Professional Documents

Culture Documents

F1-Hollow Ti Rod

Uploaded by

ManuelLentiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F1-Hollow Ti Rod

Uploaded by

ManuelLentiCopyright:

Available Formats

Development of Hollow Titanium Connecting Rod

Sadami MINATO*

Ken MIZOGAWA*

ABSTRACT

It is necessary to reduce the reciprocating mass in order to increase the engine speed and power of Formula One

engines. The project discussed in this paper therefore set out to increase the section modulus of the shaft of the

connecting rod while maintaining its rigidity and achieving weight savings. To this end, the diffusion bonding method

was optimized, and a process of manufacturing a hollow connecting rod was developed. The developed connecting

rod is lighter in weight and higher in rigidity than a rod with a conventional I-type section produced by forging, and

has contributed to enabling engines to be increased in speed.

1. Introduction

As one of the main kinetic components enabling the

operation of high-speed and high-power Formula One

engines, connecting rods (conrods) are the subject of a

constant quest for weight reductions and increases in

strength and rigidity. For this reason, titanium alloys

displaying high specific strength were applied in their

manufacture. In 2000, weight savings were achieved

through the use of a -rich + titanium alloy, SP-700(1),

which possesses 25% higher fatigue strength than that

of the formerly used 6A14V titanium alloy. However,

responding to demands for further weight savings

exclusively by means of increasing strength was bringing

materials close to the limit of rigidity design, a situation

which necessitated a new technological breakthrough.

The potential for the use of a hollow conrod structure

as a means of achieving weight savings while

maintaining a geometrical rigidity was therefore studied.

phase, and therefore does not affect the base material by

heating. In addition, titanium displays a high oxygen

solubility limit, so oxide layers easily diffuse and

disappear on titanium surfaces. Diffusion bonding was

therefore focused on, and manufacturing methods for the

component were studied on this basis.

2.2. Mechanism of Diffusion Bonding

Diffusion bonding is a bonding method in which the

temperature of the materials to be bonded is maintained

at 0.7 Tm (Tm = melting point) or more in a vacuum

or reductive gas environment, and pressure is applied in

order to promote diffusion. Figure 1 shows a model of

the diffusion process(2). In the initial stage of the process,

the asperities on the surface to be bonded are deformed

and their close adherence promoted by increasing

pressure and heat. Next, diffusion causes the grain

boundaries at the interface between the materials to

migrate and vacancies to disappear. In the final stage of

the process, the remaining vacancies disappear through

2. Developed Technology

2.1. Study of Method for Hollowing Conrod

A variety of potential methods of realizing a hollow

conrod structure were studied. One suggested method

was to form a hollow shaft extending from the big end

by means of electrochemical or mechanical machining,

which would then be cover-welded using electron beam

welding (EBW), thus forming a hollow structure.

However, this method was unable to resolve the issue

of the strength of the joints. Issues of reduced strength

also arose in the cases of casting and wax soldering.

Diffusion bonding, as employed in the manufacture

of aircraft turbines, involves the diffusion of a solid

* Automobile R&D Center

251

Fig. 1

Model of diffusion bonding process

Development of Hollow Titanium Connecting Rod

Developed

(hollow)

Rolled plate

(t19)

Blanking

(water Jet)

T-joint piece

Diffusion bonded tensile test piece

1200

60

1000

50

800

40

600

30

400

20

200

10

Hot forging

0.2%YS-T

0.2%YS-L

UTS-T

UTS-L

EL-T

EL-L

RA-T

RA-L

0

DB-Rt 1.6

DB-Rt 6.3

0.2%YS : 0.2% yield strength

UTS : Ultimate tensile strength

EL : Elongation

RA : Reduction area

Microstructure of diffusion bonded area of

connecting rod

Cut

L-joint piece

EL / RA [%]

Fig. 4

25 m

Round bar

( 50)

10

45

Base (no-DB)

Conventional

(solid)

M6

17

10

Diffusion bonded area

Fig. 2

2.5

0

R1

2.3. Conrod Bonding Process

Because the conrod is solution-aged at a temperature

lower than the transformation temperature (870 C) in

order to obtain a predetermined level of strength, the

bonding temperature was set at 830 C, equivalent to the

solution treatment temperature. The maximum pressure

was set at 4.0 MPa, and the diffusion time kept for 5.0

hr. A hot press vacuum furnace owned by Kinzoku

Giken Co., Ltd., capable of independent load control in

16 axes, was employed in the diffusion bonding.

Figure 3 shows the process of manufacture of the

hollow conrod. A rolled sheet is roughly blanked using

a water jet, after which it is machined into a half blank,

forming a hollow shaft. These half blanks are

superimposed and diffusion bonded.

The use of dowels positioned at the big and small

ends controls relative displacement during bonding to

within 0.13 mm at the upper limit of standard deviation.

The amount of crushing in the direction of thickness was

set at 4% of the initial thickness of the material, based

on the height of the carbon stopper plates during hot

pressing.

The level of roughness and cleanliness of the bonding

surface affects the mechanical properties of the bonded

section. Tests were therefore conducted to determine the

effects of these factors using tensile test pieces bonded

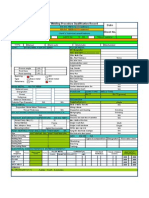

by means of two joint types (Fig. 4). Figure 5 shows

tensile properties for different levels of bonded surface

roughness. The level of surface roughness had a

particular effect on the elongation and reduction area of

the T-joint, and was therefore set at Rt1.6 or below in

order to obtain tensile properties equivalent to those of

the base material.

0.2%YS / UTS [MPa]

volume diffusion, and bonding is completed. Figure 2

shows the bonded microstructure realized in the conrod

in this project. A continuous metallic microstructure with

no remaining asperities at the bonding interface has been

obtained.

Fig. 5

Heat treatment

(STA)

Half-blank machining

(dowel at S/B end)

Machining

Acid

cleaning

Effect of surface roughness on tensile

properties of diffusion bonded test piece

Surface treatment

Diffusion bonding

(hot pressing)

Finished product

Work

Stopper plate

Fig. 3

Developed process of manufacture of hollow connecting rod

252

Honda R&D Technical Review 2009

F1 Special (The Third Era Activities)

3. Achieved Performance

A hollow structure in which diffusion bonding is

employed in the central section of the conrod thickness

has been developed, as shown in Fig. 6. This has

increased the modulus section of the shaft of the conrod

while enabling thickness to be minimized. Compared to

a conventional I-type section, an 8% reduction in weight,

2.5 times increase in the rigidity of the shaft, and 18%

increase in the rigidity of the circulation of the big end

have also been achieved. In addition, as a result of the

reduction in the load on the conrod bearings, the

potential for a 250 rpm increase in engine speed has

been demonstrated in durability tests in a real engine.

Diffusion

bonded area

Conventional

Fig. 6

Hollow shape

Comparison of conventional and hollow conrod

4. Conclusion

A method of manufacture of a hollow conrod using

diffusion bonding has been developed. The weight

savings achieved enabled engines to be increased in

speed and power, and the technology was introduced to

race engines in 2003.

References

(1) Ouchi, C., Minakawa, K., Takahashi, K., Ogawa, A.,

Ishikawa, M.: Development of -rich + Titanium

Alloy SP-700, NKK Technical Review, No. 65, p. 6167 (1992)

(2) Owczarski, W. A., Paulonis, D. F.: Application of

Diffusion Welding in the USA, Welding Journal, Vol.

60, No. 2, p. 22-33 (1981)

Author

Sadami MINATO

253

Ken MIZOGAWA

You might also like

- Solids 8 - 4Document89 pagesSolids 8 - 4dppriya1984No ratings yet

- Learning Exercise 4 GT-Power/GT-Suite Simulation Exercises Part 2: Building Up A Simulation Model For A Turbocharged 6-Cylinder Diesel Engine (10p)Document3 pagesLearning Exercise 4 GT-Power/GT-Suite Simulation Exercises Part 2: Building Up A Simulation Model For A Turbocharged 6-Cylinder Diesel Engine (10p)ManuelLentiNo ratings yet

- Italian Engine EvolutionDocument11 pagesItalian Engine EvolutionManuelLentiNo ratings yet

- GT-Power Exercise 2 Instructions - 2018Document15 pagesGT-Power Exercise 2 Instructions - 2018ManuelLentiNo ratings yet

- Power Process Simulation LE3Document4 pagesPower Process Simulation LE3ManuelLentiNo ratings yet

- Sunon: Specification For ApprovalDocument16 pagesSunon: Specification For ApprovalManuelLentiNo ratings yet

- Compressors and Turbines 2018Document25 pagesCompressors and Turbines 2018ManuelLentiNo ratings yet

- Step-by-Step Resume Guide & Templates: O: o o o o o o o - o o o oDocument12 pagesStep-by-Step Resume Guide & Templates: O: o o o o o o o - o o o oManuelLentiNo ratings yet

- RosinDocument15 pagesRosinManuelLentiNo ratings yet

- Di Workbook BarnesDocument19 pagesDi Workbook BarnesCesar CuenNo ratings yet

- En 228 PDFDocument11 pagesEn 228 PDFhugogeurdesNo ratings yet

- Kul144400 QuestionsDocument1 pageKul144400 QuestionsManuelLentiNo ratings yet

- Jasper 1972Document169 pagesJasper 1972ManuelLentiNo ratings yet

- Racecar Engineering June 2017Document101 pagesRacecar Engineering June 2017Big FloresNo ratings yet

- MP L00 - 02 - IET - Guide To Technical Writing PDFDocument18 pagesMP L00 - 02 - IET - Guide To Technical Writing PDFManuelLentiNo ratings yet

- Example of QuestionsDocument1 pageExample of QuestionsManuelLentiNo ratings yet

- E85Document58 pagesE85Kushal DhokareNo ratings yet

- I18-09 Use of MBD For HV Efficient CalibrationDocument1 pageI18-09 Use of MBD For HV Efficient CalibrationManuelLentiNo ratings yet

- United States Patent ?ice: Patented Mar. 3, 1964Document3 pagesUnited States Patent ?ice: Patented Mar. 3, 1964ManuelLentiNo ratings yet

- Potential of A Production DI Two-Stroke Engine Adapted For Range Extender and Motorcycle ApplicationsDocument24 pagesPotential of A Production DI Two-Stroke Engine Adapted For Range Extender and Motorcycle ApplicationsManuelLentiNo ratings yet

- Math Prerequisite: Advanced Automotive Engineering Automatic ControlsDocument9 pagesMath Prerequisite: Advanced Automotive Engineering Automatic ControlsManuelLentiNo ratings yet

- (Marco - Carricato.meccanica Delle Macchine M 2016-17) Chapter06.2.2 MultiDOF-Systems QuadcopterDocument39 pages(Marco - Carricato.meccanica Delle Macchine M 2016-17) Chapter06.2.2 MultiDOF-Systems QuadcopterManuelLenti100% (1)

- Combustione Benzina 2015 2 CleanDocument22 pagesCombustione Benzina 2015 2 CleanManuelLentiNo ratings yet

- Chapter06.1 1DOF-Systems DynamicsDocument115 pagesChapter06.1 1DOF-Systems DynamicsManuelLentiNo ratings yet

- BibliografiaDocument26 pagesBibliografiaManuelLentiNo ratings yet

- 10 1 1 126 3437 PDFDocument100 pages10 1 1 126 3437 PDFManuelLentiNo ratings yet

- Chapter06.03 VehicleDynamicsDocument69 pagesChapter06.03 VehicleDynamicsManuelLentiNo ratings yet

- United States Patent ?ice: Patented Mar. 3, 1964Document3 pagesUnited States Patent ?ice: Patented Mar. 3, 1964ManuelLentiNo ratings yet

- 1-I Materiali CeramiciDocument41 pages1-I Materiali CeramiciManuelLentiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Nitoproof 600 UAEDocument4 pagesNitoproof 600 UAECharles FernandesNo ratings yet

- Solid Carbide End Mills For 48HRC: Micro Grain 10% Co Grade 2 Flute Iso CodeDocument10 pagesSolid Carbide End Mills For 48HRC: Micro Grain 10% Co Grade 2 Flute Iso CodepromoNo ratings yet

- Form U1 ASME VIIIDocument8 pagesForm U1 ASME VIIImilagrosNo ratings yet

- Strategies For Eliminating DecarburizationDocument3 pagesStrategies For Eliminating Decarburizationmp87_ingNo ratings yet

- Instructions For Application of Ced Primers TE-8800: Cationic Epoxy ElectrocoatingDocument11 pagesInstructions For Application of Ced Primers TE-8800: Cationic Epoxy ElectrocoatingSushil KumarNo ratings yet

- Construction Materials Used in Marine Diesel EnginesDocument4 pagesConstruction Materials Used in Marine Diesel Enginesshihab100% (1)

- Chemical Kinetics: Aa BB CC DD + +Document1 pageChemical Kinetics: Aa BB CC DD + +Chandra Vamsi AdhikariNo ratings yet

- Mec108 - Workshop PracticeDocument3 pagesMec108 - Workshop PracticeRohan KatyalNo ratings yet

- Forging and Extrusion: M Jamil Ms/IeDocument51 pagesForging and Extrusion: M Jamil Ms/IeM. RazaNo ratings yet

- ESAB SvetshandbokDocument60 pagesESAB SvetshandbokThomas SjölingNo ratings yet

- 04 ExtrusionDocument57 pages04 Extrusion9811923100% (1)

- Assembly InstructionsDocument4 pagesAssembly InstructionsoconcheiroNo ratings yet

- Summer Internship ReportDocument34 pagesSummer Internship ReportSubhash Patel100% (2)

- Blueprint Smart Plate-ModelDocument1 pageBlueprint Smart Plate-ModelKarl BellezaNo ratings yet

- WPQR SMAW EN-2 - 30mm (Under Modification)Document2 pagesWPQR SMAW EN-2 - 30mm (Under Modification)Mohamed Reda HusseinNo ratings yet

- Trilon C FTDocument1 pageTrilon C FTjean carlos murillo hernandezNo ratings yet

- FW0061Document7 pagesFW0061alefeli26No ratings yet

- Name of Project Facility For Manufacturing of Battery CaseDocument1 pageName of Project Facility For Manufacturing of Battery CaseEyock PierreNo ratings yet

- BME RFI Template - Supplier Profile - 2021Document30 pagesBME RFI Template - Supplier Profile - 2021Amir KaračićNo ratings yet

- CastingDocument6 pagesCastingSmer AlaliNo ratings yet

- Test For Spray RateDocument61 pagesTest For Spray Ratenitish JhaNo ratings yet

- WPARDocument2 pagesWPARSc TanNo ratings yet

- Standard And/or Project Stage TC: Filter The ListDocument10 pagesStandard And/or Project Stage TC: Filter The ListIsmailNo ratings yet

- Application Guide - Jotun Guard Style D MDocument8 pagesApplication Guide - Jotun Guard Style D Mabdulaziz mohammedNo ratings yet

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument4 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNo ratings yet

- Refineries: Application Focus: HydroprocessingDocument4 pagesRefineries: Application Focus: HydroprocessingmudrikaNo ratings yet

- Why Use Wire Cut Machine?Document3 pagesWhy Use Wire Cut Machine?Mahmoud ElsayedNo ratings yet

- Larsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007Document4 pagesLarsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007punitg_2No ratings yet

- Basic Injection Moulding Trouble Shooting GuideDocument14 pagesBasic Injection Moulding Trouble Shooting GuidetmisiakNo ratings yet

- Mould ElementsDocument72 pagesMould Elementsvinayak100% (4)