Professional Documents

Culture Documents

PSC2

Uploaded by

Shah KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PSC2

Uploaded by

Shah KhanCopyright:

Available Formats

Multistrand post-tensioning anchor.

Bonded post-tensioned concrete is the descriptive term for a method of

applying compressionafter pouring concrete and during the curing process (in situ). The concrete

is cast around a plastic, steel or aluminium curved duct, to follow the area where otherwise

tension would occur in the concrete element.

A set of tendons are fished through the duct and the concrete is poured. Once the concrete has

hardened, the tendons are tensioned byhydraulic jacks that react (push) against the concrete

member itself.

When the tendons have stretched sufficiently, according to the design specifications

(see Hooke's law), they are wedged in position and maintain tension after the jacks are removed,

transferring pressure to the concrete. The duct is then grouted to protect the tendons

fromcorrosion.

This method is commonly used to create monolithic slabs for house construction in locations

where expansive soils (sometimes called adobe clay) create problems for the typical perimeter

foundation. All stresses from seasonal expansion and contraction of the underlying soil are taken

into the entire tensioned slab, which supports the building without significant flexure.

Post-tensioning is also used in the construction of various bridges, both after concrete is cured

after support by falsework and by the assembly of prefabricated sections, as in thesegmental

bridge.

Among the advantages of this system over unbonded post-tensioning are:

Large reduction in traditional reinforcement requirements as tendons cannot destress in

accidents.

Tendons can be easily "woven" allowing a more efficient design approach.

Higher ultimate strength due to bond generated between the strand and concrete.

No long term issues with maintaining the integrity of the anchor/dead end.

History of problems with bonded post-tensioned bridges[edit]

The popularity of this form of prestressing for bridge construction in Europe increased

significantly around the 1950s and 60s. However, a history of problems have been encountered

that has cast doubt over the long-term durability of such structures.

Due to poor workmanship or quality control during construction, sometimes the ducts containing

the prestressing tendons are not fully filled, leaving voids in the grout where the steel is not

protected from corrosion. The situation is exacerbated if water and chloride (from de-icing salts)

from the highway are able to penetrate into these voids.

Notable events are listed below:

The Ynys-y-Gwas bridge in West Glamorgan, Walesa segmental post-tensioned

structure, particularly vulnerable to defects in the post-tensioning systemcollapsed without

warning in 1985.[1]

The Melle bridge, constructed in Belgium during the 1950s, collapsed in 1992 due to

failure of post-tensioned tie down members following tendon corrosion.

Following discovery of tendon corrosion in several bridges in England, the Highways

Agency issued a moratorium on the construction of new internal grouted post-tensioned

bridges and embarked on a 5-year programme of inspections on its existing post-tensioned

bridge stock.

In 2000, a large number of people were injured when a section of a footbridge at

the Charlotte Motor Speedway, USA, gave way and dropped to the ground. In this case,

corrosion was exacerbated by calcium chloride that had been used as a concrete admixture,

rather than sodium chloride from de-icing salts.

In 2011, the Hammersmith Flyover in London, England, was subject to an emergency

closure after defects in the post-tensioning system were discovered. [1]

Unbonded post-tensioned concrete[edit]

Unbonded post-tensioned concrete differs from bonded post-tensioning by providing each

individual cable permanent freedom of movement relative to the concrete. To achieve this, each

individual tendon is coated with a grease (generally lithium based) and covered by a plastic

sheathing formed in an extrusion process.[2] The transfer of tension to the concrete is achieved by

the steel cable acting against steel anchors embedded in the perimeter of the slab. The main

disadvantage over bonded post-tensioning is the fact that a cable can destress itself and burst

out of the slab if damaged (such as during repair on the slab). The advantages of this system

over bonded post-tensioning are:

The ability to individually adjust cables based on poor field conditions (For example:

shifting a group of 4 cables around an opening by placing 2 on each side).

The procedure of post-stress grouting is eliminated.

The ability to de-stress the tendons before attempting repair work.[3]

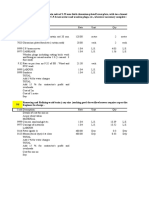

Picture number one (below) shows rolls of post-tensioning (PT) cables with the holding end

anchors displayed. The holding end anchors are fastened to rebar placed above and below the

cable and buried in the concrete locking that end. Pictures numbered two, three and four shows

a series of black pulling end anchors from the rear along the floor edge form. Rebar is placed

above and below the cable both in front and behind the face of the pulling end anchor. The above

and below placement of the rebar can be seen in picture number three and the placement of the

rebar in front and behind can be seen in picture number four. The blue cable seen in picture

number four is electrical conduit. Picture number five shows the plastic sheathing stripped from

the ends of the post-tensioning cables before placement through the pulling end anchors. Picture

number six shows the post-tensioning cables in place for concrete pouring. The plastic sheathing

has been removed from the end of the cable and the cable has been pushed through the black

pulling end anchor attached to the inside of the concrete floor side form. The greased cable can

be seen protruding from the concrete floor side form. Pictures seven and eight show the posttension cables protruding from the poured concrete floor. After the concrete floor has been

poured and has set for about a week, the cable ends will be pulled with a hydraulic jack.

1. Rolls of post-tension cables

2. Pulling anchors for post-tension cables

3. Pulling anchors for post-tension cables

4. Pulling anchors for post-tension cables

5. Post-tension cables stripped for placement in pulling anchors

6. Positioned post-tension cables

7. Post-tension cable ends extending from freshly poured concrete

8. Post-tension cable ends extending from concrete slab

9. Hydraulic jack for tension cables

10. Cable conduits in formwork

Applications[edit]

Prestressed concrete is the main material for floors in high-rise buildings and the entire

containment vessels of nuclear reactors.

Unbonded post-tensioning tendons are commonly used in parking garages as barrier cable.

[4]

Also, due to its ability to be stressed and then de-stressed, it can be used to temporarily repair

a damaged building by holding up a damaged wall or floor until permanent repairs can be made.

The advantages of prestressed concrete include crack control and lower construction costs;

thinner slabsespecially important in high rise buildings in which floor thickness savings can

translate into additional floors for the same (or lower) cost and fewer joints, since the distance

that can be spanned by post-tensioned slabs exceeds that of reinforced constructions with the

same thickness. Increasing span lengths increases the usable unencumbered floorspace in

buildings; diminishing the number of joints leads to lower maintenance costs over the design life

of a building, since joints are the major focus of weakness in concrete buildings.

The first prestressed concrete bridge in North America was the Walnut Lane Memorial

Bridge in Philadelphia, Pennsylvania. It was completed and opened to traffic in 1951.

[5]

Prestressing can also be accomplished on circular concrete pipes used for water transmission.

High tensile strength steel wire is helically-wrapped around the outside of the pipe under

controlled tension and spacing which induces a circumferential compressive stress in the core

concrete. This enables the pipe to handle high internal pressures and the effects of external

earth and traffic loads.

Design agencies and regulations[edit]

In the United States, pre-stressed concrete design and construction is aided by organizations

such as Post-Tensioning Institute (PTI) and Precast/Prestressed Concrete Institute(PCI). In

Canada the Canadian Precast/Prestressed Concrete Institute (CPCI) assumes this role for both

post-tensioned and pre-tensioned concrete structures.

Europe also has its own associations and institutes. It is important to note that these

organizations are not the authorities of building codes or standards, but rather exist to promote

the understanding and development of pre-stressed design, codes and best practices. In the UK,

the Post-Tensioning Association fulfills this role.[6]

Rules for the detailing of reinforcement and prestressing tendons are provided in Section 8 of the

European standard EN 1992-2:2005 Eurocode 2: Design of concrete structures Concrete

bridges: design and detailing rules.

In Australia the code of practice used to design reinforced and prestressed concrete is AS 36002009.

See also[edit]

Wikimedia Commons has

media related to Prestressed

concrete.

Dyckerhoff & Widmann (Dywidag)

Eugne Freyssinet

Hollow-core slab

Prestressed structure

Reinforced cement concrete

References[edit]

1.

2.

^ Jump up to:a b Ed Davey and Rebecca Cafe (3 December 2012). "TfL report warned

of Hammersmith Flyover collapse risk". BBC News, London. Retrieved 3 December 2012.

Jump up^ How is Unbonded Post Tensioning Made?

You might also like

- MindtreeDocument2 pagesMindtreeShah KhanNo ratings yet

- Abt WhasappDocument1 pageAbt WhasappShah KhanNo ratings yet

- Abt WhasappDocument1 pageAbt WhasappShah KhanNo ratings yet

- Abt InstagramDocument1 pageAbt InstagramShah KhanNo ratings yet

- Solutions Social Aspects of Engg. - 08Document12 pagesSolutions Social Aspects of Engg. - 08Shah KhanNo ratings yet

- Kehs102 PDFDocument74 pagesKehs102 PDFShah KhanNo ratings yet

- 1077imguf - ESE 2020 Mains BatchDocument1 page1077imguf - ESE 2020 Mains BatchShah KhanNo ratings yet

- Abt WhasappDocument1 pageAbt WhasappShah KhanNo ratings yet

- Abt WhasappDocument1 pageAbt WhasappShah KhanNo ratings yet

- Ivas 101Document20 pagesIvas 101theo VINo ratings yet

- Hindi (Mains) Test Solution (CE, EE, ME) - 34Document3 pagesHindi (Mains) Test Solution (CE, EE, ME) - 34Shah KhanNo ratings yet

- Nptel - Iitm.ac - in Courses IIT-MADRAS Design Steel Structures I 5 Compression 7 Design StrengthDocument6 pagesNptel - Iitm.ac - in Courses IIT-MADRAS Design Steel Structures I 5 Compression 7 Design StrengthShaik BademiyaNo ratings yet

- NPTELDocument3 pagesNPTELmaheshNo ratings yet

- Guidelines On Clinical Management of Severe Acute Respiratory Illness PDFDocument11 pagesGuidelines On Clinical Management of Severe Acute Respiratory Illness PDFSandeepNo ratings yet

- Inspiring Thoughts Apj Abdul Kalam PDFDocument2 pagesInspiring Thoughts Apj Abdul Kalam PDFNeeraj KatheriaNo ratings yet

- Survey Methodology 20Document2 pagesSurvey Methodology 20Shah KhanNo ratings yet

- Survey Methodology 20Document2 pagesSurvey Methodology 20Shah KhanNo ratings yet

- Survey methodology techniquesDocument1 pageSurvey methodology techniquesShah KhanNo ratings yet

- Survey methodology techniquesDocument1 pageSurvey methodology techniquesShah KhanNo ratings yet

- Survey Methodology 18Document2 pagesSurvey Methodology 18Shah KhanNo ratings yet

- Survey Methodology 20Document2 pagesSurvey Methodology 20Shah KhanNo ratings yet

- Survey Methodology 20Document2 pagesSurvey Methodology 20Shah KhanNo ratings yet

- Survey Methodology 18Document2 pagesSurvey Methodology 18Shah KhanNo ratings yet

- Survey Methodology 20Document2 pagesSurvey Methodology 20Shah KhanNo ratings yet

- Survey Methodology 14Document3 pagesSurvey Methodology 14Shah KhanNo ratings yet

- Survey Methodology 15Document2 pagesSurvey Methodology 15Shah KhanNo ratings yet

- Survey Methodology 17Document2 pagesSurvey Methodology 17Shah KhanNo ratings yet

- Survey Methodology 15Document2 pagesSurvey Methodology 15Shah KhanNo ratings yet

- Survey Methodology: See AlsoDocument3 pagesSurvey Methodology: See AlsoShah KhanNo ratings yet

- Survey Methodology: See AlsoDocument3 pagesSurvey Methodology: See AlsoShah KhanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Flyer Herwig Products FinalDocument2 pagesFlyer Herwig Products Finalkls.thorodinsonNo ratings yet

- Engineers Handbook: Download: WWW - Tungaloyuk.co - Uk/handbookDocument32 pagesEngineers Handbook: Download: WWW - Tungaloyuk.co - Uk/handbookGnwantt RajputNo ratings yet

- Fluorolined PVDF Series III Horizontal Pump 558434Document14 pagesFluorolined PVDF Series III Horizontal Pump 558434khaled younis100% (1)

- Material Product Data Sheet Copper & Copper Alloy (Brass, Bronze) Thermal Spray WiresDocument4 pagesMaterial Product Data Sheet Copper & Copper Alloy (Brass, Bronze) Thermal Spray WiresJesus D. Gutierrez G.No ratings yet

- CLADTEK A3 BROCHURE 15SEPT22 FLAT CompressedDocument12 pagesCLADTEK A3 BROCHURE 15SEPT22 FLAT CompressedAlireza KhodabandehNo ratings yet

- NSCP 2015 PDFDocument1,032 pagesNSCP 2015 PDFAljay Dhen81% (26)

- Aqua-Cure VOXDocument2 pagesAqua-Cure VOXChris ChanonaNo ratings yet

- 2017 PermitsDocument37 pages2017 PermitsL. A. PatersonNo ratings yet

- E-Bill PHED, Madhyapur1Document6 pagesE-Bill PHED, Madhyapur1Bhargov PeguNo ratings yet

- 1 57Document23 pages1 57Ricardo Argentton FicanhaNo ratings yet

- Shroud Segments, Support Segment Rings and Shroud Pads - Inspection/CheckDocument23 pagesShroud Segments, Support Segment Rings and Shroud Pads - Inspection/CheckdavidNo ratings yet

- RR MasonryDocument1 pageRR MasonrySAMICDPNo ratings yet

- Curtain RodDocument4 pagesCurtain RodAnonymous 9b8vCz1WNo ratings yet

- Catálogo FarrisDocument20 pagesCatálogo FarrissueNo ratings yet

- ME 472 - Corrosion Engineering 1Document2 pagesME 472 - Corrosion Engineering 1Faraz JamshaidNo ratings yet

- Modular & Services QuotationDocument50 pagesModular & Services Quotationsayaliofficial05No ratings yet

- Mil STD 403c RivetDocument32 pagesMil STD 403c RivetFaizy NohNo ratings yet

- 1-Normal Consistency TestDocument3 pages1-Normal Consistency TestYoukhanna ZayiaNo ratings yet

- ASTM D2661 - Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe and FittingsDocument5 pagesASTM D2661 - Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe and FittingsSurat - SonaliSolarNo ratings yet

- Piping and flange dimensions documentDocument59 pagesPiping and flange dimensions documentExsan Othman100% (1)

- Deltabeam Peikkogroup 8-2014Document32 pagesDeltabeam Peikkogroup 8-2014RonaldD.BerdugoQ.No ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4ceca nikolicNo ratings yet

- Civil Engineering Project TopicsDocument3 pagesCivil Engineering Project TopicsAlisa Jane TuboroNo ratings yet

- Technical interview questions and answers for civil site engineersDocument32 pagesTechnical interview questions and answers for civil site engineersUsman Shahid0% (1)

- Method Statement:: Dr. Fixit Roofseal Top Coat - Insulating Elastomeric Waterproof Coating For RoofsDocument4 pagesMethod Statement:: Dr. Fixit Roofseal Top Coat - Insulating Elastomeric Waterproof Coating For RoofsSudarshan KambleNo ratings yet

- Standard Specification For Structural Steel For Bridges: Designation: A709/A709MDocument8 pagesStandard Specification For Structural Steel For Bridges: Designation: A709/A709MLeviGatsosNo ratings yet

- 316 & 316LDocument4 pages316 & 316LMechanicalNo ratings yet

- Technical Bulletin - Timber Frame StructuresDocument24 pagesTechnical Bulletin - Timber Frame Structuresrexo100% (1)

- En 14399 Preloaded AssembliesDocument47 pagesEn 14399 Preloaded AssembliesAngelo VieitoNo ratings yet

- AnnealingDocument9 pagesAnnealingRathne AbeynayakeNo ratings yet