Professional Documents

Culture Documents

Type of Draft in Spinning

Uploaded by

Venkat PrasannaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Type of Draft in Spinning

Uploaded by

Venkat PrasannaCopyright:

Available Formats

ISSN-1997-2571 (Online)

J. Innov. Dev. Strategy 5(1):17-21(April 2011)

STUDY OF THE EFFECT OF CHANGING DRAFT OF SPINNING FRAME ON THE QUALITY OF

BLENDED YARN

A.N.M.A. ULLAH1, M.A. HOSSAIN2, A.K.M. MAHABUBUZZAMAN3 AND M.A. JALIL4

1

Department of Textile Engineering, Southeast University; 2Department of Physics, Jahangirnagar University; 3Bangladesh Jute Research

Institute; 4Department Of Textile Engineering, Mawlana Bhashani Science And Technology University, Santosh, Tangail-1902, Bangladesh.

Corresponding author & address: A.N.M.A. Ullah, E-mail: tahminamita@yahoo.com.au

Accepted for publication on 30 March 2011

ABSTRACT

Ullah ANMA, Hossain MA, Mahabubuzzaman AKM, Jalil MA (2011) Study of the effect of changing draft of spinning frame on the quality

of blended yarn. J. Innov. Dev. Strategy 5(1), 17-21.

Effect of draft variation on yarn along with its different sliver weight was studied. From this study, it was noted that

with the changes of drafts, CV% varied. The yarn spun at actual twist level of 6.8 Twists Per Inch is relatively nearer

to the optimum quality yarn. This may be said the better result of yarn in comparison to the others. Therefore, applied

draft 20 on yarn offers better quality ratio.

Key words: yarn, acrylic, jute, spinning

INTRODUCTION

Jute is a natural cellulosic bast fibre which is extracted from the stems of plants belonging to the botanical genus

Corchorus. Approximately 40 species are known, only two viz, capsularies and olitorius are cultivated commercially. Capsularies is knows as white and olitorieus as Tossa Jute It is a textile fibre of good spinnable character (Barella 1966). Jute is facing tough competition with synthetic fibres. Hence, for the survival of this environment friendly fibre, it is necessary to diversify the use of jute by making new products with jute & blending

with other fibres. Usually coarser yarns are manufactured from Jute fibre through the Flyer Spinning, Ring spinning, Modified apron draft spinning and Centrifugal spinning, which we usually used to spin jute yarn. Through

modified apron draft spinning of jute such as shopping bag, furnishing fabric, decorative fabrics, finer fabrics

etc. As a result, jute fibre may be used in the production of fabric that may further enhance its uses in various

fields of textiles. Quality is an important factor for any production-oriented industry. In order to achieve quality

products it is necessary to determine the appropriate draft of apron draft spinning system for production of the

blended yarn.

Any long chain synthetic polymer composed of at least 85 percent by weight of acrylonitrile units. Which may

be used as clothing, carpeting, automobile components, telephone and computer casings, sports equipement,

produced plastic that are inpermeable to gases and are ideal for shatter proof bottles which is used for holding

chemicals and cosmetics, clear blister packs that keep meats fresh and medical supplies sterile and packaging

for many other products. It is also a component in plastic resins, paints, adhesive and coatings etc.

Figure 1. Acrylic Fibre

Copyright 2011 Green Global Foundation

17

J. Innov. Dev. Strategy 5(1): April 2011

Ullah et al.

Figure 2. Flow chart of the manufacturing process of Orlon acrylic fibre

Most industrial acrylonitrile is produced by catalytic ammoniation of propylene.

CH3 CH CH2 +

NH3 + O2

CH2 CH C N +

H2O

After orientation and stabilization, the acrylic filaments are cut into staple length for spinning into yarn. Some of

the general common properties of acrylic fibres are:

Strength Fair

Color Fastness Good

Flamability Flammable, Toxic

Elasticity Low

Absorbacy Little

Srinkage Virtually none

Color Color less to pale yellow

Boiling Point 77 C

MATERIALS AND METHODS

The processing of the fibres for converting into yarn of 172 tex (5 lbs/spy) was made following the sequences of

conventional jute processing system (Barella and Manich, 1993).

For blending, jute and acrylic fibre were first taken by weight as per blend ratio. Then the jute fibre was softened by the application of emulsion in softener machine and piled for 48 hours. The acrylic fibre was separated

and opened up manually by hand teasing and tufts of certain weights were made. Blending was carried out by

spreading the fibres i.e. jute and acrylic in desired proportion, i.e. 80:20 ratio by weight over the breaker card

lattice. The delivered silvers from breaker card were then processed through normal jute processing system and

spun into yarns of 172 tex (5lbs/spy).

The 3rd Drawing sliver was processed for spinning into yarn with different drafts in the modified apron draft

ring spinning frame. In the spinning department, the modified apron draft ring-spinning machine of eight spindles are used in the experiment. James Mackie & sons Ltd. of Ireland manufactured the original machine. All

flyers were removed and eight spindles were installed instead of existing flyers in the machine. Instead of flyer,

travelers were used for inserting required twist in the yarns. In the flyer type spinning frame, the twist is inserted

into yarn by the effect of flyer speed. In the modified apron draft flyer spinning frame, the twist is inserted into

yarn by the effect of traveler speed and spindle speed (Kalyanaraman 1992).

In the modified apron draft ring spinning frame used TPI was 6.8 and TCP was calculated to 60.The spindle

speed was 7000 rpm.

Steps of producing blended jute-acrylic yarns.

Study the connected literature

Assortment of raw materials

Collection of raw materials (Jute and Acrylic)

Determination of fibre Properties

Blending of Jute with acrylic.

Selection of processing parameters.

Trial run

Production of yarn

Determination of physical properties of the yarn

Study the yarn performance

18

J. Innov. Dev. Strategy 5(1): April 2011

Study of the effect of changing draft of spinning frame on the quality of blended yarn

FLOW CHART OF JUTE-ACRYLIC BLENDED YARN PRODUCTION PROCESS

Selection of Jute for a batch

Acrylic fibre

Softening & lubricating

Conditioning or Piling

Breaker card

Finisher card

1st Drawing frame (2: 1)

2nd Drawing frame (3: 1)

3rd Drawing frame (2: 1)

Ring Frame (Spinning)

Preparatory machines used for the experiment:

The following back processing or preparatory machines were used for the work:

Softener, breaker card, Finisher Card. first, second and third drawing frame (Smith 2001).

Softener

The feed roller in this machine is a spirally fluted. The barrow of jute at the far end of the machine is built up

from stricks, which have passed through the machine, and these stricks are now ready for conditioning, and will

be stored in a convenient position for future treatment. After the fibre from the softening machine has been conditioned for a pre-fixed time, then is ready for next machine.

Carding

One of the most important process in the cycle of jute manufacture; which is known as carding, and is conducted in two distinctly different types of machines: The breaker card and the finisher card. The slivers travel

horizontally with the feed-sheet and enter the machine at a height of about 4 feet from the floor. They thus form,

as it were, a sheet of fibrous material at the entrance, and this sheet of fibres comes in contact with the pins of

the various pairs of rollers, the cylinder, and the doffer, in the same way as already described

(www.cottonyarnmarket.net).

Drawing frames

The sliver from the carding machine are taken-up by the first drawing frame subjected to a further process of

doubling and drafting in a very similar machine termed the second drawing frame. For the preparation of sliver

for some classes of yarn it is considered desirable to extend the drawing and doubling operation in a third drawing frame; as a rule, however, two frames are considered sufficient for most classes of ordinary yarns

(www.uster.com).

Apron Draft spinning frame

Apron draft flyer-spinning machine was used for this experiment. As we know drafting of material of machine

of a moving apron which povides a very good control of material throughout the entire drafting zone. This regularity in the yarns brings in good appearance and increased strength and also reduces the number of breaks per

unit time. This reduced breakage of slivers during spinning helps increased production and decreasede work

load on the spinner (Goswami et al. 1977).

The apron draft sliver spinning frame has an automatic cleaner which traverses full length of machine and thus

increases yarn cleanliness reducing operator work load. The machine was operated to evaluate its performance

at different ranges of parameters such as draft, twist and speed etc.

19

J. Innov. Dev. Strategy 5(1): April 2011

Ullah et al.

Figure 3. Blended Yarn

RESULTS AND DISCUSSIONS

Fibre properties

Physical properties such as strength, breaking twist, fineness and elongation of jute fibres and acrylic fibre have

been determined. Measured physical properties are furnished below.

Table 1. Physical properties of BWB Jute Fibre

Grade

BWB

Statistics

Mean

Range

CV%

Fineness

Diameter()

38.5

20-56

25

Bundle Strength

(Pressly Index)

4.8

3.0-5.16

20

Linear

Density

(Tex)

2.6

1.4-3.8

28.3

Breaking

Tenacity

(g/Tex)

28.4

11-60

35

Breaking

Elongation

(%)

0.8

0.35-1.6

30.5

Linear

Density

(Tex)

0.6

0.4-1.8

18.4

Breaking

Tenacity

(g/Tex)

4.4

1.1-6.2

15

Breaking

Elongation

(%)

0.1

0.05-1.1

20.1

Table 2. Physical Properties of Acrylic Fibre

Grade

Acrylic

Statistics

Mean

Range

CV%

Fineness Diameter()

1.88

1.5-2.1

15

Bundle Strength

(Pressly Index)

8.8

6.0-15.6

14

BWB jute and acrylic blended fibre were processed through different drafts at fixed spindle speed along same

level of twist to spin 172 tex(5 lbs/spy) yarn. After spinning, the physical properties of the yarn were measured.

The results are as follows:

Table 3. Physical characteristics of 5lbs/spy (172 tex) Jute-Acralic blended yarn

Drafts

Nominal

Count

Lbs/spy (tex)

18

19

20

22

23

5(172)

Actual Count

Lbs/spy (tex)

5.20

(179.14)

5.19

(178.79)

5.20

(179.14)

4.99

(171.90)

4.95

(170.52)

TPI

(twist per

inch)

6.8

Tensile strength in lbs (kg)

Mean

SD

CV% of

strength

4.75(2.15) 0.361

16.79

Quality

ratio

(%)

91.34

6.8

4.96(2.25)

0.355

15.78

95.56

6.8

5.20(2.36)

0.297

12.58

100.00

6.8

4.76(2.16)

0.278

12.87

95.39

6.8

4.45(2.02)

0.299

14.80

89.89

To determine the effect of different drafts on sliver of different weight of jute/acrylic blended yarn of 172 tex (5

lbs/spy) in the spinning frame:- It is found that CV% varies with the variation of drafts. From table-3, it is noted

that CV% gradually changed with the increasing of drafts. At draft 20, 6000-rpm spindle speed, TPI was 6.8

along with a quality ratio of 100%.

20

J. Innov. Dev. Strategy 5(1): April 2011

Study of the effect of changing draft of spinning frame on the quality of blended yarn

From table 3,it is found that, at different drafts, the CV% of the yarn changes which follows slightly decreasing

trend. The yarn spun with 22 drafts, found to possess CV% 12.87 with quality ratio of 95.39%. It may be mentioned that, quality ratio of produced yarn were slightly differ in different drafts. The reason of that variation

was the different weight of third drawing sliver. Although in all trials BWB grade jute and acrylic fibre were

used. In most cases quality ratios were increased upto 22 draft and at 23 drafts it is decreased (Hearle at el.

1959).

It may be concluded that increasing of draft upto a certain level i.e in optimum level quality ratio of the yarn is

increased. But further increse of draft the quality ratio is decreased.

CONCLUSION

In the experiment, effect of draft variation on yarn along with its different sliver weight was studied. From this

study, it was noted that with the changes of drafts, CV% varied (Hadina and Kovacevic, 1998). The yarn spun at

actual twist level of 6.8 Twists Per Inch is relatively nearer to the optimum quality yarn. This may be said the

better result of yarn in comparison to the others. Therefore, applied draft 20 on yarn offers better quality ratio.

REFERENCES

Barella A (1966) The Hairiness of Yarns: A Review of the Literature and a Survey of the Present Position. J.

Text. Inst. 57, T461, pp-40-45.

Barella A, Manich (1993) The hair length distribution of yarns measured by means of the Zweigle G 565 hairiness meter, J. Text Inst. Pp- 84,326.

Goswami BC, Martindle JG, Scardino FL (1977) Textile Yarns, ISBN 0-471-31900-7.

Hadina J, Kovacevic S (1998) Influence of yarn twist on the texture of fabric, Tekstil, 47, 9.

Hearle JWS, El HMA, Behery, Thakur VM (1959) J. Text. Inst., 50, T83.

Kalyanaraman AR (1992) A process to control hairiness in yarn, J. Textile Inst., 83(3), pp-407-413.

Smith J (2001) Textile ProfessorTM Physical testing of Textiles-B P Saville, pp-20-25.

www.cottonyarnmarket.net

www.uster.com

21

J. Innov. Dev. Strategy 5(1): April 2011

You might also like

- Oerlikon Manmade Fibers Teknoweb MedienmitteilungDocument3 pagesOerlikon Manmade Fibers Teknoweb MedienmitteilungVenkat PrasannaNo ratings yet

- Process Parameters in SimplexDocument3 pagesProcess Parameters in SimplexTanvir Alam100% (5)

- NE 30s CM UsterStatistics2018 - 2021-04-21 - 14-00-17Document2 pagesNE 30s CM UsterStatistics2018 - 2021-04-21 - 14-00-17Venkat PrasannaNo ratings yet

- 80s Compact QualityDocument3 pages80s Compact QualityVenkat PrasannaNo ratings yet

- Achieving 99% Utilization in SpinningDocument2 pagesAchieving 99% Utilization in SpinningVenkat PrasannaNo ratings yet

- PSG College of Arts & Science Coimbatore - 641 104Document8 pagesPSG College of Arts & Science Coimbatore - 641 104Venkat PrasannaNo ratings yet

- FactSheet Fiber Yarn Ring SpinningProcessing PDF PDFDocument7 pagesFactSheet Fiber Yarn Ring SpinningProcessing PDF PDFVenkat PrasannaNo ratings yet

- TC 20efDocument2 pagesTC 20efVenkat PrasannaNo ratings yet

- Charlie ChaplinDocument27 pagesCharlie ChaplinVenkat PrasannaNo ratings yet

- JEE (Advanced) 2017Document1 pageJEE (Advanced) 2017Venkat PrasannaNo ratings yet

- 12 Survey ReportDocument76 pages12 Survey ReportVidush Mukesh Singh ChauhanNo ratings yet

- Andavan Kattalai RajinikanthDocument40 pagesAndavan Kattalai RajinikanthVenkat PrasannaNo ratings yet

- Barre Causes and PreventionDocument19 pagesBarre Causes and PreventionReal SheriffNo ratings yet

- Cost Structures of Comparable Rotor-Spun and Ring-Spun Yarns - RieterDocument3 pagesCost Structures of Comparable Rotor-Spun and Ring-Spun Yarns - RieterVenkat Prasanna100% (1)

- Fees Circular Jan-May 2016Document5 pagesFees Circular Jan-May 2016Venkat PrasannaNo ratings yet

- IIT Madras Fees - IIT Madras Scholarships - IIT Chennai Fee StructuresDocument6 pagesIIT Madras Fees - IIT Madras Scholarships - IIT Chennai Fee StructuresVenkat PrasannaNo ratings yet

- Calender Roller Weighting PDFDocument1 pageCalender Roller Weighting PDFVenkat PrasannaNo ratings yet

- LRT PDFDocument8 pagesLRT PDFVenkat PrasannaNo ratings yet

- Asg enDocument2 pagesAsg enVenkat PrasannaNo ratings yet

- Energy SavingDocument2 pagesEnergy SavingVenkat PrasannaNo ratings yet

- What Happened in JapanDocument5 pagesWhat Happened in JapanVenkat PrasannaNo ratings yet

- LMW Recommendation in Instruction Manual R 123 - New RecommendationDocument2 pagesLMW Recommendation in Instruction Manual R 123 - New RecommendationVenkat PrasannaNo ratings yet

- Top Courses After 12th Science (Job & Salary-Wise)Document13 pagesTop Courses After 12th Science (Job & Salary-Wise)Venkat PrasannaNo ratings yet

- Fee Structure For 1st Sem 2016-17-1Document8 pagesFee Structure For 1st Sem 2016-17-1Venkat PrasannaNo ratings yet

- TamilDocument1 pageTamilVenkat PrasannaNo ratings yet

- Settings in Carding For Different Grades of Cotton PDFDocument3 pagesSettings in Carding For Different Grades of Cotton PDFVenkat PrasannaNo ratings yet

- Average YSP and RMC - For Home PageDocument2 pagesAverage YSP and RMC - For Home PageVenkat PrasannaNo ratings yet

- AR Physical Properties of Sun Yarns 01Document36 pagesAR Physical Properties of Sun Yarns 01Neeraj BhardwajNo ratings yet

- KolukkumalaiDocument5 pagesKolukkumalaiVenkat PrasannaNo ratings yet

- Fiitjee Solutions Jee Main 2016Document31 pagesFiitjee Solutions Jee Main 2016TanujNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CERT Basic Training Participant Manual - 2011Document332 pagesCERT Basic Training Participant Manual - 2011jegodfreyNo ratings yet

- MSC Syllabus AllDocument13 pagesMSC Syllabus AllOmSilence2651No ratings yet

- Oil Safety Data SheetDocument19 pagesOil Safety Data Sheetemailsepamku gorgomNo ratings yet

- Nokia N97 User Guide: 9221217 Issue 2.0Document76 pagesNokia N97 User Guide: 9221217 Issue 2.0Boris CavarNo ratings yet

- Dcom QuestionDocument3 pagesDcom Questionsushant sahooNo ratings yet

- 3.1 From Algae To Terrestrial Plants-Student SheetDocument2 pages3.1 From Algae To Terrestrial Plants-Student Sheeteshaaljamal27No ratings yet

- Li-ION Battery Charger FeaturesDocument2 pagesLi-ION Battery Charger Featureshariyadi aryoNo ratings yet

- 5.case Study: Effects of Homeopathic Medicines in AdultsDocument2 pages5.case Study: Effects of Homeopathic Medicines in AdultsAMEEN ARTSNo ratings yet

- VGHV NBV GH fc7fvbn BN NGCJHGDocument16 pagesVGHV NBV GH fc7fvbn BN NGCJHGRahul GNo ratings yet

- L4004N - 0920 - Nilfisk - Robotic-brochure-Liberty SC60Document12 pagesL4004N - 0920 - Nilfisk - Robotic-brochure-Liberty SC60Lucianderson Marques FerreiraNo ratings yet

- Diesel HatchbackDocument14 pagesDiesel HatchbackloganathprasannaNo ratings yet

- Geotechnical Elements and Models in OpenSeesDocument21 pagesGeotechnical Elements and Models in OpenSeesUmut AkınNo ratings yet

- Life Below WaterDocument10 pagesLife Below Watertrisha sobito0% (1)

- 100kw TSP Agenitor-404b Biogas 60-hz 480v En-827879Document9 pages100kw TSP Agenitor-404b Biogas 60-hz 480v En-827879Julian BarreraNo ratings yet

- Fundamentals of VolleyballDocument2 pagesFundamentals of VolleyballLawrence CezarNo ratings yet

- Tracking sports training efficiency with surface EMGDocument8 pagesTracking sports training efficiency with surface EMGsdjuknicNo ratings yet

- Steel StaircaseDocument17 pagesSteel StaircaseKarthick CrazeiNo ratings yet

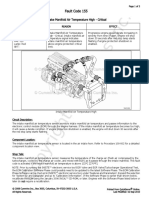

- Fault Code 155: Intake Manifold Air Temperature High - CriticalDocument3 pagesFault Code 155: Intake Manifold Air Temperature High - Criticalhamilton miranda100% (1)

- SXMDocument7 pagesSXMLi NearNo ratings yet

- Gold Grade of Epithermal Gold Ore at Lamuntet, Brang Rea, West Sumbawa District, West Nusa Tenggara Province, IndonesiaDocument10 pagesGold Grade of Epithermal Gold Ore at Lamuntet, Brang Rea, West Sumbawa District, West Nusa Tenggara Province, Indonesiasukri arjunaNo ratings yet

- Australian 9 Grade Physics Lesson 1Document32 pagesAustralian 9 Grade Physics Lesson 1binoyrajcrNo ratings yet

- Pd3c CV Swa (22kv)Document2 pagesPd3c CV Swa (22kv)เต่า วีไอNo ratings yet

- Operator Manual T2100-ST2 - ST1Document50 pagesOperator Manual T2100-ST2 - ST1Nurul FathiaNo ratings yet

- TICSA - Diesel Uno Petroleos Guatemala (13.01.23)Document1 pageTICSA - Diesel Uno Petroleos Guatemala (13.01.23)Luis M LópezNo ratings yet

- LirikDocument537 pagesLirikMuhamad Iqbal FahmiNo ratings yet

- Astrological Terms A-ZDocument63 pagesAstrological Terms A-Zmahadp08100% (1)

- Carte Automatic TransmissionsDocument20 pagesCarte Automatic TransmissionsGigelNo ratings yet

- NQ-NQM Panelboards and Qonq Load Centers Information Manual 80043-712-06 Rev.02 06-2015 2 PiezasDocument144 pagesNQ-NQM Panelboards and Qonq Load Centers Information Manual 80043-712-06 Rev.02 06-2015 2 PiezasNadia EspinozaNo ratings yet

- Module 6 - FormworksDocument8 pagesModule 6 - FormworksAldrich Francis Ortiz Peñaflor100% (1)

- DUB01CB Eng PDFDocument4 pagesDUB01CB Eng PDFAnonymous hj273CMNo ratings yet