Professional Documents

Culture Documents

Sawmill Operations and Processes Explained in 40 Characters

Uploaded by

Samuel DavisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sawmill Operations and Processes Explained in 40 Characters

Uploaded by

Samuel DavisCopyright:

Available Formats

CHAPTER 1

INTRODUCTION ON SAWMILL

Sawmill is unique training facility for Woodcutting, and it differs from the usual

method of cutting trees. Instead, you will find yourself cutting logs into more

complicated shapes than simple planks in order to gain experience. A sawmill is

a facility where logs are cut into lumber.

It is also the process of wood Editing that established according to various

incision types of lumber (cut to length round wood) lumber is produced by

cutting machining. The principal technological sections in the sawmill are: log

yard, sawmill and timber yard. For the ultimate cutting machining gang, circular

and Block band sage machineriesare used mainly tra. Its not too long ago, there

are sawmills with chipper and profiling chipper as the main machine.

Sawmill specializes in general, in particular in accordance with the technical

means for the incision of wood or coniferous lumber. Sawmills are measured by

volume for the coming to cut raw material, as well as the degree of

mechanization and automation (manual and process-driven techniques) greatly

differentiated sawmill. Given the nature of the technological process a complete

computer-based timber production in the sawmills is possible.

CHAPTER 2

REVIEW OF LITERATURE

Galluzzo&Cliver (1996) agreed with those of Ak et al. (1994b) as oak leachates

were not bactericidal towards Salmonella enteritidis, in contrast to the oak

shavings and chips tested. Even various solvent extractions were conducted on

the wood, but the antibacterial effect was not diminished. A similar antibacterial

effect was seen with filter paper. Their results therefore indicated that the

mechanism of disappearance of Salmonella from oak was rather physical than

chemical. In fact, it could be a combination of adhesion and drying effect on the

cells.

Fuwape and Onyekwelu (1995) reported that clear felling of trees by sawmills

as a source of raw material has been recognized as one of the factors responsible

for environmental degradation in arid and semi-arid parts of Africa. The

indiscriminate logging in the rainforest and uncontrolled felling of trees by saw

millers operations are reported to have adverse effect on the environment. The

adverse effect caused by the operations of forest industries includes loss of

biodiversity, migration of wildlife, ecological imbalance, soil erosion, flooding,

desert encroachment and disruption in hydrological cycle of water catchments

area.

Welford (2000) reported that there has been a rapid growth in recent years in

environmental legislation and other policies aimed at reducing environmental

impacts and as such organizations should take advantage of these. There is a

need therefore for industries and organizations to continually review their

environmental impacts in order to determine which of the environmental aspect

is most significant and needs immediate attention.

Espinoza (2010) noted that despite research on SCM in the wood products

industry, little attention has been paid to development of performance

measurement systems in wood products SCs. He also suggested a framework

for developing wood SCs, focusing on product quality and time performance

measurements linking the performance of different business units in the SC.

CHAPTER 3

OBJECTIVE

The following are the main objective:

1. To see practically full operation and process of cutting of logs.

2. To learn different method of cutting of logs.

3. Types of machine used for operation.

3. To know about type of finished goods.

4. Type of safety kits used during operation.

5. The process for selling of the timber

CHAPTER 4

MATERIALS AND METHODOLOGY

3

This is oldest sawmill of Sikkim establish in 2002 and is located in Chuba,

Radang near Singtam, east Sikkim it is look after by the utilization Division of

the Forest Department of Sikkim. Collected logs are mostly from road

widening, Danger posing trees etc.

Activities involvement on Chuba Sawmill

After trees are selected for harvest, the next step in logging is felling the

trees, and bucking them to length.

Branches are cut off the trunk.

Logs are taken by logging truck, or a log drive to the sawmill.

Logs are scaled either on the way to the mill or upon arrival at the mill.

Debarking removes bark from the logs.

Decking is the process for sorting the logs by species, size and end use

(lumber, plywood, chips).

A sawyer used horizontal head saw machine to break the log into cants

(unfinished logs to be further processed) and flitches (unfinished planks).

Depending upon the species and quality of the log, the cants will either be

further broken down by vertical head saw machine or a gang edger into

multiple flitches and/or boards

Edging was done to flitch and trim off all irregular edges leaving foursided lumber.

Trimming squares the ends at typical lumber lengths.

Drying removes naturally occurring moisture from the lumber. This can

be done with natural or air-dried.

Planning smooths the surface of the lumber leaving a uniform width and

thickness.

The Utilization Division of Forest Departmenthas authorized to sell the

timber and issue of transit permission for buyer.

4

Fig.1: - Horizontal Machine

Fig 2: - Vertical Machine

Fig 3: -Transit permit for buyer

CHAPTER 5

OBSERVATION & RESULTS

Observation at sawmill during field visit

Sawmill at Chuba consists of two machine horizontal and vertical cutting

machine. Before any operation blades of the machine are sharpened, sifting of

logs and finished goods are carried by labours present there.

Types of outlet of logs after operation.

Fig 4: - Timber

Fig 5: - Planks

8

Fig 6: - Fuel Wood

CHAPTER 6

CONCLUSION

This Project helped me to learn about the basic principles involved in sawmill

during operation and processing. Chuba sawmill which is located in east part of

Sikkim was look after by Utilization Division of Forest Department. As state

have band on green felling the logs collected was mostly from road winding,

danger posing etc.Mostly collected logs are pine, marketing of state timber is

also band inside and outside the state only Utilization Division of Forest

Department have authorised to sell timber from sawmill with in Sikkim with

Limited.

During the process in Sawmill the workers have different duties according to

performs and experience of workers they were involved in following duties in

preparing logs for cutting into lumber and storing cut lumber in sawmill:

Unloads logs from trucks or cars, rolls logs onto sawmill deck, examines logs

for defects, such as embedded pieces of iron or stone, decayed wood from splits,

and marks defects for removal by other workers, rolls logs from deck onto log

or carriage, rides log carriage of head saw and adjusts position of logs on

carriage to cut planks of required thickness, sorts and guides planks emerging

from saw onto roller tables or conveyors for trimming edges. Sharpens and

adjusts teeth of woodworking saws, they all were dressed with safety kits

throughout the operation and the entire worker involved in operation was

trained and experience, we were shown two operations in two different machine

and the logs were all pine. I found the process was very fast and in a few

minutes they can convert lots of logs into timber.

It also gave me idea about the planning records of the different species of logs

brought in the sawmill and also marketing and distribution of the Timber,

Planks and Fuel wood, and all the activities are look after by Utilization

Division of Forest Department. Lastly, through this project I have the necessary

practical knowledge for the completion of my project and also for my future

endeavour.

10

CHAPTER 7

REFERENCE

1.Belin

L.

Sawmill

alveolitis

ApplImmunol. 1987;82(3-4):440443

in

Sweden. Int

Arch

Allergy

2. Dykewicz MS, Laufer P, Patterson R, Roberts M, Sommers HM. Woodman's

disease: hypersensitivity pneumonitis from cutting live trees. J Allergy

ClinImmunol. 1988 Feb;81(2):455460.

3. Kolmodin-Hedman B, Blomquist G, Lfgren F. Chipped wood as a source of

mould exposure. Eur J Respir Dis Suppl. 1987;154:4451.

4. Charles E. Peterson, 'Sawdust Trail: Annals of Sawmilling and the Lumber

Trade' Bulletin of the Association for Preservation Technology Vol. 5, No. 2.

(1973), pp. 84-5

5. Adam Robert Lucas (2005), "Industrial Milling in the Ancient and Medieval

Worlds: A Survey of the Evidence for an Industrial Revolution in Medieval

Europe", Technology and Culture 46 (1): 1-30 [o10-1]

6. Norman Ball, 'Circular Saws and the History of Technology' Bulletin of the

Association for Preservation Technology 7(3) (1975), pp. 79-89.

7. Ritti, Tullia; Grewe, Klaus; Kessener, Paul (2007), "A Relief of a Waterpowered Stone Saw Mill on a Sarcophagus at Hierapolis and its

Implications", Journal of Roman Archaeology 20: 138163

11

You might also like

- ForestryDocument24 pagesForestryMohit Agarwal100% (1)

- Report on Attachment with State Forest Department of SikkimDocument5 pagesReport on Attachment with State Forest Department of SikkimNivesh GurungNo ratings yet

- Lec.4 - Classification of Agroforestry SystemsDocument3 pagesLec.4 - Classification of Agroforestry SystemsKani Manikandan83% (6)

- Forest Products and TradeDocument35 pagesForest Products and TradeAustin Oliver50% (2)

- Jute Geotextiles and Their Applications - Dr. AbdullahDocument33 pagesJute Geotextiles and Their Applications - Dr. AbdullahSudipta Bain0% (1)

- Improved WoodDocument17 pagesImproved WoodPavo33% (3)

- Competitive Exams: Forestry: ExamraceDocument4 pagesCompetitive Exams: Forestry: ExamraceprasanthakumarNo ratings yet

- Assisted Natural Regeneration Survey of Chilgoza Forest Suleiman Mountain Range, Sherani Balochistan Pakistan.Document45 pagesAssisted Natural Regeneration Survey of Chilgoza Forest Suleiman Mountain Range, Sherani Balochistan Pakistan.Mohammad Yahya MusakhelNo ratings yet

- TILLAGE SlideDocument18 pagesTILLAGE SlideArnab PaulNo ratings yet

- Community Forest 1Document20 pagesCommunity Forest 1Ananta ChaliseNo ratings yet

- Rubber ProductonDocument12 pagesRubber ProductonHannah JamesNo ratings yet

- AGR 318 Lec 8 - Machine & Equipment For Mechanized Estate OperationsDocument65 pagesAGR 318 Lec 8 - Machine & Equipment For Mechanized Estate OperationsHaikal Sapurata100% (1)

- 94706-K3-K2 Conveyor TPP FINAL 30-Apr-15Document394 pages94706-K3-K2 Conveyor TPP FINAL 30-Apr-15Sergio DiazNo ratings yet

- 730Document8 pages730ajaNo ratings yet

- 7 Forest and WildlifeDocument32 pages7 Forest and WildlifeFrances Joei O. PEREZNo ratings yet

- Small-scale no-tillage drill and planter designDocument26 pagesSmall-scale no-tillage drill and planter designAbhay GroverNo ratings yet

- Thermowood HandbookDocument66 pagesThermowood HandbookAdam LewisNo ratings yet

- Bullock Cart Prototyping Using Catia and 3D PrintingDocument13 pagesBullock Cart Prototyping Using Catia and 3D PrintingAzure MidoriyaNo ratings yet

- Siddharth's ProjectDocument46 pagesSiddharth's ProjectSamuel DavisNo ratings yet

- Forest PlantationDocument143 pagesForest PlantationaivillaromanNo ratings yet

- FOR 111 INTRODUCTION TO FORESTRY AND AGROFORESTRYDocument22 pagesFOR 111 INTRODUCTION TO FORESTRY AND AGROFORESTRYCharumathi K100% (1)

- Amboo Rocessing: NtroductionDocument9 pagesAmboo Rocessing: NtroductionUnodosNo ratings yet

- Reason For Processing Farm ProduceDocument2 pagesReason For Processing Farm ProduceIsraelNo ratings yet

- Selected Current Issues in The Forest Sector: P Ii SDocument18 pagesSelected Current Issues in The Forest Sector: P Ii SrajeshdhomaneNo ratings yet

- 2018 Otr Global Product Catalog PDFDocument120 pages2018 Otr Global Product Catalog PDFRaul CraciunNo ratings yet

- Organo Potato DiggerDocument21 pagesOrgano Potato DiggerArnel SisonNo ratings yet

- Tropical Natural Fibres and Their Properties: 2.1 BackgroundDocument25 pagesTropical Natural Fibres and Their Properties: 2.1 BackgroundbatazivoNo ratings yet

- Minestry of Mines ReportDocument216 pagesMinestry of Mines Reportpt naiduNo ratings yet

- Sandvik DD311Document2 pagesSandvik DD311death666darkNo ratings yet

- Fabrication of Single Wheel Plough Driven by an IC EngineDocument37 pagesFabrication of Single Wheel Plough Driven by an IC EngineJohnson ZachariaNo ratings yet

- Silviculture & AgroforestryDocument4 pagesSilviculture & AgroforestryVlamadir Jacob100% (1)

- (Forestry Sciences 15) K. A. G. Staaf, N. A. Wiksten (Auth.) - Tree Harvesting Techniques-Springer Netherlands (1984)Document367 pages(Forestry Sciences 15) K. A. G. Staaf, N. A. Wiksten (Auth.) - Tree Harvesting Techniques-Springer Netherlands (1984)ZakariaZaKiNo ratings yet

- The World of Organic AgricultureDocument340 pagesThe World of Organic AgricultureManikanta ChintalaNo ratings yet

- Forage Morphology (Grass & Legumes)Document99 pagesForage Morphology (Grass & Legumes)Al Pavillon100% (1)

- Khair InformationDocument18 pagesKhair InformationtinkulalNo ratings yet

- Manitou Underground Mine Basket (EN)Document4 pagesManitou Underground Mine Basket (EN)ManitouNo ratings yet

- Some Market Trends of Wood Products Exports in Ghana and Their Implications For Stakeholders PDFDocument8 pagesSome Market Trends of Wood Products Exports in Ghana and Their Implications For Stakeholders PDFRichard Nkosuo AcquahNo ratings yet

- Manual On Nursery Est. & MGT - Tile - Dec - 2018 - Edited FinalDocument145 pagesManual On Nursery Est. & MGT - Tile - Dec - 2018 - Edited FinalTilahun Tegene100% (1)

- Northeast India's Rubber Plantations: Need for a Holistic ApproachDocument4 pagesNortheast India's Rubber Plantations: Need for a Holistic ApproachRajesh Kumar0% (1)

- Goat or Sheep Production and ManagementDocument42 pagesGoat or Sheep Production and ManagementVictor Arrojo MirallesNo ratings yet

- Defects in Timber Structure and ClassificationDocument17 pagesDefects in Timber Structure and ClassificationAasim AzmiNo ratings yet

- Tree TransplantingDocument26 pagesTree Transplantingnarendra chandewarNo ratings yet

- Forest Resource ManagementDocument7 pagesForest Resource ManagementYusufNo ratings yet

- Supply Chain Mapping For The Forest Products Industry - HaartvDocument30 pagesSupply Chain Mapping For The Forest Products Industry - HaartvTharun SebastianNo ratings yet

- Global Growth Agro-Textiles IndustryDocument30 pagesGlobal Growth Agro-Textiles Industrydeepak kulkarniNo ratings yet

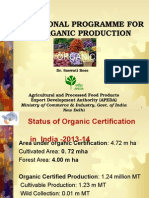

- National Programme For Organic Production: Agricultural and Processed Food Products Export Development Authority (APEDA)Document22 pagesNational Programme For Organic Production: Agricultural and Processed Food Products Export Development Authority (APEDA)govarthan1976No ratings yet

- Bamboo Craft Done.Document26 pagesBamboo Craft Done.Mohit Agarwal100% (1)

- Industry Snapshot PDF - Wood ProductsDocument8 pagesIndustry Snapshot PDF - Wood ProductsAnonymous IG9ScKNo ratings yet

- HARVESTING AND THRESHING MACHINERYDocument48 pagesHARVESTING AND THRESHING MACHINERYAnalinda SurilNo ratings yet

- Lecture Eight Primary TillageDocument35 pagesLecture Eight Primary Tillagehusni ahmed100% (1)

- Farm Machinery DefinitionsDocument11 pagesFarm Machinery Definitionscristian_iacomi3416No ratings yet

- Fldbee 01Document12 pagesFldbee 01Halim Bessouf100% (2)

- Melina (Gmelina Arborea) in Central AmericaDocument22 pagesMelina (Gmelina Arborea) in Central AmericaEuclides Fornaris GómezNo ratings yet

- Forage and Grasses PDFDocument65 pagesForage and Grasses PDFgorekaNo ratings yet

- Design and Development of Manually Operated ReaperDocument8 pagesDesign and Development of Manually Operated ReaperIOSRjournalNo ratings yet

- Forestry in PakistanDocument6 pagesForestry in Pakistanmurtazee0% (1)

- Lecture 1 - Timber PreservationDocument23 pagesLecture 1 - Timber PreservationSarahNo ratings yet

- Basics of Softwood SawmillingDocument4 pagesBasics of Softwood SawmillingChuck Achberger100% (1)

- Wood-Chipping Equipment and Materials HandlingDocument26 pagesWood-Chipping Equipment and Materials Handlingkelseynicolas69No ratings yet

- Esquierdo Assignment#3Document7 pagesEsquierdo Assignment#3itashi uchihaNo ratings yet

- Synopsis On CadburryDocument12 pagesSynopsis On CadburrySamuel DavisNo ratings yet

- ObeseityDocument12 pagesObeseitySamuel DavisNo ratings yet

- Akshay Dass CVDocument2 pagesAkshay Dass CVSamuel DavisNo ratings yet

- Birla Sun Life AdvisiorDocument111 pagesBirla Sun Life AdvisiorSamuel DavisNo ratings yet

- Mahindra Tractors – Offering tough and Reliable Tractors to farmersDocument3 pagesMahindra Tractors – Offering tough and Reliable Tractors to farmersSamuel DavisNo ratings yet

- KishanMarketing Strategies of Airtel PPPPPDocument94 pagesKishanMarketing Strategies of Airtel PPPPPSamuel DavisNo ratings yet

- Regulating Surrogacy: An Analysis of the Indian LawDocument7 pagesRegulating Surrogacy: An Analysis of the Indian LawSamuel DavisNo ratings yet

- ProjectDocument40 pagesProjectNilabjo Kanti PaulNo ratings yet

- Roll No. 38Document7 pagesRoll No. 38mohitnonuNo ratings yet

- A Study of Compterized InformationDocument79 pagesA Study of Compterized InformationSamuel DavisNo ratings yet

- Mohandas GandhiDocument38 pagesMohandas GandhiFaizan100% (1)

- Summer Training Project Report on Training and Development at Max Life InsuranceDocument54 pagesSummer Training Project Report on Training and Development at Max Life InsuranceSamuel DavisNo ratings yet

- Chandigarh Tourism Project Report SummaryDocument65 pagesChandigarh Tourism Project Report SummarySamuel DavisNo ratings yet

- HRP Report on Manpower PlanningDocument65 pagesHRP Report on Manpower PlanningSamuel DavisNo ratings yet

- Investor Investment Behaviur in Stock MarketDocument52 pagesInvestor Investment Behaviur in Stock MarketSamuel DavisNo ratings yet

- Synopsis On Organization CultureDocument13 pagesSynopsis On Organization CultureSamuel DavisNo ratings yet

- JobsDocument1 pageJobsSamuel DavisNo ratings yet

- 2review of Literature Avi.2Document15 pages2review of Literature Avi.2Samuel DavisNo ratings yet

- Prime Time Involvment of AudanceDocument60 pagesPrime Time Involvment of AudanceSamuel DavisNo ratings yet

- Employee Retention at RelainceDocument89 pagesEmployee Retention at RelainceSamuel Davis50% (8)

- ProjectDocument40 pagesProjectNilabjo Kanti PaulNo ratings yet

- Investor Investment Behaviur in Stock MarketDocument52 pagesInvestor Investment Behaviur in Stock MarketSamuel DavisNo ratings yet

- Social Security SchemeDocument40 pagesSocial Security SchemeSamuel DavisNo ratings yet

- SporstDocument53 pagesSporstSamuel DavisNo ratings yet

- Dissertation FormatDocument1 pageDissertation FormatSamuel DavisNo ratings yet

- A Comparative Study of Seed Treatment of Indian MustardDocument4 pagesA Comparative Study of Seed Treatment of Indian MustardSamuel DavisNo ratings yet

- Global Industrial Gas Market and New Application AnalysisDocument16 pagesGlobal Industrial Gas Market and New Application AnalysisSamuel DavisNo ratings yet

- Dusht 11Document80 pagesDusht 11Samuel DavisNo ratings yet

- Organization Culture and Employee MotivationDocument68 pagesOrganization Culture and Employee MotivationSamuel Davis100% (2)

- LPG Service Quality AssessmentDocument19 pagesLPG Service Quality AssessmentSamuel DavisNo ratings yet

- Impact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityDocument14 pagesImpact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityYo Vivo Fit Pablo y KarlaNo ratings yet

- Differentiation SS2Document88 pagesDifferentiation SS2merezemenike272No ratings yet

- Benedict - Ethnic Stereotypes and Colonized Peoples at World's Fairs - Fair RepresentationsDocument16 pagesBenedict - Ethnic Stereotypes and Colonized Peoples at World's Fairs - Fair RepresentationsVeronica UribeNo ratings yet

- V60 Ventilator Specifications PDFDocument4 pagesV60 Ventilator Specifications PDFJonathan Issac Dominguez RamirezNo ratings yet

- Rha GGBS 27 4Document12 pagesRha GGBS 27 4KhaDeja MawraNo ratings yet

- Amity Online Exam OdlDocument14 pagesAmity Online Exam OdlAbdullah Holif0% (1)

- 26 05 29 Hangers and Supports For Electrical SystemsDocument8 pages26 05 29 Hangers and Supports For Electrical SystemskaichosanNo ratings yet

- Westford University College readies flagship campus with new programsDocument20 pagesWestford University College readies flagship campus with new programsSaju JanardhananNo ratings yet

- Anti-Anginal DrugsDocument39 pagesAnti-Anginal Drugspoonam rana100% (1)

- Painter CardDocument1 pagePainter CardPraveen RANANo ratings yet

- Perbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACDocument15 pagesPerbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACYuli RahmawatiNo ratings yet

- PoiconverterDocument2 pagesPoiconvertertaco6541No ratings yet

- Hmdu - EnglishDocument20 pagesHmdu - EnglishAbdulaziz SeikoNo ratings yet

- Bibliography PresocraticsDocument10 pagesBibliography Presocraticsalraun66No ratings yet

- BS EN 1677-5-2001 - Inc.Document3 pagesBS EN 1677-5-2001 - Inc.Ameer Sadimin SGNo ratings yet

- Resistance and ResisivityDocument2 pagesResistance and ResisivityDeddy KismanaNo ratings yet

- Marikina Development Corporation vs. FiojoDocument8 pagesMarikina Development Corporation vs. FiojoJoshua CuentoNo ratings yet

- Linear Piston Actuators: by Sekhar Samy, CCI, and Dave Stemler, CCIDocument18 pagesLinear Piston Actuators: by Sekhar Samy, CCI, and Dave Stemler, CCIapi-3854910No ratings yet

- Ukraine and Russia E IRDocument287 pagesUkraine and Russia E IRtatgirNo ratings yet

- CPS Layoffs BreakdownDocument21 pagesCPS Layoffs BreakdownjroneillNo ratings yet

- CELTA Pre-Interview Grammar, Vocabulary and Pronunciation ExercisesDocument4 pagesCELTA Pre-Interview Grammar, Vocabulary and Pronunciation ExercisesMichelJorge100% (2)

- Analogue Lab Manual AL7212 V2.1-Panduan Praktek DSR Elektronika-DikonversiDocument235 pagesAnalogue Lab Manual AL7212 V2.1-Panduan Praktek DSR Elektronika-DikonversiAl-FarabiNo ratings yet

- Jiangsu Changjiang Electronics Technology Co., Ltd. SOT-89-3L Transistor SpecificationsDocument2 pagesJiangsu Changjiang Electronics Technology Co., Ltd. SOT-89-3L Transistor SpecificationsIsrael AldabaNo ratings yet

- Soil Testing Lab Results SummaryDocument2 pagesSoil Testing Lab Results SummaryMd SohagNo ratings yet

- UntitledDocument21 pagesUntitledRoberto RamosNo ratings yet

- 42U System Cabinet GuideDocument68 pages42U System Cabinet GuideGerman AndersNo ratings yet

- Finding My Voice in ChinatownDocument5 pagesFinding My Voice in ChinatownMagalí MainumbyNo ratings yet

- New Microwave Lab ManualDocument35 pagesNew Microwave Lab ManualRadhikaNo ratings yet

- JC Metcalfe - The Power of WeaknessDocument3 pagesJC Metcalfe - The Power of Weaknesschopin23No ratings yet

- English ProjectDocument10 pagesEnglish ProjectHarshman Singh HarshmanNo ratings yet