Professional Documents

Culture Documents

Brick Bats 2

Uploaded by

Nambi HarishCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brick Bats 2

Uploaded by

Nambi HarishCopyright:

Available Formats

Nigerian Journal of Technology (NIJOTECH)

Vol. 32, No. 1, March, 2013, pp. 712.

Copyright

2013 Faculty of Engineering,

University of Nigeria. ISSN 1115-8443

COMPARATIVE ANALYSIS OF THE COMPRESSIVE

STRENGTH OF CONCRETE WITH GRAVEL AND CRUSHED

OVER BURNT BRICKS AS COARSE AGGREGATES

N.S. Apebo1,a , M.B. Iorwuab , J.C. Agunwamba2,a

a Department

of Civil Engineering, University of Nigeria, Nsukka, Nigeria.

Emails: 1 apebsonfreedom@yahoo.com 2 jcagunwamba@yahoo.com

b Department of Building Technology, Lobi Polytechnic, Makurdi, Nigeria. Email: iorwuabemmichael@gmail.com

Abstract

The research was conducted to study the possibility of utilizing the waste over burnt bricks abundantly available in most parts of Gwer-West Local Government Area of Benue State, particularly

Naka, the Local Government capital, as coarse aggregates in structural concrete. Trial mixes were

prepared using the crushed over burnt bricks known also as brick bats as coarse aggregates only,

mixture of crushed over burnt bricks and river wash gravel as well as using river washed gravel

from River Benue. Cubes of concrete were prepared and tested to study the compressive strength.

The result indicate that the concrete having brick bats as aggregates may be termed as medium

light weight concrete having a density between 2000-2200 kg/m3. To produce the same workability,

the brick aggregates concrete requires greater proportion of water than the normal gravel aggregate

concrete. Use of broken over burnt bricks as coarse aggregate for structural concrete is recommended when natural aggregate is not easily available, high strength of concrete is not required

and the bearing capacity of the soil is low.

Keywords:

compressive strength, concrete, crushed burnt bricks, coarse aggregates

1. Introduction

Concrete is a versatile engineering material consisting of cementing substance, aggregates, water and often controlled amount of entrained air. It is initially a

plastic, workable mixture which can be moulded into

a wide variety of shapes when wet. The strength is

developed from the hydration due to the reaction between cement and water. The products, mainly calcium silicate, calcium aluminates and calcium hydroxide are relatively insoluble which bind the aggregate in

a hardened matrix. Concrete is considerably stronger

in compression than in tension, for structures required

to carry only compressive loads such as massive gravity dams and heavy foundations, reinforcement is not

required and the concrete is consequently called plain

concrete. When the structure is to be subjected to

tensile stresses, steel bars are embedded in the concrete.

The requisite quantities of material for a given grade

of concrete are usually obtained from mix design.

The constituent materials, when properly batched and

thoroughly mix, set through the process of hydration

Nigerian Journal of Technology

and harden into a mass of concrete capable of resisting compressive stresses. The extent to which a given

concrete resists the compressive stresses to which it is

subjected depends largely on the compressive strength

of the concrete which in turn depends on the quality of

the concrete. Since seventy five per cent of concrete is

made up of aggregates, its types, quality and general

properties determine the quality of concrete [1].

Concrete is one of the most widely used construction material. The raw materials from which it is prepared; cement and aggregates, affect both the quality and cost of construction. Aggregates are usually

cheaper than cement and constitute over 70% the volume of concrete. The availability and proximity of

aggregate to the construction site also affect the cost

of construction.

At present, the most commonly used coarse aggregates for concrete production in Benue State of Nigeria is the river washed gravel due mainly to the presence of River Benue and its deposits. But these are

not readily available in some local government areas

which are not serviced by the river. Thus the cost of

transporting gravel to the areas outside the catchment

Vol. 32, No. 1, March 2013.

N.S. APEBO, M.B. IORWUA & J.C. AGUNWAMBA

of the river tends to increase the cost of construction

even at relatively low labour. This necessitates the

use of alternative coarse aggregates which are locally

obtained. One of such coarse aggregate is brick bat or

crushed burnt bricks obtained from the production of

burnt bricks.

In many countries, the need for locally manufactured building materials can hardly be overemphasized because there is an imbalance between the demands for housing and expensive conventional building materials coupled with the depletion of traditional

building materials. To address this situation, attention has been focused on low-cost alternative building

materials [2, 3].

According to Tse and Akpen [4], a significant decline in the utilization of all cement manufacturing

plants in Nigeria since the 1990s has raised the already exorbitant cost of cement above the reach of

the average Nigerian thereby encouraging a rise in

the emergence of a strong local burnt bricks industry

in many parts of Nigeria and Benue state in particular. The raw materials for burnt brick production

which comprise predominately of various proportions

of sand, silt and clay soils are derived from the deposits along the flood plains of major rivers and seasonal streams. These deposits when mixed, kneaded,

compacted in moulds and fired, produce bricks for

building construction. It is however interesting to note

that burnt bricks fired at a kiln temperature, of 1000

produce red to reddish brown bricks but beyond this

temperature, a dark blue coloured vitrified clinker results which melts and fuses together in a heap usually

discarded by natives and referred to as iron stone.

This research is therefore important as it tries to

compare the compressive strength of concrete made

with the conventional gravel and crushed burnt bricks

as the coarse aggregates. In recent times there has

been significant decline in the capacity utilization of

all cement manufacturing plants given rise to the

emergence of a strong local burnt bricks industry. The

bricks are made in various sizes using a local adaptation of the standards process controlled burnt bricks

technology. The raw materials compromise solely of

soil deposits found along the flood plains of major

rivers and seasonal streams. The process involves

excavating the earth material with a hoe, followed

by manual mixing with water into a plastic paste.

The mix is then kneaded and compacted into wooden

moulds, extruded and air dried under the sun and

fired with wood fuel. The firing techniques requires

the careful arrangement of the sun dried bricks in tabular or pyramid shaped heaps provided with several

interconnecting tunnels to allow for circulation of air

and heat. The tunnels are then stuffed with dry wood

which is the source of fuel and fired until the colour

of the bricks turn from natural gray into red at temperatures of between 600 1300 [4]. At extreme

Nigerian Journal of Technology

heating to a temperature of not less than 1600 the

burnt bricks changes from red to blue black ceramics

colour and in most cases fuses.

According to Chong [5], there are four recognized

stages in firing of burnt bricks:

(a) Drying (up to about 100 ). Water of plasticity

(shrinkage water) is removed and the clay product

becomes rigid but brittle.

(b) Dehydration (between 100 and 700 ). The clay

minerals lose their water of crystallization.

(c) Oxidation (between 550 and 900 ). Iron compounds are oxidized to ferric oxides (Fe2 03 ) and

all carbonaceous impurities are burnt out before

the temperature reaches 800 .

(d) Vitrification (950 and above). Crystallization

of mullite (Al6 Si02 013 ) begins the mullite crystals grow as the temperature is increased and the

glassy phase contracts causing a severe shrinkage.

At the onset of the vitrification, there is sintering

of the individual clay particles. During this period

dimensional shrinking of up to 15% occurs. Firing

ultimately produces a consolidated but porous mass

which contains both microcrystalline mullite and vitreous materials, together with unchanged quartz [6].

The vitrified brick can then be crushed and used as

coarse aggregate in concrete production.

Rashid et al [7] investigate the properties of higher

strength concrete made with crushed brick as coarse

aggregate and found that higher strength concrete

(fcu = 31.0 to 45.5 N/mm2 ) with brick aggregate is

achievable whose strength is much higher than the

parent uncrushed brick implying that the compressive

strength of brick aggregate concrete can be increased

by decreasing its water-cement ratio.

Bricks are a versatile and durable building and construction material, with good load-bearing properties.

Various researches have been carried out on porosity, permeability and absorption of bricks. Cachim

[8] have reported the properties of concrete which

use crushed bricks as natural coarse aggregate partial substitute. Experimental investigation has also

been done to achieve higher strength concrete using

crushed brick aggregate. It has been found that even

recycled brick can also be used as coarse aggregate

in concrete. Kesegic et al [9] have showed that concrete can be successfully produced by using recycled

aggregates that have been produced from demolition

and construction waste. According to Bhattacharjee

et al [10], the specific gravity and water absorption of

over burnt brick is found out to be 1.71 and 6.502%

respectively.

2. Materials and Method

The sand and gravel used for this project were obtained at the River Benue deposits. The over burnt

Vol. 32, No. 1, March 2013.

Comparison of Gravel & Crushed Over Burnt Bricks as Concrete Coarse Aggregates

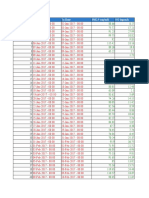

Table 1: Average Specific Gravities of Constituent Materials.

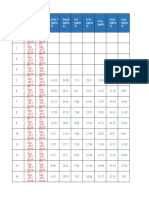

Table 3: Mixed Proportion of Gravel to crushed over Burnt

Bricks, W/C Ratio and Slump.

Material

Cement

Sand

Gravel

Crushed over

Burnt Bricks

Water

Specific Gravity

3.11

2.55

2.71

2.17

1.00

Mixed Proportion

4:0

3:1

2:2

1:3

0:4

Water/ Cement

Ratio

0.45

0.50

0.50

0.45

0.50

Slump

(mm)

39

45

35

30

25

Table 2: Aggregates Water Absorption.

Aggregate

Sand

Gravel

Crushed over

burnt bricks

Water absorption

(AWA)

6.3%

1.2%

4.4%

bricks samples were collected at a bricks production

site at Ana area of Naka, Gwer West Local Government Area of Benue State. Ordinary Portland cement

from Benue Cement Company (BCC), Gboko, Nigeria

was used as binding agent and water used for mixing

was from the Makurdi water works. The apparatus

used are: Specific Gravity Bottle, Balance, Tamping Rod, Ruler, Head Pan, Shovel, 75mm Diameter x

50mm Deep Measuring Cylinder, Timer, Slump Cone,

14mm, 10mm and 2.35mm BS sieves. Others are:

Hand Trowel, Compacting Machine, 0.15m 0.15m

0.15m Mould, Curing Tank, Scoops, Spanners, Electric Vibrator, Plunger, Base Plate, Compression Machine and Towel as well as stark of BS sieves and sieves

Shaker.

Specific gravity (G.S), aggregate impact value

(AIV) and aggregate crushing value (ACV) tests were

carried according to BS 882[11], BS 812-112[12] and

BS 812-110[13] respectively. Aggregate water absorption (AWA) test was conducted in compliance with

BS 812-109 [14] while particle size distribution analysis was carried out according to BS 812-103.1 [15].

The result of the specific gravity test is shown in Table 1. While that of water absorption is shown in

Table 2.

The concrete was batched and mixed according to

BS EN 206-1 [16]. Slump test was carried out on the

fresh concrete to determine the workability of the various proportions of the gravel to crushed burnt bricks

in accordance with BS 1881-102 [17]. The result of

the slump test is shown in Table 3 and Fig. 1.

The cube moulds were cleaned and oiled before each

casting. Nine concrete cubes of 150mm were produced

for each mix. A mix ratio of 1:2:4 was used. The

coarse aggregate was a mixture of crushed burnt bricks

and gravel in the proportions of 0:4, 1:3, 2:2, 3:1 and

Nigerian Journal of Technology

Figure 1: Workability of concrete using gravel and crushed

over burnt bricks in various mixed proportions measured by

slump.

4:0 of crushed burnt bricks to gravel. Water/Cement

ratios of 0.45, 0.50 and 0.60 were used.

Demoulding of the cubes was done between 18 hours

to 24 hours after casting. The hardened cubes were

transferred immediately into the curing tank at room

temperature. The cubes were removed at the end of

7, 14 and 28 days from the curing tank and air dried

for about 3 hours before testing. The results of the

compression tests at 28 days are given in Table 4 and

Fig. 2.

3. Results and Discussions

3.1. Sieve analysis

The result of the particle size distribution carried

out in accordance with BS 812-103.1 [15] is presented

in Figures 2 4.

From Fig. 2 more than 90% of the aggregate passed

through sieve 4.75mm which places the aggregate as

fine aggregate as (BS882) [11], and the assessment of

the particle size distribution revealed that the aggregate is well graded.

3.2. Specific gravity

The specific gravity test result of sand, gravel and

crushed over burnt bricks were respectively determined to be 2.55, 2.71 and 2.17 as shown in Table

Vol. 32, No. 1, March 2013.

10

N.S. APEBO, M.B. IORWUA & J.C. AGUNWAMBA

Table 4: Summary of Compressive Strength Test Results of Cubes Cast Using Various Mix Proportions of Gravel and crushed over

Burnt Bricks and Cured for 28 days.

Slump

(mm)

Proportion

of Gravel

39

30

35

45

25

4

1

2

3

0

Proportion

of Crushed

over burnt

bricks

0

3

2

1

4

Average

Weight

(g)

Average

Crushing

Load (kN)

Density

(kg/m3 )

Compressive

strength

(N/mm2 )

8628

7918

7851

8154

7529

470

560

490

520

570

2557

2346

2326

2416

2233

21

25

22

23

26

Figure 4:

Particle size distribution for coarse aggregate

(crushed over burnt bricks).

Figure 2: Particle size distribution for fine aggregate (sand).

1. The specific gravities of sand and gravel were

within the values reported by Bowles [18]. Crushed

over Burnt Bricks however, had a low specific gravity

of 2.17 probably because it is an artificial aggregate

whose strength and density depend on those of the

clay brick it is produced form. Bhattacharjee et al

[10] reported a value of 1.71.

3.3. Aggregate impact value

The result of aggregate impact value test for

crushed over burnt bricks is 28.2%. This mean impact value falls within the acceptable limits. BS 882

[11] prescribes maximum value of 45% for aggregate to

be used in concrete for non-wearing surfaces. The aggregate impact value is inversely related to the toughness of the aggregate, hence, the higher the value of

the impact, the lower the toughness.

3.4. Aggregate crushing value

Figure 3:

Particle size distribution for coarse aggregate

(gravel).

Nigerian Journal of Technology

The test result value for crushed over burnt bricks

is 22.8%. The value lies within maximum prescribed

value of 45% for ordinary concrete used for nonwearing surfaces by BS 882 [11]. Although there is no

direct relationship between aggregate crushing value

Vol. 32, No. 1, March 2013.

Comparison of Gravel & Crushed Over Burnt Bricks as Concrete Coarse Aggregates

11

Figure 5: The 28th day compressive strength as a function of the proportion of gravel to crushed over burnt bricks.

and the compressive strength of concrete, the test is

a guide to the expected strength of a concrete.

3.5. Aggregate water absorption

The test result of aggregate water absorption for

crushed over burnt bricks is 4.4% which is about half

of the maximum of 8.0% allowed for uncrushed bricks

by Brick [19], implying that the aggregate will be stable and durable even in wet condition.

3.6. Slump

The result of the slump test presented in Table 3

revealed a slump value of 39 mm at the W/C ratio of

0.45 for gravel to make the concrete workable. At the

gravel to crushed over burnt brick ratio of 3:1 and a

W/C ratio of 0.50, the slump increased to 45 mm.

This increment in W/C ratio is due to aggregate

water absorption of the crushed over burnt bricks

introduced. Furthermore, it can be seen that even

with a high W/C ratio of 0.50 for exclusive crushed

over burnt bricks (0:4), the workability has a slump

value of 25 mm also indicating that much of the water

may have been absorbed by the crushed over burnt

bricks. Figure 1 shows a relationship between slump

and the mixed ratio of gravel to crushed over burnt

bricks depicting the trends in the relationship.

3.7. Compressive strength

The 28th day result is presented in Table 4 and it

shows exclusive crushed over burnt bricks (0:4) having the highest strength of 26 N/mm2 while exclusive

gravel (4:0) ended up with the least strength of 21

N/mm2 . Bhattacharjee et al [10] achieved compressive strength of 29.16 N/mm2 by using a mix of 1:

1.24: 2.48 with w/c ratio of 0.48 with crushed over

Nigerian Journal of Technology

burnt bricks at 28th day. This result may probably

be as a result of absorbed water in the crushed burnt

bricks which sustained the hydration process over time

thereby increasing the compressive strength of the

concrete, bearing in mind that compressive strength

increases with the age of concrete. The variation of

the compressive strength with mix ratio of crushed

over burnt bricks to gravel is shown in Figure 2.

4. Conclusion

The following conclusions can be drawn from this

study:

1. Crushed over burnt bricks can be used as partial

replacement for river gravel in concrete production.

2. Crushed over burnt bricks can be used to produce

concrete with lower weight and hence lower dead

loads as such can be used on low bearing capacity

soils.

3. Crushed over burnt bricks can also be used to produce concrete with higher compressive strength

with reduced weights if the bricks are properly

and thoroughly burnt.

4. Recycling of crushed over burnt bricks could aid

in sanitizing the environment.

References

1. Neville, A. M. Properties of Concrete. (Fourth and

Final Edition), Pearson Educational Limited, Delhi,

1995.

Vol. 32, No. 1, March 2013.

12

N.S. APEBO, M.B. IORWUA & J.C. AGUNWAMBA

2. Agbede, I. O. and Manasseh, J. Use of Cement-Sand

Admixture in Laterite Brick Production for Low Cost

Housing. Leonardo Electronic Journal of Practices

and Technologies, January-June, 2008, p.164.

3. Waziri, B.S., Mohammed, A. and Bukar, A.G. Effect

of water-cement ratio on the strength properties of

Quarry-Sand Concrete (QSC). Continental Journal

of Engineering Sciences, 6(2), 2011, pp. 1621.

4. Tse, A.C. and Akpen, G.D. Suitability of Flood Plain

and Deposits for the Production of Burnt Bricks

in Parts of Benue State, Central Nigeria. Journal

of Mining and Geology, Nigerian Mining and Geosciences Society, (Accepted for publication), 2008.

5. Chong, C.V.Y. Properties of Materials. Macdonald

and Evans Publishers, London, 1981.

6. Jackson, N. and Dhir, R. K. Engineering Materials.

5th Edition, Palgrave, New York, 1996.

7. Rashid, M. A., Hossain,T. and Islam M. A. Properties of higher strength concrete made with crushed

brick as coarse aggregate. Journal of Civil Engineering (IEB), 37(1), 2009, pp. 43-52.

8. Cachim, P.B. Mechanical Properties of brick aggregate concrete. Construction and Building Materials,

23, 2009, pp. 1292-1297.

9. Kesegic, I., Netinger, I. and Bjegovic, D. Recycled

Clay Brick as an aggregate for concrete. Technical

Gazette, 15(3),2008, pp. 35-40.

10. Bhattacharjee, E., Nag, D., Sarkar, P. P. and Haldar,

L. An Experimental Investigation of Properties of

Crushed over Burnt Brick Aggregate Concrete. International Journal of Engineering Research and Technology, Volume 4, Number 1, 2011, pp. 21-30.

11. BS 882. Specifications for Aggregate for Natural

Sources for Concrete. British Standard Institution,

London, 1992.

12. BS 812-112. Testing Concrete-Methods for determination of Aggregate Impact Value. British Standard

Institution, London, 1990.

13. BS 812-110. Testing Concrete-Methods of determination of Aggregate Crushing Value. British Standard

Institution, London, 1992.

14. BS 812-109. Testing Concrete-Methods for determination of moisture content. British Standard Institution, London, 1990.

15. BS 812-103.1 Methods for determination of particle

size distribution-Sieve tests. British Standard Institution, London, 1985.

16. BS EN 206-1. Concrete-Specification, performance,

production and conformity. British Standard Institution, London, 2000.

17. BS 1881-102. Testing Concrete-Method for determination of slump. British Standard Institution, London, 1983.

18. Bowles, J.E. Foundation Analysis and Design. 4th

Edition, McGraw Hills International, New York,

1997.

19. Bricks, S. Clay Bricks Specification. Shawberick, New

York, 2000.

Nigerian Journal of Technology

Vol. 32, No. 1, March 2013.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Group Case Study Rubric 3Document3 pagesGroup Case Study Rubric 3Saraswathi Asirvatham67% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- L GSR ChartsDocument16 pagesL GSR ChartsEmerald GrNo ratings yet

- Levels of CommunicationDocument3 pagesLevels of CommunicationAiyaz ShaikhNo ratings yet

- Is 3812 Specification For Fly Ash For Use As Pozzolana and A.182132528Document11 pagesIs 3812 Specification For Fly Ash For Use As Pozzolana and A.182132528Nambi Harish67% (6)

- Executive Summary: 2013 Edelman Trust BarometerDocument12 pagesExecutive Summary: 2013 Edelman Trust BarometerEdelman100% (4)

- Aashto M288-17 Product Selection GuideDocument1 pageAashto M288-17 Product Selection GuideDem DemNo ratings yet

- Sprinkler Sizing en v1Document12 pagesSprinkler Sizing en v1CristianDumitru0% (1)

- Lecture No.4BDocument163 pagesLecture No.4BNambi HarishNo ratings yet

- Construction Project - Life Cycle PhasesDocument4 pagesConstruction Project - Life Cycle Phasesaymanmomani2111No ratings yet

- Modern Construction HandbookDocument498 pagesModern Construction HandbookRui Sousa100% (3)

- Techniques of Artificial Recharge To Ground WaterDocument3 pagesTechniques of Artificial Recharge To Ground WaterNambi HarishNo ratings yet

- Data Visualization With Ggplot2::: Cheat SheetDocument2 pagesData Visualization With Ggplot2::: Cheat SheetNambi HarishNo ratings yet

- Chandeep Telangana-SanathnagarDocument370 pagesChandeep Telangana-SanathnagarNambi HarishNo ratings yet

- Air Pollution Data - Anand Kala Ke - Rajamen - A.P.Document516 pagesAir Pollution Data - Anand Kala Ke - Rajamen - A.P.Nambi HarishNo ratings yet

- Bhaskarpeenaya BNGLR K.A.Document1,032 pagesBhaskarpeenaya BNGLR K.A.Nambi HarishNo ratings yet

- 17ce31e5 Rs&GisDocument2 pages17ce31e5 Rs&GisNambi HarishNo ratings yet

- Air Pollution Data AmaravatiDocument486 pagesAir Pollution Data AmaravatiNambi HarishNo ratings yet

- Sourcebook of Alternative Technologies For Freshwater Augumentation in Some Countries in AsiaDocument5 pagesSourcebook of Alternative Technologies For Freshwater Augumentation in Some Countries in AsiaNambi HarishNo ratings yet

- Ijrsg 06 16Document5 pagesIjrsg 06 16Nambi HarishNo ratings yet

- Acid RainDocument16 pagesAcid RainNambi HarishNo ratings yet

- Arg Gis GeoreferenceDocument28 pagesArg Gis GeoreferenceNambi HarishNo ratings yet

- Recent Trends in Replacement of Natural Sand With Different AlternativesDocument8 pagesRecent Trends in Replacement of Natural Sand With Different AlternativesNambi HarishNo ratings yet

- CÁC HÌNH THỨC BỔ SUNG NƯỚC NGẦMDocument18 pagesCÁC HÌNH THỨC BỔ SUNG NƯỚC NGẦMLê Mỹ LàiNo ratings yet

- AEE I& CADDocument28 pagesAEE I& CADNarendra BabuNo ratings yet

- Art 3A10.1007 2Fs00254 005 1284 4 PDFDocument13 pagesArt 3A10.1007 2Fs00254 005 1284 4 PDFNambi HarishNo ratings yet

- Insat 3d BrochureDocument6 pagesInsat 3d BrochureNambi HarishNo ratings yet

- Soil Loss Estimation Thriugh MUSLE Using Kirpich & Williams Times of Concentration Using RS & GIS Techniques - A Case StudyDocument11 pagesSoil Loss Estimation Thriugh MUSLE Using Kirpich & Williams Times of Concentration Using RS & GIS Techniques - A Case StudyNambi HarishNo ratings yet

- One Rank One PensionDocument1 pageOne Rank One PensionNambi HarishNo ratings yet

- Clustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaDocument18 pagesClustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaAji LaksonoNo ratings yet

- Ethernet/Ip Parallel Redundancy Protocol: Application TechniqueDocument50 pagesEthernet/Ip Parallel Redundancy Protocol: Application Techniquegnazareth_No ratings yet

- Poster-Shading PaperDocument1 pagePoster-Shading PaperOsama AljenabiNo ratings yet

- FIR FliterDocument10 pagesFIR FliterasfsfsafsafasNo ratings yet

- Banking Ombudsman 58Document4 pagesBanking Ombudsman 58Sahil GauravNo ratings yet

- Digital Systems Project: IITB CPUDocument7 pagesDigital Systems Project: IITB CPUAnoushka DeyNo ratings yet

- Course Outline ENTR401 - Second Sem 2022 - 2023Document6 pagesCourse Outline ENTR401 - Second Sem 2022 - 2023mahdi khunaiziNo ratings yet

- Michael Clapis Cylinder BlocksDocument5 pagesMichael Clapis Cylinder Blocksapi-734979884No ratings yet

- Names of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: KindergartenDocument4 pagesNames of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: Kindergartenapi-428128701No ratings yet

- Categorical SyllogismDocument3 pagesCategorical SyllogismYan Lean DollisonNo ratings yet

- FS-1040 FS-1060DN: Parts ListDocument23 pagesFS-1040 FS-1060DN: Parts List1980cvvrNo ratings yet

- Plan Lectie Clasa 5 D HaineDocument5 pagesPlan Lectie Clasa 5 D HaineCristina GrapinoiuNo ratings yet

- File RecordsDocument161 pagesFile RecordsAtharva Thite100% (2)

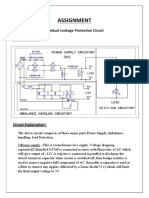

- Assignment: Residual Leakage Protection Circuit Circuit DiagramDocument2 pagesAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaNo ratings yet

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Document2 pagesSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhNo ratings yet

- Table of Reinforcement Anchorage Length & Lap Length - Eurocode 2Document7 pagesTable of Reinforcement Anchorage Length & Lap Length - Eurocode 2NgJackyNo ratings yet

- ME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Document85 pagesME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Nathar ShaNo ratings yet

- Documentation Report On School's Direction SettingDocument24 pagesDocumentation Report On School's Direction SettingSheila May FielNo ratings yet

- Internal Resistance To Corrosion in SHS - To Go On WebsiteDocument48 pagesInternal Resistance To Corrosion in SHS - To Go On WebsitetheodorebayuNo ratings yet

- str-w6754 Ds enDocument8 pagesstr-w6754 Ds enAdah BumbonNo ratings yet

- BDocument28 pagesBLubaNo ratings yet

- Civil Rights Vocabulary Lesson PlanDocument4 pagesCivil Rights Vocabulary Lesson PlanKati ArmstrongNo ratings yet