Professional Documents

Culture Documents

Profis Anchor Calculation for Three-storey Building

Uploaded by

antonioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Profis Anchor Calculation for Three-storey Building

Uploaded by

antonioCopyright:

Available Formats

Profis Anchor 2.5.

www.hilti.com.ph

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Engr. Antonio Lanya

Quezon City

0928-83320628 |

antoniolanya@ymail.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

Three-storey Building

5/22/2015

Specifier's comments: This calculation is subject to the approval of the structural engineer of the projectq

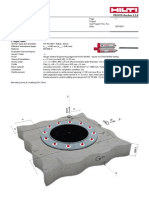

1 Input data

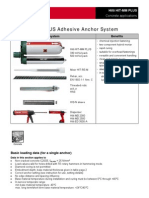

Anchor type and diameter:

HIT-RE 500-SD + HIT-V (5.8) M16

Dynamic set or any suitable annular gap filling solution

Effective embedment depth:

hef,act = 70 mm (hef,limit = - mm)

Material:

5.8

Evaluation Service Report:

ETA 07/0260

Issued I Valid:

6/26/2013 | 5/16/2018

Proof:

Design method Engineering judgement SOFA BOND - based on ETAG BOND testing

Stand-off installation:

eb = 0 mm (no stand-off); t = 20 mm

Anchor plate:

lx x ly x t = 250 mm x 900 mm x 20 mm; (Recommended plate thickness: not calculated)

Profile:

W shape (AISC); (L x W x T x FT) = 462 mm x 192 mm x 11 mm x 18 mm

Base material:

uncracked concrete, C20/25, fc = 25.00 N/mm2; h = 350 mm, Temp. short/long: 40/24 C

Installation:

hammer drilled hole, Installation condition: Dry

Reinforcement:

no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

no longitudinal edge reinforcement

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com.ph

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

2

Three-storey Building

Page:

Project:

Sub-Project I Pos. No.:

Date:

Engr. Antonio Lanya

Quezon City

0928-83320628 |

antoniolanya@ymail.com

2 Load case/Resulting anchor forces

5/22/2015

Load case: Design loads

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Tension force

Shear force

Shear force x

Anchor

1

0.000

22.083

0.000

2

0.000

22.083

0.000

3

0.000

22.083

0.000

4

0.000

22.083

0.000

5

0.000

22.083

0.000

6

0.000

22.083

0.000

7

0.000

22.083

0.000

8

0.000

22.083

0.000

9

0.000

22.083

0.000

10

0.000

22.083

0.000

11

0.000

22.083

0.000

12

0.000

22.083

0.000

max. concrete compressive strain:

- []

max. concrete compressive stress:

- [N/mm2]

resulting tension force in (x/y)=(0/0):

0.000 [kN]

resulting compression force in (x/y)=(0/0): 0.000 [kN]

y

Shear force y

-22.083

-22.083

-22.083

-22.083

-22.083

-22.083

-22.083

-22.083

-22.083

-22.083

-22.083

-22.083

6

x

10

11

12

3 Tension load (EOTA TR 029, Section 5.2.2)

Load [kN]

N/A

Capacity [kN]

N/A

Utilization bN [%]

N/A

Status

N/A

Combined pullout-concrete cone failure**

N/A

N/A

N/A

N/A

Concrete Breakout Strength**

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Steel Strength*

Splitting failure**

* anchor having the highest loading

**anchor group (anchors in tension)

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com.ph

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

Engr. Antonio Lanya

Quezon City

0928-83320628 |

antoniolanya@ymail.com

3

Three-storey Building

5/22/2015

4 Shear load (EOTA TR 029, Section 5.2.3)

Load [kN]

22.083

Steel Strength (without lever arm)*

Steel failure (with lever arm)*

Capacity [kN]

31.200

Utilization bV [%]

71

Status

OK

N/A

N/A

N/A

N/A

Pryout Strength**

265.000

268.397

99

OK

Concrete edge failure in direction x+**

132.500

134.499

99

OK

* anchor having the highest loading

**anchor group (relevant anchors)

4.1 Steel Strength (without lever arm)

VRk,s [kN]

39.000

gM,s

1.250

VRd,s [kN]

31.200

VSd [kN]

22.083

4.2 Pryout Strength (Concrete Breakout Strength controls)

Ac,N [mm2]

300150

A0c,N [mm2]

44100

ccr,N [mm]

105

scr,N [mm]

210

k-factor

2.000

ec1,V [mm]

0

yec1,N

1.000

ec2,V [mm]

0

yec2,N

1.000

ys,N

1.000

N0Rk,c [kN]

29.576

gM,c,p

1.500

VRd,c1 [kN]

268.397

VSd [kN]

265.000

a

0.080

b

0.068

yec,V

1.000

yre,N

1.000

4.3 Concrete edge failure in direction x+

lf [mm]

70

dnom [mm]

16.0

k1

2.400

c1 [mm]

110

Ac,V [mm2]

190575

A0c,V [mm2]

54450

ys,V

1.000

yh,V

1.000

ya,V

2.500

ec,V [mm]

0

V0Rk,c [kN]

23.057

gM,c

1.500

VRd,c [kN]

134.499

VSd [kN]

132.500

yre,V

1.000

5 Displacements (highest loaded anchor)

Short term loading:

NSk

0.000 [kN]

dN

0.000 [mm]

VSk

16.358 [kN]

dV

0.654 [mm]

dNV

0.654 [mm]

Long term loading:

NSk

0.000 [kN]

dN

0.000 [mm]

VSk

16.358 [kN]

dV

0.981 [mm]

dNV

0.981 [mm]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com.ph

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Engr. Antonio Lanya

Quezon City

0928-83320628 |

antoniolanya@ymail.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

Three-storey Building

5/22/2015

6 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

Checking the transfer of loads into the base material is required in accordance with EOTA TR 029, Section 7!

The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of EOTA TR029! For larger

diameters of the clearance hole see Chapter 1.1. of EOTA TR029!

The design method ETAG (filled holes) assumes that no hole clearance between the anchors and the fixture is present. This can

be

achieved by filling the gap with mortar of sufficient compressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

Characteristic bond resistances depend on short- and long-term temperatures.

Please contact Hilti to check feasibility of HIT-V rod supply.

The design method SOFA assumes that no hole clearance between the anchors and the fixture is present. This can be achieved by filling

the gap with mortar of sufficient compressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means.

The compliance with current standards (e.g. EC3) is the responsibility of the user

An SLS-check is not performed for SOFA and has to be provided by the user!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com.ph

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

5

Three-storey Building

Page:

Project:

Sub-Project I Pos. No.:

Date:

Engr. Antonio Lanya

Quezon City

0928-83320628 |

antoniolanya@ymail.com

5/22/2015

7 Installation data

Anchor plate, steel: Profile: W shape (AISC); 462 x 192 x 11 x 18 mm

Hole diameter in the fixture: df = 18 mm

Plate thickness (input): 20 mm

Recommended plate thickness: not calculated

Cleaning: Premium cleaning of the drilled hole is required

Anchor type and diameter: HIT-RE 500-SD + HIT-V (5.8) M16

Installation torque: 0.080 kNm

Hole diameter in the base material: 18 mm

Hole depth in the base material: 70 mm

Minimum thickness of the base material: 106 mm

7.1 Recommended accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

Compressed air with required

accessories to blow from the bottom of

the hole

Proper diameter wire brush

y

125

38

125

Setting

Dispenser including cassette and mixer

Dynamic set

Torque wrench

6

165

165

450

165

10

11

12

85

80

38

165

450

165

85

Coordinates Anchor [mm]

Anchor

1

2

3

4

5

6

x

-40

40

-40

40

-40

40

y

413

413

248

248

83

83

c-x

110

190

110

190

110

190

c+x

190

110

190

110

190

110

c-y

-

c+y

-

Anchor

7

8

9

10

11

12

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

x

-40

40

-40

40

-40

40

y

-83

-83

-248

-248

-413

-413

c-x

110

190

110

190

110

190

c+x

190

110

190

110

190

110

c-y

-

c+y

-

Profis Anchor 2.5.2

www.hilti.com.ph

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Engr. Antonio Lanya

Quezon City

0928-83320628 |

antoniolanya@ymail.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

6

Three-storey Building

5/22/2015

8 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- 1 Input Data: Profis Anchor 2.6.6Document6 pages1 Input Data: Profis Anchor 2.6.6Collin NguNo ratings yet

- 290mm Thick Slab and 540mm EcenDocument6 pages290mm Thick Slab and 540mm EcenihpeterNo ratings yet

- H 200mm Thick Slab - Pa2Document6 pagesH 200mm Thick Slab - Pa2ihpeterNo ratings yet

- PROFIS Anchor 2.2.6: WWW - Hilti.inDocument6 pagesPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007No ratings yet

- Hilti AnchorDocument5 pagesHilti AnchorGopi KrishnanNo ratings yet

- Canopy M16 HIT-RE500Document5 pagesCanopy M16 HIT-RE500marchus09No ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument6 pages1 Input Data: WWW - Hilti.co - UkihpeterNo ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- Hilti Bolt DesignDocument7 pagesHilti Bolt Designcheligp1981No ratings yet

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument5 pages1 Input Data: WWW - Hilti.inpudumaiNo ratings yet

- 1 Input Data: Profis Anchor 2.2.4Document6 pages1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinNo ratings yet

- PROFIS Anchor 2.0.7Document4 pagesPROFIS Anchor 2.0.7Miky CastenNo ratings yet

- Machine RoomDocument6 pagesMachine RoomRonnie De Joya AguirreNo ratings yet

- 1 Input Data: WWW - HiltiDocument5 pages1 Input Data: WWW - HiltiCibotaru MihaiNo ratings yet

- Connection d01 1Document6 pagesConnection d01 1Win ThanNo ratings yet

- 1 Input Data: Profis Anchor 2.4.6Document6 pages1 Input Data: Profis Anchor 2.4.6Naresh KumarNo ratings yet

- 1 Input Data: Profis Anchor 2.5.2Document5 pages1 Input Data: Profis Anchor 2.5.2jasekan.dcNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- PROFIS Anchor 2.1.4: WWW - Hilti.atDocument5 pagesPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15No ratings yet

- Rowad Debugging MachineDocument6 pagesRowad Debugging MachineRonnie De Joya AguirreNo ratings yet

- Kempinski Hilti Rc-ODocument6 pagesKempinski Hilti Rc-OsobhiNo ratings yet

- HILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsDocument21 pagesHILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsGeorge KaridisNo ratings yet

- PES Hilti M10 HSA Report RunnerDocument4 pagesPES Hilti M10 HSA Report RunnerCollin NguNo ratings yet

- Hilti AnchorsDocument58 pagesHilti AnchorsPaulSwinbankNo ratings yet

- Profis Anchor 2.6.1 Design SoftwareDocument5 pagesProfis Anchor 2.6.1 Design SoftwareihpeterNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocument6 pagesPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNo ratings yet

- Profis Anchor Design for KWIK HUS-EZ AnchorDocument6 pagesProfis Anchor Design for KWIK HUS-EZ AnchorJester AbucayNo ratings yet

- Hilti Anchor Design CalculationsDocument5 pagesHilti Anchor Design CalculationsadelhelmiNo ratings yet

- PES Hilti M10 HSA ReportDocument4 pagesPES Hilti M10 HSA ReportCollin NguNo ratings yet

- Hy-200 FTM 2012-09Document70 pagesHy-200 FTM 2012-09Inhinyero SibilNo ratings yet

- Anclaje Quimico HILTIDocument84 pagesAnclaje Quimico HILTIWuceirNo ratings yet

- Hilti Hit Hy 200 With Hit VDocument18 pagesHilti Hit Hy 200 With Hit VRobinReyndersNo ratings yet

- Shaft B, Hb1 Kempinski 11-1-17.pa2Document7 pagesShaft B, Hb1 Kempinski 11-1-17.pa2sobhiNo ratings yet

- Anchor Presentation Hilti 2011 PDFDocument8 pagesAnchor Presentation Hilti 2011 PDFNelsonDay100% (1)

- Profis Rebar ReportDocument5 pagesProfis Rebar ReportSowmya MajumderNo ratings yet

- Technical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175Document85 pagesTechnical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175ing urbanNo ratings yet

- Flupec Catalog Etansari Translatie PDFDocument446 pagesFlupec Catalog Etansari Translatie PDFRadu VasileNo ratings yet

- Hilti - Profis Anchor Design Report 594Document5 pagesHilti - Profis Anchor Design Report 594Madhu GuptaNo ratings yet

- Hilti - Calculo Manual de Re500Document41 pagesHilti - Calculo Manual de Re500James ClaytonNo ratings yet

- Anchor Design - Hilti (HP)Document6 pagesAnchor Design - Hilti (HP)Harikrishnan PNo ratings yet

- Hilti HIT-HY 150 MAX anchor systemDocument12 pagesHilti HIT-HY 150 MAX anchor systemMihnea-Bogdan NicolaescuNo ratings yet

- Hilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodDocument16 pagesHilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodsandeepsharmafjNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- Hilti HIT MM Plus 1Document14 pagesHilti HIT MM Plus 1Mihnea-Bogdan NicolaescuNo ratings yet

- Cable Transit Brochure W4310 (22.10.15) PDFDocument28 pagesCable Transit Brochure W4310 (22.10.15) PDFgoomar6No ratings yet

- Hilti HIT HY 150 MAX With RebarDocument14 pagesHilti HIT HY 150 MAX With RebarNelly BuquironNo ratings yet

- Anchor 2013 Full EnglishDocument62 pagesAnchor 2013 Full EnglishFhjkda LfljkdNo ratings yet

- Construction Methodology For TG Pedestal Column - R2Document11 pagesConstruction Methodology For TG Pedestal Column - R2Hariom Gupta100% (1)

- Hilti Hit Re 500 Cu Has Hit-V His-N 1Document36 pagesHilti Hit Re 500 Cu Has Hit-V His-N 1Sorin RaduNo ratings yet

- Base CHS X 10tDocument7 pagesBase CHS X 10tCollin NguNo ratings yet

- WIT-PE 500 Design Manual RBDocument24 pagesWIT-PE 500 Design Manual RBMadusha TisseraNo ratings yet

- B3L01 - Detail 1Document7 pagesB3L01 - Detail 1vikramjain66No ratings yet

- Hilti Hit Re 500 With Hit V HasDocument16 pagesHilti Hit Re 500 With Hit V HaslaurentiubnNo ratings yet

- Anchor Bolt PDFDocument7 pagesAnchor Bolt PDFRonnie Albert MonteroNo ratings yet

- Drafts - WT 07 - TOP BracketDocument13 pagesDrafts - WT 07 - TOP BracketAniket InarkarNo ratings yet

- ListProjectsJointVenture 20150709Document1 pageListProjectsJointVenture 20150709antonioNo ratings yet

- FFDocument57 pagesFFSunish DasNo ratings yet

- Acttual ALMA 2014 Recover Recover-Layout1Document1 pageActtual ALMA 2014 Recover Recover-Layout1antonioNo ratings yet

- Basics For Organizing TradeBasics For Organizing Trade Fairs Fairs For WebDocument68 pagesBasics For Organizing TradeBasics For Organizing Trade Fairs Fairs For WebwadNo ratings yet

- c1030 B Mountingheights PDFDocument1 pagec1030 B Mountingheights PDFantonioNo ratings yet

- Selected List of ProjectsDocument4 pagesSelected List of ProjectsantonioNo ratings yet

- Fire Reel Fixed Hose Reels Red EmperorDocument5 pagesFire Reel Fixed Hose Reels Red EmperorsamehNo ratings yet

- Re-500-Sd +hit-V - FTM - 2012-09 PDFDocument16 pagesRe-500-Sd +hit-V - FTM - 2012-09 PDFantonioNo ratings yet

- Elevator Installation Contract - 2022 - CNMDocument5 pagesElevator Installation Contract - 2022 - CNMsolid groupNo ratings yet

- OSHA Standard For Fixed Ladders SummaryDocument12 pagesOSHA Standard For Fixed Ladders SummarysesabcdNo ratings yet

- Concrete Pipe Installation Guide-CPMDocument17 pagesConcrete Pipe Installation Guide-CPMSankar CdmNo ratings yet

- IIT-JEE-Physics-1997: Time: Three HourDocument9 pagesIIT-JEE-Physics-1997: Time: Three HourAdarsh UdayanNo ratings yet

- GuidewireClaimCenter Performance TestPlanDocument18 pagesGuidewireClaimCenter Performance TestPlanshanthan117No ratings yet

- 460 (Part-2)Document16 pages460 (Part-2)rambinod0% (1)

- Tractor 2017 Catalogue WebDocument36 pagesTractor 2017 Catalogue WebAnonymous 1XBCMXNo ratings yet

- Freezing pipes-FPSDocument2 pagesFreezing pipes-FPSBinu SulochananNo ratings yet

- Rectify Binary Plate Efficiency BubblesDocument4 pagesRectify Binary Plate Efficiency BubblesCsaba AndrásNo ratings yet

- Oral and Practical Tests: MechanicDocument19 pagesOral and Practical Tests: MechanicHugo AlmeidaNo ratings yet

- Solution 2 AntennaDocument7 pagesSolution 2 Antennaabdulwahab12100% (1)

- A Practical Introductory Guide On Using Satellite Technology For CommunicationsDocument15 pagesA Practical Introductory Guide On Using Satellite Technology For CommunicationsJohan PrinslooNo ratings yet

- Seedburo Germinator Controls and Monitoring InstrumentsDocument2 pagesSeedburo Germinator Controls and Monitoring InstrumentsJhony Rengifo SolsolNo ratings yet

- 1998 CAT 3126 Oper & Maint ManualDocument93 pages1998 CAT 3126 Oper & Maint Manualbatuhan kılıç100% (2)

- Electricity Scavenger HuntDocument1 pageElectricity Scavenger HuntksonicoNo ratings yet

- How To Sputter Thin Films of Metal Onto GlassDocument5 pagesHow To Sputter Thin Films of Metal Onto Glassfred_m_48601No ratings yet

- Leg Foot Massager 1026 ManualDocument5 pagesLeg Foot Massager 1026 ManualBhushan BhikeNo ratings yet

- STP of Ethifen SyrupDocument5 pagesSTP of Ethifen SyrupBejoy KarimNo ratings yet

- DseDocument20 pagesDsebrawijaya100% (1)

- Ricoh 2090Document832 pagesRicoh 2090cosmin176100% (1)

- Emergency CallDocument6 pagesEmergency CallNugrohoNo ratings yet

- 5SL43407RC Datasheet enDocument5 pages5SL43407RC Datasheet enDiana Martinez SifuentesNo ratings yet

- You Yangs RP Visitor GuideDocument2 pagesYou Yangs RP Visitor GuideSomaNo ratings yet

- Iso Dis 20283-4 2011Document27 pagesIso Dis 20283-4 2011Ricardo RamirezNo ratings yet

- Windmill ABB MachinesDocument6 pagesWindmill ABB MachinesRadu BabauNo ratings yet

- KB Rebar BrochureDocument4 pagesKB Rebar BrochureJun Xian Wai100% (1)

- Fontaine Quinta RuedaDocument2 pagesFontaine Quinta RuedaHamilton MirandaNo ratings yet

- Narayana 10 01 24 SR Star Co Scmodel A, B&C Jee Main GTM 12n Key&sDocument10 pagesNarayana 10 01 24 SR Star Co Scmodel A, B&C Jee Main GTM 12n Key&sReddyNo ratings yet

- Subnetting PracticeDocument5 pagesSubnetting PracticeUncleSamNo ratings yet

- Thermostats and Dial Thermometers PDFDocument252 pagesThermostats and Dial Thermometers PDFAsep MustopaNo ratings yet