Professional Documents

Culture Documents

00-Final Report MRT CP1106 Jakarta-Executive Summary

Uploaded by

WulanPutriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

00-Final Report MRT CP1106 Jakarta-Executive Summary

Uploaded by

WulanPutriCopyright:

Available Formats

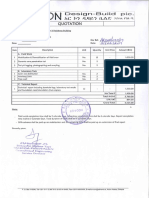

SMCC

- HK JO

SOIL INVESTIGATION REPORT

F O R

CONTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT

(UNDERGROUND SECTION CP-106)

SOIL DATA FOR CP - 106

1. DUKUH ATAS STATION

2. TUNNEL SECTION

3. BUNDERAN HI

SEPTEMBER 2013

SOIL INVESTIGATION REPORT

FOR

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT

UNDERGROUND SECTION - CP106

TABLE OF CONTENT

1.0 INTRODUCTION

1.1

Project Content

2.0 SOIL INVESTIGATION WORK

2.1

Location of Boreholes

2.2

Exploratory Drilling

2.3

Standard Penetration Test

2.4

Undisturbed Soil Sampling

2.5

Pressuremeter (LLT) Test

2.6

Insitu Permeability Test

12

2.7

Seismic Downhole Test

12

2.8

Laboratory Tests

18

APPENDIX

A.1 DUKUH ATAS STATION

Field Test Results

-- Cross Sectional Profiles

-- Log of Borings

-- Photographs of Core Samples

-- Pressuremeter (LLT) Test

-- Casagrande and Permeability Test

-- Downhole Seismic Test

Laboratory Test Results

-- Summary of Test

-- Grain Size Distribution

-- Unconfined Compression Test

A.1 TUNNEL SECTION

Field Test Results

-- Cross Sectional Profiles

-- Log of Borings

-- Photographs of Core Samples

-- Pressuremeter (LLT) Test

-- Casagrande and Permeability Test

-- Downhole Seismic Test

Laboratory Test Results

-- Summary of Test

-- Grain Size Distribution

-- Unconfined Compression Test

A.1 BUNDERAN HI STATION

Field Test Results

-- Cross Sectional Profiles

-- Log of Borings

-- Photographs of Core Samples

-- Pressuremeter (LLT) Test

-- Casagrande and Permeability Test

-- Downhole Seismic Test

Laboratory Test Results

-- Summary of Test

-- Grain Size Distribution

-- Unconfined Compression Test

-- Consolidation Test

APPENDIX

B EQUIPMENT AND METHOD USED IN THIS INVESTIGATION

-- Exploratory Drilling Machine

-- Undisturbed Sampling

-- Standard Penetration Test

-- Pressuremeter Test

-- Downhole Seismic Test

-- Permeability Test

ii

Soil Investigation Report

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

SOIL INVESTIGATION REPORT

FOR

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT

UNDERGROUND SECTION - CP106

1.0 INTRODUCTION

The purpose of this soil investigation work is to obtain subsurface of the deeper soil layers, in

particular at the underground section of CP106 which includes the Dukuh Atas,

Bunderan HI

Stations, and the tunnel section between the two stations.

The Soil Investigation includes drilling at eighteen locations and performing in-situ lateral Load Tests

(LLT), Standard Penetration Test, undisturbed sampling, Downhole seismic Logging Test, and

performing permeability tests in the sand layers

The recovered

undisturbed soil samples were tested in the

laboratory for their index and

mechanical properties .

This report presents all data of the soil investigation

1.1 PROJECT CONTENT

Following are the features of this soil investigation work:

a. Name of Project

: Soil Investigation at MRT Underground Section CP106

at Stations :Dukuh Atas and Bunderan HI and part of tunne between

the above stations.

c. Main Contractor

: SMCC - HK JO

d. Geotechnical Contractor

: P.T. SOFOCO (Soil & Foundation Engineering Corporation)

e. Scope of work

I Field Work

Wash-boring at 19 boreholes to 25m ~60m depth

Core Drilling at 3 boreholes to 17 ~ 36m depth

Standard Penetration Test

561 nos

Cone Penetratio test

4 nos

Downhole Seismic Logging Test .

3 nos

Undisturbed Thin Walled Sampling

121 nos

Pressuremeter Test

46 nos

In Situ Permeability Test

7nos

II Laboratory tests on undisturbed samples

Index properties : Sieve Analysis, Liquid and

Plastic Limits, Moisture Content , Bulk and

Dry Density, Void Ratio , Wet Unit Weight

Uniaxial Unconfined Compression (Uc) Test

Consolidation Test

Chemical Test

121 nos

104 nos

5 nos

12 nos

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

2. SOIL INVESTIGATION WORK

The soil investigation work consists of 19 boreholes that were carried out along the proposed

underground railway track at the Dukuh Atas to the proposed BUnderan HI station

Figure 1.1 Location Map of Boreholes at Dukuh Atas Station

Figure 1.2 Location Map of Boreholes at Bunderan HI Station - 1

Figure 1.2 Location Map of Boreholes at Bunderan HI Station -2

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

The positions of the boreholes and their elevation and chainage is shown in the following Table 1.

Table 1. Location of Boreholes

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Section

DUKUHATAS

STATION

TUNNEL

BUNDERANHI

STATION

BoreholeNo.

106BR1

106BR2

106BR3

106BR4

106BR5

106BR6

106BR7

106BR21REV

106BR21

106BR22

106BR23

106BR11

106BR12

106BR13

106BR14

106BR15

106BR16

106BR17

106BR18

Easting(X)

701663.901

701673.718

701673.718

701682.892

701690.883

701688.912

701664.500

701590.249

701609.420

701620.826

701717.323

701713.173

701673.718

701710.385

701709.215

701707.823

701706.105

701706.944

701705.967

Northing(Y)

9314121.169

9314220.225

9314220.225

9314263.773

9314314.892

9314176.912

9314187.508

9313453.243

9313583.387

9313839.795

9314816.887

9315025.132

9314220.225

9315136.459

9315201.035

9315255.609

9315368.927

9315427.511

9315398.24

Elevation

6.198

4.464

4.766

4.6

4.586

9.387

4.632

11.188

10.854

10.831

4.471

4.86

4.766

4.688

4.576

4.514

4.565

3.632

3.918

2.2 Exploratory Drilling

Four rotary-type drilling machines were mobilized to perform the exploratory drilling at 19 locations.

The boreholes were advanced by rotary core drilling method as described in Appendix C.I.

The diameter of the borehole was 89 mm and the cores are 70mm.

The cores were placed in coreboxes for visual classification and identification of the soils

encountered.

2.3 Standard Penetration Test

The standard penetration tests (SPT) were performed to determine the consistency of the subsoil

and to obtain soil samples for visual description. The tests were carried out at every 1.5 m or 2.0

depth intervals.

The standard Automatic SPT system was used to ensure the free-fall of the SPT hammer with

constant drop energy. The drilling logs in Appendix A display the SPT N-values, i.e., the blow counts

required to penetrate the SPT split spoon sampler into the soil for the last 30cm penetration.

Appendix C.2 describes the method of the test.The result of the borehole drilling and tests are

describes in soil boring profiles, and is shown in Appendix A1. and to obtain an overall view of the

soil layers, is presented in crossectional profiles as is shown in figure 2.1 to 2.5

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Figure 2.1 Cross-sectional Soil Profile at Dukuh Atas Sstation

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Figure 2.2 Cross-Sectional Soil Profile at Dukuh Atas Station

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Figure 2.3 Cross-sectional Soil Profile at Tunnel Section

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Figure 2.4 Cross-sectional Soil Profile at Bunderan HI Station

7

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Figure 2.5 Cross-sectional Soil Profile at Bunderan HI station

8

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

2.4 Undisturbed Soil Sampling

Undisturbed soil samples were taken from selected boreholes, particularly at the underground

section of the railway line, particularly from borehole locations

Stainless steel thin walled tubes of 75mm diameter and 1000m long tubes were used to recover

cohesive soil samples and for further determination of their physical and engineering properties in

the laboratory.

The equipment and method used for sampling is presented in Appendix C.

In total fifteen undisturbed samples were recovered for further testing of soil in the laboratory.

2.5 Pressuremeter Test

The elastic properties of the soil were determined by means of the Lateral Load Test equipment in

boreholes to determine the elastic properties of the soil, such as the earth pressure at rest, yield and

failure pressure, subgrade soil reaction and elastic modulus.

The test consists of the insertion of a rubber tube probe into the borehole and by inflating the tube

their pressure and corresponding increase of the probe radius are measured.

The tests were performed by allowing two loading cycles. The linear slope of the 2nd loading cycle

was used to determined the stiffness of the soil.

Th eelastic modulus is calculated according to the following equaotion:

E = (1 +) . rm . Km

where :

E = Elastic Deformation Modulus

= Poisson Ratio

rm = radius of borehole

Kmv= Modulus Coefficient of Soil Reaction

( = P/r)

The results of the fourty four tests performed are shown in Appendix A3, and summarized as shown

in the following Table

Table 2. Summary Result of LLT Test

Test

Location

Type of soil

N-SPT

Depth

(meter)

Coefficient of

Soil Reaction

km (MN/m3)

Elastic

Modulus

Es (MN/m2)

BR-1

Soft brown Silty Clay

3.0 ~ 4.0

51.8

2.85

Stiff Brown Clayey Silt

31

8.0 ~ 9.0

368.0

20.92

Hard Brown Sandy-Clayey Silt

19

13.0 ~ 14.0

252.6

140.93

Vey Hard Black Sand

29

18.0 ~ 19.0

302.8

19.11

Very Hard Black Sandy Silt

21

23.5 ~ 24.0

1585

59.61

17

28.0 ~ 29.0

420.8

23.9

25

33.0 ~ 34.0

132.1

8.16

24

38.0 ~ 39.0

666..7

34.23

23

17.0 ~ 18.0

390.0

21.60

24

22.0 ~ 23.0

475.2

26.31

Stiff grayish Brown Clayey Silt

Medium Stiff& brown Sandy

Silt

Very Sift grayish Brown Sandy

Silt

Medium Dense blackish gray

Silty Sand

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Test

Location

Type of soil

N-SPT

Depth

(meter)

Coefficient of

Soil Reaction

km (MN/m3)

Elastic

Modulus

Es (MN/m2)

BR-3

Soft brown Silty Clay

38

5.0 ~ 6.0

156.1

58.68

Stiff Brown Clayey Silt

27

10.0 ~ 11.0

301.25

113.25

Hard Brown Sandy-Clayey Silt

22

15.0 ~ 16.0

465.0

174.8

Vey Hard Black Sand

31

20.0 ~ 21.0

86.63

32.47

Very Hard Black Sandy Silt

41

25.0 ~ 26.0

50.82

19.11

26

30.0 ~ 31.0

281.3

16.3

Stiff grayish Brown Clayey Silt

21

35.0 ~ 36.0

8074.5

30.36

Medium Stiff& brown Sandy

Silt

34

40.0 ~ 41.0

21104.1

79.3

Test

Location

Type of soil

N-SPT

Depth

(meter)

Coefficient of

Soil Reaction

km (MN/m3)

Elastic

Modulus

Es (MN/m2)

BR-4

Soft brown Silty Clay

4.5~ 5.5

34.4

2.52

Stiff Brown Clayey Silt

23

9.0 ~ 10.0

125

8.67

Hard Brown Sandy-Clayey Silt

>50

13.0~ 14.0

21557.1

81.04

Vey Hard Black Sand

23

18.0 ~ 19.0

23,910.1

89.89

Very Hard Black Sandy Silt

>50

23.0 ~ 24.0

6733.1

25.31

26

29.0 ~ 30.0

128.9

7.19

21

33.0 ~ 34.0

7,969.8

28.96

Medium Stiff& Sandy Silt

23

38.0 ~ 39.0

14,031.5

52.75

Test

Location

Type of soil

N-SPT

Depth

(meter)

Coefficient of

Soil Reaction

km (MN/m3)

Elastic

Modulus

Es (MN/m2)

BR-21

Soft brown Silty Clay

7.5 ~ 8.5

119.2

6.53

Stiff grayish Brown Clayey Silt

Stiff Brown Clayey Silt

12.5 ~ 13.5

Hard Brown Sandy-Clayey Silt

21

16.0~ 17.0

171.4

9.59

Very Hard Black Sandy Silt

23

21.5 ~ 22.5

37,314.5

140.28

BR-23

Dark Grey Fine Sand

30

16.0 ~ 17.0

263.2

16.9

Test

Location

Type of soil

N-SPT

Depth

(meter)

Coefficient of

Soil Reaction

km (MN/m3)

Elastic

Modulus

Es(MN/m2)

BR-11

Soft brown Silty Clay

2.5 ~ 3.5

56.7

3.30

Stiff Brown Sity Clay

19

7.5 ~ 8.5

81.1

4.74

Hard Brown Sandy-Cemented Silt

37

12.5 ~ 13.5

100.0

6.60

Hard Brown Clayay SILT

35

17.5 ~ 18.5

450

25.94

Hard BlackSilty Clay

15

22.5 ~ 23.5

61.7

3.65

Hard BlackSilty Clay

16

27.5 ~ 28.5

233.3

13.60

10

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

N-SPT

Depth

(meter)

Coefficient of

Soil Reaction

km (MN/m3)

Elastic

Modulus

Es(MN/m2)

Soft brown Yellowish Silty Clay

4.0 ~ 5.0

42.0

2.54

Medium Stiff Clayey Silt

18

9.0~ 10.0

337.5

16.88

Hard grey Sandy-Clayey Silt

44

14.0 ~ 15.0

350

20.30

Vey Hard Black Sand

31

19.0~ 20.0

450

25.94

Very Stiff Dark Grey Silty Clay

16

24.0 ~ 25.0

16825.2

59.24

Very Stiff Dark Grey Silty Clay

18

27.8 ~ 28.8

8854.9

31.18

V. Loose Clayey Sand

4.0 ~ 5.0

28.0

1.74

Soft Black & Brown Clay

11

9.0~ 10.0

63.7

4.49

Black Silty Cay trace Organic

14.0 ~ 15.0

32.5

2.13

Medium stiff Grey Sity Clay

19.0~ 20.0

148.9

11.47

Stiff grey Brwn Sity clay

11

25.0 ~ 26.0

54.2

4.74

Very Stiff Brown Yellowish Silty

Clay

23

29.0 ~ 30.8

12061.6

42.47

Type of soil

Test

Location

BR-15

BR-17

2.6 Insitu Permeability Test

In situ permeability tests have been performed in selected boreholes at the f tunnel location.

The test consist of inserting a steel casing to the designated depth where sand is encountered, and

after sealing the casing from possible infiltration of surface water into the borehole, then drilling at

inside the casing is performed until reaching approximately 1.0m below the bottom of casing and to

form a un-cased cylindrical shaft cavity and to enable to measure the lateral water flow.

The method used for measuring the soil permeability is by means of the falling head method.

After firstly measuring the initial level of the ground water table, then the casing is filled with water

until reaching the top of the casing pipe. The water drop-down is measured at certain time

intervals until reaching the stable or up to the first initial water level.

By tabulating, calculation and graph, the soil permeability can be determined, and the results are

shown in Appendix A.

A summary of the insitu permeability tests is shown in Table 3 below.

Test Location

Table 3 Soil Permeability by Falling Head in Sand Layer

Permeability

Type of soil

Depth

(meter)

cm/second

meter/day

BR21

v. dense Sand

21 ~ 22.0

2.62 x 10

-4

BR22

v. dense Sand

21.50

2.62 x 10

-4

BR2-Rev

v. dense Sand

16.00

5.72 x 10-5

4.95x 10-2

2.415x 10-1

8.344x 10

BR23

v. dense Sand

18.50

2.49 x 10

-4

BR15

v. dense Sand

19.00

9.66 x 10

-5

BR16

v. dense Sand

15.00

7.27 x 10-6

BR17

v. dense Sand

32.50

2.97 x 10

11

-6

-1

2.27 x 10

2.267x 10

-1

-2

6.28x 10-3

2.566x 10

-3

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

2.6 Seismic Downhole Test

In situ seismic downhole tests have been performed in three boreholes and at each Dukuh Atas

station (at BR 3), at the Tunnel Section at ( BR 15) and ( BR21),

The test consist of inserting a steel casing to the designated depth where sand is encountered, and

after sealing the casing from possible infiltration of surface water into the borehole, then drilling at

Table 4a MECHANICAL PARAMETER S FROM DOWNHOLE SEISMIC TEST AT T BOREHOLE: BR-03

*)

Poisson

Ratio

Dynamic

Shear

Modulus

(Mpa)

Dynamic

Young

Modulus

(Mpa)

Dynamic

Bulk Modulus

(Mpa)

Depth

(m)

Vp

(m/s)

Vs

(m/s)

Density

(Ton/m3)

326.1

164.8

1.72

0.328

46.7

124.2

120.6

347.5

163.8

1.72

0.357

46.2

125.3

146.1

438.4

151.5

1.72

0.432

39.5

113.1

277.9

428.0

153.1

1.72

0.427

40.3

115.1

261.3

1504.5

165.4

1.72

0.494

47.0

140.6

3,830.6

1487.7

232.4

1.72

0.487

92.9

276.3

3,683.0

1787.9

317.2

1.72

0.484

173.1

513.6

5,267.5

1868.2

352.7

1.53

0.482

190.4

564.1

5,086.0

2143.7

354.8

1.53

0.486

192.6

572.3

6,774.1

2371.2

336.3

1.53

0.490

173.1

515.7

8,371.4

10

2051.9

346.1

1.53

0.485

183.3

544.6

6,197.1

11

2137.8

341.8

1.53

0.487

178.8

531.7

6,754.1

12

2204.2

325.1

1.63

0.489

172.2

512.8

7,689.8

13

1849.4

308.6

1.63

0.486

155.2

461.2

5,367.8

14

1874.1

310.7

1.63

0.486

157.4

467.6

5,515.2

15

1893.7

278.3

1.63

0.489

126.3

376.0

5,676.8

16

1909.3

264.7

1.63

0.490

114.2

340.4

5,789.9

17

1922.0

258.6

1.63

0.491

109.0

325.0

5,875.9

18

1932.3

259.1

1.63

0.491

109.4

326.3

5,940.3

19

1940.8

259.5

1.63

0.491

109.8

327.4

5,993.7

20

1948.0

259.9

1.63

0.491

110.1

328.3

6,038.3

21

1953.9

253.7

1.63

0.491

104.9

312.8

6,083.1

22

1959.0

290.4

1.70

0.489

143.4

427.0

6,332.6

23

1963.3

290.8

1.70

0.489

143.7

428.0

6,360.8

24

2444.0

340.2

1.70

0.490

196.8

586.4

9,891.6

25

2449.6

340.6

1.70

0.490

197.3

587.9

9,937.8

26

2454.5

341.0

1.70

0.490

197.7

589.2

9,977.9

27

1975.9

291.8

1.75

0.489

149.0

443.8

6,633.4

28

1977.9

248.7

1.75

0.492

108.2

322.9

6,702.1

29

1979.8

242.8

1.75

0.492

103.1

307.8

6,721.5

30

1981.4

242.8

1.75

0.492

103.2

308.0

6,732.6

12

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Dynamic

Shear

Modulus

(Mpa)

Dynamic

Young

Modulus

(Mpa)

Dynamic

Bulk

Modulus

(Mpa)

0.493

98.4

293.9

6,748.9

1.75

0.493

94.0

280.6

6,763.7

243.0

1.75

0.492

103.3

308.4

6,759.2

1986.3

255.4

1.75

0.492

114.2

340.6

6,751.9

35

1987.2

262.1

1.75

0.491

120.3

358.6

6,750.2

36

2479.2

331.5

1.75

0.491

192.3

573.4

10,499.8

37

2480.6

342.9

1.51

0.490

177.6

529.3

9,054.9

38

2481.9

343.1

1.51

0.490

177.7

529.7

9,064.3

39

2483.1

355.3

1.51

0.490

190.6

567.9

9,055.8

40

2484.1

355.4

1.51

0.490

190.8

568.3

9,063.6

41

1991.5

343.4

1.51

0.485

178.0

528.6

5,751.4

42

1992.0

332.1

1.60

0.486

176.4

524.2

6,113.5

43

1992.4

321.5

1.60

0.487

165.4

491.6

6,131.0

44

1992.8

321.5

1.60

0.487

165.4

491.8

6,133.5

45

1993.2

321.6

1.60

0.487

165.5

492.0

6,135.7

46

1993.5

355.9

1.60

0.484

202.7

601.3

6,088.3

47

1993.8

356.0

1.70

0.484

215.4

639.1

6,470.9

48

1994.1

356.0

1.70

0.484

215.5

639.3

6,472.8

49

1994.4

343.9

1.70

0.485

201.0

596.8

6,494.0

50

1994.7

332.5

1.70

0.486

187.9

558.4

6,513.2

51

1994.9

302.4

1.70

0.488

155.5

462.7

6,558.1

52

1995.1

293.6

1.70

0.489

146.5

436.3

6,571.5

53

1995.3

277.3

1.70

0.490

130.8

389.7

6,594.0

54

2492.1

277.3

1.70

0.494

130.8

390.7

10,383.3

55

2492.4

369.5

1.70

0.489

232.0

690.9

10,251.3

56

2492.8

369.5

1.70

0.489

232.1

691.1

10,254.1

57

2493.1

369.5

1.70

0.489

232.1

691.2

10,256.7

58

2493.4

369.6

1.70

0.489

232.2

691.3

10,259.1

59

2493.6

369.6

1.70

0.489

232.2

691.4

10,261.4

2493.9

369.6

1.70

0.489

232.3

691.6

10,263.6

*)

Depth

(m)

Vp

(m/s)

Vs

(m/s)

Density

(Ton/m3)

31

1982.8

237.2

1.75

32

1984.1

231.7

33

1985.2

34

60

Poisson

Ratio

*) From laboratory test samples

13

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 4b MECHANICAL PARAMETER S FROM DOWNHOLE SEISMIC TEST AT T BOREHOLE: BR-15

Depth

(m)

Vp

(m/s)

Vs

(m/s)

Density*)

3

(Ton/m )

Poisson

Ratio

Dynamic

Shear

Modulus

(Mpa)

Dynamic

Young

Modulus

(Mpa)

Dynamic

Bulk

Modulus

(Mpa)

294.1

136.4

1.50

0.363

27.9

76.0

92.6

310.0

143.7

1.50

0.363

31.0

84.5

102.9

393.2

134.0

1.50

0.434

26.9

77.2

196.0

767.9

186.0

1.50

0.469

51.9

152.4

815.4

855.5

172.4

1.50

0.479

44.6

131.8

1,038.3

979.5

120.9

1.50

0.492

21.9

65.4

1,409.9

897.3

141.0

1.50

0.487

29.8

88.7

1,168.0

897.7

140.7

1.50

0.487

29.7

88.4

1,169.2

945.6

141.3

1.53

0.489

30.5

90.9

1,327.4

1834.8

176.7

1.53

0.495

47.7

142.8

5,087.1

10

1963.5

212.6

1.53

0.494

69.1

206.6

5,806.3

11

2064.3

259.7

1.53

0.492

103.2

307.8

6,382.5

12

2143.2

368.3

1.53

0.485

207.6

616.3

6,751.2

13

2205.1

376.8

1.64

0.485

232.8

691.4

7,664.3

14

1846.9

369.5

1.64

0.479

223.9

662.5

5,295.8

15

1871.0

374.3

1.64

0.479

229.8

679.8

5,434.9

16

1890.3

378.2

1.64

0.479

234.5

693.8

5,547.4

17

1905.9

321.0

1.64

0.485

169.0

502.0

5,731.7

18

1918.6

322.6

1.64

0.485

170.7

507.1

5,809.2

19

1929.1

324.0

1.64

0.485

172.1

511.4

5,873.4

20

1937.8

325.1

1.64

0.486

173.3

514.9

5,927.0

21

1945.1

326.0

1.64

0.486

174.3

517.9

5,972.1

22

1951.2

230.0

1.64

0.493

86.8

259.0

6,128.2

23

1956.5

230.2

1.64

0.493

86.9

259.6

6,161.6

24

1641.5

247.4

1.64

0.488

100.4

298.8

4,285.4

25

1643.9

241.7

1.64

0.489

95.8

285.2

4,304.3

Continue to next page

14

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Dynamic

Young

Modulus

(Mpa)

Dynamic

Bulk

Modulus

(Mpa)

102.4

304.8

4,604.7

0.490

89.2

265.8

4,632.8

1.75

0.490

93.4

278.3

4,636.3

225.9

1.75

0.490

89.3

266.3

4,649.8

1652.0

226.0

1.75

0.490

89.4

266.5

4,657.0

31

1653.2

254.8

1.75

0.488

113.6

338.0

4,631.1

32

1654.1

254.9

1.75

0.488

113.7

338.3

4,636.7

33

1655.0

255.0

1.75

0.488

113.8

338.6

4,641.8

34

1655.8

261.7

1.75

0.487

119.9

356.6

4,638.3

35

1656.6

261.8

1.60

0.487

109.7

326.3

4,244.4

36

1657.2

255.2

1.60

0.488

104.2

310.2

4,255.2

37

1657.8

262.0

1.60

0.487

109.8

326.6

4,250.9

38

1658.4

292.6

1.60

0.484

137.0

406.6

4,217.5

39

2478.8

301.5

1.60

0.492

145.5

434.2

9,637.3

40

2480.2

355.0

1.60

0.490

201.6

600.7

9,573.3

41

2481.4

355.1

1.60

0.490

201.8

601.1

9,583.0

42

2482.6

355.2

1.60

0.490

201.9

601.5

9,591.9

43

2483.6

355.4

1.60

0.490

202.0

601.9

9,600.0

44

2484.6

343.3

1.60

0.490

188.5

562.0

9,625.6

45

2485.5

332.0

1.70

0.491

187.4

558.7

10,251.9

46

2486.3

321.4

1.70

0.492

175.6

523.9

10,274.4

47

1992.5

311.5

1.70

0.487

164.9

490.7

6,529.1

48

1992.9

311.5

1.70

0.487

165.0

490.8

6,531.6

49

1993.2

302.2

1.70

0.488

155.2

462.0

6,547.0

50

1993.5

293.4

1.70

0.489

146.3

435.7

6,561.1

*)

Poisson

Ratio

Depth

(m)

Vp

(m/s)

Vs

(m/s)

Density

(Ton/m3)

26

1646.0

241.9

1.75

0.489

27

1647.8

225.7

1.75

28

1649.4

231.0

29

1650.8

30

*) From laboratory test samples

15

Dynamic

Shear

Modulus

(Mpa)

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 4c MECHANICAL PARAMETER S FROM DOWNHOLE SEISMIC TEST AT T BOREHOLE: BR-21

Depth

(m)

Vp

(m/s)

Vs

(m/s)

Density*)

3

(Ton/m )

Poisson

Ratio

Dynamic

Shear

Modulus

(Mpa)

Dynamic

Young

Modulus

(Mpa)

Dynamic

Bulk

Modulus

(Mpa)

361.4

100.0

1.53

0.459

15.3

44.6

179.5

340.0

100.4

1.53

0.452

15.4

44.8

156.3

353.6

149.7

1.53

0.391

34.3

95.4

145.6

728.4

161.3

1.53

0.474

39.8

117.4

758.6

794.8

167.8

1.53

0.477

43.1

127.2

909.0

646.4

166.3

1.53

0.465

42.3

123.9

583.0

708.1

187.1

1.53

0.462

53.5

156.6

695.7

754.7

159.8

1.53

0.477

39.1

115.4

819.4

734.9

161.2

1.53

0.475

39.7

117.2

773.3

704.9

129.6

1.53

0.483

25.7

76.2

726.0

10

903.5

153.4

1.53

0.485

36.0

106.9

1,200.9

11

921.8

154.7

1.53

0.486

36.6

108.7

1,251.4

12

1286.1

160.5

1.53

0.492

39.4

117.6

2,478.2

13

1311.0

273.1

1.63

0.477

121.6

359.3

2,639.2

14

1330.4

276.6

1.63

0.477

124.7

368.4

2,718.7

15

1345.7

251.7

1.63

0.482

103.3

306.1

2,814.3

16

1358.0

273.8

1.63

0.479

122.2

361.4

2,843.2

17

1368.0

275.4

1.63

0.479

123.7

365.8

2,885.3

18

1376.1

269.4

1.63

0.480

118.3

350.3

2,928.7

19

1382.8

270.5

1.63

0.480

119.2

353.0

2,957.6

20

1388.3

278.8

1.63

0.479

126.7

374.8

2,972.7

21

1393.0

279.6

1.63

0.479

127.4

376.9

2,992.9

22

1931.6

288.3

1.70

0.489

141.3

420.6

6,154.7

23

1939.2

297.4

1.70

0.488

150.4

447.4

6,192.5

24

1945.7

327.0

1.70

0.485

181.7

539.9

6,193.4

25

1951.3

350.4

1.70

0.483

208.7

619.2

6,194.3

26

1956.1

328.1

1.70

0.486

183.1

543.9

6,260.4

27

1960.2

328.6

1.70

0.486

183.6

545.4

6,287.6

28

1963.9

260.8

1.60

0.491

108.8

324.5

6,025.9

29

1967.1

340.5

1.60

0.485

185.5

550.8

5,943.7

30

1969.9

300.2

1.60

0.488

144.1

429.0

6,016.6

16

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

2.7 Laboratory Tests

The following laboratory tests were conducted for all the undisturbed soil samples and selected SPT

samples:

Index Property Tests

Unit weight

Specific gravity

Natural water content

Atterberg limits (liquid and plastic limits)

Grain size analysis

Mechanical Property Tests

Unconfined Compression Test

Unconsolidated-Undrained (UU) Triaxial Compression Test

__ Consolidation Test

The soil samples that have been recovered from the boreholes, were tested in the laboratory in

order to obtain their index as well their engineering properties. The results are tabulated as shown

in the Appendix. A summary of the soil index properties results of each borehole is presented

below:

17

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 5.a Summary of Laboratory Test Results at Dukuh Atas Station

18

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 5.b Summary of Laboratory Test Results at Dukuh Atas Station

19

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 5.c Summary of Laboratory Test Results at Dukuh Atas Station

20

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 5.d Summary of Laboratory Test Results at Tunnel Section

21

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 5.e Summary of Laboratory Test Results at Tunnel Section

22

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 5.f Summary of Laboratory Test Results at Bunderan HI Station

23

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 5.g Summary of Laboratory Test Results at Bunderan HI Station

24

SOIL INVESTIGATION REPORT

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Table 5.h Summary of Laboratory Test Results at Bunderan HI Station

25

Soil Investigation Report

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

APPENDIX C

23

Soil Investigation Report

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

APPENDIX C.1

EXPLORATORY DRILLING

The boreholes were drilled using rotary type drilling rig. Figure B.I.I shows the general set-up of a

rotary drilling rig. The diameter of the boreholes in the present study was 89mm. Flush-jointed

casing pipes that suit the desired borehole diameter were installed to prevent the borehole wall from

collapsing and to maintain a clean hole.

24

Soil Investigation Report

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Core boring is one of the drilling method to advance the exploratory boreholes. In core boring

method, a single barrel with a crown bit is lowered to the bottom of the borehole by drill rods. The

borehole is advanced by rotating the core barrel with gentle thrust actions and, at the same time,

muddy water is pumped through the drilling bit to flush out the soil cuttings. The mud-water also

serves as the coolant for the drill bit and helps to stabilize the borehole from collapsing or caving in.

When the drilling reaches to the anticipated depth for undisturbed sampling or other in-situ tests, the

core barrel is withdrawn from the borehole and to recover the soil samples that have been retained

in the barrel.

Flush joint casing pipes that suit the desired borehole diameter were commonly installed to prevent

the borehole wall from collapsing and to maintain a clean hole. If the borehole is sunk in soil layers

having high potential of collapsing, casing pipes have to be installed immediately after the advance

of the borehole to about 0.5m above the bottom of the borehole. In stable soil layers, casing pipes

are usually installed in upper weak ground only to prevent necking of the borehole and serve as

guide pipe. Thick bentonite slurry is sometimes used as drilling fluid which can be effectively

stabilizing the borehole without the use of casing pipes.

25

Soil Investigation Report

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

APPENDIX C.2

UNDISTURBED SAMPLING

a. Open-drive Sampling Method

Open-drive sampling method is normally used to obtain soft to medium stiff cohesive soils. The

sampler consists of a thin wall tube attached to a sampler head, as shown in Figure A.1

The sampler head is equipped with a ball valve which allows water or air above the sample to

freely escape when the tube is driven into the soil. The ball valve closes the air passage and helps

retaining the sample when the sampler is pulled out from the ground. Figure B.3.2 illustrates the

sampling mechanism.

To obtain an undisturbed soil sample, a clean open borehole is drilled to the desire sampling

depth. Before the sampling operation, the borehole is carefully cleaned to the sampling depth and

the sampler is then lowered to the bottom of the borehole.

In sampling operation, the thin wall tube is pushed into the ground by mechanical jacking or driven

by SPT hammer. After the thin wall tube penetrates to the soil approximately 80% of the tube

length, it is left for a few minutes for the recovery of the adhesion between the soil sample with the

tube wall. Finally, the sampler is pulled out of the borehole. Both ends of the thin wall tube are

sealed with paraffin wax immediately after the tube is separated from the sampler head.

Figure A.1 Thin Wall Tube sampler

26

Soil Investigation Report

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

APPENDIX C.3

STANFDARD PENETRATION TEST

The purpose of performing the tests is to determine relative density or consistency of soils and to obtain

soil samples for identification A split barrel sampler of 50mm outer diameter as sown in Figure B 2 1 is

lowered to the bottom of the borehole by drill rods The sampler was then dnven45Qmm in the soil by a

o"3 5 kg automatic and self tripping free fall drive hammer, as shown in Figure B 2 2, over a height of

760mm The first 15mm penetration is regarded as the seating drive, hence the number of blows to achieve

this penetration is not included in the SPT N-value The total cumulative numbers of the blow counts

required for each 75mm of the last 300mm penetration is recorded as the N-value. The recovered soil

samples are kept in plastic jars for soil identification.

Figure A.2 Standard Penetration Sampler

27

Soil Investigation Report

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

Figure A.3. Automatic SPT Trip Hammer

28

Soil Investigation Report

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

APPENDIX C4

PRESSUREMETER TEST

The Pressuremeter Test is an in-situ apparatus to measure the relationship between ground stress

and deformation.

The pressuremeter test was using the LLT (Lateral Load Tester) type M from OYO CorporationJapan.

The apparatus consists of a probe or sonde of 70mm diameter ruber tube that is inflated at the

bottom borehole and the soil is pressurized incrementally and laterally until reaching to a maximum

shear strength where the soil has yielded.

Figure A.4.1 Typical Pressuremeter Apparatus

29

Soil Investigation Report

CONSTRUCTION OF JAKARTA MASS RAPID TRANSIT PROJECT - UNDERGROUND SECTION - CP106

APPENDIX C5

PERMEABILITY TEST

The Permeability Test shall be performed by following the Falling Head Permeability Test

and is in accordance to BS 9530-1981. The procedure of the test is as follows:

Procedure of Test

a. Drill a hole of 76mm diameter to designated depth level for permeability test

b. Install steel casing of 76 diameter into the borehole until designated depth level

c. Drill to inside casing until 1.0m below casing bottom end

d. Clean and flush the borehole by clear water

e. Measure the ground water leveling the borehole

f.

Fill clear water until the top level of casing

g. Measure the water level at elapsed time until the water level is at constant level .

h. The measurement is input in the table and based on the following eqution

permeability is determined

30

the soil

You might also like

- Review Comments Geotechnical Section 7 2,8 20180929Document10 pagesReview Comments Geotechnical Section 7 2,8 20180929Zhao QinglongNo ratings yet

- J2910R1 Factual Report Pakubuwono Menteng PDFDocument175 pagesJ2910R1 Factual Report Pakubuwono Menteng PDFayumarysaNo ratings yet

- Soil Investigation Report & RecomendationsDocument35 pagesSoil Investigation Report & RecomendationsmadhuNo ratings yet

- ZHB042, Soil Report PDFDocument35 pagesZHB042, Soil Report PDFA.K.M Shafiq MondolNo ratings yet

- SOP - Standard Penetration TestDocument5 pagesSOP - Standard Penetration TestGajendra PandeyNo ratings yet

- Pressure Meter TestDocument2 pagesPressure Meter TestPaula Patrisha RoxasNo ratings yet

- Geotech Report For Water PipelineDocument106 pagesGeotech Report For Water PipelineZohair AtaullahNo ratings yet

- Main Report Plot#1494, Street#50, Sector-M, Phase-VIII, Bahria Town RWPDocument11 pagesMain Report Plot#1494, Street#50, Sector-M, Phase-VIII, Bahria Town RWPMian Muhammad Jazib100% (1)

- ZHB037, Soil ReportDocument35 pagesZHB037, Soil ReportA.K.M Shafiq Mondol100% (1)

- Rekayasa Fondasi Dalam: Tiang Pancang Dan Tiang BorDocument38 pagesRekayasa Fondasi Dalam: Tiang Pancang Dan Tiang BorAriq AhmadNo ratings yet

- REPORT Soil Test Sondir Dan BoringDocument10 pagesREPORT Soil Test Sondir Dan BoringRento ChotanNo ratings yet

- Rajiv Geotech InvestigationDocument75 pagesRajiv Geotech Investigationmayank007aggarwalNo ratings yet

- Geotechnical - Investigation - For Bilika PV - Hybrid - Power - PlantDocument20 pagesGeotechnical - Investigation - For Bilika PV - Hybrid - Power - Plantmessay100% (1)

- Laporan Penyelidikan Geoteknik Cirebon PDFDocument213 pagesLaporan Penyelidikan Geoteknik Cirebon PDFHendra SaputraNo ratings yet

- NDTDocument35 pagesNDTningshaNo ratings yet

- Shallow Foundation 1Document48 pagesShallow Foundation 1Nimas Az-zahra SofaNo ratings yet

- Hatanaka, M., and A. Uchida, 1996, Internal Friction Angle of Sandy Soil.Document9 pagesHatanaka, M., and A. Uchida, 1996, Internal Friction Angle of Sandy Soil.Yutong LuNo ratings yet

- Soil Test ReportDocument97 pagesSoil Test ReportMin Min Mit100% (5)

- Soil Test ReportDocument41 pagesSoil Test ReportGul KhanNo ratings yet

- Soil Investigation ReportDocument15 pagesSoil Investigation ReportShallborn PaulNo ratings yet

- Proforma For Geotechnical Inv. Using Test Pit & DCP Tets - G+3 BuildingDocument1 pageProforma For Geotechnical Inv. Using Test Pit & DCP Tets - G+3 BuildingsintayhuNo ratings yet

- Si ReportDocument9 pagesSi Reportnor muhammadNo ratings yet

- Hydraulic ConductivityDocument8 pagesHydraulic ConductivityDara MoralesNo ratings yet

- Calculating Foundation SettlementDocument52 pagesCalculating Foundation SettlementMuhammad Fahmi AnbNo ratings yet

- Lecture - Field Tests and Instuments - 2022Document116 pagesLecture - Field Tests and Instuments - 2022Zanele MbathaNo ratings yet

- Soil Test ReportDocument37 pagesSoil Test ReportSathish kumarNo ratings yet

- Numerical Modelling of Tunis Soft ClayDocument9 pagesNumerical Modelling of Tunis Soft Claykika boubaNo ratings yet

- Geotechnical Assessment Report On Zone-A Settlement (2013!07!08) - Rev.03-1 CorrectionDocument35 pagesGeotechnical Assessment Report On Zone-A Settlement (2013!07!08) - Rev.03-1 CorrectionKesavanMohanadasNo ratings yet

- Foundations On Soft Soils For Khulna MedicalDocument6 pagesFoundations On Soft Soils For Khulna MedicalJahid Jahidul Islam KhanNo ratings yet

- Soil Test Report KhagariaDocument28 pagesSoil Test Report KhagariaSajan SinghNo ratings yet

- GEOTECHNICAL REPORT FOR WORKERS RESIDENTIAL CITYDocument174 pagesGEOTECHNICAL REPORT FOR WORKERS RESIDENTIAL CITYErnest NavarroNo ratings yet

- Subgrade Compaction and Proof Rolling SpecificationsDocument6 pagesSubgrade Compaction and Proof Rolling Specificationsroldski100% (1)

- Laporan Soil Investigation Pertamina PanjangDocument60 pagesLaporan Soil Investigation Pertamina PanjangAlex SudrajatNo ratings yet

- Shoring System (Tie Back Wall) 2DDocument10 pagesShoring System (Tie Back Wall) 2DAndiNo ratings yet

- Session 5 - 6 Bearing Capacity of Shallow Foundation: Course: S0484/Foundation Engineering Year: 2007: 1/0Document41 pagesSession 5 - 6 Bearing Capacity of Shallow Foundation: Course: S0484/Foundation Engineering Year: 2007: 1/0rasputin0780803494No ratings yet

- Geo-technical Report for Proposed BuildingDocument20 pagesGeo-technical Report for Proposed Buildingboddu ramakrishnaNo ratings yet

- Correlation Between Soaked CBR Value and CBR Obtained With DCPDocument8 pagesCorrelation Between Soaked CBR Value and CBR Obtained With DCPIvan MasubaNo ratings yet

- Geotechnical Investigation ReportDocument70 pagesGeotechnical Investigation ReportanishmetaNo ratings yet

- Soil ReportDocument10 pagesSoil ReportRomyMohanNo ratings yet

- Site Investigation of Foundation For NPPDocument21 pagesSite Investigation of Foundation For NPPAdly Al-SaafinNo ratings yet

- Gempa03 Pengukuran GempaDocument55 pagesGempa03 Pengukuran GempaFarid MarufNo ratings yet

- Constant Head Permeability Test Lab ManualDocument3 pagesConstant Head Permeability Test Lab ManualmmNo ratings yet

- Standard Penetration Test Method for Soil SamplingDocument9 pagesStandard Penetration Test Method for Soil SamplingFranco PretellNo ratings yet

- Investigation of The Resistance of Pile Caps To Lateral LoadingDocument322 pagesInvestigation of The Resistance of Pile Caps To Lateral LoadingJorge Luis Gutierrez100% (1)

- Geogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFDocument115 pagesGeogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFChan Hoi KitNo ratings yet

- KM 146+172 To KM 162+620 On Guwahati Bypass (Nh-37)Document34 pagesKM 146+172 To KM 162+620 On Guwahati Bypass (Nh-37)RAJAT SHARMANo ratings yet

- Penentuan Koefiesien GempaDocument45 pagesPenentuan Koefiesien GempaadhiNo ratings yet

- PLAXIS2DCE V21.00 02 Reference 2DDocument576 pagesPLAXIS2DCE V21.00 02 Reference 2DHasnat QureshiNo ratings yet

- Soil CompactionDocument24 pagesSoil Compactionsyah123No ratings yet

- CIV 341: Sand Cone Test for Field DensityDocument14 pagesCIV 341: Sand Cone Test for Field DensityRobert Bui0% (1)

- Remedial Measures To A Building Settlement ProblemDocument5 pagesRemedial Measures To A Building Settlement ProblemEswara PrasadNo ratings yet

- Ce 382 Soil Compaction 1442Document70 pagesCe 382 Soil Compaction 1442Princess Sandoval100% (1)

- Bearing Capacity of Foundation Piles: State of the Art MethodsDocument17 pagesBearing Capacity of Foundation Piles: State of the Art MethodssathishNo ratings yet

- Final Report 00 - 1187-Rev00Document31 pagesFinal Report 00 - 1187-Rev00wafikmh4No ratings yet

- 4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - ParadeepDocument48 pages4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - Paradeepvignesh_freeboterNo ratings yet

- Onyancha - Geological and Geotechnical Conditions of NairobiDocument234 pagesOnyancha - Geological and Geotechnical Conditions of NairobichristopherNo ratings yet

- Soil Investigation ReportDocument511 pagesSoil Investigation ReportPraveen Bhavishyat100% (1)

- Report KhanyarDocument64 pagesReport KhanyarSumaira SyedNo ratings yet

- Pipe Jacking in HKDocument6 pagesPipe Jacking in HKRead Do WanNo ratings yet

- DLN Nofa - K - F - LN : Multi Lab (P) LTDDocument20 pagesDLN Nofa - K - F - LN : Multi Lab (P) LTDRajendra AcharyaNo ratings yet

- Recycle Bin Icon Does Not Refresh Correctly When Using Custom Icons WinhelponlineDocument1 pageRecycle Bin Icon Does Not Refresh Correctly When Using Custom Icons Winhelponlinecharlie_sheens_noseNo ratings yet

- A Friend's MemoryDocument5 pagesA Friend's MemoryRockstar Productions ShubhamNo ratings yet

- My Letterland Reading Booklet PDFDocument42 pagesMy Letterland Reading Booklet PDFVivienne100% (2)

- Add Audacity Soundtrack to SlideshowDocument15 pagesAdd Audacity Soundtrack to SlideshowMarija LuloNo ratings yet

- Acer Travelmate 660 Series: Service GuideDocument114 pagesAcer Travelmate 660 Series: Service GuidescribdermaniacNo ratings yet

- Easy Chinese Recipes PDFDocument151 pagesEasy Chinese Recipes PDFTrafalgar100% (10)

- I. Directions: Give The Two Original Words That Were Combined To Form The Following Blended Words. An Example Given To Help Guide YouDocument1 pageI. Directions: Give The Two Original Words That Were Combined To Form The Following Blended Words. An Example Given To Help Guide YouMarisa LeeNo ratings yet

- QPDocument3 pagesQPlandscapesinthemistNo ratings yet

- Tawara Adventures Newsletter: Uk Centres Family FunDocument2 pagesTawara Adventures Newsletter: Uk Centres Family FunAbril MendezNo ratings yet

- Chef John's Calabrian Chicken RecipeDocument2 pagesChef John's Calabrian Chicken RecipearkcaverNo ratings yet

- Azaadi SongbookDocument4 pagesAzaadi SongbookSanjay Varma100% (1)

- Ejercicios Pasado SimpleDocument2 pagesEjercicios Pasado Simplenuevavida35No ratings yet

- EVD EVO Display Updating Procedure ENDocument4 pagesEVD EVO Display Updating Procedure ENHasaan HussainNo ratings yet

- R HDB 40 2002 Oas PDF eDocument65 pagesR HDB 40 2002 Oas PDF eBao Quoc MaiNo ratings yet

- Workout Routine - Arnold SchwarzeneggerDocument21 pagesWorkout Routine - Arnold SchwarzeneggerW Martin Canales AyalaNo ratings yet

- The Bralette, Perfect Undergarment For Summer: You Can Read More About This Pattern Over at So Sew EasyDocument8 pagesThe Bralette, Perfect Undergarment For Summer: You Can Read More About This Pattern Over at So Sew EasyPamelaNo ratings yet

- International Student Guide to Study and Work PermitsDocument7 pagesInternational Student Guide to Study and Work PermitsBlazing FastNo ratings yet

- Ilok License Manager: - The ManualDocument28 pagesIlok License Manager: - The ManualjavabeanNo ratings yet

- TecladoDocument10 pagesTecladoPedro RodriguezNo ratings yet

- DMS IIT Delhi Dress Code for Corporate EventsDocument3 pagesDMS IIT Delhi Dress Code for Corporate EventsSantu BiswaaNo ratings yet

- MFL69365752 01 PDFDocument292 pagesMFL69365752 01 PDFGeorgescu FlorentinNo ratings yet

- Vedic HymnsDocument54 pagesVedic HymnsAbyssman ManNo ratings yet

- Multi-channel formats in electroacoustic compositionDocument4 pagesMulti-channel formats in electroacoustic compositionNikos StavropoulosNo ratings yet

- A Seminar Presentation On: "5G Wireless Technnology"Document20 pagesA Seminar Presentation On: "5G Wireless Technnology"Rahul prabhaNo ratings yet

- EE339 Sheet 1Document4 pagesEE339 Sheet 1Tenia FebriantiNo ratings yet

- Catalogo CGI EXPORTwines-eDocument9 pagesCatalogo CGI EXPORTwines-eCarlos GrandeNo ratings yet

- Technology in Education Technology Presentation in Blue Peach Illustrative StyleDocument37 pagesTechnology in Education Technology Presentation in Blue Peach Illustrative StyleAngel “Miley” SamileyNo ratings yet

- Lays ChipsDocument2 pagesLays Chipsadnan nurNo ratings yet

- HirePro Video Proctored Assessment System RequirementsDocument1 pageHirePro Video Proctored Assessment System RequirementsKrishna RockNo ratings yet

- Important message about deactivated Amazon seller accountDocument1 pageImportant message about deactivated Amazon seller accountMuhmmad UmairNo ratings yet