Professional Documents

Culture Documents

Grundfos Alldos Product Information: The Universal Diaphragm Dosing Pump

Uploaded by

36Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grundfos Alldos Product Information: The Universal Diaphragm Dosing Pump

Uploaded by

36Copyright:

Available Formats

GRUNDFOS alldos

product information

DMI

The universal diaphragm dosing pump

Measurements

DMI

l DMI with manual deaeration

156

113

145

A

105

120

n DMI with automatic deaeration

113

p DMI Inside

92

66

105

116

C1

51

3/8"

D1

6.5

105

4.8

Drilling scheme DMI model 208

B1

84.5

L

100%

70

40

50

60

Drilling scheme DMI Inside

PE

20

10

90

30

80

A1*

A1

90

75

4.

Measurements in mm

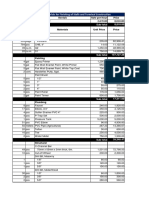

Measurements / Types

DMI

Measurements

DMI models

ln

A1

A1*

B1

C1

D1

208-0.3 (IN)

225

13.7

175.5

112

G 3/8

208-0.8 (IN) to -1.1 (IN)

225

112

13.7

29

175.5

58

112

G 3/8

208-1.6 (IN) to -3.0 (IN)

225

223

218

112

13.7

13.7

29

175.5

221.6

58

112

161

G 3/8

208-3.6 (IN) to -6.0 (IN)

225

223

218

112

13.7

13.7

29

175.5

221.6

58

112

161

G 3/8

208-9.0 (IN) to -18 (IN)

230

228.6

244

133

19.7

19.7

35

184.5

226.6

60

133

175

G 5/8

Pump types

Mains voltage 230 V 10 %, 50/60 Hz, with cable and Euro plug

No electronics, manual stroke adjustment, strokes per minute: 120 at 50 Hz, 144 at 60 Hz

Connections please see page 4

50 Hz

Q

Pmax

[l/h]

[bar]

60 Hz

Q

[l/h]

Pmax

[bar]

Q

[USg/h]

Pmax

[psi]

Vstroke

[cm3]

DMI models

208

208 Inside

Max. backpressure 10 bars at 50 Hz

0.3

10

0.36

10

0.095

145

0.04

208-0.3

1.0

10

1.2

10

0.317

145

0.14

208-1.0

208-1.0 IN

1.6

10

1.92

10

0.507

145

0.22

208-1.6

208-1.6 IN

2.9

10

3.5

0.925

102

0.42

208-3.0

208-3.0 IN

4.0

4.8

1.270

87

0.55

208-4.0

208-4.0 IN

5.0

1.580

72.5

0.69

208-5.0

208-5.0 IN

6.0

7.2

1.902

87

0.84

208-6.0

208-6.0 IN

9.0

11

5.5

2.853

80

1.24

208-9.0

208-9.0 IN

14

16.8

4.439

44

1.92

208-14

208-14 IN

18

3.5

21.6

5.702

44

2.46

208-18

208-18 IN

208-0.8 IN

DMI

Max. backpressure 16 bars at 50 Hz

0.8

16

0.96

16

0.254

232

0.13

208-0.8

1.1

16

1.32

16

0.349

232

0.16

208-1.1

208-1.1 IN

3.6

16

4.32

13

1.140

189

0.50

208-3.6

208-3.6 IN

Max. backpressure 10 bars, with automatic deaeration, at 50 Hz

0.75

10

0.9

10

0.238

145

0.14

208-1.0

1.2

10

1.44

10

0.380

145

0.22

208-1.6

2.5

3.0

0.792

102

0.42

208-3.0

3.5

4.2

1.109

87

0.55

208-4.0

4.4

5.28

1.394

72,5

0.69

208-5.0

5.47

6.5

1.711

87

0.84

208-6.0

8.3

10

2.630

58

1.24

208-9.0

13.3

16

4.213

44

1.92

208-14

17

2.5

20.40

5.386

29

2.46

208-18

Built-in pump DMI Inside 208-...IN

Technical data

DMI

Technical data

With automatic

deaeration

Especially suitable for violently degassing and crystallizing fluids (e.g. hydrogen peroxide or peracetic acid)

Accuracy

Dosing flow variation 1.5 %, linearity 4 %

Noise emission

approx. 45 dB(A), testing following DIN 45635-01-KL3

Max. suction height

6 m WC, for filled suction line and dosing head, continous operation

these details refer to non degassing media with viscosity similar to water

Admission/backpressure

max. 0.2 bar admission pressure at suction side / min. 1 bar backpressure at pressure side

Max. viscosity

up to 200 mPa s (with automatic deaeraton up to 50 mPa s)

Max. temperature

max. ambient temperature 40 C

Parts in contact with media

PVC/Viton/glass, PVC/EPDM/ceramics, PP/Viton/glass, PVDF/PTFE/PTFE

or stainless steel/PTFE/stainless steel; dosing diaphragm Viton /PTFE coated

Motor

Synchronous motor with gear reduction 230 V or 115 V, 50/60 Hz

11 W: for DMI model 208-0.3 / -1.0 / -1.6 / -3.0 / -4.0 / -5.0

22 W: for DMI model 208-0.8 / -1.1/ -3.6/ -6.0/ - 9.0/ -14/ -18

Protection level

IP 65 (pump protection)

Weight

approx. 2.9 kg / RAL 6017; except DMI model 208 Inside: approx. 1.5 kg

Not suitable for chlorine bleaching!

Except 208-0.3: flooded suction!

Except DMI model 208 Inside: IP 20

Connections

Pumps 10 bars

DMI 208-0.3 /-1.0 /-1.6 /-3.0 /-4.0 /-5.0 /-6.0

DMI 208-0.9 / -14 / -18

suction side: PVC or PE hose 4/6, PVDF pipe 4/6, steel pipe 4/6

pressure side: PE hose 4/6, PVDF pipe 4/6

No PVC hose!

suction /pressure side: PVC hose 6/12, PP pipe 12/16 or PVDF pipe 14/16, steel pipe 1/4

10 bars < pumps 16 bars

DMI 208-0.8 / -1.1 / -3.6

suction side: PVC or PE hose 4/6, PVDF pipe 4/6, steel pipe 4/6

pressure side: PVC hose 6/12, PP pipe 12/16 or PVDF pipe 14/16

Functional drawing

1

Synchronous motor (11 W / 22 W)

Eccentric drive

Stroke adjustment

4 Energy storage (for DMI model

208-3.6 and 208-6.0 to 208-18)

5

Dosing diaphragm

6 Dosing head

7

Suction valve

8 Pressure valve

9 Dosing head deaeration

10 Pump enclosure

11 Enclosure for connections and

electronics

Versions / Options

DMI

Dosing head and valve versions

Material

Dosing head Valve body

Seat

Options: dosing head with

Gaskets

Valve ball

4/6

1)

6/12

12/16

14/16

special valves

spring-loaset for visded pressure cous liquids 2)

valve

>100 mPa s

automatic

deaeration

valve 3)

diaphragm

breakage

indication

Dosing head with manual deaeration valve

PVC

PVC

Viton

Viton

glass

glass

PVC

PVC

EPDM

EPDM

ceramics

PTFE

PP

PP

Viton

Viton

glass

glass

PP

PP

EPDM

EPDM

ceramics

PTFE

PVDF

PVDF

PTFE

PTFE

ceramics

PTFE

stainl. steel

stainl. steel

Viton

Viton

stainl. steel

stainl. steel

stainl. steel

stainl. steel

PTFE

PTFE

stainl. steel

stainl. steel

1) material depending on the connection size

2) suction and pressure side : spring-loaded valve with steel ball, connection 4/6 (208-0.3) or 6/12 (from 208-0.8);

DMI model 208-9.0/-18: suction side 9/12, pressure side 6/12

3) not for DMI model 208-0.3 and not for DMI model 208 Inside

Options

Mains voltage:

Mains plug / -cable

Electronics

220-240 V, 50/60 Hz

Euro / 1.5 m

Diaphragm leakage indication

110-120 V, 50/60 Hz

Switzerland / 1.5 m

Dosing controller

24 V, 50/60 Hz, not for 208-18IN

without mains plug / 1.5 m

DMI P3

Optional electronics Etron

Contact signal and stroke frequency signal electronics

Electronics not available for DMI model 208 Inside!

Electronics without outputs

Etron

Input contacts N. O.

Unidos

Input contacts N. O.

Electronics with outputs

Outputs for error signal + pre-alert signal, contacts N. O.

Etron, with multiplier /divisor

Outputs for error signal + stroke signal, contacts N. O.

Outputs for error signal + pre-alert signal, contacts N. C.

Outputs for error signal + stroke signal with Hall sensor, contacts N. O.

Unidos, contact signal 1:1

Outputs for error signal + stroke signal, contacts N. O.

Outputs for error signal + stroke signal with Hall sensor, contacts N. O.

Accessories

DMI

Accessories and armatures

(see separate Data Booklet Accessories)

6

Flow scheme of a complete dosing installation

1

Dosing tank 502

Electric agitator 509

Dosing pump DMI

3

2

8

4 Suction line 531 with empty signal

5

Pressure relief valve 525

6 Pulsation damper 517

7

Pressure loading valve 525

8 Injection unit 522

Transparent cover

For dirt protection: optional for pumps with horizontal display

Description

Order number

Transparent cover (Makrolon)

553-1456

Wall console

With fastening material

Description

Order number

PE black

539-006

Signal transmission

Description

Order number

Cable with plug, length 2 m

for contact input, analog signal input and remote On/Off

321-205

for outputs pre-alert / error signal and stroke signal

321-206

Cable with plug, length 5 m

for contact input, analog signal input and remote On/Off

321-207

for outputs pre-alert / error signal and stroke signal

321-208

Combined plug / cable for diaphragm leakage indication and dosing controller

combined plug 5 poles

321-210

cable 5 poles, length 5 m

321-223

Spare parts

DMI

Spare parts sets

Suction and pressure valves (steel: only inner valve parts), gaskets for dosing head

and valves, 1 deaeration cartridge, 1 dosing diaphragm, 4 screws for dosing head

Pump

Material

Order number

Dosing head with manual deaeration valve

PVC / Viton / glass

553-1395

PVC / EPDM / ceramics

553-1399

PVC / Viton / ceramics

553-1526

PP / Viton / glass

553-1396

PP / EPDM / ceramics

553-1400

PP / Viton / ceramics

553-1693

PVDF / PTFE / ceramics

553-1401

Stainless steel / PTFE / st. steel

553-1402

PVC / Viton / glass

553-1403

PVC / EPDM / ceramics

553-1407

DMI 208-0.8 to

DMI 208-4.0

PVC / Viton / ceramics

553-1597

PP / Viton / glass

553-1404

DMI 208-0.8 IN to

DMI 208-4.0 IN

PP / EPDM / ceramics

553-1408

PP / Viton / ceramics

553-1694

PVDF / PTFE / ceramics

553-1409

Stainless steel / PTFE / st. steel

553-1410

PVC / Viton / glass

553-1411

PVC / EPDM / ceramics

553-1415

DMI 208-5.0 and

DMI 208-6.0

PVC / Viton / ceramics

553-1598

PP / Viton / glass

553-1412

DMI 208-5.0 IN and

DMI 208-6.0 IN

PP / EPDM / ceramics

553-1416

PP / Viton / ceramics

553-1695

PVDF / PTFE / ceramics

553-1417

Stainless steel / PTFE / st. steel

553-1418

PVC / Viton / glass

553-1419

DMI 208-0.3

DMI 208-0.3 IN

PVC / EPDM / PTFE

553-1423

DMI 208-9.0 to

DMI 208-18

PVC / Viton / ceramics

553-1708

PP / Viton / glass

553-1420

DMI 208-9.0 IN to

DMI 208-18 IN

PP / EPDM / PTFE

553-1424

PP / Viton / ceramics

553-1709

PVDF / PTFE / PTFE

553-1425

Stainless steel / PTFE / st. steel

553-1426

Dosing head with automatic deaeration valve

DMI 208-1.6 to

DMI 208-4.0

PTFE / Viton / PTFE

10.8274-616

PTFE / EPDM / PTFE

10.8274-615

DMI 208-5.0 and

DMI 208-6.0

PTFE / Viton / PTFE

10.8274-616

PTFE / EPDM / PTFE

10.8274-615

DMI 208-9.0 to

DMI 208-18

PTFE / Viton / PTFE

10.8274-616

PTFE / EPDM / PTFE

10.8274-615

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

96681612 0307

15.820002 V6.0

EN

Grundfos Alldos

Dosing & Disinfection

ALLDOS Eichler GmbH

www.grundfosalldos.com

Subject to change.

You might also like

- CAT 330 B - Parts Catalog PDFDocument1,343 pagesCAT 330 B - Parts Catalog PDFSumudu Adikari91% (11)

- Adeverinta DonatDocument1 pageAdeverinta Donat36No ratings yet

- BAUER Trench Cutter Systems - 905-679-2!02!12Document32 pagesBAUER Trench Cutter Systems - 905-679-2!02!1236100% (1)

- Haulotte 1300RTDocument2 pagesHaulotte 1300RT36No ratings yet

- Boilere Electrice Compact Line TesyDocument6 pagesBoilere Electrice Compact Line Tesy36No ratings yet

- MBP16Document20 pagesMBP1636No ratings yet

- Instructiuni in Limbajul de Program Are PascalDocument4 pagesInstructiuni in Limbajul de Program Are Pascalrodica2007No ratings yet

- Airo SG 1000 New eDocument2 pagesAiro SG 1000 New e36No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 1 Engine Overview MR479QDocument25 pages1 Engine Overview MR479QAdi WidiantoNo ratings yet

- (23540192 - Mechanics and Mechanical Engineering) Kinematic and Dynamic Analysis For A New MacPherson Strut Suspension SystemDocument16 pages(23540192 - Mechanics and Mechanical Engineering) Kinematic and Dynamic Analysis For A New MacPherson Strut Suspension SystemIulian NgiNo ratings yet

- Flower Duet in G Voices OnlyDocument80 pagesFlower Duet in G Voices Onlym1d0r1No ratings yet

- Mfe24pi1505 Design of Production Toolingdrill BushingsDocument14 pagesMfe24pi1505 Design of Production Toolingdrill BushingsSubrat pandaNo ratings yet

- Paper Id (Me302) : Nav'.O (Document2 pagesPaper Id (Me302) : Nav'.O (RaJan GargNo ratings yet

- ABSC-2452 Blast Machine - 200 LTR.: Instruction ManualDocument18 pagesABSC-2452 Blast Machine - 200 LTR.: Instruction ManualUtomoNo ratings yet

- Developer Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseDocument18 pagesDeveloper Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseGokul SelvarajNo ratings yet

- Honeywell Electro-Hydraulic Servo Valves EHSVDocument2 pagesHoneywell Electro-Hydraulic Servo Valves EHSVAhua HuangNo ratings yet

- Implant Abutment NeckDocument7 pagesImplant Abutment NecknobelcyrilNo ratings yet

- CondenserDocument5 pagesCondensersandeshNo ratings yet

- Axle Boot MarutiDocument2 pagesAxle Boot MarutinrjmanitNo ratings yet

- Power System Protection - Part 10Document22 pagesPower System Protection - Part 10Matthew WongNo ratings yet

- Flue Gas CalculationDocument2 pagesFlue Gas CalculationhcorpdgpNo ratings yet

- 3 Hrs Motor Grader 2,670.00 8,010.00: Detailed Bill of Materials For Finishing of Stalls and Terminal ConstructionDocument2 pages3 Hrs Motor Grader 2,670.00 8,010.00: Detailed Bill of Materials For Finishing of Stalls and Terminal ConstructionKris Aileen CortezNo ratings yet

- Mech ANM 2019R1 WS04D-Anisotropic HyperelasticityDocument14 pagesMech ANM 2019R1 WS04D-Anisotropic HyperelasticityDong LINo ratings yet

- Entropy of Mixing PDFDocument16 pagesEntropy of Mixing PDFrupaliroyNo ratings yet

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- Correlation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001Document21 pagesCorrelation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001lram70No ratings yet

- flowIT FTBGDW-16Document1 pageflowIT FTBGDW-16technicalsupportNo ratings yet

- Aeromodelling DesignDocument70 pagesAeromodelling DesignMayank AgrawalNo ratings yet

- Kolbitsch PPPDocument23 pagesKolbitsch PPPradanpetricaNo ratings yet

- Tube HydraulicsDocument8 pagesTube HydraulicsrijalharunNo ratings yet

- BRS Manual Rev 4-10Document38 pagesBRS Manual Rev 4-10RondrashNo ratings yet

- ZoellerDocument4 pagesZoellerWharfedaleNo ratings yet

- FlushFlo - Flush Bottom ValveDocument2 pagesFlushFlo - Flush Bottom ValveVarun PatelNo ratings yet

- GATE 2021 Test Series 1 1 PDFDocument6 pagesGATE 2021 Test Series 1 1 PDFSatyajit SahuNo ratings yet

- Liebherr HS 873 HDDocument8 pagesLiebherr HS 873 HDLukmanNo ratings yet

- Reinforced Concrete Design of A 5 Storey Seminary Main BuildingDocument117 pagesReinforced Concrete Design of A 5 Storey Seminary Main Buildingjedsclement100% (1)

- Goodyear OTR Databook2009Document169 pagesGoodyear OTR Databook2009otr-tireman100% (1)

- Lecture 1 Ultimate Bearing CapacityDocument22 pagesLecture 1 Ultimate Bearing CapacityErica Jane TatelNo ratings yet