Professional Documents

Culture Documents

AFT Impulse Chicago Bridge Iron Case Study

Uploaded by

erjainrachit0 ratings0% found this document useful (0 votes)

54 views2 pagesCase Study

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCase Study

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

54 views2 pagesAFT Impulse Chicago Bridge Iron Case Study

Uploaded by

erjainrachitCase Study

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Case Study

Cooling System Surge Analysis with AFT ImpulseTM

Company:

Address:

Telephone:

Chicago Bridge & Iron

Process Engineering Division

14105 South Route 59

Plainfield, IL 60544

815-439-6303

Chicago Bridge & Iron Company, with more than 60

locations and approximately 11,000 employees, is a

leading engineering, procurement and construction

company, specializing in lump-sum turnkey projects

for customers that produce, process, store and

distribute the world's natural resources.

Chicago Bridge & Irons Process Engineering

Division was tasked with developing the design for a

gasification system serving an LNG off-loading

terminal. An innovative and energy efficient

approach was taken utilizing waste heat from a

nearby power plant. A key criterion in the design

was to insure the new, interconnecting system did

not compromise the mechanical integrity or

operation of the plant cooling system.

A previous analysis resulted in a design

incorporating check valves, flow control valves,

booster pump bypass valves and full voltage booster

pumps. While meeting some of the design criteria,

an analysis of the system using AFT Impulse

revealed vacuum conditions would exist in the piping

under various operational scenarios, including pump

trip. As information was not available on the vacuum

capabilities of the existing piping, a new system

design was developed to eliminate these possible

problem areas.

The AFT Impulse model consisted of both the

existing cooling water system and the new,

interconnecting system flowing in excess of 108,000

gpm. The existing system included:

Six cell cooling tower with two vortex breakers

Two circulating pumps

Two condensers

All interconnecting piping, valves,

fittings, etc.

One of the first steps was to benchmark the

existing system. Running steady-state cases in AFT

Impulse, Doug DeGraaf, CBI Senior Engineer,

determined discrepancies in predicted and

measured parameters was due to differences in the

theoretical and actual losses in the condensers due

to plugged tubes and fouling. Condenser loss values

were adjusted to calibrate the model. As Doug

explains; AFT Impulse allowed the separation of

reality from theoretical to arrive at a true model of

the existing system.

Several transient cases were studied including

tripping combinations of the existing circulating

pumps and added booster pumps and closing of the

new connecting valves. Dynamic modeling revealed

considerable flow would continue after pump trip due

to the momentum of the water in the long pipelines.

This continued flow after pump trip caused low

pressure in the existing cooling tower return lines

resulting in reverse flow and air being drawn into

these lines.

Initially check valves and other components had

been included to avoid such conditions, but AFT

Impulse revealed this would result in transient

pressures below atmospheric, a situation that

needed to be avoided. Using AFT Impulse a revised

design was developed that eliminated all of the

check valves, bypass valves, flow control valves and

made use of variable speed drives for the pumps.

Results of this new design yielded not only a

system with no mechanical integrity issues, but also

a significant reduction in the system components

required and simplified system control.

Adding to this the new, interconnecting system

included;

Four booster pumps

Seven plate-frame heat exchangers

Tower connecting valves

interconnecting piping, valves,

fittings, etc.

Applied Flow Technology 2955 Professional Place, Suite 301, Colorado Springs, CO 80904 USA www.aft.com

Additional benefits derived from modeling the

system with AFT Impulse were development of

several recommendations to improve operability. By

implementing these recommendations the resulting

system will be able to restart quickly after an upset

with minimal operational concerns.

Describing his experience using AFT Impulse for

this project, Doug stated it; proved to be both easy

to model and easily understandable as it relates to

what was actually taking place during valve and

pump transients. Program outputs included model

input synopsis, graphical output of pressures,

flowrates, etc. at any time or place in the model, and

steady-state analysis outputs (prior to initiation of

transients).

Pump speed vs. time graph for one of the

existing circulating pumps and one of the new

booster pumps after tripping

Pressure vs. time graph at pump discharge and inlet of cooling tower riser after

pump trip

Applied Flow Technology 2955 Professional Place, Suite 301, Colorado Springs, CO 80904 USA www.aft.com

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Geothermal Energy: A Renewable Source of Homegrown PowerDocument12 pagesGeothermal Energy: A Renewable Source of Homegrown PowerAxell CasimiroNo ratings yet

- TM2500 BrochureDocument8 pagesTM2500 BrochuregustiramadaniNo ratings yet

- Standard Operating Procedure FOR HP HeaterDocument6 pagesStandard Operating Procedure FOR HP HeatersambhuNo ratings yet

- Heat Recovery Steam GeneratorDocument4 pagesHeat Recovery Steam Generatorrr1819100% (1)

- Document N1684Document1 pageDocument N1684erjainrachitNo ratings yet

- Water Pipelines and Its TypesDocument1 pageWater Pipelines and Its TypeserjainrachitNo ratings yet

- AFT Utility Suite 2 Data SheetDocument2 pagesAFT Utility Suite 2 Data SheeterjainrachitNo ratings yet

- Basics 0 - 0Document1 pageBasics 0 - 0erjainrachitNo ratings yet

- FSM Flyer 2017Document2 pagesFSM Flyer 2017erjainrachitNo ratings yet

- Water Pipelines and Its TypesDocument1 pageWater Pipelines and Its TypeserjainrachitNo ratings yet

- Water PipelinesDocument1 pageWater PipelineserjainrachitNo ratings yet

- 1st Year Eng Courses BCE BME ED/EG BEE Workshop Practice CP Eng MechanicsDocument1 page1st Year Eng Courses BCE BME ED/EG BEE Workshop Practice CP Eng MechanicserjainrachitNo ratings yet

- Valve ClosureDocument1 pageValve ClosureerjainrachitNo ratings yet

- Mechanical Engineering Chemical Engineering Civil Engineering Electrical EngineeringDocument1 pageMechanical Engineering Chemical Engineering Civil Engineering Electrical EngineeringerjainrachitNo ratings yet

- BasicsDocument1 pageBasicserjainrachitNo ratings yet

- Sizing of Pressure Relief Devices For Liquid ServicesDocument1 pageSizing of Pressure Relief Devices For Liquid ServiceserjainrachitNo ratings yet

- Gradient Method Linear Theory Method Hardy Cross Method Newton Raphson's MethodDocument1 pageGradient Method Linear Theory Method Hardy Cross Method Newton Raphson's MethoderjainrachitNo ratings yet

- Mechanical EngineeringDocument1 pageMechanical EngineeringerjainrachitNo ratings yet

- AFT Impulse 6 Data SheetDocument2 pagesAFT Impulse 6 Data SheeterjainrachitNo ratings yet

- Wave Speed Equation PDFDocument1 pageWave Speed Equation PDFerjainrachitNo ratings yet

- AFT Arrow 6 Data SheetDocument2 pagesAFT Arrow 6 Data SheeterjainrachitNo ratings yet

- Joukowski Equation PDFDocument1 pageJoukowski Equation PDFerjainrachit0% (1)

- Major Losses in PipesDocument1 pageMajor Losses in PipeserjainrachitNo ratings yet

- API 1969 Formula For F-Factor CalculationDocument1 pageAPI 1969 Formula For F-Factor CalculationerjainrachitNo ratings yet

- Joukowski Equation PDFDocument1 pageJoukowski Equation PDFerjainrachitNo ratings yet

- Liquid Transients and Surge Analysis Software - AFT ImpulseDocument1 pageLiquid Transients and Surge Analysis Software - AFT ImpulseerjainrachitNo ratings yet

- Hazen William's FactorDocument1 pageHazen William's FactorerjainrachitNo ratings yet

- Pump Power CalculationDocument1 pagePump Power CalculationerjainrachitNo ratings yet

- Instantaneous Water Hammer Wave Speed (Bulk Modulus (K), Modulus of Elasticity (E), Roughness (E), Density)Document1 pageInstantaneous Water Hammer Wave Speed (Bulk Modulus (K), Modulus of Elasticity (E), Roughness (E), Density)erjainrachitNo ratings yet

- Joukowski EquationDocument1 pageJoukowski EquationerjainrachitNo ratings yet

- Network Layouts: Linear Networks Branched Networks Looped NetworksDocument1 pageNetwork Layouts: Linear Networks Branched Networks Looped NetworkserjainrachitNo ratings yet

- JOIN Special Training Program On P&IDDocument1 pageJOIN Special Training Program On P&IDerjainrachitNo ratings yet

- Major Losses in Pipes - Hazen Williams EquationDocument1 pageMajor Losses in Pipes - Hazen Williams EquationerjainrachitNo ratings yet

- Pump and PipingDocument1 pagePump and PipingerjainrachitNo ratings yet

- Puz-Hwm140vha - BSDocument2 pagesPuz-Hwm140vha - BSvga1234No ratings yet

- Solar Series Converter: Key FeaturesDocument2 pagesSolar Series Converter: Key FeaturesEhsan RohaniNo ratings yet

- CT2 circuit diagramDocument1 pageCT2 circuit diagramPasupathiNo ratings yet

- Ch2 - GT Power CycleDocument73 pagesCh2 - GT Power Cycleم.عبدالله الشامان ُEng:Abdullah AlShamanNo ratings yet

- Diesel Engine - Britannica Online EncyclopediaDocument9 pagesDiesel Engine - Britannica Online Encyclopediaali universityNo ratings yet

- Elliott Brush Ring Seals: Installation KitDocument2 pagesElliott Brush Ring Seals: Installation Kitfouzi gher100% (1)

- System 48V Solar AC BookDocument12 pagesSystem 48V Solar AC BookFran Garsos100% (1)

- PT PJB Services - Local Grid - Hybrid Power Plants On The Bawean Island Isolated SystemDocument21 pagesPT PJB Services - Local Grid - Hybrid Power Plants On The Bawean Island Isolated SystemilhamNo ratings yet

- Chimney Sizing Chart For Fireplaces: 100 50 30 20 15 10 8 Flue Area, inDocument1 pageChimney Sizing Chart For Fireplaces: 100 50 30 20 15 10 8 Flue Area, inBen ZithaNo ratings yet

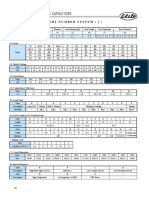

- Aluminum Electrolytic Capacitors: Part Number SystemDocument3 pagesAluminum Electrolytic Capacitors: Part Number SystemVALTERNo ratings yet

- Literature Review: Forced Draft and Induced Draft FansDocument6 pagesLiterature Review: Forced Draft and Induced Draft FansAlif Nur FirdausNo ratings yet

- Role of RELAP - SCDAPSIM in Nuclear Safety - TOPSAVEDocument21 pagesRole of RELAP - SCDAPSIM in Nuclear Safety - TOPSAVELazarescu ElenaNo ratings yet

- Fabrication and Analysis of A Vapour Compression CycleDocument25 pagesFabrication and Analysis of A Vapour Compression CycleAbhishek TripathiNo ratings yet

- 35 Basic HVAC Interview Questions & Answers: Follow Us On LinkedinDocument7 pages35 Basic HVAC Interview Questions & Answers: Follow Us On Linkedinshaul hameedNo ratings yet

- Power from knowledge: Boiler protection handbookDocument67 pagesPower from knowledge: Boiler protection handbookarjunsen2009No ratings yet

- 28990-Turbinebypass Prds PDFDocument12 pages28990-Turbinebypass Prds PDFbuddhivasu100% (2)

- Understanding the Development of Jet Aircraft PropulsionDocument23 pagesUnderstanding the Development of Jet Aircraft PropulsionMuhammad Hussain100% (1)

- Eneloop Battery Charger - Bq-cc17Document8 pagesEneloop Battery Charger - Bq-cc17crispy888_898257432No ratings yet

- 04 Pen 17529 S17 Model AnswerDocument18 pages04 Pen 17529 S17 Model AnswerSachinNo ratings yet

- 30kW Capstone MicroturbineDocument2 pages30kW Capstone MicroturbineMal KukuraNo ratings yet

- Pub - Engineered Systems January 2012 PDFDocument94 pagesPub - Engineered Systems January 2012 PDFGreefield JasonNo ratings yet

- Thermal Engineering Question BankDocument19 pagesThermal Engineering Question BankK Nallathambi K NallathambiNo ratings yet

- EBL 220-2Document2 pagesEBL 220-2Emilio Rodríguez FernándezNo ratings yet

- Coil Wound Heat Exchangers - tcm19 407186 PDFDocument16 pagesCoil Wound Heat Exchangers - tcm19 407186 PDFpsnmurthy333No ratings yet

- Multi V S BrochureDocument13 pagesMulti V S BrochureEliya MbwanjiNo ratings yet

- CCGT Project Construction and Commissioning ScheduleDocument1 pageCCGT Project Construction and Commissioning ScheduleprojectmanaNo ratings yet