Professional Documents

Culture Documents

VA1 NHI 00100 M M1C MAN 1001 Rev0 MGS4766 Double Inlet and Double Outlet Coal Mill Instruction (Dextral)

Uploaded by

hoangduythanhqbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VA1 NHI 00100 M M1C MAN 1001 Rev0 MGS4766 Double Inlet and Double Outlet Coal Mill Instruction (Dextral)

Uploaded by

hoangduythanhqbCopyright:

Available Formats

DOCUMENT SUBMISSION STATUS: FC

2012-11-01

REV

DATE

DESCRIPTION

OWNER

ZhangPengxiao

Li Hongsheng

Yu Tingwei

DRWN

CHKD

APPN

OWNERS CONSULTANT

POYRY ENERGY LTD

VIETNAM OIL AND GAS GROUP (PVN)

EPC CONTRACTOR

EPC CONTRACTORS CONSULTANT

VIETNAM MACHINERY

INSTALLATIONCORPPORATION (LILAMA)

FICHTNER GmbH & Co. KG

PROJECT TITLE

VUNG ANG 1 THERMAL POWER PLANT 2 x 600MW

CONTRACT No.

251209/LILAMA-NHI

DRAWING TITLE

MGS4766 Double-inlet and Double-outlet Coal Mill Instruction

(Dextral)

SUB-CONTRACTOR

FUNCTION

NAME

SIGN

DATE

DRWN

Zhang Pengxiao

2012-11-01

CHKD

Li Hongsheng

2012-11-01

APPD

Yu Tingwei

2012-11-01

NORTHERN HEAVY INDUSTRIES GROUP CO.LTD

SCALE

DOCUMENT No.

VA1-NHI-00100-M-M1C-MAN 1001

REV

Instruction

Name

Product

DZMS0007.00

SM

Instruction

Code

MGS4766 Double-inlet and Double-outlet

Coal Mill

Manu.

M121507

No.

Page 2 / 5

PUR No.

1 Application

The double-inlet and double-outlet coal mill is used for the

pulverization of coals, and is the main device in the direct

pulverized-coal system. The mill is mainly assembled with the

boiler in large thermal power plant, and can also be used as the

pulverization device in territories of chemical industry, building

material, phosphoresce, etc.

2Specification and Performance

Performance Parameter of MGS4766 Double-inlet and

No.

1

2

3

4

5

6

7

8

10

Double-out Coal Mill

Description

Output (HGI=42, H2O=8.2%,

92% through 200 mesh)

Effective Internal Diameter

of Shell

Effective Length of Shell

Rotational Speed of Shell

Effective Capacity of Shell

Maximum Ball Charging

Quantity

Flow Rate of Sealing air

Diameter of Classifier

Module

Tooth Number

Gear and

of Girth Gear

Pinion

Tooth Number

of Pinion

Center distance

Speed

Transmission

Reducer

Ratio

Page 2 of 5

Unit

Data

t/h

53.6

mm

4650

mm

r/min

m3

6740

15.3

114.46

117

kg/h

mm

mm

4950

3200

25

228

28

mm

1080

7.1

Instruction

Name

Product

Code

MGS4766 Double-inlet and Double-outlet

Coal Mill

Manu.

M121507

No.

Page 3 / 5

PUR No.

11

DZMS0007.00

SM

Instruction

Type

Power

(kW)

Voltage

(V)

YTM800-6

2300

10000

Motor

Rotational

Speed

( r/min)

993

33Outline Drawing

See Drawing No.1

4Structure and Operation Principle

The double-inlet and double-outlet coal mill comprises shell,

screw convey device, main bearing, sealing air device, mixer,

Page 3 of 5

Instruction

Name

Product

DZMS0007.00

SM

Instruction

Code

MGS4766 Double-inlet and Double-outlet

Coal Mill

Manu.

M121507

No.

Page 4 / 5

PUR No.

classifier, gear and pinion in transmission system, lubrication for

main bearing, spray lubrication system for gear, differential pressure

detector, electric ear detector, low-speed drive system, etc. The coal

mill is connected with the coal feeder. Simultaneously, the

accessories such as ball charging device, pulverized coal cut-off

valve and sound-proof shield are also assembled.

The raw coal with particle size between 0~30mm is conveyed

to the chute by a coal feeder, and falls into the mixer, in which the

coal is dried by by-pass air. Then the coal goes through the coal

falling pipe, and gets to the screw convey device which is arranged

at the center of the hollow shaft. The convey device rotates with the

shell of the coal mill, and the raw coal gets into the shell through the

hollow shaft. In accordance to the technology of the coal mill, the

shell is charged by steel balls (with diameter of50, 40, 30).

During the rotation of the shell, the raw coal is impacted and crushed

by the steel balls into pulverized coal. The primary hot air is blown

into the coal mill through the hollow pipe to dry the raw coal and

pulverized coal, and is blown out of coal mill with pulverized coal

from the opposite direction to the raw coal inlet. The primary hot air

meets the by-pass air at the outlet of coal mill, and gets into the

Page 4 of 5

Instruction

Name

Product

DZMS0007.00

SM

Instruction

Code

MGS4766 Double-inlet and Double-outlet

Coal Mill

Manu.

M121507

No.

Page 5 / 5

PUR No.

classifier through the pulverized coal pipe. The classifier is provided

with adjustable laminas which can be used for adjusting and

controlling the fineness of the pulverized coal. The qualified

pulverized coal is sent to the burner of the boiler through the outlet

at the upper part of the classifier, and the unqualified coal falls back

to the coal mill by gravity for re-pulverization.

5Lubrication System

The lubrication system can be divided into the lubrication

system for main bearing, and spray lubrication system for girth gear.

The applications refer to the instructions.

6The installation, commissioning and pre-operation refer to the

Double inlet and double outlet coal mill installation operation

instruction.

7The guidelines for operation refer to Double inlet and double

outlet coal mill trial operation guide.

Page 5 of 5

You might also like

- Modelling of A Coil Steam Generator For CSP ApplicationsDocument10 pagesModelling of A Coil Steam Generator For CSP ApplicationsAnonymous 3fTYXaW7WNo ratings yet

- TA-Luft:: Cummins Engine Company, Inc FR-10302 QSX15-G8Document1 pageTA-Luft:: Cummins Engine Company, Inc FR-10302 QSX15-G8mohsen_cumminsNo ratings yet

- Guideline On Testing Procedures160519 IEA Task 49 D3 1Document53 pagesGuideline On Testing Procedures160519 IEA Task 49 D3 1Antonio PatauNo ratings yet

- Irp 2011Document771 pagesIrp 2011Eric RehmNo ratings yet

- Energies 10 00205Document19 pagesEnergies 10 00205radanpetricaNo ratings yet

- VA1-LLM18-00100-GE-M8-PRO-00005 Rev.A (Cover)Document1 pageVA1-LLM18-00100-GE-M8-PRO-00005 Rev.A (Cover)Anonymous JtYvKt5XENo ratings yet

- Indian - Standards - BIS ConnectDocument433 pagesIndian - Standards - BIS ConnectVaradha rajanNo ratings yet

- 1st Review PPT Solar ThermalDocument11 pages1st Review PPT Solar ThermalAnand RajNo ratings yet

- BE Engineering Guide VDC Air Cooled CondenserDocument46 pagesBE Engineering Guide VDC Air Cooled Condensernauta007No ratings yet

- Continuous Steam Blow 3 Sheet 1 of 4 Rev. 0Document4 pagesContinuous Steam Blow 3 Sheet 1 of 4 Rev. 0Anonymous JtYvKt5XENo ratings yet

- NE1 700MW CSP + 250MW PV Hybrid Project Punch Items ListDocument10 pagesNE1 700MW CSP + 250MW PV Hybrid Project Punch Items ListFuqingliNo ratings yet

- 1GT Base Load - BypassDocument1 page1GT Base Load - Bypasswael zakariaNo ratings yet

- Turbine BOP Drawing SubmissionDocument1 pageTurbine BOP Drawing SubmissionAnonymous JtYvKt5XENo ratings yet

- Technical Documents of The BoilerDocument20 pagesTechnical Documents of The BoilerMatias Mancilla0% (1)

- Practical Guidelines For Determining Electrical Area ClassificationDocument17 pagesPractical Guidelines For Determining Electrical Area ClassificationOmar AzzainNo ratings yet

- TurboDocument8 pagesTurboKorichiKarimNo ratings yet

- Aux Boiler Steam Blow ProcedureDocument30 pagesAux Boiler Steam Blow ProcedureAnonymous JtYvKt5XENo ratings yet

- HRSG Steam Blow (Load 20 MW) PDFDocument2 pagesHRSG Steam Blow (Load 20 MW) PDFKanzanah PettaraniNo ratings yet

- Practical Guidelines For Electrical Area Classification inDocument11 pagesPractical Guidelines For Electrical Area Classification inaliris322No ratings yet

- 20.12 - GEK72281f Steam Purity Recommendations For Steam TurbinesDocument14 pages20.12 - GEK72281f Steam Purity Recommendations For Steam TurbinesLIUNo ratings yet

- Boiler Piping System Instruction Document Submission StatusDocument8 pagesBoiler Piping System Instruction Document Submission StatusHai NguyenNo ratings yet

- 29H-YM English PDFDocument108 pages29H-YM English PDFdeni subandiNo ratings yet

- HRSG references overviewDocument24 pagesHRSG references overviewthanhtbk2000No ratings yet

- VA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWDocument2 pagesVA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWhoangduythanhqbNo ratings yet

- NT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping SystemDocument15 pagesNT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping SystemHuynh Thanh TamNo ratings yet

- MD1-0-T-030-05-00397-A - ITP For STGDocument25 pagesMD1-0-T-030-05-00397-A - ITP For STGTran KhuynhNo ratings yet

- Va1 Dec 00100 I M1D Pid 8204 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8204 PDFAnonymous JtYvKt5XENo ratings yet

- ACC - Offer 000984 Rev PDFDocument31 pagesACC - Offer 000984 Rev PDFMohamed SaaDNo ratings yet

- 19 Boiler ESP System Commissioning Procedure-Töàtéëtö TÖñs Ÿt +T+ƑF Âf Ò Ä Û+Document31 pages19 Boiler ESP System Commissioning Procedure-Töàtéëtö TÖñs Ÿt +T+ƑF Âf Ò Ä Û+kvsagarNo ratings yet

- Uong Bi 300 MW Extension Power Plant: OwnerDocument29 pagesUong Bi 300 MW Extension Power Plant: OwnerAmEnPro100% (1)

- Va1 Dec 00100 I M1D Pid 8301 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8301 PDFAnonymous JtYvKt5XENo ratings yet

- Requisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)Document206 pagesRequisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)ThiruppathirajanNo ratings yet

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Document10 pagesDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182No ratings yet

- DL5000Document301 pagesDL5000ananizisikimNo ratings yet

- 锅炉一次风机及其系统调试措施Boiler PAF Commissioning ProcedureDocument34 pages锅炉一次风机及其系统调试措施Boiler PAF Commissioning ProcedurekvsagarNo ratings yet

- IAWPS GUIDELINE Volatile-2015Document32 pagesIAWPS GUIDELINE Volatile-2015prakashNo ratings yet

- Acc Vs Heller CTDocument37 pagesAcc Vs Heller CTkiddjoe1470No ratings yet

- Ethanol Plant Commissioning Startup and ShutdownDocument5 pagesEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083No ratings yet

- O&Msec2 Heat & Material BalanceDocument8 pagesO&Msec2 Heat & Material Balanceugun87No ratings yet

- 2 Boiler FDF and System Commissioning Procedure-TöàtéëTÇüTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+Document35 pages2 Boiler FDF and System Commissioning Procedure-TöàtéëTÇüTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+kvsagarNo ratings yet

- HRSG Water Chemistry and Inspection OverviewDocument5 pagesHRSG Water Chemistry and Inspection OverviewRahul ChoubeyNo ratings yet

- Mds HPH 1 - Skoda PowerDocument3 pagesMds HPH 1 - Skoda PoweridilfitriNo ratings yet

- Power Magazine - July 2016Document73 pagesPower Magazine - July 2016sergey500No ratings yet

- 9112 575 Opr 704 00046 - 01Document16 pages9112 575 Opr 704 00046 - 01Anonymous qT80dF24dNo ratings yet

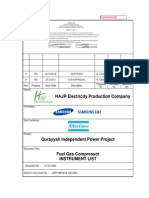

- QIPP MPN018 J00 2304 (1) Instr ListDocument9 pagesQIPP MPN018 J00 2304 (1) Instr Listsivasri999No ratings yet

- Vindh 9 CAVT ReportDocument20 pagesVindh 9 CAVT ReportSamNo ratings yet

- RideDocument8 pagesRidewahyuNo ratings yet

- Gresik Gas Cogeneration Plant PT Pembangunan Perumahan Gresik Gas Cogeneration Plant ProjectDocument56 pagesGresik Gas Cogeneration Plant PT Pembangunan Perumahan Gresik Gas Cogeneration Plant ProjectwahyuNo ratings yet

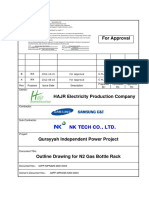

- N2 Gas Bottle Outline DrawingDocument2 pagesN2 Gas Bottle Outline DrawingMathivanan AnbazhaganNo ratings yet

- UTW CJSC Steam TurbinesDocument36 pagesUTW CJSC Steam TurbinesvamsiklNo ratings yet

- Reference LAC50 DMDocument41 pagesReference LAC50 DMVivek Singh100% (1)

- Product Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwDocument3 pagesProduct Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwCarlos ACNo ratings yet

- Bi-Drum Vs Single Drum - Research Paper 2Document6 pagesBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- Steam BlowingDocument11 pagesSteam Blowingheppy prastyo nugrohoNo ratings yet

- SEC A Bekasi Design SpecDocument20 pagesSEC A Bekasi Design Speccharleselitb92No ratings yet

- List Document 20150311Document23 pagesList Document 20150311citramuaraNo ratings yet

- VA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualDocument29 pagesVA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualhoangduythanhqbNo ratings yet

- Coal Mill in Thermal Power PlantDocument3 pagesCoal Mill in Thermal Power Plantkiki270977No ratings yet

- VA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualDocument29 pagesVA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualhoangduythanhqbNo ratings yet

- VA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualDocument29 pagesVA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualhoangduythanhqbNo ratings yet

- VA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualDocument29 pagesVA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualhoangduythanhqbNo ratings yet

- Steam Turbine Q&ADocument46 pagesSteam Turbine Q&Ahoangduythanhqb100% (1)

- Va1 Ac 00qea M M4B Dal 0002Document1 pageVa1 Ac 00qea M M4B Dal 0002hoangduythanhqbNo ratings yet

- 6.va1 Gedi 00HTC M M5 SPC 0001 - 0 PDFDocument11 pages6.va1 Gedi 00HTC M M5 SPC 0001 - 0 PDFhoangduythanhqbNo ratings yet

- 2.va1 Gedi 00HTF M M5 PHL 0001 - 1Document23 pages2.va1 Gedi 00HTF M M5 PHL 0001 - 1hoangduythanhqbNo ratings yet

- Va1 Tatl 00100 M M7 Cal 0001Document3 pagesVa1 Tatl 00100 M M7 Cal 0001hoangduythanhqbNo ratings yet

- Va1 Ac 00qea M M4B Dal 0001Document1 pageVa1 Ac 00qea M M4B Dal 0001hoangduythanhqbNo ratings yet

- VA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWDocument2 pagesVA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWhoangduythanhqbNo ratings yet

- SAP Sample Questions ReviewDocument18 pagesSAP Sample Questions ReviewYasir Yamin SadiNo ratings yet

- Sokolowski Robert Logic Parts Wholes in Husserls InvestigationsDocument18 pagesSokolowski Robert Logic Parts Wholes in Husserls InvestigationsveronicavronskyNo ratings yet

- C Programming Viva Questions for InterviewsDocument5 pagesC Programming Viva Questions for InterviewsParandaman Sampathkumar SNo ratings yet

- Snorks Udl Lesson Plan-1Document4 pagesSnorks Udl Lesson Plan-1api-253110466No ratings yet

- Postgresql Management and Automation With ClustercontrolDocument42 pagesPostgresql Management and Automation With ClustercontrolYiannisZormpas50% (2)

- Manuel V. Gallego Foundation Colleges, Inc. Cabanatuan City, PhilippinesDocument12 pagesManuel V. Gallego Foundation Colleges, Inc. Cabanatuan City, PhilippinesEdelmar BenosaNo ratings yet

- LocationDocument12 pagesLocationPavithra GowthamNo ratings yet

- Automatic Payment Program SAP Easy Access GuideDocument19 pagesAutomatic Payment Program SAP Easy Access GuidePrakash PalanisamyNo ratings yet

- Principles of Management All ChaptersDocument263 pagesPrinciples of Management All ChaptersRushabh Vora81% (21)

- C T Butler and Amy Rothstein On Conflict and Consensus A Handbook On Formal Consensus DecisionmDocument53 pagesC T Butler and Amy Rothstein On Conflict and Consensus A Handbook On Formal Consensus DecisionmdefoedefoeNo ratings yet

- PHP Jeremy Djakoure BEDJEDocument6 pagesPHP Jeremy Djakoure BEDJEjbedjeNo ratings yet

- Delete Entries On TRBAT and TRJOB Tables ..Document3 pagesDelete Entries On TRBAT and TRJOB Tables ..ssssssssssNo ratings yet

- SLR140 - ArDocument51 pagesSLR140 - ArDeepak Ojha100% (1)

- E Role of Natural Resources in Economic Development PDFDocument31 pagesE Role of Natural Resources in Economic Development PDFLisaMarieGaranNo ratings yet

- Flex Module (IFLEX MFLEX UFLEX) Level 1Document79 pagesFlex Module (IFLEX MFLEX UFLEX) Level 1John Mark EspalmadoNo ratings yet

- Prospectus 2023-24Document11 pagesProspectus 2023-24Niranjan SahooNo ratings yet

- SOFTWARE ARCHITECTURE DOCUMENT-OnlineCateringService Sample ExampleDocument10 pagesSOFTWARE ARCHITECTURE DOCUMENT-OnlineCateringService Sample ExampleMehwish HussainNo ratings yet

- COMSATS University Pakistan Studies Industrial Sector Challenges ProjectDocument3 pagesCOMSATS University Pakistan Studies Industrial Sector Challenges ProjectLaiba KhanNo ratings yet

- Pakistan Academy School Al-Ahmadi Kuwait Monthly Test Schedule Class: 9 FBISEDocument16 pagesPakistan Academy School Al-Ahmadi Kuwait Monthly Test Schedule Class: 9 FBISEapi-126472277No ratings yet

- Java Programming EbookDocument110 pagesJava Programming EbookShaina Mae M. UngsonNo ratings yet

- HydroVision Brochure Q Eye PSC 2014Document4 pagesHydroVision Brochure Q Eye PSC 2014sreeyukthaNo ratings yet

- Bethesda Softworks LLC v. Behaviour Interactive, Inc. and Warner Bros. Entertainment Inc.Document34 pagesBethesda Softworks LLC v. Behaviour Interactive, Inc. and Warner Bros. Entertainment Inc.Polygondotcom100% (1)

- Design Rule Check: By:-Chandan ROLL NO. 15/914 B.SC (Hons.) ELECTRONICS ScienceDocument9 pagesDesign Rule Check: By:-Chandan ROLL NO. 15/914 B.SC (Hons.) ELECTRONICS ScienceChandan KumarNo ratings yet

- Theoryt. PR.: of Birth H-GHRDocument1 pageTheoryt. PR.: of Birth H-GHRSanjay TripathiNo ratings yet

- Fisher Faculty Letter Re Giuliani 04.17.15Document2 pagesFisher Faculty Letter Re Giuliani 04.17.15Rochester Democrat and ChronicleNo ratings yet

- Juniper Baseline Operation GuideDocument380 pagesJuniper Baseline Operation GuideMushtaq HussainNo ratings yet

- A Detailed Lesson Plan in (Teaching Science)Document8 pagesA Detailed Lesson Plan in (Teaching Science)Evan Jane Jumamil67% (3)

- Notification JNTU Anantapur Assistant Professor Posts PDFDocument7 pagesNotification JNTU Anantapur Assistant Professor Posts PDFNagabhushanaNo ratings yet

- Cyril Acott - Occultism - An Alternative To Scientific HumanismDocument20 pagesCyril Acott - Occultism - An Alternative To Scientific Humanismparadigmshifter6360100% (2)

- PX Method 2 - Tim Ferriss - Sample Landing PageDocument5 pagesPX Method 2 - Tim Ferriss - Sample Landing PageshruikunNo ratings yet