Professional Documents

Culture Documents

Fuel Meter GRACO

Uploaded by

NAO_198Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Meter GRACO

Uploaded by

NAO_198Copyright:

Available Formats

Instructions - Parts List

Fuel Meter

For metering fuels.

80 psi (0.55 MPa, 5.5 bar) Maximum Working Pressure

Model 260405, measures in gallons

Model 260414, measures in liters

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Meter Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Meter Assembly and Disassembly . . . . . . . . . . . . 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 10

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 10

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2005, Graco Inc. is registered to I.S. EN ISO 9001

311309B

Warnings

Warnings

The following general warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. Additional, more specific warnings may be found throughout the body of this manual

where applicable. Symbols appearing in the body of the manual refer to these general warnings.

When these symbols appear throughout the manual, refer back to these pages for a description

of the specific hazard.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield

wiper fluid, be aware that flammable fumes can ignite or explode. To help prevent fire

and explosion:

Use equipment only in well ventilated area.

Eliminate all ignition sources, such as cigarettes and portable electric lamps.

Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

Do not plug or unplug power cords or turn lights on or off when flammable fumes

are present.

Ground all equipment in the work area.

Use only grounded hoses.

If there is static sparking or you feel a shock, stop operation immediately. Do not

use equipment until you identify and correct the problem.

Keep a fire extinguisher in the work area.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in

the operating area of the equipment to help protect you from serious injury, including

eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes

but is not limited to:

Protective eyewear

Clothing and respirator as recommended by the fluid and solvent manufacturer

Gloves

Hearing protection

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the

eyes or on skin and cause serious injury.

Tighten all fluid connections before operating the equipment.

Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

311309B

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

Do not operate the unit when fatigued or under the influence of drugs or alcohol.

Do not exceed the maximum working pressure or temperature rating of the lowest

rated system component. See Technical Data in all equipment manuals.

Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturers warnings. For complete information about your material, request MSDS forms from

distributor or retailer.

Check equipment daily. Repair or replace worn or damaged parts immediately with

genuine Graco replacement parts only.

Do not alter or modify equipment.

Use equipment only for its intended purpose. Call your Graco distributor for information.

Route hoses and cables away from traffic areas, sharp edges, moving parts, and

hot surfaces.

Do not kink or over bend hoses or use hoses to pull equipment.

Keep children and animals away from work area.

Comply with all applicable safety regulations.

311309B

Installation

Installation

Meter Calibration

See Parts, page 8.

The meter is factory calibrated for use with diesel fuel. To recalibrate meter for different fluids,

or to recalibrate meter after service work has

been performed, use the following procedure.

See Parts, page 8.

1. When unpacking meter, check for shipping

damage. Report any shipping damage to

delivering carrier immediately.

1. Operate the pump to fill the meter, hose,

and system with fluid. Make sure all air is

out of system.

2. To install meter on pump, apply PTFE tape

or pipe sealer to 3/4 in. npt nipple (20) and

screw into meter inlet port. Apply PTFE

tape or pipe sealant to opposite end of nipple and screw nipple into pump outlet port

by turning the meter assembly clockwise.

Do not overtighten.

2. Reset counter to 000 by turning the reset

knob (9) counterclockwise.

Meter

3. The meter is shipped with the counter

assembly positioned so the meter outlet

port is in the straight down position, with

the hose out the bottom of the meter. To

locate the hose on the sides or top, position

the meter as desired (see step 2 above).

To rotate the counter assembly (16), see

steps 2-3 under Meter Assembly and Disassembly, page 5. Rotate the counter

assembly so that the number wheels are

horizontal. To reassemble meter, install

parts in reverse order, making sure all seals

are in place.

4. Apply PTFE tape or sealant to all threaded

joints, then install hose in meter outlet port.

3. Fill a measured container to the 5 gallon

mark (19.0 liters).

4. Note meter reading. If reading is less than

5.0 gallons (19.0 liters), turn adjustment

screw (18) clockwise. If meter reading is

more than 5.0 gallons (19.0 liters), turn

screw (18) counterclockwise. Repeat above

procedure until counter reading agrees with

measured amount of fluid.

Operation

The 260405 registers the fluid in gallons. The

top (larger) number wheel can be reset to zero

by turning the reset knob (9) counterclockwise.

The bottom (smaller) number wheels are a

totalizing counter and cannot be reset. The

resettable counter registers up to 99.9 gallons.

The totalizer registers up to 9999.9 gallons.

The 260414 registers the fluid in liters. The

operation of the 260414 is the same as the

260405. The resettable counter registers up to

99.9 liters. The totalizer registers up to 9999.9

liters.

311309B

Repair

Repair

Meter Assembly and

Disassembly

To replace any of the major assemblies, disassemble meter as follows. See Parts, page 8.

1. Remove the reset knob (9) by pulling it

straight out.

4. To remove disk assembly (3, 4, 5), remove

two screws (7) and washers (6). Disk parts

must be replaced as an assembly; order kit

number 260429 for model 260405 (gallons)

and kit number 260430 for model 260414

(liters).

5. Reassemble in reverse order of disassembly. Make sure all seals are in place.

2. Remove two screws (11) and take off

counter cover (14).

3. Remove four hex head bolts (15) to remove

counter assembly (16).

311309B

Troubleshooting

Troubleshooting

Problem

Meter runs in reverse.

Fluid leakage in counter.

Cause

Meter installed backward.

Seal on counter input shaft

leaking.

Dust and dirt in counter cover. Cover seal (8) or knob seal

(10) missing or improperly

installed.

Meter counter does not oper- Broken parts in counter

ate, fuel delivery normal.

assembly.

Broken drive pin on disk (4).

Foreign material in counter

assembly.

Misaligned disk assembly.

Fluid Leaks from meter.

Low or no outlet flow.

Solution

Install meter with port marked

inlet to pump outlet.

Replace counter assembly.

Install missing seal, or correct

installation.

Replace counter assembly.

Replace disk assembly.

Clean or replace counter

assembly.

Check disk assembly and

clean; make sure alignment is

correct. Make sure outlet is

engaged with hole in outlet

port, that o-ring seal (17) is

installed, and that hold down

screw (7) and washer (6) are

tight.

Defective or worn disk assem- Replace disk assembly.

bly.

Pipe fitting or hose installed

Apply pipe sealant and reinwithout sealant.

stall.

O-ring seal (2) worn or improp- Replace seal.

erly installed.

Fastener (15) loose.

Tighten fastener.

System problem other than

Check other system compometer.

nents for problem.

Foreign material in disk assem- Clean or replace damaged disk

bly.

assembly.

311309B

Troubleshooting

311309B

Parts

Parts

Models 260405, 260414

10

11

20

19

14

11

15

17

16

Ref.

No. Description

1 HOUSING, meter

2 SEAL, o-ring

3 CHAMBER, lower

4 DISK

5 CHAMBER, upper

6 WASHER

7 SCREW; 6-32 x 1/4 in.

8 SEAL, o-ring

9 KNOB, reset

Qty.

1

1

1

1

1

2

2

1

1

18

Ref.

No. Description

Qty.

10 SEAL, grommet

1

11 SCREW; 8-32 x 1/4 in.

2

14 HOUSING, counter, cover

1

15 HEX BOLT; 1/4-20 x 3/4 in.

4

16a COUNTER, assembly, gallons

1

16b COUNTER, assembly, liters

1

17 SEAL, o-ring

1

18 SCREW, adjustment

1

19 SEAL, o-ring

1

20 NIPPLE, pipe; 3/4 in. npt x 2.0 in.

1

Kits

Kit

Number

260427

260428

260429

260430

Description

KIT, Knob

KIT, Air Adjustment

KIT, Metering (gallons)

KIT, Metering (liters)

Includes Items

9, 10

18, 19

2, 3, 4, 5, 7, 8, 15, 16a, 17

2, 3, 4, 5, 7, 8, 15, 16b, 17

311309B

Technical Data

Technical Data

Working Pressure

Inlet Size

Outlet Size

Weight

Wetted Parts

80 psi (0.55 MPa, 5.5 bar)

3/4 in. npt

3/4 in. npt

2.5 lb (1.1 kg)

diecast aluminum, carbon steel with zinc plating, 12L14 steel with zinc plating, 416 stainless

steel, Valox, nylon, fluoroelastomer

Valox is a registered trademark of GE Plastics

311309B

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Gracos written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Gracos sole obligation and buyers sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rdaction du prsente document sera en Anglais, ainsi que tous documents, avis et procdures judiciaires excuts, donns ou intents, la suite

de ou en rapport, directement ou indirectement, avec les procdures concernes.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 311309

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

www.graco.com

311309 11/2005 Revised 12/2006

You might also like

- SADocument2 pagesSANAO_1980% (1)

- 2011SS Federal RegulationsDocument169 pages2011SS Federal RegulationsSharon FreemanNo ratings yet

- AmmoniaDocument63 pagesAmmoniaNAO_198No ratings yet

- Fuel Meter: Instructions - Parts ListDocument10 pagesFuel Meter: Instructions - Parts ListNAO_198No ratings yet

- Astm Spec.Document52 pagesAstm Spec.frenchieNo ratings yet

- Face To Face Dimensions of Flanged ValvesDocument2 pagesFace To Face Dimensions of Flanged ValvesNAO_198No ratings yet

- Control ValveDocument25 pagesControl ValveAsad RazaNo ratings yet

- Face To Face Dimensions of Flanged ValvesDocument2 pagesFace To Face Dimensions of Flanged ValvesNAO_198No ratings yet

- Beggs & Brill MethodDocument9 pagesBeggs & Brill Methodmatrix69No ratings yet

- Industrial Commercial Water Softeners SF 150s SF 150SDocument2 pagesIndustrial Commercial Water Softeners SF 150s SF 150SNAO_198No ratings yet

- Pure Aqua (2013) - Profoma Invoice 2013 PI-13098 Tervap LtdaDocument1 pagePure Aqua (2013) - Profoma Invoice 2013 PI-13098 Tervap LtdaNAO_198No ratings yet

- IC-3001 Introduction To Control Networks in An Industrial SettingDocument23 pagesIC-3001 Introduction To Control Networks in An Industrial SettingNAO_198No ratings yet

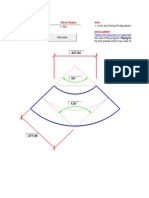

- Pipe Size Pipe OD Elbow Radius Note: Piping-Info Assumes No Responsibility For Any Damage or Loss Resulting FromDocument4 pagesPipe Size Pipe OD Elbow Radius Note: Piping-Info Assumes No Responsibility For Any Damage or Loss Resulting FromNAO_198No ratings yet

- Industrial Commercial Water Softeners SF 150s SF 150SDocument2 pagesIndustrial Commercial Water Softeners SF 150s SF 150SNAO_198No ratings yet

- Instrumentation CablesDocument24 pagesInstrumentation CablesNAO_198No ratings yet

- Chapter-4 Pipe Soil StructureDocument14 pagesChapter-4 Pipe Soil StructureahmaborashedNo ratings yet

- Project Management: CHEE470 2003/2004Document16 pagesProject Management: CHEE470 2003/2004NAO_198No ratings yet

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- P206 Effectively Managing Multiple ProjectsDocument23 pagesP206 Effectively Managing Multiple ProjectsNAO_198100% (1)

- 170Document6 pages170AmimaniaNo ratings yet

- Training Manual: Piping SpoolsDocument72 pagesTraining Manual: Piping SpoolsvsajuNo ratings yet

- Refinery TankagesDocument4 pagesRefinery Tankagesmayuresh1101100% (1)

- Autocad Plant3d Quick Reference GuideDocument2 pagesAutocad Plant3d Quick Reference GuideNAO_198No ratings yet

- Heat Loss From PipeDocument11 pagesHeat Loss From Pipedeion29No ratings yet

- Reports Training Manual: Vantage Training Vantage Training Vantage Training Vantage TrainingDocument17 pagesReports Training Manual: Vantage Training Vantage Training Vantage Training Vantage TrainingawarkopsNo ratings yet

- Confined Space FatalitiesDocument4 pagesConfined Space FatalitiesAshwin KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Product Development and Commercialization ProcDocument2 pagesThe Product Development and Commercialization ProcAlexandra LicaNo ratings yet

- EnerSys Global Leader in Industrial BatteriesDocument32 pagesEnerSys Global Leader in Industrial BatteriesAshredNo ratings yet

- Emergency Room Delivery RecordDocument7 pagesEmergency Room Delivery RecordMariel VillamorNo ratings yet

- Instagram Dan Buli Siber Dalam Kalangan Remaja Di Malaysia: Jasmyn Tan YuxuanDocument13 pagesInstagram Dan Buli Siber Dalam Kalangan Remaja Di Malaysia: Jasmyn Tan YuxuanXiu Jiuan SimNo ratings yet

- Feasibility StudyDocument47 pagesFeasibility StudyCyril Fragata100% (1)

- Afu 08504 - International Capital Bdgeting - Tutorial QuestionsDocument4 pagesAfu 08504 - International Capital Bdgeting - Tutorial QuestionsHashim SaidNo ratings yet

- Exor EPF-1032 DatasheetDocument2 pagesExor EPF-1032 DatasheetElectromateNo ratings yet

- Key formulas for introductory statisticsDocument8 pagesKey formulas for introductory statisticsimam awaluddinNo ratings yet

- Control SystemsDocument269 pagesControl SystemsAntonis SiderisNo ratings yet

- General Separator 1636422026Document55 pagesGeneral Separator 1636422026mohamed abdelazizNo ratings yet

- Transformer Oil Testing MethodsDocument10 pagesTransformer Oil Testing MethodsDEE TOTLVJANo ratings yet

- Wacker Neuson RTDocument120 pagesWacker Neuson RTJANUSZ2017100% (4)

- Environmental Assessment of Sewer ConstructionDocument32 pagesEnvironmental Assessment of Sewer ConstructionKaleab TadesseNo ratings yet

- CGV 18cs67 Lab ManualDocument45 pagesCGV 18cs67 Lab ManualNagamani DNo ratings yet

- Sekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Document11 pagesSekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Rohana YahyaNo ratings yet

- Deluxe Force Gauge: Instruction ManualDocument12 pagesDeluxe Force Gauge: Instruction ManualThomas Ramirez CastilloNo ratings yet

- Introduction To OpmDocument30 pagesIntroduction To OpmNaeem Ul HassanNo ratings yet

- Liber Chao (Final - Eng)Document27 pagesLiber Chao (Final - Eng)solgrae8409100% (2)

- Childrens Ideas Science0Document7 pagesChildrens Ideas Science0Kurtis HarperNo ratings yet

- Rheology of Polymer BlendsDocument10 pagesRheology of Polymer Blendsalireza198No ratings yet

- Ramdump Memshare GPS 2019-04-01 09-39-17 PropsDocument11 pagesRamdump Memshare GPS 2019-04-01 09-39-17 PropsArdillaNo ratings yet

- DSE61xx Configuration Suite Software Manual PDFDocument60 pagesDSE61xx Configuration Suite Software Manual PDFluisNo ratings yet

- APC Smart-UPS 1500VA LCD 230V: Part Number: SMT1500IDocument3 pagesAPC Smart-UPS 1500VA LCD 230V: Part Number: SMT1500IDesigan SannasyNo ratings yet

- S2 Retake Practice Exam PDFDocument3 pagesS2 Retake Practice Exam PDFWinnie MeiNo ratings yet

- 5505 SW 138th CT, Miami, FL 33175 ZillowDocument1 page5505 SW 138th CT, Miami, FL 33175 Zillowlisalinda29398378No ratings yet

- Cianura Pentru Un Suras de Rodica OjogDocument1 pageCianura Pentru Un Suras de Rodica OjogMaier MariaNo ratings yet

- Operation Manual: Auto Lensmeter Plm-8000Document39 pagesOperation Manual: Auto Lensmeter Plm-8000Wilson CepedaNo ratings yet

- Creatures Since Possible Tanks Regarding Dengue Transmission A Planned Out ReviewjnspeDocument1 pageCreatures Since Possible Tanks Regarding Dengue Transmission A Planned Out Reviewjnspeclientsunday82No ratings yet

- Your Inquiry EPALISPM Euro PalletsDocument3 pagesYour Inquiry EPALISPM Euro PalletsChristopher EvansNo ratings yet

- 10 Slides For A Perfect Startup Pitch DeckDocument6 pages10 Slides For A Perfect Startup Pitch DeckZakky AzhariNo ratings yet