Professional Documents

Culture Documents

1417686916-AutomationML Whitepaper Part 4 - AutomationML Logic Description v2 - Aug2013

Uploaded by

cesarmarinhorjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1417686916-AutomationML Whitepaper Part 4 - AutomationML Logic Description v2 - Aug2013

Uploaded by

cesarmarinhorjCopyright:

Available Formats

Whitepaper AutomationML

Part 4 AutomationML Logic

Description

State: May 2010

Part 4 - AutomationML Logic Description

AutomationML consortium

Version 2.0, Mai 2010

Contact: www.automationml.org

Related documents

[1]

Whitepaper AutomationML Part 1 AutomationML Architecture, May 2010.

[2]

Whitepaper AutomationML Part 2 AutomationML Libraries, May 2010

[3]

Pirsch, M.: AutomationML Editor User Guideline, May 2010

[4]

Pirsch, M.: AutomationML Engine User Guideline, May 2010

Part 4 - AutomationML Logic Description

Table of content

Table of content ...................................................................................................................................... 3

List of figures .......................................................................................................................................... 7

List of tables ........................................................................................................................................... 9

1

Introduction................................................................................................................................. 12

1.1 Logic Descriptions in Automation Engineering ...................................................................... 12

1.2 Storing Logic Descriptions within AutomationML .................................................................. 12

1.3 Interlocking Description in Automation Engineering .............................................................. 13

1.4 Structure of this Document .................................................................................................... 14

1.5 References to other Documents ............................................................................................ 14

2

Sequencing and Behaviour Models in AutomationML ............................................................... 15

2.1 Overview ................................................................................................................................ 15

2.2 Gantt Charts ........................................................................................................................... 16

2.3 PERT Charts .......................................................................................................................... 16

2.4 Impulse Diagrams .................................................................................................................. 18

2.5 Sequential Function Charts.................................................................................................... 19

2.6 State Charts ........................................................................................................................... 21

3

The Intermediate Modeling Layer .............................................................................................. 23

3.1 Overview ................................................................................................................................ 23

3.2 IML Systems Element Overview ............................................................................................ 24

3.3 Element Properties and Relations ......................................................................................... 25

3.3.1 Header Properties and Relations .............................................................................. 25

3.3.2 State Properties and Relations ................................................................................. 25

3.3.3 State Transition Properties and Relations ................................................................ 26

3.3.4 Activity Properties and Relations .............................................................................. 26

3.3.5 Jump Properties and Relations ................................................................................. 27

3.3.6 Selection Divergence Properties and Relations ........................................................ 27

3.3.7 Simultaneous Divergence Properties and Relations................................................. 27

3.3.8 Selection Convergence Properties and Relations .................................................... 27

3.3.9 Simultaneous Convergence Properties and Relations ............................................. 27

3.3.10 Event Properties ........................................................................................................ 27

3.3.11 Variable Properties and Relations ............................................................................. 28

3.3.12 Comment Properties and Relations .......................................................................... 28

3.3.13 Aditional Data properties and relation ....................................................................... 28

4

Mapping of IML to PLCopen XML SFC ...................................................................................... 29

4.1.1 Overview ................................................................................................................... 29

4.2 Additional Data ....................................................................................................................... 29

4.2.1 PLCopen XML addData ............................................................................................ 29

4.2.2 AutomationML Schema for Additional Data within the Logic Description ................. 29

4.2.3 Declaration and Usage of AutomationML Additional Data Schema in PLCopen

XML ........................................................................................................................... 37

4.3 Mapping of IML to PLCopen XML .......................................................................................... 38

4.3.1 Common Rules.......................................................................................................... 38

4.3.2 Mapping of Headers and their Relations ................................................................... 40

4.3.3 Mapping of States and their Relations ...................................................................... 41

3

Part 4 - AutomationML Logic Description

4.3.4 Mapping of State Transitions and their Relations ..................................................... 42

4.3.5 Mapping of Activities and their Relations .................................................................. 46

4.3.6 Mapping of Jumps and their Relations ...................................................................... 52

4.3.7 Mapping of Selection Divergence and their Relations .............................................. 52

4.3.8 Mapping of Simultaneous Divergences and their Relations ..................................... 53

4.3.9 Mapping of Selection Convergence and their Relations ........................................... 54

4.3.10 Mapping of Simultaneous Convergences and their Relations .................................. 55

4.3.11 Mapping of Events and their Relations ..................................................................... 56

4.3.12 Mapping of Variables and their Relations ................................................................. 57

4.3.13 Mapping of Comment Properties and their Relations ............................................... 59

4.3.14 Mapping of Additional Data Properties and their Relations ...................................... 60

5

Representation of Logic Models in AutomationML .................................................................... 62

5.1 Gantt Charts ........................................................................................................................... 62

5.1.1 Overview ................................................................................................................... 62

5.1.2 Start of a Gantt Chart ................................................................................................ 65

5.1.3 Bar ............................................................................................................................. 65

5.1.4 Bar Startpoint ............................................................................................................ 66

5.1.5 Bar Endpoint.............................................................................................................. 66

5.1.6 Successor Bar ........................................................................................................... 66

5.1.7 Predecessor Bar........................................................................................................ 67

5.1.8 End of a Gantt Chart ................................................................................................. 69

5.1.9 Transformation Examples for Gantt Charts .............................................................. 70

5.2 PERT Charts .......................................................................................................................... 74

5.2.1 Overview ................................................................................................................... 74

5.2.2 Start of a PERT Chart ............................................................................................... 76

5.2.3 Node .......................................................................................................................... 76

5.2.4 Node Earliest Startpoint ............................................................................................ 77

5.2.5 Node Duration ........................................................................................................... 77

5.2.6 Further Node Times .................................................................................................. 77

5.2.7 Successor Nodes ...................................................................................................... 78

5.2.8 Predecessor Nodes ................................................................................................... 78

5.2.9 End of a PERT Chart ................................................................................................ 81

5.2.10 Transformation Example of PERT Charts ................................................................. 82

5.3 Impulse Diagrams .................................................................................................................. 84

5.3.1 Overview ................................................................................................................... 84

5.3.2 Start of an Impulse Diagram ..................................................................................... 87

5.3.3 Timeline ..................................................................................................................... 87

5.3.4 Resource ................................................................................................................... 88

5.3.5 Resource State .......................................................................................................... 88

5.3.6 Resource State Change ............................................................................................ 89

5.3.7 Resource State Flow ................................................................................................. 89

5.3.8 Signals ....................................................................................................................... 90

5.3.9 End of Impulse Diagram and Terminal Step ............................................................. 92

5.3.10 Impulse Diagram Details ........................................................................................... 93

5.3.11 Transformation Examples for Impulse Diagrams ...................................................... 94

5.4 State Charts ........................................................................................................................... 97

4

Part 4 - AutomationML Logic Description

5.4.1 Overview ................................................................................................................... 97

Flat State Charts .................................................................................................................... 99

5.5.1 Headers ..................................................................................................................... 99

5.5.2 States ...................................................................................................................... 100

5.5.3 Number and Structure of Predecessor States ........................................................ 100

5.5.4 Number and Structure of Successors of States ...................................................... 101

5.5.5 Entry Action ............................................................................................................. 101

5.5.6 Action within a State; Do Action .............................................................................. 102

5.5.7 Exit Action ............................................................................................................... 103

5.5.8 Events ..................................................................................................................... 103

5.5.9 Signals ..................................................................................................................... 104

5.5.10 State Transitions ..................................................................................................... 104

5.6 State Charts with Hierarchies .............................................................................................. 108

5.6.1 Hierarchy Levels...................................................................................................... 108

5.6.2 History Connector.................................................................................................... 109

5.6.3 Condition Connector ............................................................................................... 110

5.6.4 State Transition among Hierarchies ........................................................................ 111

5.7 Example Transformation for State Charts to AutomationML Logic Representation ............ 122

6

Linking AutomationML Objects with Logic Information ............................................................ 125

6.1 Overview AutomationML Top Level Architecture ................................................................ 125

6.2 Reference Mechanisms between CAEX and PLCopen XML .............................................. 125

6.2.1 Overview ................................................................................................................. 125

6.2.2 Referencing PLCopen XML documents .................................................................. 126

6.2.3 InterfaceClass ExternalDataConnector ................................................................... 127

6.2.4 InterfaceClass PLCopenXMLInterface .................................................................... 127

6.2.5 InterfaceClass LogicInterface .................................................................................. 128

6.2.6 InterfaceClass VariableInterface ............................................................................. 128

6.3 Referencing Logic Information ............................................................................................. 128

6.3.1 Conceptual Overview .............................................................................................. 128

6.3.2 Referencing PLCopen XML Logic Information ........................................................ 129

6.3.3 Referencing PLCopen XML Variables .................................................................... 129

6.4 Examples ............................................................................................................................. 130

6.4.1 Referencing a PLCopen XML Document ................................................................ 130

6.4.2 Referencing and Connecting a PLCopen XML Variable ......................................... 131

6.4.3 Referencing and Connecting Behaviour and Sequence Information ...................... 132

7

Mapping Interlocking Information to AutomationML ................................................................ 134

7.1 Overview .............................................................................................................................. 134

7.2 Component Groups and Signal Groups ............................................................................... 134

7.2.1 Concept Description ................................................................................................ 134

7.2.2 RoleClass ComponentGroup .................................................................................. 136

7.2.3 RoleClass SignalGroup ........................................................................................... 137

7.2.4 InterfaceClass InterlockingConnector ..................................................................... 137

7.3 Boolean Logic as Interlocking Condition .............................................................................. 137

7.3.1 Concept Description ................................................................................................ 137

7.3.2 InterfaceClass InterlockingVariableInterface .......................................................... 138

7.3.3 Restricted Linking Mechanism ................................................................................ 139

5.5

Part 4 - AutomationML Logic Description

7.4

7.5

Complex Logic as Interlocking Condition ............................................................................. 140

Extended Use of Interlocking Description within AutomationML ......................................... 141

7.5.1 Interlocking as Transition Condition in Sequence Descriptions .............................. 141

7.5.2 Interlocking Networks as Behaviour Description ..................................................... 142

7.6 Example for the Usage of Interlocking Descriptions within AutomationML ......................... 143

References ......................................................................................................................................... 148

Annex A: Example for Mapping IML to PLCopen XML ...................................................................... 149

Part 4 - AutomationML Logic Description

List of figures

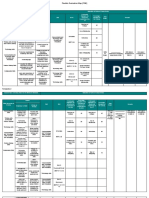

Figure 1: Transformation to PLCopen XML ......................................................................................... 13

Figure 2: Types of logic descriptions in AutomationML ....................................................................... 15

Figure 3: Example of a Gantt chart ...................................................................................................... 16

Figure 4: Example of a PERT chart ..................................................................................................... 17

Figure 5: Example of an Impulse diagram with naming conventions ................................................... 18

Figure 6: Signals in Impulse diagrams ................................................................................................. 18

Figure 7: Timing information within Impulse diagrams ......................................................................... 19

Figure 8: Example of a SFC in IEC 61131-3 ........................................................................................ 21

Figure 9: Example simple State chart .................................................................................................. 22

Figure 10: IML system entities and its relations ................................................................................... 23

Figure 11: Example of an SFC in IML .................................................................................................. 24

Figure 12: Declaration of the AutomationML additional data schema within PLCopen XML............... 38

Figure 13: Example of additional information in AutomationML ........................................................... 38

Figure 14 Used part of the PLCopen XML schema: ............................................................................ 40

Figure 15: Actions of IML for Gantt- bar representation ....................................................................... 62

Figure 16: Example of the transformation of a Gantt diagram in SFC (IML) ....................................... 63

Figure 17: SFC representation of the Gantt chart in Figure 16 ............................................................ 64

Figure 18: Gantt translation example - activities without predecessor and successor relations ......... 70

Figure 19: Gantt translation example activity sequence ................................................................... 71

Figure 20: Gantt translation example activity sequence divagation .................................................. 72

Figure 21: Gantt translation example activity sequence convergence.............................................. 73

Figure 22: Elements of a PERT chart .................................................................................................. 74

Figure 23: Boolean actions of SFC for PERT activity representation .................................................. 75

Figure 24: Example for the mapping of a PERT chart to a SFC .......................................................... 82

Figure 25: Timing behaviour of the SFC derived from a PERT chart node ......................................... 83

Figure 26: Impulse diagram example of transformation ....................................................................... 84

Figure 27: Resulting SFC for Impulse diagram example of Figure 26 ................................................. 85

Figure 28: Example transformation internal signal ............................................................................... 94

Figure 29: Example external signal ...................................................................................................... 95

Figure 30: Impulse diagram example of transformation ....................................................................... 96

Figure 31: State chart example ............................................................................................................ 97

Figure 32: IML representation of State chart example from Figure 31 ................................................ 98

Figure 33: Transformation of State chart to an IML system ................................................................. 99

Figure 34: Transformation states to IML states .................................................................................. 100

Figure 35: Transformation of predecessor states to IML elements .................................................... 100

Figure 36: Transformation of states to IML states .............................................................................. 101

Figure 37: Transformation of an entry action of states to an IML activity .......................................... 101

Figure 38: Transformation of a do action to an IML activity ............................................................... 102

Figure 39: Transformation of an exit action to an IML activity ........................................................... 103

Figure 40: Transformation of events to an IML event and PLCopen variable ................................... 103

Figure 41: Transformation of a signal to an IML variable ................................................................... 104

Figure 42: Transformation a states transition to an IML transition ..................................................... 104

Figure 43: Transformation of a state transition without an action to IML elements ........................... 105

Figure 44: Transformation of a state transition with an action to IML elements ................................ 106

7

Part 4 - AutomationML Logic Description

Figure 45: Transformation of a hierarchical State chart to an IML System ........................................ 108

Figure 46: Transformation of a history connector to IML elements .................................................... 109

Figure 47: Transformation of a condition connector to IML elements ................................................ 110

Figure 48: Transformation of a state transition over different hierarchy level to IML element ........... 111

Figure 49: Transformation of a state transition from a higher state without an action to IML

elements............................................................................................................................... 112

Figure 50: Transformation of a state transition from a higher state with an action to IML

elements............................................................................................................................... 114

Figure 51: Transformation of a state transition from a lower level state without an action to IML

elements............................................................................................................................... 116

Figure 52: Transformation of a state transition from a lower level state with an action to IML

elements............................................................................................................................... 119

Figure 53: Example: transformation of a simple cyclic State chart .................................................... 122

Figure 54: Example: transformation of a State chart with states with different predecessors and

successors ........................................................................................................................... 122

Figure 55: Example: transformation of a State chart with actions ...................................................... 123

Figure 56: Example: transformation of a State charts with a condition connector ............................. 123

Figure 57: Example: transformation of a State chart with simple hierarchy ....................................... 124

Figure 58: Example: transformation of a State chart with complex hierarchy and connectors .......... 124

Figure 59: AutomationML top level architecture ................................................................................. 125

Figure 60: Storage of logics information with AutomationML ............................................................. 128

Figure 61: Referencing logic information ........................................................................................... 129

Figure 62: Publishing PLCopen variables .......................................................................................... 129

Figure 63: Example drilling system .................................................................................................... 130

Figure 64: Reference to logic description ........................................................................................... 131

Figure 65: Reference to variable within logic description ................................................................... 132

Figure 66: Reference to multiple logic information ............................................................................. 133

Figure 67: Example production system .............................................................................................. 134

Figure 68: Principle usage of signal and component groups ............................................................. 135

Figure 69: Linking of signal and component groups .......................................................................... 135

Figure 70 Example of creating signal and component groups ........................................................... 136

Figure 71: General reference mechanism for interlocking condition .................................................. 138

Figure 72: Example of use of InterfaceClass InterlockingVariableInterface ...................................... 139

Figure 73: Example FBD for second level of interlocking description ................................................ 139

Figure 74: Complex FBD networks for interlocking descriptions ....................................................... 141

Figure 75: Interlocking condition as additional transition condition within a network ......................... 142

Figure 76: Example of an interlocking network as behaviour description .......................................... 142

Figure 77: Interlocking example cell structure .................................................................................... 143

Figure 78: Interlocking example with modeled signal and component groups .................................. 144

Figure 79: Interlocking example with linked signal and component groups ....................................... 145

Figure 80: Interlocking example with references PLCopen XML document ...................................... 146

Figure 81: Interlocking example with references to PLCopen XML variables ................................... 147

Figure 82: Example IML system ......................................................................................................... 149

Part 4 - AutomationML Logic Description

List of tables

Table 1: AutomationML element .......................................................................................................... 30

Table 2: <Time> element ..................................................................................................................... 31

Table 3: <Duration> element ............................................................................................................ 31

Table 4: <EarliestStart> element ................................................................................................. 31

Table 5: <LatestStart> element ..................................................................................................... 32

Table 6: <EarliestEnd> element ..................................................................................................... 32

Table 7: <Latest> element ................................................................................................................ 32

Table 8: <Delay> element .................................................................................................................. 32

Table 9: <ChartType> element .......................................................................................................... 33

Table 10: <ResourceStateChangeDefinition> element ............................................................ 33

Table 11: <DefinitionName> element ............................................................................................. 33

Table 12: <Durationn> element ........................................................................................................ 33

Table 13: <InteruptableAction> element .................................................................................... 34

Table 14: <StateChartSubCharts> element .................................................................................. 34

Table 15: <POURef> element .............................................................................................................. 34

Table 16: <StateChartStateType> Element.................................................................................. 35

Table 17: <StateChartActionType> Element ............................................................................... 35

Table 18: <ImpulseChartResourceGroup> element ..................................................................... 35

Table 19: <ImpulseDiagramPLCVariable> element ..................................................................... 36

Table 20: <Name> element ................................................................................................................... 36

Table 21: <Datatype> element .......................................................................................................... 36

Table 22: <Address> element ............................................................................................................ 36

Table 23: <StateStatus> element ................................................................................................... 37

Table 24: <ActionStatus> element ................................................................................................. 37

Table 25: Mapping of IML header to PLCopen XML ............................................................................ 40

Table 26: Example transformation IML header to PLCopen XML ....................................................... 41

Table 27: Mapping of IML state to PLCopen XML ............................................................................... 42

Table 28: Example transformation IML state to PLCopen XML ........................................................... 42

Table 29: Mapping of IML state transition to PLCopen XML ............................................................... 45

Table 30: Example transformation IML state transition to PLCopen XML ........................................... 46

Table 31: Mapping of IML activity to PLCopen XML ............................................................................ 50

Table 32: Example transformation IML activity to PLCopen XML ........................................................ 51

Table 33: Mapping of IML jump to PLCopen XML ............................................................................... 52

Table 34: Example transformation IML jump to PLCopen XML ........................................................... 52

Table 35: Mapping of IML selection divergence to PLCopen XML ...................................................... 53

Table 36: Example transformation IML selection divergence to PLCopen XML .................................. 53

Table 37: Mapping of IML simultaneous divergencies to PLCopen XML ............................................ 54

Table 38: Example transformation IML simultaneous divergencies to PLCopen XML ........................ 54

Table 39: Mapping of IML selection convergence to PLCopen XML ................................................... 55

Table 40: Example transformation IML selection convergence to PLCopen XML ............................... 55

Table 41: Mapping of IML simultaneous divergences to PLCopen XML ............................................. 56

Table 42: Example transformation IML simultaneous divergences to PLCopen XML ......................... 56

Part 4 - AutomationML Logic Description

Table 43: Mapping of IML event to PLCopen XML .............................................................................. 56

Table 44: Example transformation IML event to PLCopen XML .......................................................... 57

Table 45: Mapping of IML variable to PLCopen XML .......................................................................... 58

Table 46: Example transformation IML variable to PLCopen XML ...................................................... 59

Table 47: Mapping of IML comment to PLCopen XML ........................................................................ 59

Table 48: Example transformation IML comment to PLCopen XML .................................................... 60

Table 49: Mapping of IML addData to PLCopen XML ......................................................................... 60

Table 50: Example transformation IML addData to PLCopen XML ..................................................... 61

Table 51: Transformation of the start of a Gantt chart to IML elements .............................................. 65

Table 52: Transformation of Gantt chart bars to IML elements ........................................................... 65

Table 53: Transformation of Gantt chart bar start point to IML elements ............................................ 66

Table 54: Transformation of Gantt chart bar endpoint to IML elements .............................................. 66

Table 55: Transformation of Gantt chart bar successor activities to IML ............................................. 67

Table 56: Transformation of Gantt chart predecessor bar to IML elements ........................................ 69

Table 57: Transformation of the end of a Gantt chart to IML elements ............................................... 69

Table 58: Transformation of a PERT node to IML elements ................................................................ 76

Table 59: Transformation of PERT chart nodes to IML elements ........................................................ 76

Table 60: Transformation of PERT chart node earliest startpoint to IML elements ............................. 77

Table 61: Transformation of PERT chart node duration to IML elements ........................................... 77

Table 62: Transformation of PERT chart node duration to IML elements ........................................... 77

Table 63: Transformation of PERT diagram activity successor activity to IML .................................... 78

Table 64: Transformation of a PERT diagram predecessor activity to IML elements.......................... 80

Table 65: Transformation of PERT diagram Terminal Step to IML elements ...................................... 81

Table 66: Transformation of the start of Impulse Diagrams to IML elements ...................................... 87

Table 67: Transformation of a timeline to IML elements ...................................................................... 88

Table 68: Transformation of resources to IML elements ..................................................................... 88

Table 69: Transformation of resource states to IML elements............................................................. 88

Table 70: Transformation of resource state changes to IML elements ................................................ 89

Table 71: Transformation of the resource state flows to IML elements ............................................... 90

Table 72: Transformation of signals to IML elements .......................................................................... 91

Table 73: Transformation of Impulse Diagram end to IML elements ................................................... 92

Table 74: Transformation of Impulse Diagram details to IML elements .............................................. 93

Table 75: Attribute values for flat State chart representation as IML system .................................... 100

Table 76: Attribute values for state representation in IML ................................................................. 100

Table 77: Attribute values for representation of multiple predecessors in IML .................................. 101

Table 78: Attribute values for the representation of multiple successors of a state in IML ................ 101

Table 79: Attribute values for an entry action representation in IML .................................................. 102

Table 80: Attribute values for a do action representation in IML ........................................................ 102

Table 81: Attribute values for an exit action representation in IML .................................................... 103

Table 82: Attribute values for an exit action representation in IML .................................................... 104

Table 83: Attribute values for signal representations in IML .............................................................. 104

Table 84: Distinction of cases for the mapping of state transitions in flat State charts ...................... 105

Table 85: Attribute values for signal representation in IML ................................................................ 105

Table 86: Attribute values for a state transition with an action in IML ................................................ 107

Table 87: Attribute values for hierarchical State chart representation as IML systems ..................... 108

Table 88: Attribute values for flat State chart representation as IML systems ................................... 108

10

Part 4 - AutomationML Logic Description

Table 89: Attribute values for transformation of a history connector in IML ....................................... 109

Table 90: Attribute values for transformation of a history connector in IML ....................................... 110

Table 91: Attribute values for the condition connector representation in IML .................................... 111

Table 92: Distinction of cases for the mapping of state transitions in hierarchical State charts ........ 111

Table 93: Attribute values for state transition representation in IML within hierarchical State

charts ................................................................................................................................... 112

Table 94: Attribute values for state transition representation in IML within the sub State charts ...... 113

Table 95: Attribute values for state transition representation in IML within hierarchical State

charts ................................................................................................................................... 114

Table 96: Attribute values for state transition representation in IML within the sub State charts ...... 116

Table 97: Attribute values the representation of state transition among hierarchies in IML at the

higher level ........................................................................................................................... 117

Table 98: Attribute values for the state transition representation in IML within the sub State

charts ................................................................................................................................... 118

Table 99: Attribute values the representation of state transition among hierarchies in IML .............. 120

Table 100: Attribute values for state transition representation in IML within the sub State charts .... 121

Table 101: InterfaceClasses of the AutomationMLInterfaceClassLib ................................................ 126

Table 102: Examples for the attribute refURI .................................................................................. 127

Table 103: InterfaceClass ExternalDataConnector ............................................................................ 127

Table 104: InterfaceClass PLCopenXMLInterface ............................................................................. 127

Table 105: InterfaceClass LogicInterface ........................................................................................... 128

Table 106: InterfaceClass VariableInterface ...................................................................................... 128

Table 107: RoleClass ComponentGroup ........................................................................................... 136

Table 108: RoleClass SignalGroup .................................................................................................... 137

Table 109: InterfaceClass InterlockingConnector .............................................................................. 137

Table 110: InterfaceClass InterlockingVariableInterface ................................................................... 138

Table 111: Restrictions for the linking of signal and component groups............................................ 140

11

Part 4 - AutomationML Logic Description

1

Introduction

1.1

Logic Descriptions in Automation Engineering

AutomationML (Automation Markup Language) is a neutral and XML-schema-based data format

designed for the vendor-independent storage of plant engineering information. The goal of

AutomationML is to interconnect the heterogeneous tool landscape of engineering tools in their

different disciplines, e.g. mechanical plant engineering, electrical design, HMI development, PLC, and

robot control programming.

Whereas [1] gives a top-level architecture overview of AutomationML, this document focuses on the

storage of logic information - an important aspect for electrical design, HMI development, PLC and

robot control programming.

AutomationML must be able to cover logic data from different tools and disciplines, and supports

different phases in the iterative plant engineering workflow covering different levels of detail.

AutomationML simplifies the engineering of production systems from the first engineering steps such

as plant design to the final commissioning of complete systems. Thus, different types of logic

information belonging to an industrial plant or to single components have to be stored.

This variety of information can be differentiated into two main concepts: sequencing and behaviour

which serve different purposes, but which can overlap depending on the point of view and utilization of

elements in AutomationML:

Description of behaviour of AutomationML objects as a given (uncontrolled) model of reaction of a

part on external inputs, e.g. behaviour of a gripper or valve.

Description of sequencing as required controlled behaviour of a system or part, which often

represents a program executed in one or more controllers, e.g. robot controller, PLC.

Intelligent devices with both behaviour and sequencing, e.g. robots or conveyors.

AutomationML provides a rich selection of typical logic description models for important phases of the

engineering process and data. These models are:

Gantt charts typically used during the first planning phases

PERT charts used in a similar way with complex timing conditions

Impulse diagrams to describe sequences in detail and to introduce real signals

State charts to describe internal behaviour in detail

Sequence Funktion Charts (SFCs) for executable PLC programs including a mapping to real

control hardware

1.2

Storing Logic Descriptions within AutomationML

AutomationML uses one common data model to describe both types of logic information, namely

Sequential Function Charts (SFC) as one of the PLC programming languages defined in IEC 61131-3

[IEC61131-3]. Thus, transformation rules to and from SFCs out of various input formats are essential

parts of the AutomationML logic concept.

Complete logic representations are stored in external documents, while the top-level format contains

selected published information only. Target data format for logic information is PLCopen XML.

To store a given logic description in AutomationML it has to be translated to SFCs described by a

PLCopen XML representation strictly following the rules defined in this document.

12

Part 4 - AutomationML Logic Description

Mapping Rules based

on transformation of

Model elements

Mapping rules for

transformation of

IML elements to

XML structures

Gantt chart

PERT chart

Impulse diagram

Intermediate

Modeling Layer

PLCopen XML

...

Specific models and charts

(Propriety data format)

Set of model

elements

XML

Figure 1: Transformation to PLCopen XML

To decouple the target format PLCopen XML from various input and output data formats,

AutomationML defines an Intermediate Modeling Layer (IML) as depicted in Figure 1. In this way the

complex transformation rules from and to PLCopen XML specifics need to be defined only once, for

each specific input format only transformation rules to the simpler intermediate layer need to be

defined, improving the extensibility of AutomationML for new input formats.

To summarize the main categories and to give them a formal background the Intermediate Modeling

Layer (IML) is defined for clarification and simplification of the mapping process of different model

types to AutomationML. Nevertheless, it does not constitute a new modeling language.

For the import of a logic description out of SFCs, a tool has to interpret them in an appropriate way to

restore the original format or create another representation of the information. Thus, tools can also use

AutomationML to transfer logic formats. In this case the user must be aware of possible information

loss, since AutomationML cannot compensate different modeling power of formats, e.g. a PERT chart

can be interpreted as Gantt chart but some PERT specific timing information will be lost.

1.3

Interlocking Description in Automation Engineering

The second part of logic information covered by AutomationML is the interlocking description in

different level of detail belonging to an industrial plant or to single components.

AutomationML distinguishes between two different types of interlocking information. It reflects the two

main concepts:

the causes of an interlocking condition and

the resulting effects of an interlocking condition.

Hereby, the cause represents the situation resulting in the need to interlock something. This case is

covered by the definition and description of signal groups. The effect to other groups of objects is

expressed by the definition, description, and association of component groups.

These relations between signal group and component group will express the relation between cause

and effect within an interlocking. In AutomationML different levels of detail are used to exchange these

logical interlocking conditions. Therefore, AutomationML provides common rules and mechanisms to

store different interlocking models for important phases of the engineering process.

AutomationML uses two concepts to store interlocking description. To describe signal group and

component group the basic AutomationML group concept is used. This concept exploits fundamental

CAEX capabilities and enables an integration of the necessary information within the AutomationML

top level documents. To express the relation between both types of groups and to express the internal

logical relation within the groups Function Block Diagrams (FBD) of the IEC 61131-3 are used. They

are stored in PLCopen XML documents similar to behaviour descriptions.

For the import of an interlocking description, a tool has to interpret according to its use case the signal

and component groups within the top level description or the FBD description within the refrenced

PLCopen XML documents. Of course it is possible to use both concepts in combination.

13

Part 4 - AutomationML Logic Description

1.4

Structure of this Document

This document gives an introduction to the handling of logic information in AutomationML and

describes basic concepts and application rules for storing and reading different kinds of logic

information using AutomationML.

After a brief introduction chapter one presents the problem of storing logic information out of different

input models and charts within one common AutomationML logic description.

Chapter 2 describes the logic concepts with the corresponding logic models and charts considered in

AutomationML.

The Intermediate Modelling Layer (IML) as basement for a transparent mapping of logic models to the

target logic data format - PLCopen XML- is introduced in chapter 3.

In the following chapter 4 the detailed transformation rules necessary to transform IML described logic

models to the target format PLCopen XML are specified.

The complex transformation rules for the logic input formats Gantt chart, PERT chart, Impulse

diagrams and State charts to IML are defined in chapter 5.

Chapter 6 starts with a short overview about the AutomationML Top Level Architecture. This is used

for as basis for the detailed description of the mechanisms to link AutomationML logic description into

the top level format.

Finally the document closes with the AutomationML specification of the AutomationML interlocking

description in chapter 7.

1.5

References to other Documents

The AutomationML top-level architecture provides the ability to store all the different facets of the plant

engineering information including plant topology, geometry, kinematics, behaviour, references and

relations [1].

The international standard CAEX (Computer Aided Engineering Exchange) according to IEC 62424 is

a neutral data exchange format for storing hierarchical object information and properties [IEC62424].

PLCopen XML is a vendor-neutral data exchange format for the storage of PLC program information

according to IEC 61131-3 [PLCopen2010].

The international standard IEC 61131-3 specifies five programming languages for the implementation

of programs for programmable logic controllers (PLC) [IEC61131].

The COLLADA standard has been developed for the vendor-neutral data exchange for 3D graphical

assets [Collada2010].

Unified Modeling Language (UML) is a standardized general-purpose modeling language in the field of

software engineering. It is created by, the Object Management Group [UML2010].

14

Part 4 - AutomationML Logic Description

2

Sequencing and Behaviour Models in AutomationML

2.1

Overview

For logic descriptions, AutomationML covers data of different tools and disciplines, and supports

different phases in engineering with different levels of detail. AutomationML simplifies the engineering

of production systems from the first engineering steps such as plant design to final commissioning of

complete systems. Thus, different types of logic information belonging to a production system or to

single parts have to be stored. This variety of information can be differentiated into two main concepts,

namely sequencing and behaviour, but may overlap depending on the point of view and utilization of

elements in AutomationML:

Description of behaviour of AutomationML objects as a given uncontrolled model of reaction of a

part on external inputs, typically used in a white-box manner,

Description of sequencing as required controlled behaviour of a system or part, which often

represents a program executed in one or more controllers, e.g. robot controller, PLC etc..

The two concepts are typically used within AutomationML in the following contexts:

1. Uncontrolled behaviour of a single mechatronical unit:

An example of this type is the behaviour of a gripper. The interfaces of this element are

required for triggering the behaviour or signaling its states. In most cases, they represent the

same signals as the ones of the real physical element.

2. Sequences of cells or plants:

Sequences of cells or plants typically are descriptions of subsequent actions as high-level

input for PLC programming, e.g. in form of Gantt charts. They are normally bound to

compound elements such as a cell or controller. Interfaces are required for interaction with

other elements of the logic description, and consist of real signals or simplifications of these

signals. The evolution of sequences starts with a high level of abstract description of required

operations of a larger scale unit (cell, line, plant etc.), and ends with executable programs,

typically with several refinements in between.

3. Behaviour and sequencing of intelligent devices:

Intelligent devices can have both behaviour and sequencing. From an external view device

programs can be controlled by means of behaviour. From an internal view single programs

could be described as sequences. An example of this combined type is the behaviour of a

robot realized by programs interacting with a PLC as overall cell controller. It is important to

note that this example can be interpreted as both behaviour or sequencing, depending on the

point of view.

Mechatronical Units with:

Project

sequencing

AutomationML Objects with Logic Description

Station

Reference

behavior

Sequencing

sequencing/behavior

Sequencing

Robot

Behavior

Gripper

Behavior

Device

Figure 2: Types of logic descriptions in AutomationML

15

Part 4 - AutomationML Logic Description

AutomationML provides a rich selection of typical models for important phases of the engineering

process and data:

Gantt charts are typically used to define sequences of operations during the first planning phases.

PERT charts are used in a similar way, but can additionally express complex timing conditions of

processes.

Impulse diagrams allow to describe sequences in detail and to introduce real signals and additional

conditions.

State charts are used to describe behaviour of mechatronical units.

SFCs can be used to describe complex sequences with loops and conditional execution; in later

engineering phases SFCs can describe executable PLC programs including mapping to real

control hardware.

The logic description within AutomationML is designed to be extensible for further models.

2.2

Gantt Charts

Gantt charts are a graphical representation of discrete event models typically used to describe the

order and execution time of activities, which are represented as bars, on a high level of abstraction.

They are used within early plant engineering phases to represent the timing of manufacturing

processes.

The main information stored within Gantt charts are start and end times of bars and

predecessor/successor relations among bars. Hence, the main modeling means of Gantt charts are:

bars with start and end point of time as well as duration,

ordering relations representing a predecessor-successor-relation between bars.

Usually Gantt charts enable the modeling of half ordered sets of sequential and concurrent running

activities. Thereby, Gantt charts enable the modeling of an AND divergence and convergence of

control flows. They do not provide modeling means for the modeling of alternatives or cycles.

Gantt charts have no fixed time scale, i.e. it is possible to represent the start and end points of bars

with respect to a global clock but also with respect to several local clocks started by end dates of bars.

Nevertheless, the most used version is the global clock which is also supported by AutomationML.

An example of a Gantt chart is given in Figure 3. It describes the processes of transport of a work

piece and its machining by a robot within a cell.

Sequence 2

Id

Name Prede- Start Dura- End

cessor time tion time

1

Handover to HTR002

2

Move to Lift Position

3

Lift skid

4

Lower skid

5

Move to end of 110HTR002

6

Initialise Robot 1

7 Execute Manufacturing Robot 1

8

Postprocess Robot 1

9

Initialise Robot 2

10 Execute Manufacturing Robot 2

11

Postprocess Robot 2

1

2

7

4

3, 6

7

6

7, 9

10

0

4

7

23

27

0

9

18

6

18

23

4

3

2

4

7

6

9

4

4

5

3

10

15

20

25

30

35

40

4

7

9

27

34

6

18

22

10

23

26

Figure 3: Example of a Gantt chart

2.3

PERT Charts

PERT charts belong to the group of network plans. They are used to describe and analyze temporal

relations of the execution of a set of interdependent nodes. Network plans are applied within early

16

45

50

Part 4 - AutomationML Logic Description

stages of the engineering process to represent the timing and interdependence of manufacturing

processes with an enriched capability for timing description compared to Gantt charts.

The main information stored within PERT charts is:

Nodes with earliest and latest start time point, earliest and latest end time point, duration, as well

as delay

Ordering relations representing a predecessor-successor-relation between nodes

Generally, the ordering relations of network plans permit the following rules for two nodes to be

defined:

1. End-start relation: Node 2 starts after the end of node 1.

2. Start-start relation: Node 2 starts after the start of node 1.

3. Start-end relation: Node 2 ends after the start of node 1.

4. End-end relation: Node 2 ends after the end of node 1.

Since only end-start relations are commonly used in PERT charts, AutomationML supports only this

type of ordering relation.

Usually, PERT charts enable the modeling of concurrent nodes, i.e. the modeling of an AND

divergence and convergence of control flows. As Gantt charts, they do not provide means for the

modeling of alternatives or cycles.

The following figure shows an example of a PERT chart.

0

Handover to HTR002

1

23

12

18

31

18

24

24

30

10

18

23

23

26

Execute Manufacturing

Robot 2

24

31

27

36

36

Postprocess Robot 2

31

34

Move to end of 110HTR002

22

12

24

26

Postprocess Robot 1

12

4

Lower skid

Initialse Robot 2

18

2

Lift Skid

Execute Manufacturing

Robot 1

Initialse Robot 1

4

Move to Lift Position

35

Figure 4: Example of a PERT chart

17

45

Part 4 - AutomationML Logic Description

2.4

Impulse Diagrams

Impulse diagrams are used to describe the temporal course of states of system components together

with signals among them to activate state changes. To describe the value sequences and relations of

signals over time, a global timescale or internal clocks of the components can be used.

Some conventions are made for the naming of modeling elements of Impulse diagrams as illustrated

in Figure 5:

An object within the diagram representing a signal or state of an mechatronical unit with different

possible values will be named a resource. In the Impulse diagram each resource will be

represented by a set of rows indicating possible states of the resource.

Resources can be organized within groups representing hierarchies of mechatronical unit.

A resource can attain resource states, e.g. indicating different discrete values of an associated real

I/O signal or variable. Changes of the state of resource are named resource state changes.

A sequence of resource states and resource state changes in the diagram is named a resource

state flow. Remaining in a resource state is indicated by horizontal line; resource state changes are

visualized by lines connecting the predecessing and successing resource state.

Signals in the Impulse diagram are links between resource state flows representing

dependencies. When entering a new resource state, signals can trigger state changes of another

resource (internal signal). Resources can also fire internal signals when leaving states after a given

duration.

The timeline within an Impulse diagram represents a time scale with discrete points in time that is

used globally within the system. At any point in time, signals can be fired from the timeline (external

signal).

Timeline

State

Resource

Resource

Pos1

Device 1

10

Resource State Flow

Resource

State

Pos2

Pos3

High

Device 2

Signal

Low

Resource

State Change

Figure 5: Example of an Impulse diagram with naming conventions

Resource

State

Pos1

Resource 1

A

B

10

15

E

E

Pos2

B

Pos3

Pos1

Resource 2

Pos2

Pos1

Resource 3

Pos2

Pos1

Resource 4

&

Pos2

Pos1

Resource 5

Pos2

Figure 6: Signals in Impulse diagrams

18

Part 4 - AutomationML Logic Description

Signals have the following properties and types:

External signals have an origin outside of resource state flows in the diagram; thus, they are not

bound to resource state changes, but may occur at any point in time. They are fired by the timeline.

A special case is a start signal occurring at time point zero (A in Figure 6).

Internal signals result from the end of a resource state change or from leaving a resource state

after a pre-defined duration and may trigger other resource state changes (B in Figure 6).

One signal can trigger several resource state changes of different resources (C in Figure 6).

Resource state changes can depend on more than one signal. These signals are in a logical

relation, but need not occur at the same point in time (D in Figure 6).

Signals resulting of the end of a resource state change can be consumed by the corresponding

resource internally, e.g. to trigger a subsequent resource state change (E in Figure 6).

Resource state changes can also be triggered by the resource internally without signals, e.g. by an

internal clock (F in Figure 6).

Two types of timing information have to be considered and illustrated in Figure 7:

The delay between two subsequent external signals is defined as signal time delay (std)

The duration of a resource state change or a predefined duration within a resource state is defined

as time delay (td)

std

Resource

State

t

Pos1

Device 1

Pos2

td1

td2

td3

tdn

Figure 7: Timing information within Impulse diagrams

Impulse diagrams may contain additional information, which is not considered here:

Names of groups (in a hierarchy),

Names of resource state changes,

Names of signal inputs associated to resource states,

Names of actuator outputs associated to resource states,

Pre-defined durations with respect to the global clock for:

2.5

Remaining within a resource state,

Resource state changes.

Sequential Function Charts

Sequential Function Charts (SFC) are one of the programming languages of IEC 61131-3. They have

been developed to provide means for easy implementation of sequences of operations within a

controlled system.

Therefore, SFCs serve for the representation of state based operation sequences with a variety of

temporal conditions to control the operation execution timing and provide basic rules for the

development of control programs.

The main but not exhaustive modeling means of SFCs are:

Steps represent stable situations within the system enabling the execution of operations.

Transitions represent the condition-based change between steps.

19

Part 4 - AutomationML Logic Description

Actions represent the execution of operations. They can be associated to one or more than one

step grouped within action blocks. Actions may have timing conditions controlling the time point

and duration of execution of the covered operations.

Convergences and divergences represent the selective or parallel threading of the control flow

within a SFC.

Jump steps represent timeless hops to defined steps.

Timing conditions represent temporal conditions of actions related to the activity of steps. Thereby

it is possible to execute an activity:

o

as long as the step it belongs to is active

as long until it is directly switched of

for a certain amount of time

after a certain amount of time

An example of an SFC is depicted in Figure 8.

20

Part 4 - AutomationML Logic Description

S1

A1

T1

S2

Step

D

17

D

20

A2

A3

Activity

T2

Simultaneous Divergence

S3

L

25

A4

S4

SL

15

SL

10

SD

5

SD

0

LatestEnd._A5

EarliestEnd._A5

LatestStart._A5

A5

Selection Divergence

T3

S5

T4

L

10

A6

S6

T5

T6

D

5

L

15

Delay._A7

A7

Selection Convergence

S7

A8

Simultaneous Convergence

T7

S1

Transition

Figure 8: Example of a SFC inT017

IEC 61131-3

2.6

State Charts

S1

A State chart is a discrete event model based on the work of Harel [Harel1988]. They are widely

known as part of the Unified Modeling Language (UML). Usually they are used to describe the

behaviour of a system in terms of its reachable state space. Hence, within the engineering chain of

manufacturing systems they are mostly applied during the design of system components to represent

their uncontrolled behaviour. Within the simulation and verification of controlled systems they typically

serve as counterpart of the controller to close the control loop.

The main modeling elements of State charts are states, transitions, activities, guards and events as

trigger conditions. In addition State charts enable the design of hierarchical and concurrent acting

systems by providing means for the modeling of concurrent sub-states.

21

Part 4 - AutomationML Logic Description

Within AutomationML the following modeling elements and concepts are used:

States representing stable situations within the system enabling or requiring the execution of

operations. Initial state and terminal state are special states.

Actions associated to states representing operations which are executed at the moment of the

state entry, during the duration of the state, or at the moment of state exit.

State transitions representing the control flow over states. Associated guards and events are used

as trigger conditions.

Actions associated to state transitions representing operations made during the state transition.

Note: The AutomationML concept for logic description implements a mechanism for the modelling

of run to completion. This allows to store State charts into the target format PLCopen XML.

Events representing external signals and driving the control flow within the modeled system.

States may contain sub states; these are organized in one or more concurrent State charts. Thus,

State charts can have a state hierarchy.

State transitions may connect states of different levels of the state hierarchy.

History connectors represent the last recent state valid within a State chart. They replace all states

of a State chart region and can be the end point of a state transition but not its beginning.

Condition connectors represent a state transition split expressing a decision between two or more

states depending on its attached events and guards.

An example of a State chart as considered within AutomationML is given in Figure 9.

State 1

Event 4 / [Guard 5]

H

Event 4 / [Guard 4]

State 2

State 1.1

State 1.3

Event 2

[Guard 6.1]

Event 2

Event 1 / [Guard 1]

State 1.2

C

Event 5

Event 3 / [Guard 3]

Guard 2 / Activity 1

State 1.3

[Guard 6.2]

Event 6

[Guard 6]

State 3

Entrance Activity 2

Activity 3

Exit Activity 4

Figure 9: Example simple State chart

AutomationML does not provide mechanisms to evaluate State charts but only a data exchange

format for logic data expressed by State charts. Nevertheless, AutomationML will enable the mapping

of behaviour relevant information which is not coded within the structure of State charts.

AutomationML will consider therefore the following information:

State internal charts can be distinguished with respect to its level of execution completeness at the

moment of chart drop out. It is possible to define that a chart can be left only if its execution has

reached a terminal state.

22

Part 4 - AutomationML Logic Description

3

The Intermediate Modeling Layer

3.1

Overview

The purpose of the Intermediate Modeling Layer (IML) is to decouple the target format PLCopen XML

from various input and output data formats. It is quite comparable to SFCs of the IEC 61131-3, but

extended to support further models and diagrams. The IML shall be used for the description of

sequencing and behaviour of different elements and not for further information like interlocking

information.

An IML system consists of elements with their properties and relations, and rules for the definition of

valid IML models as depicted in Figure 10.

Jump j

j.Pre

j.ID

j.Pre

j.State

SimultaneousDivergence simDiv

j.Pre

simDiv.ID

State s

Activity a

a.ID

a.Name

a.Init

a.Current

a.Terminal

a.Time

a.Formula

a.Pre

s.Pre

s.ID

s.Name

s.Init

s.Current

s.Terminal

simDiv.Pre

SelectionConvergence selCon

s.Pre

selCon.ID

simCon.Pre

selDiv.Pre

SelectionDivergence selDiv

s.Pre

a.FiredEvents

st.Pre

st.Guard. StateTransition st

ConsumedEvents

st.ID

st.Name

st.Guard

st.Pre

st.Pre

simCon.Pre

simDiv.ID

SimultaneousConvergence simCon

simCon.ID

st.Guard.Boolean

Variable var

Event ev

ev.Name

var.ID

var.Name

var.Type

Var.Content

var.SIUnit

var.InitialValue

var.Address

Comment com

com.Content

All entities

com.Pre

h.Members

Header h

h.ID

h.Name

ad.Pre

addData ad

ad.ID

ad.Type

ad.Name

Figure 10: IML system entities and its relations

An example of an IML system with all IML elements is depicted in Figure 11; its mapping to PLCopen

XML is described in Annex A in detail.

23

Part 4 - AutomationML Logic Description

InitialInitial

StateState

ID= ISID_20090303_001,

Init=TRUE, Current=FALSE,

Terminal =FALSE

Transition 1

ID= ISID_20090303_002,

Guard.Var=a,[2;17],

Event

Variable

ID=ISID_20090303_013

Name=e

ID= ISID_20090303_011,

Name=b, Type=Boolean,

InitialValue=FALSE

Variable

Variable

ID= ISID_20090303_010,

Name=a, Type=Int,

InitialValue=9

ID= ISID_20090303_012,

Name=c, Type=Boolean,

InitialValue=TRUE

Intermediate State

Action 1

ID= ISID_20090303_003,

Init=FALSE, Current=TRUE,

Terminal =FALSE

ID= ISID_20090303_008, Init=FALSE,

Current=TRUE, Terminal =FALSE,

Formula=[a=TRUE], FiredEvent={e},

Time.Duration=12, Time.Delay=6,

SelectionDivergence

Transition 2

ID= ISID_20090303_004,

Guard.Boolean=b,

ConsumedEvents={e}

ID= ISID_20090303_009

Transition 3

ID=

ISID_20090303_006,

Guard.Boolean=c,

ConsumedEvents={e}

Terminal State

JumpInitialState

ID= ISID_20090303_005, Init=

FALSE, Current=FALSE,

Terminal = TRUE

ID= ISID_20090303_007,

State=InitialState

Figure 11: Example of an SFC in IML

The following sections cover the description of abstract IML elements. These elements represent the

main categories usually exploited within logic models.

These IML elements and their meaning in AutomationML are defined in the second section of this