Professional Documents

Culture Documents

1.piping Introduction and Fundamentals

Uploaded by

John Larry CorpuzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.piping Introduction and Fundamentals

Uploaded by

John Larry CorpuzCopyright:

Available Formats

PIPING INTRODUCTION

2014

PIPING INTRODUCTION

SUMIT

Er.sumit_sharma@outlook.com

PIPING INTRODUCTION

INDEX

CODE

PIPING V /S PIPELINE

PRINCIPLES OF PIPING ENGINEER

STANDARDS

PLANT DISCIPLINE

PIPING FUNDAMENTALS

PIPE

PIPING ASPECTS

PIPING INTRODUCTION

PIPING INTRODUCTION AND FUNDAMENTALS:

Oil/gas refinery

Petrochemical plant

Chemical plant

Ammine plant

Alcohol plant

Pesticide plant

Textile plant

Cement plant

Hygienic plant: (s.s is used)

Pharmaceutical plant: more precaution is taken

Food plant:

Dairy plant

Chocolate plant

Pepsi/ coke plant

Green field project: to be constructing

Brown field project: working

ASME American society of mechanical engineering

Or

ANSI American national standard institute

CODE:

Definition: it consist of standards for design, fabrication, installation, testing and m/L

instructions

Complexity of process plant:

Fluid

Normal

Flammable

Toxic- H2

Viscous

Corrosive

PIPING INTRODUCTION

Temperature > 1000f

Pressure > 6000 psi

ASME 31.3: process piping code

ASME 31.1: power piping code

ASME 31.4: liquid transportation pipe lines

ASME 31.8: gas transportation pipelines

PIPING V/S PIPELINES

Piping system inside the plant only

Pipe line b/w 2 plants/ cities/ countries

PRINCIPLES OF PIPING ENGINEER:

1) Safety:

The piping system which is design and constructed should be safe (by using

codes and standards)

2) Constructability:

The piping system which is design should also be construct able

3) Operability : the piping system which is design and constructed should also be

operable

4) Maintainability:

The piping system which is design and constructed and operated should also

be maintained which requires placing the facilities in the area by following

their maintenance requirements.

Like: a valve during the operation may have maintenance requirement so it

should be located where it can be excess by the plant technician to reduce

maintenance time.

5) Economy:

The piping system which is design, constructed, operated and maintained will

should also be economical.

PIPING INTRODUCTION

STANDARDS:

These are documents prepared by professionals for the components which are to be

used in the market of piping system.

PLANT DISCIPLINES:

Process engg. ( chemical engg)

Piping engineer

Mechanical engg.

Civil engg

Electrical engg

Instrumentation engg

PLANT

25%

50% mechanical equipment

50%

25%

23 to 25 % piping

25 to 27 %

civil,instrumental,electrical

PIPING INTRODUCTION

PIPING FUNDAMENTALS:

1) Drawings

Flow diagram

Block flow diagram

Process flow diagram

P & id

Utility flow diagram

Layouts

Isometrics

2) Equipment supports

3) Piping supports

4) Design calculation

5) Stress analysis- Caesar II

PIPE:

It is cylindrical shape structure used to transfer the fluid, solid or semi solids from one

pt. to another under pressure.

Fluid :

Liquids( water)

Gases( air)

Solids :

pellets( tablets)

powder ( cement)

semi solids:

slurry( crude oil, grease)

PIPING INTRODUCTION

PIPING ASPECTS:

1. Diameter:

IPS: ( iron pipe size)

It is dimensionless pipe designator (indicator) of pipe. It represents the

I.D of the pipe in inches.

Ex: IPS 6 I.D of the pipe is 6

NPS: ( nominal pipe size)

It is dimensional pipe designator of pipe. It represents O.D of pipe in

inches.

Ex: NPS 6OD of pipe is 6.625

NPS 14OD of pipe is 14

NB: ( nominal bore)

It is dimensional pipe designator of pipe. It represents OD of pipe in

mm.

Ex: NB 100 OD of pipe is 114 mm

NB 400OD of pipe is 400 mm

DN: ( diameter nominal)

It is dimensionless designator of pipe. It represents OD of pipe in mm.

Ex: DN 100 OD of pipe is 114 mm

DN 400 OD of pipe is 400 mm

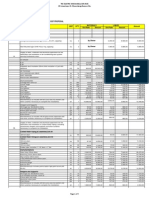

NPS

1

2

3

4

6

8

10

12

14

OD

1.315

2.375

3.5

4.5

6.625

8.625

10.75

12.75

14

NB/DN

25

50

80

100

150

200

250

300

350

PIPING INTRODUCTION

Note:

Up to NPS 12 , OD > NPS

From NPS 14, OD = NPS

Note:

Smallest pipe size : 3mm or 1/8

Max pipe size : 60 ( 5 feet)

Note:

Pipe of size < NPS 2 are called small bore pipes

Pipe of size > NPS 2 are called big bore pipes

Highest of small bore size = 1.5

2. Wall thickness:

It is represented by following terms.

(i).

Schedule no. ( SCH)

(ii). Pipe weight designation

(i)

SCH:

It is a no. which has standardize thickness as per the standards

Sch no. range :

5, 5s, 10, 10s,20,20s,30,40,60,80,100,120,140,160

Sch no. without s is for CS and AS

Sch no with s is for ss

Ex: NPS 6 SCH 10

NPS 6 SCH 10s

Pipe weight designation:

It is alternative way for representing pipe thickness

STD standard weight thickness

XS/XH extra strong /extra heavy

XXS/XXH double extra strong/ double extra heavy

(ii)

Ex: NPS 6 SCH STD

STD SCH 40 for diff. pipe size

XS SCH 80

PIPING INTRODUCTION

i)

ii)

iii)

iv)

t = P do/ 2(SEW + PY)

tm = t + A

= tm 12.5 % mill tolerance

Sch thickness from standards

Here:

t = thickness

P = internal pressure

Do = outer diameter

S = basic allowable stress from code

E = longitudinal weld joint quality factor from code

W = weld joint stress reduction factor from code

Y = coeff. For m/L from code

tm = min thickness

A = sum of corrosion, erosion, thread depth allowance (TDA)

= nominal thickness

3. Pipe length :

Single random length : 6 m ( 20 feet)

Double random line : 12m ( 40 feet)

Customize length : as per customer requirement ( for pipelines)

10

PIPING INTRODUCTION

4. Pipe ends:

Plane ends: for small bores

Screwed / threaded ends: for small bores

Straight

Tapered : used in process piping and also known as NPT(

national standard tapper pipe thread )

Beveled ends: 37.5 is most commonly used bevels.

5. Pipe joining methods:

(i).

(ii).

(iii).

Screwed joining method

Socket weld method(sw)- for plane ends pipes

Butt weld method(bw)

PIPING INTRODUCTION

(i)

(ii)

Screwed joining method:

It requires an external ad for joining two pipes.

Advantages:

It can be easily made on the site

It can be used where welding is not permitted due to fire hazard

Disadvantages:

It is not used for big bores and high pressure and temp. Lines.

There is joint leaks

A seal weld can be used for threaded joint but the code doesnt

allow to consider the welding strength as the joint strength

Socket weld joining method:

Gap of 1/16 or 1.5 mm is to be maintain to accommodate pipe

thermal expansion

Two circumferential weld is done

11

12

PIPING INTRODUCTION

(iii)

Advantages:

End preparation is not required

Alignment if end is not required

The welding is less time consuming

Disadvantages:

Not used for big bores and high press. and temp. lines

1.5 mm gap pocket fluid is not permitted by code for corrosive

and abrasive fluids.

Butt weld method:

It is generally used for joining big bore pipes

Root gap for proper weld preparation , mostly 75

Advantages:

It is the best way for joining big bore, high temp and pressure

lines

The joint is reliable and leak proof

The joint can be radiograph

PIPING INTRODUCTION

o NDT techniques

Radiography

VT

MPT

DPT

RT: to find weld defects

UT: to find the flow dimension

Radiography:

it is the method in which welding flaws (defects) are

found by passing radiation through the welding by

placing a source ( radiation emitter) (ex:cobalt)

whose radiation forms a lighter and bitter shape of

image on film wrapped on welding from pipe

outside which helps in finding the defects in

welding.

Disadvantages

End preparation is necessary

Alignment of ends is necessary

Welding is more time consuming than the socket weld

A backing ring is required to avoid weld penetration to pipe ID

o Backing ring shapes:

Circular

Square

Rectangular

o M/L of backing ring:

Ferrous or non ferrous

Consumable or non consumable

6. Pipe manufacturing methods:

(i).

(ii).

(iii).

(iv).

(v).

(vi).

Seamless ( E=1)

ERW(electric resistance weld)

EFW(electric fusion weld)

FBW(fusion butt weld)

SAW(submerge arc weld)

DSAW(double submerge arc weld)

Ex: NPS 8 SCH 40 ERW

13

14

PIPING INTRODUCTION

Note: other than seamless, all other methods (E< 1)

7. Piping grades:

(i).

Carbon steel :

Max temp : 800f( 427c)

Max carbon content : 0.35 %

Grades:

A, B, C

C is better than A & B

PIPING INTRODUCTION

Ex:

ASTM A53 GR A for ambient condition

ASTM A53 GR B for high temp

ASTM A106 GR B for high temp

ASTM A106 GR C for high temp

A53 is most commonly used carbon steel m/L

ASTM : American society for testing & m/L

Note:

Killing steel:

Killing is the process in which oxygen is removed by adding aluminum (Al2O3) and

manganese (Mno) which can be used for temp beyond 8000 f

(ii)

Alloy steel:

Main alloy elements Cr,Mo

Max temp 1200f

Grades:

P1,P2,P5,P11,P12,P22

Ex:

ASTM A335 Gr P1

ASTM A335 Gr P11

ASTM A335 Gr P12

(iii)

Stainless steel:

Main alloy elements: Cr,Ni

Called as austenite ss due to the presence of Ni

Carbon content : 0.08 %

Max temp: 1600 f

Note:

It is used for ambient temp also for corrosive fluid

Grades:

304, 304L, 316, 316L, etc

Ex:

ASTM A312 TP 304

ASTM A312 TP 304L

15

16

PIPING INTRODUCTION

ASTM A312 TP 316

ASTM A312 TP 316L

TP- tabular product

L- Low carbon content: 0.03 % max

Note:

At high temp. carbon present in the ss reacts with cr to form

crc(chromium carbide) due to which the white surface layer of

chromium(cr) is depleted, making steel prom to corrosion, to

avoid this either low carbon ss or ss with stabilizer like

chromium , titanium is used which have more attraction and

reaction to carbon than chromium.

Most commonly used ss is 304 with 18 %Cr and 8 %

Ni

8. Pipe symbols:

Rise symbol:

It is for pipe going up/coming towards us.

PIPING INTRODUCTION

Drop symbol:

It is for pipe going away from us/dropping/ going down

Incomplete circle with pipe going inside it.

Single line drawing symbol:

In this the pipe is drawn with solid central line, this type is used up to

size 6 inch or 12 inch

Double line drawing symbol:

In this type the pipe is drawn in double line or the actual size of pipe is

drawn to scale with the chain dotted central line. (CL)

17

18

PIPING INTRODUCTION

Joint symbols:

Threaded joints

Socket weld joint(SW)

Butt weld joint(BW)

Note:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Ee Mapping 2Document6 pagesEe Mapping 2John Larry CorpuzNo ratings yet

- Schedule Engineering Mathematics CoursesDocument2 pagesSchedule Engineering Mathematics CoursesJohn Larry CorpuzNo ratings yet

- BS Ee-EceDocument5 pagesBS Ee-EceJohn Larry CorpuzNo ratings yet

- Electromagnetics Drill Solution Hayt8e Chapter 1to5Document19 pagesElectromagnetics Drill Solution Hayt8e Chapter 1to5John Larry Corpuz100% (1)

- Vector: fx-991EX Is Capable of Handling Vector Calculations With Vectors in 2 or 3 DimensionsDocument3 pagesVector: fx-991EX Is Capable of Handling Vector Calculations With Vectors in 2 or 3 DimensionsJohn Larry CorpuzNo ratings yet

- Ethel See You SEA YouthDocument1 pageEthel See You SEA YouthJohn Larry CorpuzNo ratings yet

- Differential Equations: - Engr. Joel R. PalacolDocument16 pagesDifferential Equations: - Engr. Joel R. PalacolJohn Larry CorpuzNo ratings yet

- Linear EquationsDocument3 pagesLinear EquationsJohn Larry CorpuzNo ratings yet

- Gen 0107 Differential EquationsDocument11 pagesGen 0107 Differential EquationsJohn Larry CorpuzNo ratings yet

- Elimination of Arbitrary ConstantsDocument8 pagesElimination of Arbitrary ConstantsJohn Larry CorpuzNo ratings yet

- Problem 1 Problem 3Document2 pagesProblem 1 Problem 3John Larry CorpuzNo ratings yet

- Ice Course Schedule First Semester Ay 2015-16 FinalDocument4 pagesIce Course Schedule First Semester Ay 2015-16 FinalJohn Larry CorpuzNo ratings yet

- Exercises-Linear EquationsDocument1 pageExercises-Linear EquationsJohn Larry CorpuzNo ratings yet

- Family of Curves: - Joel R. PalacolDocument12 pagesFamily of Curves: - Joel R. PalacolJohn Larry Corpuz100% (1)

- Rosco Company Profile - 20141001Document15 pagesRosco Company Profile - 20141001John Larry CorpuzNo ratings yet

- 1mtech Ee PCDDocument89 pages1mtech Ee PCDJohn Larry CorpuzNo ratings yet

- Vector: fx-991EX Is Capable of Handling Vector Calculations With Vectors in 2 or 3 DimensionsDocument3 pagesVector: fx-991EX Is Capable of Handling Vector Calculations With Vectors in 2 or 3 DimensionsJohn Larry CorpuzNo ratings yet

- 101-2015 Cost Proposal For Alfairuz Lebanese Cuisine-Mechanical Works R-1 E-MailDocument3 pages101-2015 Cost Proposal For Alfairuz Lebanese Cuisine-Mechanical Works R-1 E-MailJohn Larry CorpuzNo ratings yet

- Bs Instrumentation Engineering CurriculumDocument2 pagesBs Instrumentation Engineering CurriculumJohn Larry CorpuzNo ratings yet

- Bs Instrumentation Engineering CurriculumDocument2 pagesBs Instrumentation Engineering CurriculumJohn Larry CorpuzNo ratings yet

- Bachelor POL (En)Document17 pagesBachelor POL (En)John Larry CorpuzNo ratings yet

- StatDocument9 pagesStatJohn Larry CorpuzNo ratings yet

- HPM3000B DrawingDocument1 pageHPM3000B DrawingJohn Larry CorpuzNo ratings yet

- College Student Handbook Revised 2017 PDFDocument153 pagesCollege Student Handbook Revised 2017 PDFjohn GordonNo ratings yet

- Flow Chart 2010 Updated 1 Jan 2015Document1 pageFlow Chart 2010 Updated 1 Jan 2015John Larry CorpuzNo ratings yet

- Syllabus Short Course C++ ProgrammingDocument1 pageSyllabus Short Course C++ ProgrammingJohn Larry CorpuzNo ratings yet

- ZymDocument2 pagesZymJohn Larry CorpuzNo ratings yet

- SANI0115bp 012615Document1 pageSANI0115bp 012615John Larry CorpuzNo ratings yet

- ZymDocument2 pagesZymJohn Larry CorpuzNo ratings yet

- Last Week: Analysis of Pinion-Rack W Velocity Feedback: e ( ) (For K 100)Document14 pagesLast Week: Analysis of Pinion-Rack W Velocity Feedback: e ( ) (For K 100)John Larry CorpuzNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Curriculum Vitae: INDIA: +91-8344756618Document4 pagesCurriculum Vitae: INDIA: +91-8344756618Ujwal KhandokarNo ratings yet

- The Farmer and The Magic TreeDocument3 pagesThe Farmer and The Magic TreeEidda Abdul RahmanNo ratings yet

- Food - Fruits, Vegetables & NutsDocument58 pagesFood - Fruits, Vegetables & NutsThe 18th Century Material Culture Resource Center100% (3)

- Zahras Arabian Oud CatalogDocument66 pagesZahras Arabian Oud CatalogZahra GajNo ratings yet

- Shear and Compressive Strength Parallel To Grain of Mango Mangifera Indica at Two Moisture Regimes in A Humid EnvironmentDocument6 pagesShear and Compressive Strength Parallel To Grain of Mango Mangifera Indica at Two Moisture Regimes in A Humid EnvironmentCrystian Kobee EmpeynadoNo ratings yet

- Autumn LeavesDocument6 pagesAutumn LeavesNguyễn Lê Ti NaNo ratings yet

- Cover Letter Template General ApplicationDocument4 pagesCover Letter Template General ApplicationM SIREESHANo ratings yet

- Mycoplasma: Scientific ClassificationDocument16 pagesMycoplasma: Scientific ClassificationShowkat AhmadNo ratings yet

- Ravi CropDocument12 pagesRavi CropRanjan Rashmi ParhiNo ratings yet

- Roman & Byzantine LandscapeDocument2 pagesRoman & Byzantine Landscapeaishwarya903No ratings yet

- Operations Manual-Ktps, Version02Document110 pagesOperations Manual-Ktps, Version02Ganesh DasaraNo ratings yet

- Ultra-High Density Plantation of Mango - New Technology For Increasing The Income of The FarmersDocument8 pagesUltra-High Density Plantation of Mango - New Technology For Increasing The Income of The FarmersAdyantKumarSingh100% (2)

- Some Physical Properties of Gbafilo ( - I - Chrysobalanus Icaco - I - ) Fruits and Kernels Preparatory To Primary ProcessingDocument11 pagesSome Physical Properties of Gbafilo ( - I - Chrysobalanus Icaco - I - ) Fruits and Kernels Preparatory To Primary ProcessingSNNo ratings yet

- NEPAL MASTER PLAN REPORT OHL Standards PDFDocument55 pagesNEPAL MASTER PLAN REPORT OHL Standards PDFAshish Regmi100% (1)

- Describing My KitchenDocument3 pagesDescribing My KitchenDaniel RamirezNo ratings yet

- Assignment On PinusDocument9 pagesAssignment On PinusNazmul Tanjeel KhanNo ratings yet

- Brochure HorticultureDocument46 pagesBrochure HorticulturezulfiqaralimalikNo ratings yet

- The Craftsman - 1903 - 07 - JulyDocument123 pagesThe Craftsman - 1903 - 07 - Julymdc2013100% (3)

- Prepare and Cook Fruit and VegetablesDocument16 pagesPrepare and Cook Fruit and VegetablesMuhunthan A. MurugaiahNo ratings yet

- Freedom Sports Complex, San Jose, Pili, Camarines Sur: Department of Education Region V Division of Camarines SurDocument5 pagesFreedom Sports Complex, San Jose, Pili, Camarines Sur: Department of Education Region V Division of Camarines SurAnnie Bagalacsa Cepe-TeodoroNo ratings yet

- Physical Examination of MilkDocument7 pagesPhysical Examination of Milkusamatayyab100% (2)

- Als Mock TestDocument31 pagesAls Mock TestFlora CoelieNo ratings yet

- Identifikasi Morfologi Dan Anatomi Tipe StomataDocument9 pagesIdentifikasi Morfologi Dan Anatomi Tipe StomataDella AndreanaNo ratings yet

- The Romantic Symbolism of TreesDocument11 pagesThe Romantic Symbolism of TreesSol AbarcaNo ratings yet

- 11 Biology Revision Study Material Chapter 8Document8 pages11 Biology Revision Study Material Chapter 8Saurav SoniNo ratings yet

- Ch. 6 Division of LabourDocument8 pagesCh. 6 Division of LabourFrengky WijayaNo ratings yet

- Print For ChrysoberylDocument2 pagesPrint For ChrysoberylToh Yang75% (4)

- Cupressus SempervirensDocument2 pagesCupressus SempervirensKelvin Llantoy VallejosNo ratings yet

- September 2012 K-5 Lunch MenuDocument1 pageSeptember 2012 K-5 Lunch MenuMedford Public Schools and City of Medford, MANo ratings yet

- 13 TaylorDocument12 pages13 TaylorAlberto SanchezNo ratings yet