Professional Documents

Culture Documents

Baker Multistage Annular Fracturing

Uploaded by

zbhdzp0 ratings0% found this document useful (0 votes)

127 views16 pagesBAKER

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBAKER

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

127 views16 pagesBaker Multistage Annular Fracturing

Uploaded by

zbhdzpBAKER

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 16

Multistage Annular Fracturing

BHI OptiPort combined with Optifrac

SureSet enables 49 frac stages, with over

3 million pounds of proppant placed in

record time!

Multistage Annular Fracturing

Agenda:

Optifrac/SureSet Overview (Video)

Challenges of annular fracturing

49 Stage Barnett Shale frac obstacles

Questions?

2011 Baker Hughes Incorporated. All Rights Reserved.

Multistage Annular Fracturing

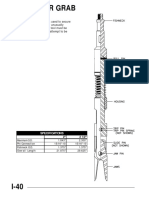

BHI Optifrac SureSet BHA

Coiled Tubing Conveyed Annular Fracturing BHA

Features include:

Hi clearance BHA - 0.4 (10mm) on diameter

On board abrasive perforator

Mechanical CCL

Hydraulic operation, fail safe design

Multiple casing sizes/weights

2011 Baker Hughes Incorporated. All Rights Reserved.

Multistage Annular Fracturing

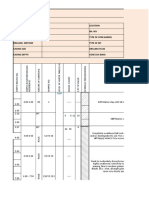

BHI OptiPort

Sliding sleeve frac port

Run with the casing/completion by the drilling rig

Can be used with external casing packers, or cemented liners

Defines frac initiation point

Provides full bore ID of casing

Equal pressure rating to casing

Functioned (opened) with properly placed frac tool or packer

Multistage Annular Fracturing

Multistage Annular Fracturing

Challenges of annular fracturing

Getting Stuck! High clearance helps!

Available WOB to set Packer element (horizontal)

Packer design to withstand hi pressure @ temp

Ability to accurately locate, especially with OptiPort

Tool reliability/longevity in erosive environments

Speed, to reposition and operate BHA

The number of intervals/well is increasing!

Multistage Annular Fracturing

49 Stage Barnett Shale frac obstacles:

Speed! Optiport/SureSet combo < 10 min between fracs

Long horizontal wellbore provides less than 2k # WOB

Downhole temp in excess of 85C

High Breakdown pressures (tight formation)

Challenging recovery from screen out with 2 CT

High rate frac/erosion of BHA at perforations

Daylight pumping only- trip BHA-RIH to depth/penetrate sand in

wellbore

Tool reliability

Multistage Annular Fracturing

Long horizontal wellbore provides less than 2k #

WOB!

Carefully modeled using BHI Circa TFA software

Proprietary low activation force packer element utilized

Horizontal length will become a limitation

Multistage Annular Fracturing

Speed! Less than 10 min between fracs!

By using the Optiport system, abrasive perforating is eliminated

Fluid savings of approx 10 cubic meters of fluid/stage

First stage can be SJ perforated or use P sleeve

Mechanical CCL provides accurate first time locating feedback

Multistage Annular Fracturing

Downhole temp in excess of 85C

Conventional elastomer elements will begin to flow

BHI propietary unconventional element will withstand high temp

@ high pressure with repeated pressure/temp cycles, while still

being high clearance

Multistage Annular Fracturing

High Breakdown pressures (tight formation)

Barnet shale formation may require isolation differentials up to

7000 PSI (48 MPA)

Not only challenging for the packer element, but all down-hole

sealing devices; aggravated by high temp

Multistage Annular Fracturing

Challenging recovery from screen out with 2 CT

With 2 CT in 5.5 completion, annular velocity required to clean

out proppant is generally limited by friction from the CT itself

BHI CIRCA modelling software is used to tailor the cleanout to

reduce the recovery time to a minimum

Clean out times can range from 1-10 hours, optimization is

critical

Sand placement in the wellbore is critical to promote fracture

growth/initiation, sand in the wellbore can simply cause a

screenout shortly into the pad!

Multistage Annular Fracturing

High rate frac/erosion of BHA at perforations

Shale formation = high rate slickwater frac

Major errosion can occur at the transition of fluid velocity from

the annulus, around the corner, into the perorations/formation

Over 3 million pounds of proppant pumped past the BHA!

Extremely hard surfaced BHA components provide tool

longevity.

Goal is to provide up to 50 stages per BHA deployment.

To date max stages per BHA is 27

BHA failure in this case was worn/rounded anchor slip teeth

Multistage Annular Fracturing

Daylight pumping- trip BHA-RIH to depth/penetrate

sand in wellbore

Operations dictate the BHA/CT must be brought to the vertical

section of the wellbore overnight

Proppant migration into the well bore will restrict entrance, 10%

full?

BHA flow through capability allows this proppant to be fluidized,

and be penetrated.

Multistage Annular Fracturing

Tool reliability

Ever increasing number of stages/wellbore

Optiport can be SJ perforated in the event of malfunction

Ultra reliability by using high end materials/components saves

the customer $$

Each faulty tool string can cost up to $50K in standby/tripping!

Especially important in Daylight only areas!

Questions?

You might also like

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyFrom EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Oilproduction - Hetrick IOGCC Well To Well CommunicationsDocument34 pagesOilproduction - Hetrick IOGCC Well To Well Communicationstojavi_abrahamNo ratings yet

- Overcoming Torque and Drag in HorizontalDocument15 pagesOvercoming Torque and Drag in HorizontalSohaib RashidNo ratings yet

- H03280 04 Horizontal Systems PDFDocument20 pagesH03280 04 Horizontal Systems PDFKeshav PujeriNo ratings yet

- Increase well productivity with hydraulic fracturingDocument153 pagesIncrease well productivity with hydraulic fracturingMAyur100% (1)

- Introduction To Well InterventionDocument33 pagesIntroduction To Well InterventionYovaraj KarunakaranNo ratings yet

- 13 - Baker Hughes - Kennedy enDocument36 pages13 - Baker Hughes - Kennedy enSpecule100% (1)

- A Guide To Understanding Rotary Steerable Technology: Baker Hughes INTEQDocument8 pagesA Guide To Understanding Rotary Steerable Technology: Baker Hughes INTEQdiegoilNo ratings yet

- 03 CT WellControlEquip NEXTDocument19 pages03 CT WellControlEquip NEXTFauzan Rahman HaqNo ratings yet

- Alternate Path Technology: Higher Production From Gravel-Packed WellsDocument8 pagesAlternate Path Technology: Higher Production From Gravel-Packed WellsNatasha Perez EscobarNo ratings yet

- Sonatrach's - Well CompletionsDocument76 pagesSonatrach's - Well CompletionsKunle AwomoyiNo ratings yet

- Chapter 3 - Perforating MethodsDocument40 pagesChapter 3 - Perforating MethodsKamran Haider Tunio73% (11)

- Hydraulic FracturingDocument3 pagesHydraulic FracturingTarek TarkanNo ratings yet

- Formation Isolation ValveDocument8 pagesFormation Isolation Valvelaurentiufrusinoiu9701No ratings yet

- Evo-Trieve® EB0 Retrievable Straddle - HalliburtonDocument2 pagesEvo-Trieve® EB0 Retrievable Straddle - HalliburtonYovaraj KarunakaranNo ratings yet

- SPE-203872-MS - Multistage FracutringDocument24 pagesSPE-203872-MS - Multistage Fracutringzach100% (1)

- Schlumberger AR 1984Document52 pagesSchlumberger AR 1984Cesar Mora100% (1)

- Gas Well Testing TechniquesDocument106 pagesGas Well Testing TechniquesanggityaNo ratings yet

- COIL TUBING DEPLOYED ESP INSTALLATION IN MALAYSIAN OFFSHOREDocument6 pagesCOIL TUBING DEPLOYED ESP INSTALLATION IN MALAYSIAN OFFSHOREJhon Doe100% (1)

- Packer Technology: Joshua BeierDocument75 pagesPacker Technology: Joshua BeierOctopus100% (1)

- Coiled-Tubing Drillin PracticeDocument9 pagesCoiled-Tubing Drillin PracticedagingoNo ratings yet

- Smart Well Control PresentationDocument15 pagesSmart Well Control PresentationOkafor StanleyNo ratings yet

- Underbalanced Coiled Tubing Drilled Horizontal Well in The North SeaDocument6 pagesUnderbalanced Coiled Tubing Drilled Horizontal Well in The North Seatarang_tusharNo ratings yet

- Optimize EOR Projects and Reduce Costs in Volatile MarketsDocument8 pagesOptimize EOR Projects and Reduce Costs in Volatile MarketsAnand SelveindranNo ratings yet

- Drill Bench 5Document12 pagesDrill Bench 5Abdalla Magdy DarwishNo ratings yet

- Managed Pressure Drilling Techniques ThesisDocument65 pagesManaged Pressure Drilling Techniques Thesisrizaldi76No ratings yet

- Understanding Downhole Tractors: Gulf Coast Section, SPE Northside, December 12, 2000Document24 pagesUnderstanding Downhole Tractors: Gulf Coast Section, SPE Northside, December 12, 2000southernorNo ratings yet

- AMA-73 Hydraulic Fracturing Proposal PDFDocument15 pagesAMA-73 Hydraulic Fracturing Proposal PDFdino100% (1)

- Orienting Perforations in The Right DirectionDocument16 pagesOrienting Perforations in The Right Directionbm_niculescuNo ratings yet

- Mud Removal TechniquesDocument70 pagesMud Removal TechniquesMohamed ElshoraNo ratings yet

- Buckling Analysis in Deviated Wells A Practical MethodDocument10 pagesBuckling Analysis in Deviated Wells A Practical Methodsabilco13No ratings yet

- Baker Oil Tools Well CompletionDocument39 pagesBaker Oil Tools Well CompletionMohamed Hashem100% (1)

- S2 2015 336441 Chapter1Document15 pagesS2 2015 336441 Chapter1arispriyatmonoNo ratings yet

- Halad 9Document2 pagesHalad 9muratNo ratings yet

- Advanced Technology Solutions For Next Generation HPHT WellsDocument15 pagesAdvanced Technology Solutions For Next Generation HPHT Wellsandrew sinagaNo ratings yet

- Oil and Gas Well Perforation TechniquesDocument27 pagesOil and Gas Well Perforation TechniquesAiham AltayehNo ratings yet

- Why Coiled Tubing Fails and HowDocument56 pagesWhy Coiled Tubing Fails and HowArdita S IrwanNo ratings yet

- C200-047-09-Man Mha 2.125Document18 pagesC200-047-09-Man Mha 2.125Virnando Nainggolan100% (1)

- Packer Testing Program Design and Management: August 2013Document7 pagesPacker Testing Program Design and Management: August 2013wily784No ratings yet

- G19PA Tutorials - Chapter 2 (Conventional Completion)Document19 pagesG19PA Tutorials - Chapter 2 (Conventional Completion)Roshan GillNo ratings yet

- Hydro-Mechanical Anderreamer Tech SummaryDocument2 pagesHydro-Mechanical Anderreamer Tech SummaryYaqoob Ibrahim100% (1)

- 13 Remedial SqueezeDocument26 pages13 Remedial SqueezeLenin DiazNo ratings yet

- MPD Brochure BeyondDocument10 pagesMPD Brochure BeyondIRLANDA100% (1)

- Coiled Tubing CompletionDocument9 pagesCoiled Tubing Completionreborn2No ratings yet

- Drilling OperationDocument25 pagesDrilling OperationMohammed Mushtaq Abu OmarNo ratings yet

- 24 - Candidate Selection For AcidizingDocument9 pages24 - Candidate Selection For AcidizingStan Andrei100% (1)

- Introduction To Coiled TubingDocument8 pagesIntroduction To Coiled TubingFauzan Rahman HaqNo ratings yet

- DC Sept08 DeepwaterCementingDocument6 pagesDC Sept08 DeepwaterCementinganon_634030219No ratings yet

- Coil Tubing TractorDocument7 pagesCoil Tubing TractorRamanamurthy Palli100% (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分337 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分337 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分301 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分301 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分159 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分159 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分335Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分335zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分167Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分167zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分127 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分127 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分225Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分225zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分177 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分177 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分149Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分149zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分167Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分167zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分135 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分135 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分121 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分121 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分135 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分135 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分275Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分275zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分189 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分189 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分190 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分190 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分379Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分379zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分177Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分177zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分305 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分305 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分301 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分301 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分283Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分283zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分317Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分317zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分327 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分327 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分303 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分303 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分311Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分311zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分313Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分313zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分311Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分311zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分301Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分301zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分117 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分117 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分337Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分337zbhdzpNo ratings yet

- Research TestDocument13 pagesResearch TestOrnelAsperasNo ratings yet

- Geo-Technical Order: DefDocument3 pagesGeo-Technical Order: Defkrsunil1740% (10)

- Assignment IDocument12 pagesAssignment IrakshakdhungelNo ratings yet

- Pin ContentDocument20 pagesPin ContentSwetha100% (2)

- Engg SOPDocument2 pagesEngg SOPapi-19509948No ratings yet

- Behaviour of Sand Confined With Single and Multiple GeocellsDocument14 pagesBehaviour of Sand Confined With Single and Multiple Geocellssundeep48100% (1)

- Engineering Geology: MD Farhad Hasan, Hossam Abuel-Naga, E.-C. LeongDocument10 pagesEngineering Geology: MD Farhad Hasan, Hossam Abuel-Naga, E.-C. LeongFernando Andrés Ortega JiménezNo ratings yet

- CE322 Soil Formation - A Historical..Document44 pagesCE322 Soil Formation - A Historical..reanNo ratings yet

- Stuck Pipe PDFDocument27 pagesStuck Pipe PDFduncmcleod100% (1)

- Bored Socket in BasaltDocument8 pagesBored Socket in BasaltGULF PILING LLCNo ratings yet

- HidrometerDocument9 pagesHidrometerMeliana NovaaNo ratings yet

- Shallow Foundation NotesDocument52 pagesShallow Foundation NotesBAMSNo ratings yet

- 00079896Document13 pages00079896JohnSmithNo ratings yet

- ECUADOR Report GEER-049-v1b PDFDocument604 pagesECUADOR Report GEER-049-v1b PDFjavengarNo ratings yet

- Soil Liquefaction ExplainedDocument21 pagesSoil Liquefaction ExplainedanpyaaNo ratings yet

- 1118 Malcolm Barker Maroon Dam NZSOLD 2013 FinalDocument28 pages1118 Malcolm Barker Maroon Dam NZSOLD 2013 FinalManuel SueroNo ratings yet

- Branches of Civil EngineeringDocument16 pagesBranches of Civil EngineeringAndrésDíazNo ratings yet

- Bore LogDocument4 pagesBore LogVardhanNo ratings yet

- Bray-EQ Fault Rupture-CUEE2009Document9 pagesBray-EQ Fault Rupture-CUEE2009Gilmar BastidasNo ratings yet

- Geotechnical Investigations For Design and Construction of Airfield PavementsDocument63 pagesGeotechnical Investigations For Design and Construction of Airfield PavementsBajocarNo ratings yet

- Top Causes of Dam FailuresDocument6 pagesTop Causes of Dam Failuresvenkateswara rao pothinaNo ratings yet

- Rig Equipent CatalogueDocument30 pagesRig Equipent CatalogueAnonymous VNu3ODGavNo ratings yet

- Equivalent Interface Properties To Model Soil-Facing Interactions With Zero-Thickness and Continuum Element MethodologiesDocument9 pagesEquivalent Interface Properties To Model Soil-Facing Interactions With Zero-Thickness and Continuum Element MethodologiesHamzah Al-HashemiNo ratings yet

- Introduction to Oil, Gas & Geothermal FieldsDocument10 pagesIntroduction to Oil, Gas & Geothermal FieldsGusmar PakidingNo ratings yet

- Cantilever Retaining Wall Design: ASDIP Retain 3.7.1Document9 pagesCantilever Retaining Wall Design: ASDIP Retain 3.7.1Rahayu Jati PermanaNo ratings yet

- Week 2 - Interpretation of SI Borelog and Lab Parameters Foundation EngineeringDocument18 pagesWeek 2 - Interpretation of SI Borelog and Lab Parameters Foundation EngineeringMUSLIHAH AQILAH MUSAFFENDYNo ratings yet

- Mit 2018Document233 pagesMit 2018masterhamzamNo ratings yet

- Spe 77357 MSDocument14 pagesSpe 77357 MSmohamedabbas_us3813No ratings yet

- ERBC (6TH) Dec16Document1 pageERBC (6TH) Dec16Jagdish JøshiNo ratings yet

- The Implication of Subsoil Geology in Foundation Failure Using Geotechnical Methodsa Case Study of Lagos Southwestern NigeriaDocument10 pagesThe Implication of Subsoil Geology in Foundation Failure Using Geotechnical Methodsa Case Study of Lagos Southwestern NigeriaIJARP PublicationsNo ratings yet