Professional Documents

Culture Documents

Triac Red Snubber

Uploaded by

Dandy ChavezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Triac Red Snubber

Uploaded by

Dandy ChavezCopyright:

Available Formats

AN439

APPLICATION NOTE

IMPROVEMENT IN THE TRIAC COMMUTATION

INTRODUCTION

In the last few years, the use of triacs has spread to all areas of electronics, including domestic appliances

and industrial applications.

The use of triacs has been traditionally limited by their switching behavior in applications where there is a

risk of spontaneous firing after conduction.

In order to obtain the required reliability in todays equipment, the designer must take a certain number of

precautions: over dimensioning of the device, switching aid networks (snubber), significant margin of security of the junction temperature, etc. This generally involves additional costs.

After a brief discussion of commutation problem when a triac is turned off, this article will describe the

progress made in this area and the newest possibilities now offered to triac user thanks to the new series

Logic Level and SNUBBERLESSTM triac.

The commutation problem of the triac In its electrical representation the triac can be compared to two thyristors mounted in anti-parallel and coupled with a control device which allows activation of this AC switch

with only one gate (see Figure 1a).

In considering the structure of a triac (see Figure 1b), one notices that the conduction zones, corresponding to these two thyristors and which control the current in one direction and then in the other, narrowly

overlap each other and the control zone.

During the conduction time, a certain quantity of charges is injected into the structure. The biggest part of

these charges disappears by recombining during the fall of the current in the circuit, while another part is

extracted at the moment of blocking by the inverse recovery current.

Nonetheless an excess charge remains, particularly in the neighboring regions of the gate, which can provoke in certain cases the firing of the other conduction zone at the moment when the supply voltage of the

circuit is reapplied across the triac. This is the problem of commutation.

For a given structure at a determined junction temperature, the switching behavior depends on:

1. The quantity of charges which remains at the moment when the current drops to zero. this number of

charges is linked to the value of the current which was circulating in the triac approximately 100

microseconds before the cut-off. (This time corresponds to two or three times the life time of the minority

carriers). Thus, the parameter to consider here will be the slope of the decreasing current which is called

the commutating di/dt, or (di/dt)c. (see Figure 2)

2. The speed at which the reapplied voltage increases at the moment when the triac turns off, which is

called the commutating dv/dt, or (dv/dt)c. (see Figure 2) A capacitive current, proportional to the (dv/

dt)c, flows into the structure, and therefore injected charges are added to those coming from the

previous conduction.

April 2004

REV. D2A - 3577

1/14

AN439 APPLICATION NOTE

Figure 1. (A) Simplified equivalent schematic of triac circuit; (B) Example of a triac structure

I+

I-

A1

G

P1

N1

N4

I+

Cde

IN2

P2

A2

N3

CONTROL

AREA

Characterization

In order to characterize the switching behavior of a triac when it turns off, we consider a circuit in which

we can vary the slope of the decrease in current (di/dt)c. In addition, we control the slope of the reapplied

voltage by using, for example, a circuit of resistors and capacitors connected across triac to be measured.

For a determined (dv/dt)c, we progressively increase the (di/dt)c until a certain level which provokes the

spontaneous firing of the triac. This the critical (di/dt)c value.

Therefore, for different (dv/dt)c values, we note the critical (di/dt)c value for each sample. This makes possible to trace the curve of the commutation behavior of the triac under consideration.

Figure 3 represents the results obtained with a standard 12A triac (IGT 50mA) and a sensitive gate, 6A

triac (IGT 10mA). For standard triacs the critical (di/dt)c is sightly modified when we vary the (dv/dt)c. For

sensitive gate triacs, this parameter noticeably decreases when the slope of the reapplied voltage is increased.

2/14

AN439 APPLICATION NOTE

Figure 2. Triac voltage and current at commutation

IT (Triac current)

(di/dt)c

0

ro

VT (Triac voltage)

Voltage in conducting state

0

t

(dv/dt)c

Voltage in blocked state

Figure 3. Critical (di/dt)c versus (dv/dt)c (below the curve the triac turns on spontaneously)

(di/dt)c

CRITICAL (dI/dt)c VERSUS (dV/dt)c

(A/ms)

20

SAMPLE #1

12A TRIAC

A2

10

B2

A1

C2

5

SAMPLE #2

SENSITIVE TRIAC

B1

2

C1

0

1

.2

.5

10

20

50

100 (dv/dt)c

(V/s)

Note: A1 and A2: The rate of re-application of the off-state voltage of these points corresponds to the mains (sinusoidal wave form) at zero

crossing.

B1 and B2: The (dv/dt)c is limited by a snubber at the values generally specified in the data sheets (5V/ms or 10V/ms).

C1 and C2: These points are obtained without snubber.

3/14

AN439 APPLICATION NOTE

In practice, the current waveform, and thus the (di/dt)c, is imposed by the circuit. Generally we cannot

change it.

So, in triacs applications it is always necessary to know the (di/dt)c of the circuit in order to choose a triac

with a suitable critical (di/dt)c. This is the most important parameter.

Suppose a circuit in which the (di/dt)c reaches 15A/ms. The triac n1 characterized by the upper curve in

Figure 3 is not suitable in such a circuit even if the (dv/dt)c is reduced nearly to zero by connecting a huge

snubber network across it.

Applications in basic circuits

When considering the constraints in commutation at the turn off of a triac, we can distinguish two cases:

1. The use of a triac on resistive load (see Figure 5). In this case the current and the voltage are in

phase. When the triac switches off (i.e. when the current drops to zero), the supply voltage is nullified at

this instant and will increase across the triac according to the sinusoidal law:

V = Vm sint

Example:

For the European mains of Vrms = 220V at 50Hz, the slope will be:

( dv dt )c = Vm = Vrms 2 = 01V

----------s

This relatively low (dv/dt)c corresponds to points A1 and A2 on the curves in Figure 3.

As far as the (di/dt)c is concerned in the circuit, it depends on the load. For a resistance of loads R and

under a Vrms voltage, we will have:

2

( dv dt )c = Im = Vrms -------

R

2. The use of a triac on inductive load. In this case there is a phase lag between the current and the

supply voltage (see Figure 6).

When the currents drops to zero the triac turns off and the voltage is abruptly pushed to its terminals. To

limit the speed of the increasing voltage, we generally use a resistive/capacitive network mounted in parallel with the triac. This "snubber" is calculated to limit the (dv/dt)c to 5 or 10V/s according to the specified

value in the data sheet. This case corresponds to points B1 and B2 in Figure 3. The (di/dt)c is also determined in this case by load impedance (z) and the supply voltage.

4/14

AN439 APPLICATION NOTE

Figure 4. Current and voltage ware forms for resistive loads: (A) Case On / Off switching; (B) Case

of phase control)

Gate trigger

Gate trigger

0

t

I Triac

t

I Triac

(dI/dt)c

(dI/dt)c

0

0

t

V Triac

V Triac

(dV/dt)c

(dV/dt)c

0

0

t

Supply Voltage

(A)

(B)

5/14

AN439 APPLICATION NOTE

Figure 5. Current and voltage ware forms for inductance loads: (A) Case On / Off switching;

(B) Case of phase control

Gate trigger

Gate trigger

0

t

I Triac

I Triac

(dI/dt)c

(dI/dt)c

0

t

V Triac

V Triac

(dV/dt)c

(dV/dt)c

0

Supply Voltage

(A)

(B)

The use of a triac without a snubber network

The triac can thus be considered as a switch which turns off at the moment when the current is cut off in

the dampened oscillating circuit constituted by the loads L and R and the internal capacity of the triac Ct

(see Figure 6). In the case of a pure inductive load, the maximum reapplied (dv/dt) is:

dv

------ c =

dt

2 Vrms Irms -----Ct

For example, the internal capacitance of a 12A triac is about 70pF. Therefore, on inductive load, the maximum (dv/dt)c without snubber will be limited to 50 or 100 V/S according to the characteristics of the load.

It is interesting to know the behavior of the triac, in particular the critical (di/dt)c value, in these conditions.

This characterization corresponds to the points C1 and C2 of the curve Figure 3.

6/14

AN439 APPLICATION NOTE

Figure 6. Triac commutation on an inductance load without a snubber network

LOAD

L

LOAD

R

L

+VC

VT

R

+VC

CT

VT

(dV/dt)c

t

A PROGRESS: THE NEW TECHNOLOGY

To make significant progress in the triac area is to essentially improve the commutative behavior at the

turn off of the triac. In other words the critical (di/dt)c has to be improved.

In order to reach this goal, a new structure has been developed. In this structure, the different active zones

have been de-coupled to the maximum in such a way as to separate the elementary thyristors and the

gate area. This is made possible by sacrificing the gate triggering in the fourth quadrant. In practice this

does not pose a problem because the gate drive circuits of a triac generally use two of the third first quadrants (see Figure 7).

Figure 7. Triac commutation on an inductance load without a snubber network

VCC

R

DIAC

OPTO

COUPLEUR

(Photo Triac)

1

IC

For a given technology, the commutative behavior of triacs depends on the sensitivity of the gate. The correlation between the critical (di/dt)c and the gate current for 12A triacs is represented in Figure 8. In the

same chart, we can see the results obtained with conventional triacs versus the new technology triacs. As

can be seen, the progress that has been made at this level is significant.

7/14

AN439 APPLICATION NOTE

The performances and specifications

Figure 8. Correlation between commutative behavior and sensitivity. (Measurements performed

on several lots of 12A triacs)

Critical

(dI/dt)c

V A/mS

30

NEW TECHNOLOGY PARTS

CONVENTIONAL TRIACS

25

20

15

10

5

Igt 3rd quadrant (mA)

10

20

30

40

50

60

The new technology has been put into place with the manufacturing of the two new series, Logic Level

and SNUBBERLESS Triacs. In the data sheets of these new triacs a critical (di/dt)c limit is specified at the

maximum junction temperature (Tj max).

Logic Level triacs

In this category we consider sensitive triacs in which the maximum gate current (IGT) is 5mA for the TW

type and 10mA for the SW one.

In the data sheets of the Logic Level triacs a minimum (di/dt)c is specified for the following cases:

Resistive load with a (dv/dt)c of 0.1V/s.

Inductive load with a (dv/dt)c of 20V/s

For example the 6A triac is specified as follows:

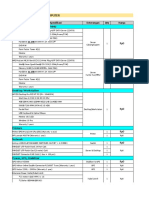

Table 1. Triac specifications

Suffix

Symbol

tGT

(di/dt)c 1

Test conditions

VD = VDRM; IG = 90mA; dIG/dt = 0.8A/ms

Quadrant

Tj = 25C

dV/dt = 0.1V/ms

I - II - III

Unit

TW

SW

Typ

Min

3.5

4.5

Min

1.8

3.5

Tj = 110C

dV/dt = 20V/ms

s

A/ms

Note: 1. For either polarity of electrode A2 voltage with reference to electrode A1.

SNUBBERLESS Triacs

This series of triacs presently covers the range 6 to 25A with gate currents of 35mA (CW type) and 50mA

(BW type) according to the type required.This series has been specially designed so that the triacs switches from the on state to the off state without the use of an external snubber circuit.

8/14

AN439 APPLICATION NOTE

Whatever the nature of the load, there is absolutely no risk of spurious firing at the turn off of the triac as

long as it is functioning under the specified (di/dt)c value.

The SNUBBERLESS triacs are specified at critical (di/dt)c values which are greater than the decreasing

slope of the nominal current in a sinusoidal configuration. For example, the slope of the current in a triac

conducting 16A when the current drops to zero is:

di

---- c = Irms 2 = 7A/ms at 50Hz

dt

The BTA/BTB16-600BW is specified at (di/dt)c = 14A/ms.

Table 2 summarizes the characteristics of the BW, CW SNUBBERLESS triacs which are presently available:

Table 2. Characteristics of the BW, CW SNUBBERLESS triacs presently available

WITHOUT SNUBBER

Type

Current

Voltage

Suffix

IGT Max (mA)

Static dV/dt Min (V/s)

(dI/dt)c Min (A/ms)

BTA / BTB

06A

200 to 800V

BW

CW

50

35

500

250

5

3.5

BTA / BTB

08A

200 to 800V

BW

CW

50

35

500

250

7

4.5

BTA / BTB

10A

200 to 800V

BW

CW

50

35

500

250

9

5.5

BTA / BTB

12A

200 to 800V

BW

CW

50

35

500

250

12

6.5

BTA / BTB

16A

200 to 800V

BW

CW

50

35

500

250

14

8.5

BTA / BTB

20A

200 to 800V

BW

CW

50

35

500

250

18

11

BTB

24A

200 to 800V

BW

CW

50

35

500

250

22

13

BTA

26A

200 to 800V

BW

CW

50

35

500

250

22

13

THE ADVANTAGES AND APPLICATIONS

Logic Level

The goal of these triacs is to be controlled directly by logic circuits and microcontrollers like the ST6 series:

Outputs of ST6 can sink currents up to 20mA per I/O line, and therefore drive TW and SW.

These triacs are ideal interface for power components supplied by 110 or 220V, such as valves, heating

resistances, and small motors.

The specification of the critical (di/dt)c value on both resistive and inductive loads allows one

1. to know the margin of security of the circuit in relation to the risk of the spurious firing, which results in

improved reliability, and

2. to optimize the performance of the triac to be used, which results in a cost reduction.

9/14

AN439 APPLICATION NOTE

Figure 9. Triac commutation on an inductance load without a snubber network

LINE

+5V

FUSE

DD

19

PA0

18

100

A1

3 x 4.7M

RESET

PB0 15

TOUCH SENSOR

PA1

MODE

+5V

A2

BTA 08-400SW

ST6210

13 PB2

12

PB3

100k

0V

11

14

PUSH BUTTON

NMI 5

0V

TEST 6

V SS 20

OSCOUT OSCIN

PB4

10 PB5

220k

100k

PB1

4

220k

+5V

3

8MHz

10p

220k

POTENTIOMETER

10p

22k

0V

0V

0V

0V

0V

+5V

BZW55C5V6

100

6.3V

820

NEUTRAL

220n

400V

1/2W

1N4148

All resistors:

1/4W unless otherwise specified

0V

SNUBBERLESS Triacs

The commutation of SNUBBERLESS triacs is specified without a limitation (dv/dt)c. With the suppression

of the snubber in the circuit, there is a noticeable cost reduction.

Each SNUBBERLESS triac series is specified with a critical (di/dt)c value and the static (dv/dt) at the highest possible level, taking into consideration the gate sensitivity (IGT). The minimum specified levels for

these two parameters allows the use of these products in circuits where there is a need for high safety

factor, such as:

Static relays in which the load is not well defined. With conventional triacs it is difficult to adapt the

snubber to all possible cases.

SNUBBERLESS triacs resolve this problem (see Figure 10).

Motor drive circuits. Figure 11 shows an inversion circuit of an asynchronous motor where spurious firing of the triac, normally assumed to be in off-state, must be absolutely be avoided.

The critical (di/dt)c of SNUBBERLESS triacs is greater than the slope of the nominal current of the specific

type under consideration. This is important for several applications, including:

Circuits in which the (di/dt)c in a transient state is greater than in the steady state. This is the case for universal motors controlled by AC phase control circuit. Table 3 shows how to the use of a SNUBBERLESS

triac can optimize the efficiency of the circuit.

Circuits which generate wave forms with a very high (di/dt)c, such as inductive load supplied by a diode

bridge (see Figure 12). It is only limited by the parasitic inductance of the AC circuit.

10/14

AN439 APPLICATION NOTE

Figure 10. Solid state relay diagram

INPUT

LOAD

OPTO INSULATED

DRIVE CIRCUIT

+

ZERO CROSSING

CIRCUIT

LINE

Figure 11. Triac commutation on an inductance load without a snubber network

MOTOR

LINE

(220 VRMS)

C

LS+R

T1

GATE DRIVE

CIRCUIT

T2

Table 3. Universal motor control: Triac choise must comply with maximum (dI/dt)c

(For example, a SNUBBERLESS 10A triac is sufficient to control a 110V AC 600 W motor)

Supply

Voltage

Nominal

Current

Max Current

to Control

Triac

Range

(di/dt)c

Max(1)

Standards

Triac

SNUBBERLESS

Triac

600 W

220V/50Hz

110V/60Hz

3 ARMS

6 ARMS

3.5 A

7A

6A

10 A

A A/ms

7 A/ms

BTA10-600B

BTA16-400B(2)

BTA06-600BW

BTA10-400BW

1200 W

220V/50Hz

110V/60Hz

6 ARMS

12 ARMS

7A

14 A

10 A

16 A

7 A/ms

15 A/ms

BTA16-600B

BTB24-400B

BTA10-600BW

BTA20-600BW

Power

Note: 1. Maximum transient (dI/dt)c. This parameter depends very much on the type of the motor.

2. This type specified at 7A/ms munumum can be too small certain applications could need 25 A standard triac.

11/14

AN439 APPLICATION NOTE

Figure 12. Triac commutation on an inductance load without a snubber network

Inductive load

(Motor, valve, ...)

CONCLUSION

Thanks to the recent progress made in triac technology, the designer now has at disposal devices with a

commutating behavior which is compatible with all applications in the 50 or 60Hz range. This includes

phase control and static commutation for loads going from a few watts to several kilowatts.

The capability of this new generation of triacs allows:

1. To increase the reliability of circuits, particularly where there is a risk of spontaneous firing even in the

most difficult configurations.

2. To reduce the cost by using sensitive gate, LOGIC LEVEL triacs without the need for an interface

between the gate and the logic circuit, or utilizing SNUBBERLESS triacs which are specified without a

resistive/capacitive network.

Additionally, the limit of the (di/dt)c parameter is now listed in ST data sheets.

This permits the optimization of the circuit by specifying stricter guidelines in the choice of the component.

12/14

AN439 APPLICATION NOTE

REVISION HISTORY

Table 4. Revision History

Date

Revision

Description of Changes

May-1992

First Issue

19-Apr-2004

Stylesheet update. No content change.

13/14

AN439 APPLICATION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

2004 STMicroelectronics - All rights reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

www.st.com

14/14

You might also like

- Triac 400v 15aDocument14 pagesTriac 400v 15aVG1975No ratings yet

- New Triacs - Is The Snubber Circuit NecessaryDocument7 pagesNew Triacs - Is The Snubber Circuit NecessaryAlexa DjokicNo ratings yet

- An436 Application NoteDocument9 pagesAn436 Application NoteEdgar MuñozNo ratings yet

- RC Snubber Network For ThyristorsDocument22 pagesRC Snubber Network For ThyristorsCintya CardozoNo ratings yet

- An Quadrants I and IIIDocument6 pagesAn Quadrants I and IIIADVgamerNo ratings yet

- 5SYA 2020-02 Feb 08 Design of RC-CircuitsDocument14 pages5SYA 2020-02 Feb 08 Design of RC-Circuitsleo232No ratings yet

- Carga Inductiva Con TriacDocument11 pagesCarga Inductiva Con Triacanon_274509247No ratings yet

- ACS Switch Application Note PDFDocument18 pagesACS Switch Application Note PDFnassimNo ratings yet

- Triacs For Microwave OvenDocument8 pagesTriacs For Microwave Ovenlucjan52No ratings yet

- Snubber PDFDocument5 pagesSnubber PDFJ Milk SilvaNo ratings yet

- Implement An AC-switch Triggering Circuit Using An Optical Triac PDFDocument3 pagesImplement An AC-switch Triggering Circuit Using An Optical Triac PDFIvana PrezimeNo ratings yet

- Light Dimmer CircuitDocument4 pagesLight Dimmer Circuithamza abdo mohamoudNo ratings yet

- 11 - L-19 (SSG) (Pe) ( (Ee) Nptel)Document1 page11 - L-19 (SSG) (Pe) ( (Ee) Nptel)CharkNo ratings yet

- Triac - Basic ConceptsDocument8 pagesTriac - Basic ConceptsjimNo ratings yet

- Part 11Document4 pagesPart 11pravishnNo ratings yet

- Chapter 3Document6 pagesChapter 3pravi2018sNo ratings yet

- Breakover DevicesDocument37 pagesBreakover DevicesAnnalyn Duculan SoriaNo ratings yet

- Practical Power Distribution For IndustryDocument3 pagesPractical Power Distribution For Industryrajpre1213No ratings yet

- Low Voltage Fara TrafDocument8 pagesLow Voltage Fara TraftyutyuNo ratings yet

- Analysis and Control of DSTATCOM For A Line Voltage RegulationDocument6 pagesAnalysis and Control of DSTATCOM For A Line Voltage RegulationSeema P DiwanNo ratings yet

- 3.4.2 Output Capacitor: Out C, Max OutDocument14 pages3.4.2 Output Capacitor: Out C, Max OutReza RzNo ratings yet

- Experiment - 3 Object:-Study and Test The Firing Circuit of 3-Phase Full Controlled Bridge Converter. TheoryDocument3 pagesExperiment - 3 Object:-Study and Test The Firing Circuit of 3-Phase Full Controlled Bridge Converter. Theorysahumanish9240100% (1)

- Delay: Minimum Time From The Input Crossing 50% To The OutputDocument12 pagesDelay: Minimum Time From The Input Crossing 50% To The Outputakash bhumiNo ratings yet

- Snubber Circuit - RC Snubber Design Using TRIACsDocument18 pagesSnubber Circuit - RC Snubber Design Using TRIACsUtpal100% (2)

- EE 5021: Power Converter Analysis and Design Sept2020-Jan2021 Assignment 3Document3 pagesEE 5021: Power Converter Analysis and Design Sept2020-Jan2021 Assignment 3Raj JhaNo ratings yet

- Digital Simulation of DC Links and AC MachinesDocument8 pagesDigital Simulation of DC Links and AC MachinesNarges FallahNo ratings yet

- Vaz 2017Document6 pagesVaz 2017Santhosh H ANo ratings yet

- CBCTDocument14 pagesCBCTYPV TECHNICAL SERVICES100% (1)

- L-4 (DK) (Pe) ( (Ee) Nptel) 6Document5 pagesL-4 (DK) (Pe) ( (Ee) Nptel) 6GagneNo ratings yet

- High Efficiency DC-to-AC Power InverterDocument5 pagesHigh Efficiency DC-to-AC Power InverterDivyabharathi JanakiramanNo ratings yet

- C.T Requirements For VATECH Prot Products Dec03Document11 pagesC.T Requirements For VATECH Prot Products Dec03gavinilaaNo ratings yet

- Symmetrical Fault AnalysisDocument39 pagesSymmetrical Fault AnalysisViplav Chaitanya0% (1)

- Nhancement Using Solid State DevicesDocument6 pagesNhancement Using Solid State DevicesInnovative Research PublicationsNo ratings yet

- Numerical Oscillations in EMTP PDFDocument4 pagesNumerical Oscillations in EMTP PDFCarlos Lino Rojas AgüeroNo ratings yet

- Scott and L Brance TransformersDocument9 pagesScott and L Brance TransformersRicardo A VergaraNo ratings yet

- ELX303 Exam SolutionsDocument27 pagesELX303 Exam SolutionsNadeesha BandaraNo ratings yet

- 3 Discrimination by Both Time and CurrentDocument9 pages3 Discrimination by Both Time and CurrentEBENo ratings yet

- UC3879Document9 pagesUC3879Christina Tio TrisnasariNo ratings yet

- Inrush Current Control in Transformers: Seshanna PanthalaDocument4 pagesInrush Current Control in Transformers: Seshanna PanthalameraatNo ratings yet

- Graphic Era University: Switchgear & Protection. of Pwr. Sys. Lectures BookDocument108 pagesGraphic Era University: Switchgear & Protection. of Pwr. Sys. Lectures BookdoggaraviNo ratings yet

- Paralleling Cts For Line Differential ProtectionDocument15 pagesParalleling Cts For Line Differential ProtectionYeissonSanabria100% (1)

- Voltage Drop CalculationsDocument4 pagesVoltage Drop CalculationsTigrillo100% (1)

- Power Electronics Exam 2017 SolutionsDocument13 pagesPower Electronics Exam 2017 SolutionsBakri BugaNo ratings yet

- Triacs and DiacsDocument4 pagesTriacs and Diacsssami670No ratings yet

- Numerical Oscillations in EMTP-Like ProgramsDocument14 pagesNumerical Oscillations in EMTP-Like ProgramsArunkumar MuthusamyNo ratings yet

- DC Transformers 77Document15 pagesDC Transformers 77Keshavamurthy MurthyNo ratings yet

- Triacs and Diac1Document4 pagesTriacs and Diac1Shamsul Haq NtcNo ratings yet

- A Transformerless Grid Connected Photovoltaic Inverter With Switched CapacitorsDocument5 pagesA Transformerless Grid Connected Photovoltaic Inverter With Switched CapacitorsRaye PushpalathaNo ratings yet

- BS 7671 Voltage DropDocument4 pagesBS 7671 Voltage DropMohammed AbdulmuqeetNo ratings yet

- Triacs and Diacs TechnlogyDocument4 pagesTriacs and Diacs TechnlogyajjjindoreNo ratings yet

- Laboratory NR 3Document8 pagesLaboratory NR 3IonutNo ratings yet

- Design and Testing of An TCSC For Distribution Network Applications PDFDocument5 pagesDesign and Testing of An TCSC For Distribution Network Applications PDFRuchitaNo ratings yet

- 11kV CT CalculationDocument38 pages11kV CT Calculationjm.mankavil6230100% (9)

- Cable Sizing Calculator AS - NZS3008Document1 pageCable Sizing Calculator AS - NZS3008kakagoNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- How To Easily Make Your Own UC3842 PWM IC TesterDocument12 pagesHow To Easily Make Your Own UC3842 PWM IC TesterQueenie Obligado100% (1)

- MC Balance 2002 Manual English V3.0Document27 pagesMC Balance 2002 Manual English V3.0Dandy ChavezNo ratings yet

- CCTV Video Distribution Amp Specification - pdf720819733Document2 pagesCCTV Video Distribution Amp Specification - pdf720819733Dandy ChavezNo ratings yet

- Atlas Copco gx11ff Service Manual PDFDocument76 pagesAtlas Copco gx11ff Service Manual PDFWilmer De AndradeNo ratings yet

- Convertir mm2 o MM A Calibre AWGDocument2 pagesConvertir mm2 o MM A Calibre AWGDandy ChavezNo ratings yet

- Generador SenoidalDocument15 pagesGenerador SenoidalDandy ChavezNo ratings yet

- Using Schmitt Triggers For Low Slew-Rate Input: V VT GND VDocument6 pagesUsing Schmitt Triggers For Low Slew-Rate Input: V VT GND VAlexander Gómez RojasNo ratings yet

- 100 Top Operational Amplifiers Questions and Answers PDF Operational Amplifiers Questions and AnswersDocument12 pages100 Top Operational Amplifiers Questions and Answers PDF Operational Amplifiers Questions and AnswersSharanya50% (2)

- OFC & OFS ConceptsDocument27 pagesOFC & OFS ConceptsKaushal PatelNo ratings yet

- Book List For EEE Job PreparationDocument5 pagesBook List For EEE Job PreparationTanvir Alam Shishir100% (1)

- DSPDocument12 pagesDSPAshish Chandrakant ChavanNo ratings yet

- Anand KumarDocument6 pagesAnand KumarThiaga RajanNo ratings yet

- 9691 w15 Ms CompleteDocument85 pages9691 w15 Ms CompleteaskNo ratings yet

- SEMIKRON DataSheet SKiiP 03NAC12T4V1 25232540Document5 pagesSEMIKRON DataSheet SKiiP 03NAC12T4V1 25232540salesiano05No ratings yet

- Assignment-1 Microwave Transmission Lines: Microwaves and Radar 10EC54Document2 pagesAssignment-1 Microwave Transmission Lines: Microwaves and Radar 10EC54Mr saifan and Mr shehzadNo ratings yet

- Annexure - II: ESD Applications Are To Be Programmed Using SIL3 Complaint LibrariesDocument2 pagesAnnexure - II: ESD Applications Are To Be Programmed Using SIL3 Complaint LibrariesSaravana KumarNo ratings yet

- AN15932AADocument1 pageAN15932AARicardo Banegas ValleNo ratings yet

- GSM System Introduction 1Document0 pagesGSM System Introduction 1Shami TahirNo ratings yet

- 02 - 202-203 DC ContactorDocument2 pages02 - 202-203 DC Contactorshailesh284No ratings yet

- URC2981 All Languages NO LearningDocument72 pagesURC2981 All Languages NO LearningFernando Gabriel Vizcarra QuirozNo ratings yet

- Mbquart Formula Fx1700Document11 pagesMbquart Formula Fx1700galaxy.infuse4gNo ratings yet

- Seminar - Adiabatic Logic DesignDocument24 pagesSeminar - Adiabatic Logic DesignLakshmi Sri K VNo ratings yet

- 13142833663.5.6 DCVG Equipment Rev 1Document2 pages13142833663.5.6 DCVG Equipment Rev 1ilublessingNo ratings yet

- An PRC 119 Programming TroubleshootingDocument20 pagesAn PRC 119 Programming Troubleshootingdragon4036100% (1)

- Samsung Ue32f6100aw Ue40f6100aw Ue46f6100aw Ue55f6100aw Chassis U88a SM PDFDocument202 pagesSamsung Ue32f6100aw Ue40f6100aw Ue46f6100aw Ue55f6100aw Chassis U88a SM PDFGogu GoguNo ratings yet

- TVL - Computer Systems Servicing 12Document7 pagesTVL - Computer Systems Servicing 12KibasuperNo ratings yet

- Autopilot Computer - Maintenance PracticesDocument5 pagesAutopilot Computer - Maintenance PracticesEleazarNo ratings yet

- Rigol: Data SheetDocument8 pagesRigol: Data SheetFabrizio GiordanoNo ratings yet

- Sd3 (U) Over Speed: Application Point of DetectionDocument1 pageSd3 (U) Over Speed: Application Point of DetectionAce Noah SomintacNo ratings yet

- 590G-V2 in A4 CatalogueDocument6 pages590G-V2 in A4 CatalogueMATIAS_CNo ratings yet

- Chapters of Assembly Language 2Document178 pagesChapters of Assembly Language 2ezerobert56_86874258No ratings yet

- Experiment 05Document6 pagesExperiment 05ZodkingNo ratings yet

- Pricelist Peralatan KomputerDocument2 pagesPricelist Peralatan KomputerRiska RahmaniaNo ratings yet

- 1 - Installation: - Dimensions and Cut-Out Panel MountingDocument33 pages1 - Installation: - Dimensions and Cut-Out Panel MountingGopal HegdeNo ratings yet

- ETAP Report (Modified - 4pages)Document4 pagesETAP Report (Modified - 4pages)daniel.cabasa2577No ratings yet

- Rg10 BasicDocument4 pagesRg10 BasicallieNo ratings yet

- Q5492e La Service Manual-FilipsDocument141 pagesQ5492e La Service Manual-FilipsremguNo ratings yet