Professional Documents

Culture Documents

84501-9230-2L-022 Rev.2 Seamless Flowline To API 5L

Uploaded by

Nurcahyo Djati WOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

84501-9230-2L-022 Rev.2 Seamless Flowline To API 5L

Uploaded by

Nurcahyo Djati WCopyright:

Available Formats

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

SEAMLESS FLOWLINES

TO

API 5L

DOCUMENT NUMBER: 84501-9230-2L-022

REV

ISSUE

PREPARED BY

REVIEWED BY

APPROVED BY

ISSUE DATE

For use

Dean Hewitt

Steve Malkin

Alaister McIntosh

13 Dec 2002

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

2 of 18

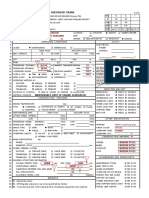

REVISION CONTROL SHEET

LATEST REV

DATE ISSUED

PREPARED

REVIEWED

APPROVED

COMMENTS

14 Aug 2002

D.Hewitt

C.Fox

A.McIntosh

8 Oct 2002

D.Hewitt

S.Malkin

A.McIntosh

Issued For Use

Amended sections

7.1, 8.5 & 10.1

13 Dec 2002

D.Hewitt

C.Fox

A.McIntosh

Logo Change

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

3 of 18

TABLE OF CONTENTS

1.

INTRODUCTION.......................................................................................................0

2.

PROCESS OF MANUFACTURE..............................................................................0

3.

CHEMICAL REQUIREMENTS.................................................................................0

4.

PRODUCTION MECHANICAL TEST REQUIREMENTS........................................0

5.

HYDROSTATIC TESTING........................................................................................0

6.

DIMENSIONAL REQUIREMENTS AND TOLERANCES........................................0

7.

NONDESTRUCTIVE TESTING................................................................................0

8.

WORKMANSHIP......................................................................................................0

9.

PIPE CONTROL TALLY SHEET..............................................................................0

10. PIPE MARKING........................................................................................................0

11.

PIPE COATING.........................................................................................................0

12. TRANSPORTATION AND HANDLING....................................................................0

13. MILL TEST CERTIFICATES.....................................................................................0

14. DOCUMENTATION AND CERTIFICATION.............................................................0

15. QUALITY ASSURANCE...........................................................................................0

16. PRODUCT INSPECTION.........................................................................................0

APPENDIX - A

MPS MINIMUM REQUIREMENTS............................................0

APPENDIX - B

CHEMICAL ANALYSIS.............................................................0

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

4 of 18

1. INTRODUCTION

1.1 Scope

This document defines the minimum standards of quality, technical requirements

and acceptability governing the design, materials, manufacture, testing, handling,

and shipping of Grade X65 and lower seamless line pipe. This specification

supplements the latest edition of API Spec 5L, which is the basic specification for

line pipe furnished to this specification. Production specification level (PSL) 2

supplementary requirements shall apply.

Contractor shall obtain Company written approval for any deviations from the

requirements of this document or specifications, standards and drawings

referenced herein or elsewhere in the Contract.

This document and the codes, specifications and referenced documents listed in

1.2 below are not intended to be all-inclusive. The requirements set forth do not

relieve Contractor of his responsibility to perform all services in a safe manner, to

meet applicable codes and standards, to comply with government regulations or

to supply a product capable of performing its intended service.

1.2 Codes, Specifications, And References

The latest editions of all applicable codes, specifications and references shall

define the minimum requirements applicable to the subject work and no

statement contained in this Specification shall be construed as limiting the work

to such minimum requirements.

Wherever conflicts or omissions between codes, specifications and contract

occur, the most onerous condition shall apply. Contractor is responsible for

reviewing the list below and informing the Company of any omissions. All conflicts

shall be formally brought to the attention of the Company.

Applicable Codes

API Spec 5L

Specification for Line Pipe

API RP 5L1

Railroad Transportation of Line Pipe

API RP 5LW

Marine Transportation of Line Pipe on Barges and Marine

Vessels

ASTM A370

Mechanical Testing of Steel Products

ASTM E59-78

Method for Sampling Steel and Iron for Determination of

Chemical Composition

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

5 of 18

ASTM E92-82

Vickers Hardness Testing of Metallic Materials

ASTM E350-88

Method for Chemical Analysis of Carbon Steel, Etc.

ASTM E112

Methods for Determining Average Grain Size

ASTM E709

Magnetic Particle Examination

ASNT-TC-1A

Personnel Qualification and Certification in Non-destructive

Testing Level II

EN 10204

Certificates on Material Testing

Company Specifications

84501-9200-9L-027

Welding Procedure & Welder Performance Qualification

84501-9230-2L-035

Welding Specification for Flowlines to API 1104 : 1999

84501-9230-2L-009

Induction Bends

2. PROCESS OF MANUFACTURE

The manufacture shall be carried out in accordance with a pre-approved

Manufacturing Procedure Specification (MPS) provided by Manufacturer. The

MPS shall include as a minimum a detailed step by step of the manufacture

process including but not limited to steel making, targeted chemical analysis, pipe

manufacture, heat treatment, end finishing, inspection, storage and transport.

The MPS shall include reference to specifications and sources of all materials

used in the manufacture of the line pipe.

Manufacturer shall state in the MPS all parameters related to the quality of the

final product as defined in the specification which can be monitored during

manufacturing. This is to enable definition of the inspection of these items. Both

nominal values and ranges of these parameters shall be stated.

The layout of the MPS shall enable Company to define easily and unambiguously

the responsibilities of Company's designated inspector during the manufacture.

Minimum MPS requirements are included in Appendix - A.

The MPS shall be approved by Company prior to commencement of the

manufacture of the line pipe.

2.1 Steelmaking

Pipe furnished to this specification shall be seamless as defined in API 5L.

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

6 of 18

All steel shall be produced by the basic oxygen process, fully killed, and made to

a fine grain practice. Continuous casting shall be used unless otherwise

approved by Company. Provisions shall be made for low sulfur and low

phosphorus refining and for sulfide shape control.

Rare earth metal additions are prohibited.

The use of mill-jointers shall not be permitted.

2.2 Pipe Fabrication

Cold expansion is not permitted, including sizing.

The line pipe shall be suitable for manual welding using conventional pipeline

welding techniques and for automatic welding employing the systems currently in

use by the major pipelay contractors. Manufacturer shall submit evidence which

demonstrates the material weldability to Companys satisfaction.

3. CHEMICAL REQUIREMENTS

3.1 Chemical Composition

In addition to the latest revision of API Spec 5L requirements, the line pipe shall

meet the chemical composition requirements stated in Appendix - B of this

Specification. The chemical composition shall be controlled within the limits

specified. Manufacturer shall submit the proposed range and target values for

each element for Companys approval. Proposed deviations from the chemical

composition stated in Appendix - B required to accommodate installation method,

such as Reel Lay, shall be approved by Company. The agreed target ranges

shall be given in the approved manufacturing procedure for production.

If any ladle or product analysis for any heat fails to meet the Specification

requirements, no pipe shall be accepted from that heat. The quenching medium

and heat treatment times and temperatures shall be specified in the MPS.

3.2 Heat Treatment

Pipe furnished to this specification shall be heat treated by either the quenched

and tempered process or the normalized process. The quenching medium and

heat treatment times and temperatures shall be specified in the MPS.

4. PRODUCTION MECHANICAL TEST REQUIREMENTS

4.1 General

Mechanical testing shall be in accordance with API Spec. 5L and as modified

below and shall be carried out on test rings cut from the ends of a randomly

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

7 of 18

selected pipe. The number and frequency of tests shall be as specified in API 5L

unless otherwise stated. All test results shall be made available to Company for

review.

Alternate ends of the pipe shall be tested after the final production heat

treatment. Significant variations shall be investigated and resolved.

4.2 Tensile Tests

Tensile tests shall be made on pipe representing each heat of steel. Yield

strength, tensile strength, elongation, and yield / tensile ratio shall be determined.

Written records of all mechanical property tests shall be furnished to Company.

The measured yield strength shall not exceed the API Spec 5L specified

minimum strength by more than 17,400 psi.

Substitution of higher strength grade of line pipe in place of the grades ordered

shall not be acceptable.

The ratio of yield stress to ultimate tensile stress in the finished pipe shall not

exceed 0.90.

The minimum elongation shall be as required by API 5L, Appendix D plus 1%.

For each pipe to be accepted, all tests must be successful.

4.3 Charpy Impact Tests

Three full size transverse Charpy V-notch impact specimens, representing one

test, shall be tested at a temperature of 0 OF (-18OC) or at least 10OC below the

minimum design temperature, whichever is less.

The minimum design

temperature shall consider the blowdown, gas filling or upset condition.

All tests are to be made in the final heat treatment condition. Testing shall be

performed in accordance with API Spec 5L SR5 and ASTM A370.

The preferred hierarchy of Charpy test specimen orientation and size is shown in

the following table. For other specimen sizes and orientations, the values

required shall be multiplied by factors given in table below:

Hierarchy of

Preference

Size

(mm)

1

2

3

4

5

6

10 x 10

10 x 7.5

10 x 10

10 x 7.5

10 x 5

10 x 5

Orientation

T = Transverse

L = Longitudinal

T

T

L

L

T

L

Check with Document Control for latest available Revision

Factor

1.0

0.75

1.5

1.125

0.5

0.75

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

8 of 18

For both Transverse and Longitudinal Specimens, the notched axis shall be

perpendicular to the pipe surface.

Full size specimen (10 mm x 10 mm) shall be used where possible. For full size

transverse specimens, the minimum average absorbed energy per set of three

specimens shall be 36 ft-lb (50 J). The minimum absorbed energy of an individual

specimen shall be 30 ft-lb (40 J).

Flattening of the pipe prior to specimen preparation is not permitted. Retesting,

for Charpy V-notch tests only, is permitted if specimens show obvious defects or

defective preparation and is in accordance with this Specification.

4.4 Retesting

If one of the tests representing a lot fails to conform to the requirements in this

specification, Manufacturer shall repeat all tests on specimens cut from 10 % of

the additional lengths of pipe from the same lot. If such specimens conform to

the requirements, all remaining pipe of the lot will be accepted. If any one of the

specimens fail, the entire lot shall be rejected. However, Manufacturer may elect

to test each individual pipe remaining in the lot. Pipes, which fail any test, shall

be rejected.

5. HYDROSTATIC TESTING

Hydrostatic testing shall be applied to each pipe to API 5L after final heat

treatment by use of inhibited water at a temperature of not less than 40 OF (4.4

O

C) nor more than 100 OF (37.8OC). The use of inhibited water shall be specified

in the MPS.

The hydrostatic test pressure shall correspond to the pressure required to

generate the hoop stress in the pipe wall equal to 90% of SMYS. The minimum

hold time for hydrostatic testing shall not be less than 15 seconds at the specified

test pressure.

Hydrostatic testing apparatus, which shall include a pressure recorder, master

gauge and working gauge, shall be used for all testing and shall provide a record

of the test pressure and duration of test. The hydrotest apparatus shall be

calibrated as required by Manufacturers quality plan, using a dead weight tester.

Written records of all hydrostatic tests shall be furnished to Company.

Any leak in the pipe body is a cause for rejection.

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

9 of 18

6. DIMENSIONAL REQUIREMENTS AND TOLERANCES

6.1 Diameter

The outside diameter (OD) shall be nominal, as specified, within 0.75 %. The

inside diameter (ID) shall be nominal, as specified, within 0.5 %. These

measurements shall be made for a distance of 4 inches (101.6 mm) on each end

and shall be checked by a diameter tape, limit gage or caliper for the OD and

diameter tape for the ID. The out of roundness for a distance of 4 inches (101.6

mm) on each OD end shall not exceed 0.5 % when checked with a limit gage.

6.2 Wall Thickness

The specified nominal wall thickness shall be 10 % measured within 6 inches

(150 mm) from each end of the pipe and +12.5 / -10 % for the remaining pipe

body. Ultrasonic testing shall be employed to show that the minimum wall

thickness is maintained.

6.3 Length

The pipe joint length shall be between 11.9 and 12.5 meters, with a minimum

average of 12.2 meters. Deviations to accommodate proposed installation

method must receive approval from Company.

6.4 Pipe End Squareness

The method of checking pipe end squareness shall be specified in the MPS.

6.5 Pipe End Bevel

Grinding of the bevel is prohibited.

6.6 Gouges and Dents

Gouge and dent repair procedures shall be specified in the MPS.

6.7 Straightness

Measurement frequency of straightness shall be five pipes per shift provided that

these are visually determined to be the worst pipe. If any of these pipes are

rejectable, then inspection frequency shall be increased to ten pipes per shift with

these ten being the worst deviations, obtained visually, after physically rolling the

pipe.

6.8 Weight

The weight of each pipe shall be in the range of +12.5/-3.5 % of nominal weight

per foot. Weight shall be determined by automatic weighing machine.

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

10 of 18

7. NON-DESTRUCTIVE TESTING

7.1 Examination Techniques

Pipe end bevels shall be subjected to magnetic particle inspection in accordance

with ASTM E709.

Seamless line pipe shall be inspected by the ultrasonic testing (UT) method in

accordance with API Spec. 5L,SR4. The reference standard shall contain two

machined N5 type notches, one on the inside surface and one on the outside

surface of the pipe, parallel to the axis of the pipe and separated by a distance

large enough to produce two separate signals. An imperfection that produces a

signal greater than the reference standard shall be considered a defect and

attended to as stated in Section 8.3 of this document.

Dynamic calibration of the ultrasonic inspection tools and reference standards

shall be employed. Inspection shall be performed at the line pipe production rate.

All bevelled ends shall be ultrasonically inspected over a width of 2 inches

(50mm) around the circumference of the pipe after bevelling. A 1/4-inch

(6.35mm) diameter flat bottom hole will be used as a rejection standard.

Laminations or other defects with a greater reflected signal than the rejection

standard are not acceptable.

All pipe joints shall be full length tested for laminar and longitudinal imperfections

in the pipe body using Ultrasonic methods.

The non-destructive testing equipment used to inspect the pipe shall be checked

with applicable reference standards in a manner similar to that used in regular

production, at least once per 8 hour operating shift. If on checking against the

reference standard, the equipment is found to be faulty or to require recalibration,

all pipe tested since the previous calibration shall be retested.

Non-destructive inspection procedures and equipment shall be subject to

approval by Company prior to manufacture of the pipe.

All non-destructive examinations shall be carried out by personnel qualified to

ASNT-SNT-TC-lA (latest edition) Level II requirements or equivalent.

7.2 Residual Magnetism

Residual magnetism may cause welding problems. The maximum permissible

magnetic flux density shall be less than 20 gauss, as measured completely

around the end of the pipe using a gauss meter. Every pipe shall be checked as

it is loaded for shipment from the pipe mill. All pipe exhibiting a magnetic flux

density greater than or equal to 20 gauss shall be degaussed prior to loading for

shipment.

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

11 of 18

7.3 Inspection

Company or Company representative may employ inspection at any stage of

production of the pipe and shall have accesses to all parts of the works whenever

work on this job is being carried out.

8. WORKMANSHIP

8.1 Compliance

Manufacturer is responsible for complying with all provisions of this specification.

Company may make any investigation necessary to verify compliance by

Manufacturer and may reject any material that fails to meet this specification.

8.2 Verification and Calibration of Measuring Devices

Automatic measuring instruments shall be calibrated or verified at least once

every operating shift. Verifying the accuracy of measuring devices shall consist

of inspection for wear and conformance to specified dimensions.

Verifying the accuracy of rulers and other non-adjustable measuring devices shall

consist of a visual check for legibility of markings and general wear of fixed

reference points at the commencement of pipeline production.

8.3 Disposition of Defects

Imperfections, described in API Spec 5L, Section 7.8, that exceed the specified

criteria shall be considered defects. Pipe containing defects must be given one

of the following dispositions:

The defect shall be removed by grinding provided the remaining pipe wall

thickness is within the limit specified in section 6.2 of this specification.

The ground areas shall be carefully dressed to ensure a smooth transition

with the surrounding surface of the pipe and that no sharp notch results.

The section of pipe containing the defect shall be cut off provided the pipe

length requirements are met.

The entire pipe shall be rejected.

Manufacturer shall submit all repair procedures to Company for approval prior to

the manufacture of pipe. Manufacturer shall take all reasonable precautions to

minimize reoccurring damage to the pipe.

8.4 Rejection

Material which shows defects on mill inspection or subsequent to acceptance at

Manufacturer's works, or which proves defective when properly applied in

service, may be rejected, and Manufacturer so notified.

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

12 of 18

8.5 Rejectable Flaws

Rejectable flaws shall include cracks,sweats, leaks and laminations. Rejects due

to non-destructive tests and end laminations shall be in accordance with the

relevant sections above.

8.6 Rejection Records

Manufacturer shall prepare a rejection rate record and maintain a current record

of all rejected pipes, complete with reasons or causes for rejection. Production

shall be halted if rejection rates become unacceptable (greater than 3 % after 10

% of the pipe in the lot has been produced). Production shall not be continued

until after the causes of this rejection rate are determined, steps are taken to

prevent these from occurring during the rest of the production order, Company is

notified, and finally, written approval by Company is given.

9. PIPE CONTROL TALLY SHEET

Manufacturer shall maintain a Pipe Control Tally Sheet that shall be updated on a

daily basis. This sheet shall show the status of all pipes in the order at all times.

10. PIPE MARKING

10.1

Requirements

Each length of pipe shall be paint-stenciled with all of the required API markings.

All marking shall be paint stenciled onto the outside surface of one end of the

pipe. Markings shall be in block capital letters with a minimum height of 0.75

inches (19 mm).

In addition, for all pipes with OD 16 and greater, markings shall be included on

the inside of the pipe at one end and shall include as a minimum:

10.2

Name of Manufacturer

Heat/lot number

Sequential pipe identifying number

Die Stamping

For all pipes, bevels shall have hard stamp numbers to ensure traceability using

a round soft-nosed die.

11. PIPE COATING

All pipes shall be furnished bare and free of all mill coating.

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

13 of 18

12. TRANSPORTATION AND HANDLING

12.1

Transportation Preparation

The billets, slabs and pipe from each heat shall remain, as much as practical,

segregated during the entire manufacturing, testing, inspection and shipping

processes.

Care shall be taken to ensure that mechanical damage is not caused during

handling and transportation of pipe. Handling procedures and details of pipe

transportation shall be submitted to Company for approval. All pipes shall be

handled, loaded and shipped in accordance with API RP 5L1 and 5LW as

applicable. The dimensional tolerances and surface conditions of each pipe shall

apply to the pipe condition as received by Company at the shipping destination.

Pipe shall be delivered without salt contamination.

12.2

Bevel Protectors

Bevel protectors are required. The use of the mill's standard steel bevel protector

shall be detailed in the MPS.

13. MILL TEST CERTIFICATES

13.1

General

Mill test certificates shall be supplied in the English language. One original and

two copies are required for each lot of not more than 100 pipe lengths. All pipes

shall be shown on the mill test certificates. All certificates shall be available prior

to pipe arrival.

13.2

Required Data

The following data are required as a minimum on all mill certificates:

Purchase order number

Heat/lot identifying numbers

Pipe identifying numbers

Ladle analysis

Product analysis

Carbon equivalent

Heat Treatment

All required mechanical test results

Specification limits

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

13.3

DOCUMENT NUMBER

84501-9230-2L-022

NDE results

Line pipe outside diameter and wall thickness.

REV

2

DATE

13 Dec 02

PAGE

14 of 18

Format

The layout of the mill certificate shall include the following as a minimum:

Signature of responsible official of Manufacturer signifying compliance with

this specifications requirements

Mill Location

Heat Number

Purchase order number

Pipe number (s)

Pipe grade

Heat treatment records

Micrographic examination record where specified

Dimensional report.

Layout of certificate may be per Manufacturers standard format, however the

data required in paragraph 13.2 shall be reported including heat treatment and

company P. O. number.

14. DOCUMENTATION AND CERTIFICATION

Manufacturer shall supply documentation relating to the supply of line pipe to

Company for approval.

Full certification of the results of inspection and testing shall be provided by

Manufacturer and shall be validated by Company representative in accordance

with EN 10204 3.1.C, except where Company agrees, prior to the start of

production, to accept EN 10204 3.1.B certificates for specific results.

Certification shall cover all results required by this specification and shall be

marked with sufficient information to enable full traceability to the items it

represents and the relevant specifications and procedures.

All reports and inspection certificates shall be signed by Manufacturer and

Company representative to signify compliance with the requirements of this

specification.

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

15 of 18

15. QUALITY ASSURANCE

15.1

General

The quality system implemented by Manufacturer shall establish and maintain a

fully documented Quality Assurance/Quality Control system.

Any verification of quality performed by Company or Company representative

shall not relieve Manufacturer of the responsibility to produce acceptable line pipe

nor shall it preclude any subsequent rejection of line pipe.

Manufacturer shall establish and maintain control of all special processes, which

are essential to production, inspection or safety. Equipment, processing

environment and Manufacturer personnel shall be subject to appropriate

qualifications or certifications.

Manufacturer shall maintain quality records as documenting evidence of

conformance to quality requirements. These records shall be made available to

Company representative for review.

15.2

Quality Plan

Prior to the start of any manufacturing process Manufacturer shall prepare a

Quality Plan which sets forth witness, hold, review, repair, and monitor points for

review and approval by Company. Manufacturers subsequent Quality Control of

the Work shall strictly adhere to the agreed Quality Plan. The implementation of

the Quality plan may be subject to monitoring by Company and in addition, may

be audited following an agreed period of notice. Manufacturer shall ensure that

the Quality Plan requirements specified are applied to all materials, equipment

and services provided.

Manufacturer shall inspect the line pipe to ensure compliance with the purchase

order requirements. A check shall be made of all inspection records to verify that

the line pipes were inspected at all points shown in the Quality Plan and that

these records are complete and available to Company representative.

Material traceability shall be maintained throughout the manufacturing process.

Manufacturer's Quality Plan shall stipulate the traceability procedures, which shall

be incorporated into the MPS.

16. PRODUCT INSPECTION

Company representative shall inspect the pipe and witness the required tests.

Reasonable notice, at least two weeks for the first production test and one day

thereafter, shall be given of the times at which the production tests are to be

made.

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

16 of 18

Company inspectors and representatives shall have free entry to all parts of

Manufacturer's facilities that concern the manufacture and testing of the ordered

pipe during all times while work on this order is being performed.

Manufacturer shall provide all reasonable facilities to Company inspectors,

without charge, to satisfy him that the pipe is being manufactured in accordance

with this specification. Such facilities shall include, but not be limited to, office

space, office equipment and telecommunication equipment. All inspection shall

be made at the place of manufacture, prior to shipment, unless otherwise

specified in the purchase order. Inspection will be so conducted as not to

interfere unnecessarily with the operation of the works.

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

APPENDIX - A

DOCUMENT NUMBER

84501-9230-2L-022

REV

2

DATE

13 Dec 02

PAGE

17 of 18

MPS Minimum Requirements

The MPS shall include but not be limited to the following items:

Name of steel mill

Steel making method

De-oxidation method

Desulphurization method

Chemical composition range and target composition

Special additions

Ladle treatments

Vacuum de-gassing

Ingot, slab or billet handling practices

Casting practices

Frequency of centerline segregation monitoring

Pipe forming practice (incl. instrumentation to ensure proper control of

processing temperatures, heat treatment procedures and other measures

utilized to ensure consistency of both the mechanical properties and

dimensional tolerances of the line pipe).

Pipe forming temperature range

Centerline segregation evaluation procedure

Heat treatment (incl. temperatures, hold times, heating and cooling rates,

cooling medium and furnace details)

Hydrostatic Test Procedure

Pipe Tracking System

Quality Plan

Non-destructive Testing Procedures (incl. visual inspection, equipment

details, calibration methods and frequency, scanning procedure and matrix,

probe details, recording/reporting methods, alarm system)

Handling, Transport and Storage Procedures

Squareness Verification Procedures

Dent and Gouge Repair Procedures

Check with Document Control for latest available Revision

CONOCO INDONESIA INC. LTD.

PROJECTS GROUP

SPECIFICATION

TITLE

SEAMLESS FLOWLINES TO API 5L

DOCUMENT NUMBER

84501-9230-2L-022

APPENDIX - B

ELEMENT

C

REV

2

DATE

13 Dec 02

PAGE

18 of 18

Chemical Analysis

Product Analysis, max

weight %

0.16

Mn

1.60

Si

0.50

0.02

0.015

Cu

0.35

Ni

0.40

Mo

0.25

Cr

0.20

Al (total)

0.06

Nb

0.05

0.10

Ti

0.05

0.01

0.0005

Ca, max

0.004

CE, max

0.40

Pcm, max

0.25

1.

For each reduction of 0.01% of the maximum allowed C content,

an increase of the Mn content of 0.05% above the maximum

specified up to 1.8% is allowed for steels with SMYS 485 MPa

2.

Mo: maximum 0.35 % if V is not intentionally added.

3.

0.5 - 1.0% Cr may be used subject to agreement.

4.

(Nb + V)% max : 0.12 %

5.

Al : N 2: 1 (not applicable to Ti killed steels)

6.

CE = C + Mn/6 + (Cr + Mo+ V )/5 + (Cu + Ni )/15

7.

Pcm = C + Si/30 + (Mn + Cr + Cu)/20+ Ni/60 + Mo/15 + V/10 +

5B

Check with Document Control for latest available Revision

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Raft TT FT FT FT FT AFT AF RAFDocument31 pagesRaft TT FT FT FT FT AFT AF RAFHugo Silva100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2a. - Compression-Members Ce134p - Escruz - LRFDDocument19 pages2a. - Compression-Members Ce134p - Escruz - LRFDJed CernechezNo ratings yet

- CIVE378 Exam1 ReviewDocument2 pagesCIVE378 Exam1 ReviewJoshtion ShahNo ratings yet

- Diesel Tank SizingDocument7 pagesDiesel Tank SizingNurcahyo Djati W100% (2)

- One Year Spare Parts and OPEX for CNG StationDocument6 pagesOne Year Spare Parts and OPEX for CNG StationNurcahyo Djati WNo ratings yet

- Load List 1Document2 pagesLoad List 1Nurcahyo Djati WNo ratings yet

- Data CompresorDocument2 pagesData CompresorNurcahyo Djati WNo ratings yet

- Capex OpexDocument5 pagesCapex OpexNurcahyo Djati WNo ratings yet

- Deliverable List ElectricalDocument8 pagesDeliverable List ElectricalNurcahyo Djati WNo ratings yet

- VENDOR LIST CNG As 100510Document4 pagesVENDOR LIST CNG As 100510Nurcahyo Djati WNo ratings yet

- Blanket Gas DemandDocument2 pagesBlanket Gas DemandNurcahyo Djati W100% (2)

- Vessel VolumeDocument5 pagesVessel VolumeNurcahyo Djati W100% (1)

- CNG Bussiness DevelopmentDocument4 pagesCNG Bussiness DevelopmentNurcahyo Djati WNo ratings yet

- Dryer NewDocument9 pagesDryer NewNurcahyo Djati WNo ratings yet

- Deliverable List ElectricalDocument8 pagesDeliverable List ElectricalNurcahyo Djati WNo ratings yet

- Gas - Pneumatic StarterDocument2 pagesGas - Pneumatic StarterNurcahyo Djati WNo ratings yet

- Deliverable List ElectricalDocument8 pagesDeliverable List ElectricalNurcahyo Djati WNo ratings yet

- Choosing A Compressed Air DryerDocument7 pagesChoosing A Compressed Air DryerNurcahyo Djati WNo ratings yet

- Ariel Non LubeDocument2 pagesAriel Non LubeNurcahyo Djati WNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Capex OpexDocument5 pagesCapex OpexNurcahyo Djati WNo ratings yet

- Crane ds2Document2 pagesCrane ds2Nurcahyo Djati WNo ratings yet

- Crane DsDocument2 pagesCrane DsNurcahyo Djati WNo ratings yet

- Air Compressor DWGDocument1 pageAir Compressor DWGNurcahyo Djati WNo ratings yet

- CNG O&MDocument15 pagesCNG O&MNurcahyo Djati W0% (1)

- ACestimateDocument4 pagesACestimateNurcahyo Djati WNo ratings yet

- DATA SHEET FOR OVERHEAD CRANEDocument2 pagesDATA SHEET FOR OVERHEAD CRANENurcahyo Djati WNo ratings yet

- Crane DsDocument2 pagesCrane DsNurcahyo Djati WNo ratings yet

- Crane DsDocument2 pagesCrane DsNurcahyo Djati WNo ratings yet

- Sheet A - 1 Volume CalculationDocument3 pagesSheet A - 1 Volume CalculationNurcahyo Djati WNo ratings yet

- APIseparator SizDocument10 pagesAPIseparator SizNurcahyo Djati WNo ratings yet

- CommDocument31 pagesCommNurcahyo Djati WNo ratings yet

- Sheet A - 1 Volume CalculationDocument3 pagesSheet A - 1 Volume CalculationNurcahyo Djati WNo ratings yet

- Experiment 3: Critical Radius of Insulating MaterialDocument5 pagesExperiment 3: Critical Radius of Insulating Materialmehul deshpande100% (1)

- IP Design and Installation of Inert Gas SystemDocument117 pagesIP Design and Installation of Inert Gas SystemArif Kuncoro Adi100% (1)

- Aero Booklet Forth Semester 2021-22Document22 pagesAero Booklet Forth Semester 2021-22PIETDS1 aeronauticalNo ratings yet

- พอฤทัย วิริยะภาค26 3.5Document2 pagesพอฤทัย วิริยะภาค26 3.55.6 25 [พิงค์แพรว]นางสาวพอฤทัย วิริยะภาคNo ratings yet

- Key information on motor dataDocument8 pagesKey information on motor dataRadj90No ratings yet

- Samsung EHS Selection - Split - Bratislava - AE090RXEDGG - EUDocument48 pagesSamsung EHS Selection - Split - Bratislava - AE090RXEDGG - EUDusan NecasNo ratings yet

- Agma 908-B89-1999Document79 pagesAgma 908-B89-1999Alex OliveiraNo ratings yet

- Crossrunner 250cc Service ManualDocument228 pagesCrossrunner 250cc Service ManualAnna RyanNo ratings yet

- Rao 1961Document10 pagesRao 1961Sãröj ShâhNo ratings yet

- Sweeper (Brushes With Convoluted Sections) (One Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperDocument3 pagesSweeper (Brushes With Convoluted Sections) (One Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperCristian SchildNo ratings yet

- Vol0010 PDFDocument6 pagesVol0010 PDFFranciscoOliveiraNo ratings yet

- Plastic Gear Moulding Design GuideDocument27 pagesPlastic Gear Moulding Design GuideMahesh Deivasiga Mani DNo ratings yet

- CD 330+ Dimension DrawingDocument1 pageCD 330+ Dimension DrawingJOSUE FERNANDO FERNANDEZNo ratings yet

- Tutorial 2-Equilibrium 1Document2 pagesTutorial 2-Equilibrium 1Sai KrishnaNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanNESTOR YUMULNo ratings yet

- Aerodynamic Aspects of The Sealing of Gas-Turbine Rotor-Stator SystemsDocument5 pagesAerodynamic Aspects of The Sealing of Gas-Turbine Rotor-Stator SystemsahmadalsaiahNo ratings yet

- SM - 3 TransmissionDocument397 pagesSM - 3 TransmissionJanNo ratings yet

- Technical Data For Configuration REV AA en 1Document19 pagesTechnical Data For Configuration REV AA en 1Isaac GumboNo ratings yet

- Gek 28138Document20 pagesGek 28138Mauricio GuanellaNo ratings yet

- 1618 TP-Sales Kit AMW 1618Document23 pages1618 TP-Sales Kit AMW 1618niharjyotilahonNo ratings yet

- Kinetic and Potential Energy: VocabularyDocument5 pagesKinetic and Potential Energy: Vocabularykaren cotingjoNo ratings yet

- A320 GACA ORAL TEST Updated 14/09/2013 Emergency EquipmentDocument20 pagesA320 GACA ORAL TEST Updated 14/09/2013 Emergency EquipmentMustafa ElbazNo ratings yet

- DTS - Ship Const & StabDocument12 pagesDTS - Ship Const & StabYASHKAR VERMA100% (2)

- 2009 BMW E60 Vibration at IdleDocument2 pages2009 BMW E60 Vibration at IdlewmirkhanNo ratings yet

- Koppel Ceiling SuspendedDocument2 pagesKoppel Ceiling SuspendedLeomark RespondeNo ratings yet

- Feejoy BrochureDocument6 pagesFeejoy BrochureOswaldo HernandezNo ratings yet

- A Review On Effect of Preheating and orDocument3 pagesA Review On Effect of Preheating and orKing SabiNo ratings yet