Professional Documents

Culture Documents

Direct Determination of The Flow Curves of No

Uploaded by

Zaid HadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Direct Determination of The Flow Curves of No

Uploaded by

Zaid HadiCopyright:

Available Formats

Direct Determination of the Flow Curves of NonNewtonian Fluids. II.

Shearing Rate in the Concentric Cylinder Viscometer

Irvin M. Krieger and Harold Elrod

Citation: J. Appl. Phys. 24, 134 (1953); doi: 10.1063/1.1721226

View online: http://dx.doi.org/10.1063/1.1721226

View Table of Contents: http://jap.aip.org/resource/1/JAPIAU/v24/i2

Published by the American Institute of Physics.

Additional information on J. Appl. Phys.

Journal Homepage: http://jap.aip.org/

Journal Information: http://jap.aip.org/about/about_the_journal

Top downloads: http://jap.aip.org/features/most_downloaded

Information for Authors: http://jap.aip.org/authors

Downloaded 30 Mar 2013 to 128.233.210.97. This article is copyrighted as indicated in the abstract. Reuse of AIP content is subject to the terms at: http://jap.aip.org/about/rights_and_permissions

JOURNAL OF APPLIED PHYSICS

VOLUME 24.

NUMBER 2

FEBRUARY. 1953

Direct Determination of the Flow Curves of Non-Newtonian Fluids.

ll. Shearing Rate in the Concentric Cylinder Viscometer

IRVIN M. KRIEGER, Department of Chemistry and Chemical Engineering, Case Institute of Technology, Cle'Deland, Ohio

AND

HAROLD ELROD,

Department of Mechanical Engineering, Case Institute of Technology, Cle'Deland, Ohio

(Received July 21, 1952)

Another method has been developed for obtaining the rate of shear '/IS shearing stress curves of nonNewtonian fluids from concentric cylinder viscometer data. The mathematical expression developed is a

rapidly converging power series in Ins, where s is the cup to bob radius ratio. An estimate of error shows

that under favorable conditions only two terms of the series are significant, and that terms past the third

will hardly ever be needed.

INTRODUCTION

Since M is constant under steady flow conditions,

HE first paper in this series reviewed the theory of

T

the concentric cylinder viscometer. There it was

shown that an exact solution in closed form for the rate

l

of shear can be obtained by treating the radius

ratio of the cylinders as a variable. To use the method

which was developed in this manner, one must obtain

torque-angular velocity data with two or more bobs of

different radii.

It was also shown that an expression for the difference

between the rates of shear at the cup and at the bOb

wall can be recovered from data taken with only one

bob. In the present paper, a solution for this difference

equation is obtained as a rapidly converging series.

(1)

The first objective of viscometry is the recovery of this

relation, called the flow equation, from experimental

data. The flow equation may be expressed in analytic,

tabular, or graphical form.

As in the previous paper, we consider a concentric

cylinder viscometer having an inner cylinder or bob

of length L and radius R l , and an outer cylinder or cup

of radius R 2 = sRI. The cup rotates with angular velocity n, while an external torque M holds the bob

stationary. When the fluid in the annular space between the cup and the bob is in laminar flow, the rate

of shear at a distance r from the axis, where the fluid

rotates with angular velocity w, is

I. M. Krieger and S. H. Maron,

(5)

IfF!

iFI

1

g(F)d InF= -2 rl

2

n= --

g(F)

~F.

(6)

.'F. F

In the previous paper, g(F) was obtained by differentiation with respect to s at constant F 2, giving

(2)

(7)

From this equation an experimental method was developed for determining the rate of shear from data

obtained using two bobs.

When (6) is differentiated with respect to Fl , a difference equation is obtained:l - a

dn

1

-=-[g(F l )-g(F2)].

dF l 2Fl

(8)

The method described here for obtaining g(F) is based

on a solution of this difference equation.

SOLUTION OF THE DIFFERENCE EQUATION

Let us define a function heFt) by the relation

(9)

From Eq. (8),

(10)

Also,

h(r2FI) = g(s-2F I) - g(s-4FI) ,

h(s~FI) = g(s-4FI)- g(s-6F I),

while the shearing stress is

F=M/27r'f2L.

g(F) = -2(dw/d InF).

g(F I) = s(an/as)F 2

The present treatment presupposes the existence of

a functional rel3;tionship between the rate of shear

dv/dyand the shearing stress F, namely,

dw dw

g(F)=r-=-,

dr d Inr

(4)

At the bob surface, F=F l and w=O, while at the cup,

F=F 2 and w=n. Integrating (5) between these limits,

one obtains

THEORY OF THE CONCENTRIC CYLINDER

VISCOMETER

dv/dy=g(F).

d InF= -2d lnr

and

(3)

J. Appl. Phys. 23, 147 (1952).

(11)

1M. D. Hersey, J. Rheol. 3, 196 (1932).

M. Mooney, J. Rheol. 2, 210 (1931).

134

Downloaded 30 Mar 2013 to 128.233.210.97. This article is copyrighted as indicated in the abstract. Reuse of AIP content is subject to the terms at: http://jap.aip.org/about/rights_and_permissions

135

FLOW CURVES OF NON-NEWTONIAN FLUIDS. II

s> 1 and g(O) = 0,

etc. Since

00

h(s-2nF 1) = g(F 1).

(12)

The sum is a slowly convergent one, which may be

asymptotically evaluated using the Euler-MacLaurin

sum formula,4

:. fen) = Lmf(X)dx+tU(O)+ f(m)]

..-0

B2k

--U(2k-l)(m)-f(2k-l)(0)]

k-l (2k) !

+

m-lfHl

E . P2r+l(X-i)J<2r-H>(x)dx.

(13)

f. h(s-2nF = L""h(r2xF 1)dx+ t[h(F 1)+h(O)]

1)

1 [d3h(S-2nF1)]""

+-1 [dh(S-2nF1)]"" -"3 + ....

12

dn

_0

720

dn

Therefore, in view of the definition of h,

-1

h(S-2xF 1)dx=-

f.0 h(y)d Iny=-.n

2 Ins 1"1

(17)

Ins

The derivatives appearing in Eq. (14) are

d2

-4 Ins

d(lnr2nF 1)2

where a and N are constants characteristic of the

fluid.6-7 Integration of Eq. (6) with this value of g(F)

gives

(22)

hence

d lnn/d InF1=N,

(23)

d 3n/ d(lnF 1)3= N3n,

etc. Thus

n [

(14)

The integral is readily evaluated by making the substitutions

y=s-2xF 1

(15)

and

dx= -dy/2y Ins.

(16)

"

(21)

g(F) = aFN,

Here Bi is the ith Bernouilli number and Pi the Bernouilli polynomial. Applying this formula to the summation in Eq. (12),

_0

A particularly attractive feature of the above result

is the fact that the bracketed term is a power series in

Ins. The better concentric cylinder viscometers are

constructed with small clearances, so that Ins rarely

exceeds 0.2 and is frequently 0.05 or less. The term

d lnn/d InFl is unity for Newtonian fluids, but may

take on higher values for non-Newtonian fluids. (Values

as high as five have been observed in this laboratory.)

The second term is therefore significant.

To estimate the error involved in terminating the

series at any given point, it is convenient to consider

the special case of a fluid whose flow equation is

(18)

etc.

g(F 1) = -

Ins

l+N Ins+

(N Ins)!

(N Ins)4

45

]

+....

(24)

Hence the error in terminating the series at the second

term is of order leN Ins)2, while carrying the third

term reduces the error to 1/45(N Ins)4.

In this connection, it is evident that an instrument

for which s is small is desirable. Comparison of two common concentric cylinder viscometers brings out this

point. For the Precision-Interchemica:l viscometer,S R2

= 1.500 cm, Rl = 1.300 cm, making s= 1.154. Here N

must be less than 1.4 in order that the series may be

terminated at two terms without exceeding 1 percent

error, while N values up to 7.0 may be used if the third

term is carried. For the Mooney-Ewart coni-cylindrical

viscometer,9 for which Rl = 2.00, R 2= 2.10, and s= 1.05,

the corresponding N values are 4.1 for two terms and

20.5 for three. The computational problem is thus

much simpler in the latter case, since a second differentiation will rarely be required.

USE OF THE METHOD

Since h(F 1) and its derivatives are zero when Fl=O,

the final asymptotic expression for the rateof shear

may be written

n[

. d Inn (Ins)2 d2n

1+Ins--+--_Ins

d InF 1

3n d(InF 1)2

g(Fl) = -

(lns)4

--.

d 4n

45n d(lnF 1)4

. ]

+ ....

(20)

4 J. Jeffreys and B. S. Jeffreys, Methods of Mathematical Physics

(Cambridge University Press, Cambridge, 1946), p. 255.

In practice, M 'VS n data are obtained, and F 1 calculated by multiplying M by the factor 1/211'R 12L. A

plot of logn 'Vs 10gFl is constructed. If this plot is linear,

the exponential flow equation applies, and g(F) may be

obtained by well-established techniques. 7 If this graph

is curved, graphical differentiation at points along the

6 A. W. Porter and P. A. M. Rao, Trans. Faraday Soc. 23, 311

(1927).

6 Farrow, Lowe, and Neale, J. Textile Inst. 19, T 18 (1928).

7 I. M. Krieger and S. H. Maron, J. Colloid Sci. 6, 528 (1952).

8 H. Green, Industrial Rheology (John Wiley and Sons, Inc.,

New York, 1949), p. 100.

9 M. Mooney and R. H. Ewart, J. Appl. Phys. 5, 530 (1934).

Downloaded 30 Mar 2013 to 128.233.210.97. This article is copyrighted as indicated in the abstract. Reuse of AIP content is subject to the terms at: http://jap.aip.org/about/rights_and_permissions

136

I. M.

KRIEGER AND HAROLD ELROD

CONCLUSIONS

curve yields the slope m, where

m=d InOld InFl

(25)

For those cases where m Ins is less than 0.2, the third

and higher terms may be neglected, and the rate of

shear calculated with an error of less than 1 percent by

g(F 1)=O/lns(1+m Ins).

(26)

When m Ins is greater than 0.2 but less than 1, an additional graphical differentiation is required to keep the

accuracy within 1 percent. Since

1

-

d20

o d(lnF 1)2

dm

+--,

d InF

m2

(27)

the third term may be obtained from slopes of a graph

of m vs InF 1. The rate of shear is then

o[

(InS)2 dm ]

g(F1)=- l+mlns+tcmIns)2+---- . (28)

Ins

3 dIn~

In the rare case when m Ins is greater than 1, the fourth

term may be required, although this has never been

necessary for the systems studied in this laboratory.

For most fluids, the first two terms should suffice.

JOURNAL OF APPLIED

PHYSICS

An alternate method has been devised for the recovery of the rate of shear of a non-Newtonian fluid

from data obtained in concentric cylinder viscometers,

thus permitting the direct determination of the flow

curves of such fluids without prior assumption of a

flow equation. The mathematical expression for the

rate of shear is a power series in the logarithm of the

radius ratio; the coefficients are derivatives of the

angular velocity with respect to shearing stress. Under

favorable conditions, terms beyond the second are

negligible, while inclusion of the third term is almost

always adequate. Instruments designed with radius

ratios near unity are more satisfactory in this respect,

since only one differential need be evaluated.

A paper is in preparation in which the flow curves of

several fluids, obtained by the various direct methods,

are intercompared. The work discussed herein was performed as part of a research project sponsored by the

Reconstruction Finance Corporation, Office of Synthetic Rubber, in connection with the Government Synthetic Rubber program. The advice and encouragement

of Dr. Samuel H. Maron are acknowledged.

VOLUME 24,

NUMBER

FEBRUARY,

1953

The Nature of the Coefficient of Friction

J. T. BURWELL * AND E. RABINOWICZ

Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge, Massachusetts

(Received August 18, 1952)

The modem theory of the friction between dry metal surfaces ascribes it to local minute welds or adhesions

between the surfaces and suggests that for a given pair of surfaces the friction force is uniquely defined by the

normal load alone. Herein it is demonstrated that this cannot in general be true and that some further condition of operation must also be defined. Experiments are reported indicating that one such possible condition is the sliding speed so that the friction force is actually a function of the normal load and the sliding

speed. It is pointed out that the speed can influence the friction force in two ways-one, by the resulting

shear strain rate in the vicinity of the welded junction, and the other by the length of time taken for a

junction of full strength to form.

HE current theory of the mechanism of dry

frictionl -3 pictures the force of friction as arising

from the shear strength of minute welds formed between two bodies in contact and distributed more or

less at random over their apparent contact area. This

can be expressed by the relation for the friction force

F=sA,

(1)

where s is the average shear strength of these welds and

A the sum of their individual areas. Since it is these

areas that actually carry the normal load W between

* Now with Horizons, Inc., Cleveland, Ohio.

1 R. Holm, Electric Contacts (Almquist and WikseUs, Uppsala,

1946).

H. Ernst and M. E. Merchant, Proc. M.I.T. Sum. Conf. on

Surface Finish, p. 76, (June 1940).

a F. P. Bowden and D. Tabor, The Friction and Lubrication of

Solids (Oxford University Press, New York, 1950).

the two bodies, we also have

(2)

W=pm A ,

where Pm is defined as the flow pressure of the softer

material in the vicinity of these local true contact areas.

Eliminating A between these two equations leads to

the familiar expression for the friction coefficient

(3)

Bowden and Tabor emphasize the point that this is

the ratio of two plastic properties of the weld and

adjacent material. It has been customarily assumed that

these two quantities are each constant for a given pair

of contacting surfaces so that p. is also a constant.

Recently, however, McFarlane and Tabor' have

4 J. S. MacFarlane and D. Tabor, Proc. Roy. Soc. (London)

A202, 244 (1950).

Downloaded 30 Mar 2013 to 128.233.210.97. This article is copyrighted as indicated in the abstract. Reuse of AIP content is subject to the terms at: http://jap.aip.org/about/rights_and_permissions

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- MR GMAT Combinatorics+Probability 6EDocument176 pagesMR GMAT Combinatorics+Probability 6EKsifounon KsifounouNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 28 Nakshatras - The Real Secrets of Vedic Astrology (An E-Book)Document44 pages28 Nakshatras - The Real Secrets of Vedic Astrology (An E-Book)Karthik Balasundaram88% (8)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Diagnostic Laboratory TestsDocument6 pagesDiagnostic Laboratory TestsKiana Mae Wong Diwag100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Foreigner Audition Information KitDocument2 pagesThe Foreigner Audition Information KitjnatchNo ratings yet

- Phonetics Exercises PDFDocument2 pagesPhonetics Exercises PDFShanti YuliastitiNo ratings yet

- Integrative Paper Unfolding The SelfDocument11 pagesIntegrative Paper Unfolding The SelfTrentox XXXNo ratings yet

- Past Tense Irregular Verbs Lesson Plan 02Document7 pagesPast Tense Irregular Verbs Lesson Plan 02drdineshbhmsNo ratings yet

- Tthe Sacrament of Reconciliation1Document47 pagesTthe Sacrament of Reconciliation1Rev. Fr. Jessie Somosierra, Jr.No ratings yet

- Global High Temperature Grease Market ReportDocument6 pagesGlobal High Temperature Grease Market ReportHari PurwadiNo ratings yet

- Properties of FluidsDocument16 pagesProperties of FluidsZaid HadiNo ratings yet

- Inflatable Structures in Hydraulic EngineeringDocument2 pagesInflatable Structures in Hydraulic EngineeringZaid HadiNo ratings yet

- B TechDocument38 pagesB TechZaid HadiNo ratings yet

- Inflatable Structures in Hydraulic EngineeringDocument2 pagesInflatable Structures in Hydraulic EngineeringZaid HadiNo ratings yet

- Stilling Basins CurvesDocument6 pagesStilling Basins CurvesZaid HadiNo ratings yet

- Ad Duce 2006669Document12 pagesAd Duce 2006669Zaid HadiNo ratings yet

- Experimental Study of Scouring Pattern Due To Circular Submerged Jet in Shallow Ambient FluidDocument6 pagesExperimental Study of Scouring Pattern Due To Circular Submerged Jet in Shallow Ambient FluidZaid HadiNo ratings yet

- Notes ءؤرلاىDocument125 pagesNotes ءؤرلاىZaid HadiNo ratings yet

- 345 S 02 P 4Document11 pages345 S 02 P 4khalidh2010No ratings yet

- A11 ManualDocument53 pagesA11 ManualZaid Hadi100% (1)

- haarsaASTP25 28 2014Document4 pageshaarsaASTP25 28 2014Zaid Hadi100% (1)

- Clark TCDocument4 pagesClark TCZaid HadiNo ratings yet

- Overton 1968Document9 pagesOverton 1968Zaid HadiNo ratings yet

- Numerical Flow Analysis For SpillwaysDocument11 pagesNumerical Flow Analysis For SpillwaysZaid HadiNo ratings yet

- Foundation Science For EngineersDocument7 pagesFoundation Science For EngineersZaid HadiNo ratings yet

- Scour Requirements For Bridge Rehabilitations: Crystal Weaver Hydraulics Manager, INDOTDocument14 pagesScour Requirements For Bridge Rehabilitations: Crystal Weaver Hydraulics Manager, INDOTZaid HadiNo ratings yet

- Facilities Development Manual: Design MethodsDocument2 pagesFacilities Development Manual: Design MethodsZaid HadiNo ratings yet

- Recitation 9Document6 pagesRecitation 9Zaid HadiNo ratings yet

- 7 13342Document8 pages7 13342Zaid HadiNo ratings yet

- The Lenovo® B490/B590 Laptop: Amazing Business Performance at A Great ValueDocument4 pagesThe Lenovo® B490/B590 Laptop: Amazing Business Performance at A Great ValueZaid HadiNo ratings yet

- Numerical Modeling of Ogee Crest Spillway and Tainter Gate Structure of A Diversion Damonca Nar River, EcuadorDocument9 pagesNumerical Modeling of Ogee Crest Spillway and Tainter Gate Structure of A Diversion Damonca Nar River, EcuadorZaid HadiNo ratings yet

- XczasdDocument13 pagesXczasdZaid HadiNo ratings yet

- Modeling Dams With Computational Fluid Dynamics Past Success and New DirectionsDocument39 pagesModeling Dams With Computational Fluid Dynamics Past Success and New DirectionsZaid HadiNo ratings yet

- Flowin Open ChannelsDocument7 pagesFlowin Open ChannelsZaid HadiNo ratings yet

- CvaDocument2 pagesCvaZaid HadiNo ratings yet

- XcdsfasazDocument4 pagesXcdsfasazZaid HadiNo ratings yet

- VFCDXZDocument3 pagesVFCDXZZaid HadiNo ratings yet

- Numerical Simulation of Scour Development Due To Submerged Horizontal JetDocument8 pagesNumerical Simulation of Scour Development Due To Submerged Horizontal JetZaid HadiNo ratings yet

- Scour Depth Downstream Weir With OpeningsrrDocument12 pagesScour Depth Downstream Weir With OpeningsrrZaid HadiNo ratings yet

- Erosion and Sedimentation Near The Renovated Weir Lock Complex of Asper in BelgiumDocument10 pagesErosion and Sedimentation Near The Renovated Weir Lock Complex of Asper in BelgiumZaid HadiNo ratings yet

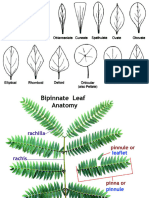

- Types, Shapes and MarginsDocument10 pagesTypes, Shapes and MarginsAkhil KanukulaNo ratings yet

- FedSupport Codebook FY2020Document259 pagesFedSupport Codebook FY2020Aaron BlackmonNo ratings yet

- CHILD WIFE FinalDocument9 pagesCHILD WIFE FinalProcurement WVMC100% (1)

- Jeff Roth CVDocument3 pagesJeff Roth CVJoseph MooreNo ratings yet

- Find Bridges in a Graph Using DFSDocument15 pagesFind Bridges in a Graph Using DFSVamshi YadavNo ratings yet

- F77 - Service ManualDocument120 pagesF77 - Service ManualStas MNo ratings yet

- SSC CGL Tier 2 Quantitative Abilities 16-Nov-2020Document17 pagesSSC CGL Tier 2 Quantitative Abilities 16-Nov-2020aNo ratings yet

- Methods of GeographyDocument3 pagesMethods of Geographyramyatan SinghNo ratings yet

- Introduction To Intelligent BuildingsDocument3 pagesIntroduction To Intelligent Buildingsmamta jainNo ratings yet

- ICE Professional Review GuidanceDocument23 pagesICE Professional Review Guidancerahulgehlot2008No ratings yet

- PB13MAT - 13 Project Stakeholder ManagementDocument30 pagesPB13MAT - 13 Project Stakeholder ManagementYudhi ChristianNo ratings yet

- OPGWDocument18 pagesOPGWGuilhermeNo ratings yet

- Sar Oumad Zemestoun v01b Music Score سر اومد زمستون، نت موسیقیDocument1 pageSar Oumad Zemestoun v01b Music Score سر اومد زمستون، نت موسیقیPayman Akhlaghi (پیمان اخلاقی)100% (3)

- Contoh Format Soal PTSDocument3 pagesContoh Format Soal PTSSmp nasional plus widiatmikaNo ratings yet

- The Names & Atributes of Allah - Abdulillah LahmamiDocument65 pagesThe Names & Atributes of Allah - Abdulillah LahmamiPanthera_No ratings yet

- Facebook Privacy FTC Complaint Docket No. C-4365Document19 pagesFacebook Privacy FTC Complaint Docket No. C-4365David SangerNo ratings yet

- Revised Organizational Structure of Railway BoardDocument4 pagesRevised Organizational Structure of Railway BoardThirunavukkarasu ThirunavukkarasuNo ratings yet

- Tong Hop Bai Tap Tieng Anh 8 Chuong Trinh Moi Co Dap AnDocument317 pagesTong Hop Bai Tap Tieng Anh 8 Chuong Trinh Moi Co Dap Anmrxuan tesol93No ratings yet

- Product Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667Document12 pagesProduct Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667jhon vargasNo ratings yet

- Starch Digestion by Amylase Lab ReportDocument10 pagesStarch Digestion by Amylase Lab Report햇님No ratings yet

- Volleyball ReflectionDocument1 pageVolleyball ReflectionJake Santos100% (1)