Professional Documents

Culture Documents

Mech - IJMPERD - CFD Analysis For Adaptability of - G S Sharma

Uploaded by

TJPRC PublicationsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mech - IJMPERD - CFD Analysis For Adaptability of - G S Sharma

Uploaded by

TJPRC PublicationsCopyright:

Available Formats

International Journal of Mechanical and Production

Engineering Research and Development (IJMPERD)

ISSN(P): 2249-6890; ISSN(E): 2249-8001

Vol. 5, Issue 2, Apr 2015, 21-32

TJPRC Pvt. Ltd.

CFD ANALYSIS FOR ADAPTABILITY OF PRODUCER GAS FOR

POWER GENERATION IN GAS TURBINES

GANGARAJU SRINIVASA SHARMA1, M. V. S. MURALI KRISHNA2 & D. N. REDDY3

1

Associate Professor, Department of ME, MVSREC, Hyderabad, Andhra Pradesh, India

2

Professor, Department of ME, CBIT, Hyderabad, Andhra Pradesh, India

3

UGC Member, India

ABSTRACT

Gas turbines are low specific fuel consumption prime movers for power generation. The situation of increasing

demand for power generation with Carbon Neutral technologies is the need of hour. Earlier research studies indicated the

feasibility of utilization of low calorific value gas in Gas turbines, but reported a large quantity of Exergy destruction in

combustion chamber. The present paper addresses the adaptability of producer gas in a combustion chamber, with a

non-premixed model using Ansys-Fluent. A 3D test combustion chamber of 15 cm diameter and 30 cm long with circular

air inlets and axially located fuel inlet are modeled and simulations are performed using commercial CFD software. A 25

KW gas turbine combustion chamber is considered with operating pressure of 4 bar absolute working on Producer gas with

the fuel composition of 19% H2, 20 % CO, 2 % CH4, 10% CO2 and remaining N2. Combustion chamber operating with the

producer gas is presented. The obtained results are compared with methane and comparative analysis is presented.

KEYWORDS: Flame Stability, Chemical Reaction

INTRODUCTION

Gas turbine combustor design represents an complex task in theoretical, numerical and experimental analysis.

Currently, preliminary combustor flow and heat transfer design procedures, which by necessity involve semi-empirical

models, are often restricted in their range of application. It was necessary to evaluate the gas turbine combustor for the

producer gas, a different fuel from that of the specified liquid fuel. The critical requirements are related to the air-to-fuel

ratio, ignition under these conditions, flame stability over the range of operating conditions and establish the inlet operating

conditions for the turbine. The simultaneous involvement of evaporation, turbulent mixing, ignition, and chemical reaction

in gas turbine combustion is too complex for complete theoretical treatment. Hence large engine manufacturers undertake

expensive engine development programs to modify previously established designs through trial-and-error.

Combustor designers without access to proprietary design procedures must derive their own methods from the

literature or from experimentation. Numerous published empirical, semi-empirical, and analytical tools have been

developed to reduce the need for costly experiments. The two extreme cases, empirical and analytical, differ by the method

of derivation. Empirical design tools are correlations derived from experimental datasets whereas analytical ones are

discretized versions of the governing equations. Simple empirical correlations provide accurate results quickly and are

easily implemented into design codes, yet they are only applicable to cases for which the measured data was based on.

Analytical methods, less accurate in comparison to empirical methods, are much more flexible as they are only restricted

www.tjprc.org

editor@tjprc.org

22

Gangaraju Srinivasa Sharma, M. V. S. Murali Krishna & D. N. Reddy

by the simplifying assumptions necessary to reduce their complexity and computation time. Hybrid semi-empirical tools

combine both empirical and analytical methods to provide a reasonable balance between accuracy and computation time.

LITERATURE REVIEW

As per the earlier research studies made by Francesco Fantozzi et al biomass to energy conversion is particularly

attractive on the micro scale where internal combustion engines such as micro turbines may be utilized coupled to an

indirect gasification system. A RANS analysis has been performed in order to simulate both natural gas and syngas

combustion.

Paolo et al have conducted CFD Analysis to study the performance of a modified combustion chamber of a micro

gas turbine with the objective to change its fuelling from natural gas to biomass pyrolysis gas. Turbulence in gas turbine

combustion chamber is considered important because of its large influence on the combustion characteristics. In order to

find optimum conditions in a combustion system, it is essential to get a good approximation of the turbulence. From this

viewpoint, multi-dimensional modeling using CFD is pursued and involves simulation with and without combustion.

One of the major challenges of CFD in the recent times is that several models need to be combined in order to simulate a

complete engine cycle. The k model is the most commonly used turbulence model in CFD, even though its deficiencies

are known as indicated by Versteeg et al, indeed k model is still considered to the best compromise between

computational time and precision.

Kanitkar et al have determined the laminar flame speed (SL) at ambient conditions (0.96 bar, 300 K) by

conducting experiments using standard flame tube apparatus for producer gas-air mixture. The gas consisted of 18-23%

H2, 17-20% CO, 3-4% CH4, 13-14% CO2 and rest N2. A wide range of mixture ratios were considered within the

flammability limits of rich and lean mixtures, namely equivalence ratio _ = 0.47 (26% fuel on volume basis) and 1.65

(56% fuel) for lean and rich limits, respectively. Experimental work at high pressures and temperatures of laminar burning

velocity (SL) of producer gas was reported by Keshavamurthy et al. The experiments were conducted in a spherical

combustion vessel. Synthetic mixtures of producer gas with a composition of 22% H2, 22% CO, 4% CH4, 10% CO2 and

42% N2 were used to determine SL at initial pressures of 0.5 to 5 bar and ambient temperature. With these initial pressures

and temperature a peak pressure of 30 bar during combustion and a maximum unburnt gas temperature of 450 K were

obtained. The unburnt gas temperatures were obtained by assuming isentropic compression of unburnt gases as the

combustion progresses.

K- MODEL

The two dimensional, steady, turbulent, compressible conservation equations were solved using ideal gas

approximation of the fluid domain. For steady flow without internal heat sources, the governing equations are continuity,

momentum and energy equation.

Continuity Equation

Impact Factor (JCC): 5.3403

Index Copernicus Value (ICV): 3.0

CFD Analysis for Adaptability of Producer Gas for Power Generation in Gas Turbines

Where

23

is the density, u, v, w are the velocity vectors.

Momentum Equations in Each Direction

Applying the Newtons second law

the conservation of momentum

equations are given by

X-Momentum Equation:

Y-Momentum Equation

Z-Momentum Equation:

The stress tensor

Where

is given by

is the molecular viscosity,

is the unit tensor, and the second term on the right hand side is the effect of

volume dilation.

Energy Equation

Energy is neither created nor destroyed. It is always conserved.

www.tjprc.org

editor@tjprc.org

24

Gangaraju Srinivasa Sharma, M. V. S. Murali Krishna & D. N. Reddy

In the above equation,

, Where sensible enthalpy

and for incompressible flows as

fraction of species and

, where

is defined for ideal gases as

in the above expression is the mass

is the reference temperature and its value is 298.15 K.

RANS Equation

=-

The left hand side of this equation represents the change in mean momentum of fluid element owing to the

unsteadiness in the mean flow and the convection by the mean flow. This change is balanced by the mean body force, the

isotropic stress owing to the mean pressure field, the viscous stresses, and apparent stress

owing to the

fluctuating velocity field, generally referred to as the Reynolds stress. These equations form a set of coupled, nonlinear

partial differential equations. It is not possible to solve these equations analytically for most engineering problems.

However, it is possible to obtain approximate computer-based solutions to the governing equations. The standard

model is a semi-empirical model based on model transport equations for the turbulence kinetic energy (k) and its

dissipation rate (). The model transport equation for k is derived from the exact equation, while the model transport

equation for was obtained using physical reasoning and bears little resemblance to its mathematically exact counterpart.

Computational model

A 3-d combustion chamber was designed using Ansys Workbench in design mode and the dimensions of the

chamber are represented in the figure 1. Grid generation represents a tedious task for CFD analysis. It is a time-consuming

task and, in spite of steady advances in automatic mesh generation, it still requires the skill of a CFD practitioner to yield a

suitable mesh. The choice of the type of grid depends on geometrical complexity and on physics. For gas simulation a

producer gas-air mixture was used with chemical composition of 20% CO, 19% H2 ,2% CH4, 10% CO2 and remaining N2.

Impact Factor (JCC): 5.3403

Index Copernicus Value (ICV): 3.0

25

CFD Analysis for Adaptability of Producer Gas for Power Generation in Gas Turbines

Calorific value of Producer gas is estimated by earlier authors and it is indicated as about 3000 Kcal/kg[]. Heat transfer

coefficient of 20 w/m2K, ambient Temperature of 298 K, Pata =1.01325 bar and density of air is 1.125 kg/m3. The thermal

properties of the producer gas and species are function of temperature.

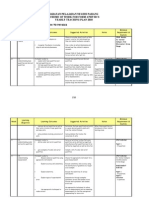

Table 1

Gas Turbine Standard Operating Parameters

Ambient Pressure(bar)

Ambient Temperature(k)

Delivery Pressure of compressor (bar)

Isentropic compressor Efficiency

Isentropic turbine Efficiency

LCV of Producer gas (KJ/Kg)

Compressor Exit temperature(K)

Turbine Inlet temperature(K)

Turbine outlet temperature(K)

Thermal Efficiency

Mass flow rate of fuel(kg/sec)

Mass flow rate of primary air (kg/sec)

Conditions

1.0325

298

4

90%

90%

6000

456

925

656

23.60%

1.39e-02

1.53e-02

Non premixed combustion model with turbulence ( K- model with standard wall functions) is considered with

the composition of gas having 19% H2 , 20 % CO, 2 % CH4 , 10% CO2 and remaining N2 is considered. The combustion

chamber is of 30 cm length and 15 cm diameter with fuel inlet at a diameter of 5 cm and 12 circular air inlets of diameter

1.25 cm. Air of mass flow rate equal to1.53e-02 kg/sec is admitted and 1.39e-02 kg/sec of fuel is admitted through fuel

inlet system. Pressure in the combustion chamber is maintained at 4 bar absolute. It is observed that there is about 0.08 bar

pressure drop in the combustion chamber. The outlet is at about 3.92 bar with no back pressure. The geometry of

combustion chamber test specimen is indicated in the figure 1. The figure 2 indicates the meshed geometry and figure 4

indicates the plots of residuals after convergence.

Figure 1: Combustion Chamber

www.tjprc.org

editor@tjprc.org

26

Gangaraju Srinivasa Sharma, M. V. S. Murali Krishna & D. N. Reddy

Figure 2: Meshed Geometry

Figure 3: Meshed Geometry with Boundary Conditions

Figure 4: Residuals Plot

RESULTS AND DISCUSSIONS

With air fuel ratio of 1.1, the temperature distribution and velocity distributions at various planes of 5cm,10 cm

and 20 cm from the fuel inlet is indicated in the figure 5 and 6. It is observed that temperature is uniformly distributed with

Impact Factor (JCC): 5.3403

Index Copernicus Value (ICV): 3.0

27

CFD Analysis for Adaptability of Producer Gas for Power Generation in Gas Turbines

average temperature of 1025 K and average velocity of 1.93 m/sec. The maximum temperature of about 1500 K is attained

at a distance of 10cm from the fuel inlet where outer surface is heated, whereas the inner core is about 900 K.

The combustion chamber is capable of generating 25 KW of electric power. The air fuel ratio is varied from 0.8 to 1.2 and

temperature, velocity and pressure plots are obtained. The pressure distribution along the axis of the combustion chamber

is indicated in the figure 9 and drop of 0.08 bar of total pressure is observed. The velocity of producer gas mixture leaving

the combustion chamber is observed to be about 3.46m/sec whereas the methane mixture is leaving with a velocity of

about 1.73 m/sec. Hence there is a chance of flame entering the post combustion region which is not recommended for gas

turbine operation. Hence secondary air has to be mixed with the flame at the locations of 5cm, 10 cm, 15 cm and 20 cm

from the fuel inlet and flame has to be quenched.

Figure 5: Temperature distribution Plots at 0, 5cm, 10 cm and 20 cm from the Fuel Inlet

Figure 6: Velocity Distribution Plots at 0, 5cm, 10 cm and 20 cm from the Fuel Inlet

www.tjprc.org

editor@tjprc.org

28

Gangaraju Srinivasa Sharma, M. V. S. Murali Krishna & D. N. Reddy

Figure 7: Velocity Contour in Combustion Chamber

Figure 8: Temperature Contour in Combustion Chamber

Figure 9: Velocity along Axial Direction

Impact Factor (JCC): 5.3403

Index Copernicus Value (ICV): 3.0

CFD Analysis for Adaptability of Producer Gas for Power Generation in Gas Turbines

29

Figure 10: Temperature along Axial Direction

Figure 11 : Temperature Distribution with Methane as Fuel

Figure 12: Temperature Distribution with Producer Gas as Fuel

www.tjprc.org

editor@tjprc.org

30

Gangaraju Srinivasa Sharma, M. V. S. Murali Krishna & D. N. Reddy

Figure 13: Velocity Distribution Using Methane as Fuel

Figure 14: Velocity Distribution Using Producer Gas

CONCLUSIONS

The gas turbine working on methane is working with high calorific value fuel approximately about 22500 KJ/Kg,

with an A/F ratio of 12:1. Whereas gas turbine working with producer gas is working on LCV gas having calorific value of

6 KJ/Kg with an A/F ratio of 1.2. Though the calorific value is less the energy density for same power generation is more

in case of producer gas than methane. The Turbine inlet temperatures at gas turbine conditions are within the specified and

recommended range of OEMs of gas turbines, which prevents the flame burnout inside the expander. The flame velocities

are higher in case of producer gas than in methane along axial direction and it is observed that the exit velocity is of the

order of 3.46 m/sec. The temperature attained at the distance of 15 cm to 20 cm from the fuel injection plane is more in

case of producer gas. Hence dilution of lame in this region is more necessary and secondary air of about 55% higher than

primary has to be provided to reduce the velocity and obtain equal temperature distribution. The fluid flow analysis

coupled with chemical kinetics has indicated that producer gas can be used as the alternate fuel for power generation in

Biomass integrated gasification/Gas turbine Technology for power generation, with average Lower calorific value of

product gas about 6MJ/kg.

Impact Factor (JCC): 5.3403

Index Copernicus Value (ICV): 3.0

31

CFD Analysis for Adaptability of Producer Gas for Power Generation in Gas Turbines

ACKNOWLEDGEMENTS

We would like to sincerely acknowledge the support and motivation provided by director, Center for Energy

Technology, Osmania University for providing facilities for conducting research on biomass gasification and testing the

gas.

REFERENCES

1.

P. J. Paul and H. S. (Editors) Mukunda. Recent advances in biomass gasification and combustion: Proc. of 4th

meet on Biomass Gasi_cation and combustion at Mysore,6-8th Jan. 1993. Interline publishing, Bangalore, India,

1993.

2.

G. Sridhar, P. J. Paul, and H. S. Mukunda. Biomass derived producer gas as a reciprocating engine fuel-an

experimental analysis. Biomass and Bioenergy, 21:61{72,2001.

3.

G. Sridhar. Experiments and modelling studies of producer gas based spark-ignited reciprocating engines. PhD

Thesis, CGPL, IISc, 2003.

4.

K. N. Lakshmisha. Computational studies on the flamability limits of premixed gases. PhD Thesis, IISc, 1991.

5.

C. J. Rallis and A. M. Garforth. The determination of laminar burning velocity. Progress

6.

in Energy and Combustion Science, 6:303{329, 1980.

7.

D.V. Sridharan. Gasifiers once solved energy problems - they might, yet again, available at.

http://www.goodnewsindia.com/Pages/content/discovery/cgpl.html, December 2001.

8.

Shashikantha, P. K. Banerjee, G. S. Khairnar, P. P. Kamat, and P. P. Parikh. Development and performance

analysis of a 15 kwe producer gas operated si engine. Proc. Of 4th meet on Biomass Gasification and combustion

at Mysore,6-8th Jan. 1993 Interline publishing, Bangalore, India, 4:219{231, 1993.

9.

A.V. Bridgewater, Renewable fuels and chemicals by thermal processing of biomass, Chemical Engineering

Journal, 91 (2003) 87-102.

www.tjprc.org

editor@tjprc.org

You might also like

- Flame Retardant Textiles For Electric Arc Flash Hazards: A ReviewDocument18 pagesFlame Retardant Textiles For Electric Arc Flash Hazards: A ReviewTJPRC PublicationsNo ratings yet

- Comparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanDocument8 pagesComparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanTJPRC PublicationsNo ratings yet

- Baluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaDocument14 pagesBaluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaTJPRC PublicationsNo ratings yet

- 2 52 1642055366 1ijpslirjun20221Document4 pages2 52 1642055366 1ijpslirjun20221TJPRC PublicationsNo ratings yet

- Using Nanoclay To Manufacture Engineered Wood Products-A ReviewDocument14 pagesUsing Nanoclay To Manufacture Engineered Wood Products-A ReviewTJPRC PublicationsNo ratings yet

- 2 29 1645708157 2ijtftjun20222Document8 pages2 29 1645708157 2ijtftjun20222TJPRC PublicationsNo ratings yet

- Development and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateDocument10 pagesDevelopment and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateTJPRC PublicationsNo ratings yet

- 2 52 1649841354 2ijpslirjun20222Document12 pages2 52 1649841354 2ijpslirjun20222TJPRC PublicationsNo ratings yet

- 2 33 1641272961 1ijsmmrdjun20221Document16 pages2 33 1641272961 1ijsmmrdjun20221TJPRC PublicationsNo ratings yet

- 2 4 1644229496 Ijrrdjun20221Document10 pages2 4 1644229496 Ijrrdjun20221TJPRC PublicationsNo ratings yet

- The Conundrum of India-China Relationship During Modi - Xi Jinping EraDocument8 pagesThe Conundrum of India-China Relationship During Modi - Xi Jinping EraTJPRC PublicationsNo ratings yet

- 2 31 1648794068 1ijpptjun20221Document8 pages2 31 1648794068 1ijpptjun20221TJPRC PublicationsNo ratings yet

- 2 51 1647598330 5ijmpsjun202205Document10 pages2 51 1647598330 5ijmpsjun202205TJPRC PublicationsNo ratings yet

- 2 51 1651909513 9ijmpsjun202209Document8 pages2 51 1651909513 9ijmpsjun202209TJPRC PublicationsNo ratings yet

- 2 44 1653632649 1ijprjun20221Document20 pages2 44 1653632649 1ijprjun20221TJPRC PublicationsNo ratings yet

- 2 67 1653022679 1ijmperdjun202201Document12 pages2 67 1653022679 1ijmperdjun202201TJPRC PublicationsNo ratings yet

- 2 51 1656420123 1ijmpsdec20221Document4 pages2 51 1656420123 1ijmpsdec20221TJPRC PublicationsNo ratings yet

- Covid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangDocument8 pagesCovid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangTJPRC PublicationsNo ratings yet

- Effect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementDocument8 pagesEffect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementTJPRC PublicationsNo ratings yet

- An Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaDocument10 pagesAn Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaTJPRC PublicationsNo ratings yet

- Self-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsDocument8 pagesSelf-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsTJPRC PublicationsNo ratings yet

- Dr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahDocument12 pagesDr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahTJPRC PublicationsNo ratings yet

- Effectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewDocument14 pagesEffectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewTJPRC PublicationsNo ratings yet

- Analysis of Bolted-Flange Joint Using Finite Element MethodDocument12 pagesAnalysis of Bolted-Flange Joint Using Finite Element MethodTJPRC PublicationsNo ratings yet

- A Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)Document8 pagesA Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)TJPRC PublicationsNo ratings yet

- 2 67 1645871199 9ijmperdfeb202209Document8 pages2 67 1645871199 9ijmperdfeb202209TJPRC PublicationsNo ratings yet

- Vitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019Document16 pagesVitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019TJPRC PublicationsNo ratings yet

- 2 67 1645017386 8ijmperdfeb202208Document6 pages2 67 1645017386 8ijmperdfeb202208TJPRC PublicationsNo ratings yet

- 2 67 1648211383 1ijmperdapr202201Document8 pages2 67 1648211383 1ijmperdapr202201TJPRC PublicationsNo ratings yet

- Numerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingDocument18 pagesNumerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingTJPRC PublicationsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Addis Ababa Science and Technology University Collage of Electrical and Mechanical Engineering Department of Electrical and Computer EngineeringDocument6 pagesAddis Ababa Science and Technology University Collage of Electrical and Mechanical Engineering Department of Electrical and Computer EngineeringABENEZER EPHREMNo ratings yet

- The Reactive System Screening Tool (RSST) : An Inexpensive and Practical Approach To Sizing Emergency Relief SystemsDocument6 pagesThe Reactive System Screening Tool (RSST) : An Inexpensive and Practical Approach To Sizing Emergency Relief SystemsKam KamNo ratings yet

- STULZ CyberOne EC DX Engineering ManualDocument30 pagesSTULZ CyberOne EC DX Engineering ManualBùi LinhNo ratings yet

- ASCE-AIr Cooled CondensersDocument9 pagesASCE-AIr Cooled CondensersYanan CamarazaNo ratings yet

- Presentation On Process 2Document8 pagesPresentation On Process 2Sourav SutradharNo ratings yet

- BASF Ultraform N2200 G53Document2 pagesBASF Ultraform N2200 G53paradoxid78No ratings yet

- Physica"l Prop.e.rtigs: of ItDocument11 pagesPhysica"l Prop.e.rtigs: of ItAhmedMahirNo ratings yet

- Cre Exp 10 Lab Report (PFR)Document10 pagesCre Exp 10 Lab Report (PFR)sukhmani100% (1)

- International Journal of Heat and Mass Transfer: Matej Kranjc, Anze Zupanic, Damijan Miklavcic, Tomaz JarmDocument7 pagesInternational Journal of Heat and Mass Transfer: Matej Kranjc, Anze Zupanic, Damijan Miklavcic, Tomaz JarmOthman Ben CheikhNo ratings yet

- Alberti PhdthesisDocument234 pagesAlberti PhdthesisUsman AliNo ratings yet

- Exercise 2 - FastenersDocument2 pagesExercise 2 - FastenersAhmed EidNo ratings yet

- S275 S355 Data Sheet 2021Document1 pageS275 S355 Data Sheet 2021CarloNo ratings yet

- 022 URTT en Rev 02 20.12.2019 20149Document89 pages022 URTT en Rev 02 20.12.2019 20149ramadan rashadNo ratings yet

- Tire Terminology Explained: 40+ Key TermsDocument6 pagesTire Terminology Explained: 40+ Key Termsgovindarun5No ratings yet

- Metodo ASTM D402Document5 pagesMetodo ASTM D402Roberto ChamorroNo ratings yet

- Heat & Mass Transfer Tutorial ProblemsDocument2 pagesHeat & Mass Transfer Tutorial ProblemsSaifullah AhmadNo ratings yet

- Earth Science Honors, Grade 7 HMH Earth's Water & Atmosphere (Module E)Document21 pagesEarth Science Honors, Grade 7 HMH Earth's Water & Atmosphere (Module E)aveen rasulNo ratings yet

- CRE NotesDocument103 pagesCRE NotesShagun DahiyaNo ratings yet

- M 236 ContentDocument103 pagesM 236 ContentgeetanandnNo ratings yet

- Magnetic Resonance Imaging: Refined To Re-Find: Review ArticleDocument4 pagesMagnetic Resonance Imaging: Refined To Re-Find: Review ArticleSam Bradley DavidsonNo ratings yet

- Physics Form 4 Yearly Lesson Plan 2010Document26 pagesPhysics Form 4 Yearly Lesson Plan 2010Mohd Khairul AnuarNo ratings yet

- Biot Response SpectrumDocument10 pagesBiot Response SpectrumMacNo ratings yet

- IFEM Ch13Document32 pagesIFEM Ch13Siri RaviNo ratings yet

- Pressure and Buoyancy Calculations from Physics ProblemsDocument5 pagesPressure and Buoyancy Calculations from Physics ProblemsRichard EngNo ratings yet

- Stone Column - LectureDocument52 pagesStone Column - LecturePratik ParekhNo ratings yet

- The Scholar's Academy: Long QuestionsDocument4 pagesThe Scholar's Academy: Long Questionspaggal janNo ratings yet

- Auditorium case study reveals sound absorption strategiesDocument16 pagesAuditorium case study reveals sound absorption strategiesAshi Chandak0% (1)

- Interview Questions (TD)Document9 pagesInterview Questions (TD)anil gautamNo ratings yet

- Tolerances To EN 10029 For Hot Rolled Plate 3mm and Above: GeneralDocument5 pagesTolerances To EN 10029 For Hot Rolled Plate 3mm and Above: GeneralKumar NawneetNo ratings yet

- Einstein's Theory of Specific Heats: Classical Concept Review 23Document2 pagesEinstein's Theory of Specific Heats: Classical Concept Review 23Agres KrismantonaNo ratings yet