FlangesSUKANTA DALAINo ratings yet

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocument9 pagesGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessCarlos Ramirez BaltazarNo ratings yet

- Simona-Catalogo Pipes & Fittings & ValvesDocument60 pagesSimona-Catalogo Pipes & Fittings & ValvesMohamed MagdyNo ratings yet

- Sa 299Document3 pagesSa 299Web LogueandoNo ratings yet

- Awwa d103 PotableDocument9 pagesAwwa d103 PotableAnonymous UArnIExNo ratings yet

- 4 Egg Crate Grills PDFDocument6 pages4 Egg Crate Grills PDFMUHAMMED SHAFEEQNo ratings yet

- Astmf436 PDFDocument6 pagesAstmf436 PDFMiguel Angel Oncoy TahuaNo ratings yet

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceDocument2 pagesSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceChandra ClarkNo ratings yet

- AFFIDAVIT OF ACCIDENT - MENESES 2ndDocument2 pagesAFFIDAVIT OF ACCIDENT - MENESES 2ndRoland Bon IntudNo ratings yet

- Negotiated Payment TermsDocument2 pagesNegotiated Payment TermsRoland Bon IntudNo ratings yet

- Items Sourced With Other Vendors at A Lower Price: Mat # Description Unit Previous Supplier New SupplierDocument6 pagesItems Sourced With Other Vendors at A Lower Price: Mat # Description Unit Previous Supplier New SupplierRoland Bon IntudNo ratings yet

- List of Discontinued Items: 3337 Rud Star EnterprisesDocument2 pagesList of Discontinued Items: 3337 Rud Star EnterprisesRoland Bon IntudNo ratings yet

- Affidavit of Adverse Claim Reni BularonDocument2 pagesAffidavit of Adverse Claim Reni BularonRoland Bon IntudNo ratings yet

- Affidiavit of Adjudication of Sole Heir - ELSA GUZMANADocument2 pagesAffidiavit of Adjudication of Sole Heir - ELSA GUZMANARoland Bon Intud100% (1)

- Affidavit of Closure - 007 GUNS AND AMMODocument1 pageAffidavit of Closure - 007 GUNS AND AMMORoland Bon IntudNo ratings yet

- Transpo Law (Beda Memory Aid)Document24 pagesTranspo Law (Beda Memory Aid)Vince LeidoNo ratings yet

- Commercial Review: Insurance: Insurance: Manila Bankers vs. AbanDocument2 pagesCommercial Review: Insurance: Insurance: Manila Bankers vs. AbanRoland Bon IntudNo ratings yet

- Affidavit of Adverse Claim Reni BularonDocument2 pagesAffidavit of Adverse Claim Reni BularonRoland Bon IntudNo ratings yet

- Third Party Claim-TerceriaDocument9 pagesThird Party Claim-TerceriaRoland Bon IntudNo ratings yet

- Affidavit of Two Disinterested Persons Abragan-SabioDocument1 pageAffidavit of Two Disinterested Persons Abragan-SabioRoland Bon IntudNo ratings yet

- Affidavit of Adverse Claim Reni BularonDocument2 pagesAffidavit of Adverse Claim Reni BularonRoland Bon IntudNo ratings yet

- Haystack TranspoLaw (2004)Document568 pagesHaystack TranspoLaw (2004)Berne Guerrero100% (5)

- Inter Orient Vs NLRCDocument4 pagesInter Orient Vs NLRCpja_14No ratings yet

- Maritime Cases: 1. Pioneer Insurance vs. Apl Co. (2017)Document5 pagesMaritime Cases: 1. Pioneer Insurance vs. Apl Co. (2017)Roland Bon IntudNo ratings yet

- Notes On TransportationDocument153 pagesNotes On TransportationRoland Bon IntudNo ratings yet

- Ipc CasesDocument4 pagesIpc CasesBaesittieeleanor MamualasNo ratings yet

- Maritime Cases: 1. Pioneer Insurance vs. Apl Co. (2017)Document5 pagesMaritime Cases: 1. Pioneer Insurance vs. Apl Co. (2017)Roland Bon IntudNo ratings yet

- Commercial Review: Anti-Money Laundering Act: Amla: PP vs. Estrada (2007) Digest 1Document6 pagesCommercial Review: Anti-Money Laundering Act: Amla: PP vs. Estrada (2007) Digest 1Roland Bon IntudNo ratings yet

- Commercial Review: Corporation CodeDocument10 pagesCommercial Review: Corporation CodeRoland Bon IntudNo ratings yet

- Maritime Cases: 1. Pioneer Insurance vs. Apl Co. (2017)Document5 pagesMaritime Cases: 1. Pioneer Insurance vs. Apl Co. (2017)Roland Bon IntudNo ratings yet

- Bank Deposit Secrecy Law: Maruqez vs. DesiertoDocument1 pageBank Deposit Secrecy Law: Maruqez vs. DesiertoRoland Bon IntudNo ratings yet

- Floating: A LAW EACH DAY (Keeps Trouble Away) by Jose C. Sison CommentsDocument2 pagesFloating: A LAW EACH DAY (Keeps Trouble Away) by Jose C. Sison CommentsRoland IntudNo ratings yet

- Dual Relationship December 18, 2013 ADOPTIONDocument1 pageDual Relationship December 18, 2013 ADOPTIONRoland IntudNo ratings yet

- Breach of Contract Can Cost Migrant Worker Damage Suit OVERSEAS EMPLOYMENT CONTRACT-BRACH OF CONTRACT AUG 7 2017Document2 pagesBreach of Contract Can Cost Migrant Worker Damage Suit OVERSEAS EMPLOYMENT CONTRACT-BRACH OF CONTRACT AUG 7 2017Roland Bon IntudNo ratings yet

- The Tale of 3 Compañeros FALSIFICATION-LEGAL ETHICS June 3, 2017Document4 pagesThe Tale of 3 Compañeros FALSIFICATION-LEGAL ETHICS June 3, 2017Roland IntudNo ratings yet

- What Constitutes Due Process in Administrative Cases DUE PROCESS-ADMINISTRATIVE AUG 15 2017Document2 pagesWhat Constitutes Due Process in Administrative Cases DUE PROCESS-ADMINISTRATIVE AUG 15 2017Roland IntudNo ratings yet

- Non IssueDocument1 pageNon IssueMichaela BalawegNo ratings yet

- Hostile and Unreasonable May 23, 2013 LABORDocument2 pagesHostile and Unreasonable May 23, 2013 LABORRoland IntudNo ratings yet

- NDP-80 Data SheetDocument9 pagesNDP-80 Data SheetSarah PerezNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Cover - Jrc12 & Jrc14Document1 pageCover - Jrc12 & Jrc14hatem hamaidiNo ratings yet

- Sika Fiber: Monofilament Polypropylene FibresDocument2 pagesSika Fiber: Monofilament Polypropylene Fibresiwan 242017021No ratings yet

- Thogoto Vocation BQDocument13 pagesThogoto Vocation BQJuancy LemaiyanNo ratings yet

- Rust Preventive Coating Materials For Automobile Parts: Nissan Engineering StandardDocument7 pagesRust Preventive Coating Materials For Automobile Parts: Nissan Engineering StandardJose BresciaNo ratings yet

- Facade GuidenceDocument83 pagesFacade GuidencebrunoNo ratings yet

- Two Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransDocument21 pagesTwo Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransJohn Michael TalanNo ratings yet

- EIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpDocument2 pagesEIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpShubham BaderiyaNo ratings yet

- Du Pont KevlarDocument23 pagesDu Pont Kevlarniks2409100% (3)

- Defects On & in SlabsDocument26 pagesDefects On & in Slabsfoush bashaNo ratings yet

- Roofing Installation Guide - Technical Guide PDFDocument12 pagesRoofing Installation Guide - Technical Guide PDFMalik RiazNo ratings yet

- Asphalt Concrete Report Final VersionDocument11 pagesAsphalt Concrete Report Final VersionLorraine Custodio100% (1)

- Welded Nickel (UNS N02200/UNS N02201) and Nickel Copper Alloy (UNS N04400) PipeDocument5 pagesWelded Nickel (UNS N02200/UNS N02201) and Nickel Copper Alloy (UNS N04400) PipeGreg Yee100% (1)

- CMFB Vol 3 Approach Bridge Substructure S1 P2Document45 pagesCMFB Vol 3 Approach Bridge Substructure S1 P2ani4576No ratings yet

- Design & Drawing Review ReportDocument4 pagesDesign & Drawing Review ReportRashel HasanNo ratings yet

- Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsDocument3 pagesRepair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsJuan Novillo RamosNo ratings yet

- AOK Spec Only 2016-02Document17 pagesAOK Spec Only 2016-02Iulian MihaiNo ratings yet

- Cable ManagementDocument60 pagesCable ManagementrakeshsinghsisodiaNo ratings yet

- Material Science & MetallurgyDocument2 pagesMaterial Science & Metallurgysameer_m_daniNo ratings yet

- Housing TechnologiesDocument9 pagesHousing TechnologiesKawaii CraftsNo ratings yet

- The Three Main Forms of Energy Used in Non-Conventional Machining Processes Are As FollowsDocument3 pagesThe Three Main Forms of Energy Used in Non-Conventional Machining Processes Are As FollowsNVNo ratings yet

- Astm D-3840 - 01Document9 pagesAstm D-3840 - 01Bipin SasikumarNo ratings yet

- R FactorsDocument5 pagesR FactorsAneesh KNo ratings yet

- Shera Board Cladding FacadeDocument1 pageShera Board Cladding Facadevabegu9No ratings yet

- BMsDocument30 pagesBMsMir Ilyas100% (1)

- Excess Flow Valves Bleed Valves and Purge ValvesDocument6 pagesExcess Flow Valves Bleed Valves and Purge ValvesNilesh MistryNo ratings yet

- DIY Hobby Spray Booth Assembly Instructions Material Cut List by Vent WorksDocument5 pagesDIY Hobby Spray Booth Assembly Instructions Material Cut List by Vent WorksDiego Alex Gomez PerezNo ratings yet

- Positive Material Identification Report: PMI - Just in CaseDocument1 pagePositive Material Identification Report: PMI - Just in CaseJuan CarlosNo ratings yet

- Dr. Fixit Pidicrete URP 171 1 PDFDocument4 pagesDr. Fixit Pidicrete URP 171 1 PDFManish Khaling RaiNo ratings yet