Professional Documents

Culture Documents

Preparación de WPS S

Uploaded by

PercyFloresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preparación de WPS S

Uploaded by

PercyFloresCopyright:

Available Formats

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

1

__________________________________________________________________________________________________________

Instructions for the Preparation and Writing of Welding

Procedure Specifications

Red Book Number: 830-1

Revised: 22/04/2002

Issuing Authority:

Tom J. Landon/Plainfield/CBI

Maintenance & Review: Corporate Welding & QA Technology

0.1

Scope: This standard provides instructions for the preparation and writing of welding

procedure specifications (WPS's) to ASME Section IX requirements, with and without a referenced

code of construction. It includes lists of the available forms and standard paragraphs to be used on

the forms for specific limitations or exceptions. The referenced forms and referenced Lotus Notes

WPS Database may also be used for welding/construction codes other than ASME.

0.2

Introduction: A welding procedure specification is a document written for a contract which

defines the materials and their preparation, the electrodes and their use and the customer, code and

CBI requirements, limitations and exceptions.

A welding procedure specification is composed of:

1

Title page (see 1.0)

2

Specific Welding Procedure Specifications for each electrode (see 3.0)

3

General Welding Procedure Specification for each process (see 2.0)

The referenced Procedure Qualification Records (PQR's) will be included in the local welding

manager's copy of the Welding Procedure Specifications package in addition to the copy maintained

by the originating Welding Embedded Engineering Groups (WEE) when WEE prepares the WPS's.

Control of WPS's and PQR's for nuclear work will be handled per the specific contract requirements.

0.3

Computer Generated WPS's: A database "WPS Database" is available in Lotus Notes for

writing, storing, retrieving and printing specific Welding Procedure Specifications (WPS's) including

the title page. It should be used to generate all WPS's except for special circumstances or when

unique contract requirements apply.

1.0

TITLE PAGE

A title page is prepared for all contracts except those involving ASME Section III (Nuclear)

vessels/components. Welding Procedure Specifications for Nuclear Work shall be handled per the

specific contract requirements.

A typical welding procedure specification title page consists of:

1

the title "Welding Procedure Specification"

2

a description of the structure(s)

3

the customer's and final owner's name(s)

4

the final location(s)

5

the CBI contract number(s)

6

an index of attachments including:

a

A listing of the Specific Welding Procedure Specifications (WPS) with revision numbers and

the contract number

b

A listing of the General Welding Procedure Specifications (GWPS)

2.0

GENERAL WELDING PROCEDURE SPECIFICATIONS (GWPS)

See Table 2.0 for a list of all attached GWPS available from Corporate Welding & QA Technology

and and available in the Forms Database in Lotus Notes. See GWPS-SMAW for a typical

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

2

__________________________________________________________________________________________________________

GWPS. GWPS used for ASME Section III (Nuclear) vessels/components are available from Corporate

Welding and QA Technology - Plainfield.

A GWPS is a general and standardized document which contains instructions applicable to a specific

welding process. If additional instructions are required for the use of a particular electrode, or if

there are limitations or restrictions to the GWPS, these should be shown on the Specific Welding

Procedure Specifications (see 3.0). The GWPS should not normally be altered.

Table 2.0 General Welding Procedure Specifications

Identification

Title

Form No.

GWPS-SMAW

General Welding

Procedure Specifications

for the Shielded

Metal Arc Process

WL 175A

GWPS-SAW

General Welding

Procedure

Specification for the

Automatic

Submerged Arc Process

WL 175B

GWPS-GMAW

General Welding

Procedure

Specification for the Gas

Metal Arc Process

WL 175C

GWPS-GTAW

General Welding

Procedure

Specifiation for the Gas

Tungsten Arc Process

WL 175D

GWPS-EGW

General Welding Process

Specificaiton for the

Automatic Electrogas

Process

WL 175E

GWPS-STUD

General Welding

Procedure

Specifications for the

Automatically

Timed Stud Welding

Equipment

WL 175F

3.0 SPECIFIC WELDING PROCEDURE SPECIFICATIONS (WPS)

A WPS is a specific document prepared on standard forms which provides information, restrictions,

limitations, and parameters for the use of a specific electrode on specific material. It consists

of completed form WL 100, WL 100A (if necessary), WL 100S (if necessary), and a

standard parameter sheet completed for the specific electrode. See 3.1 and 3.2 for

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

3

__________________________________________________________________________________________________________

completing WL 100 and WL 100A. See 4.7 for completing WL 100S. See 3.3 for a

discussion and list of available standard parameter sheets.

3.1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

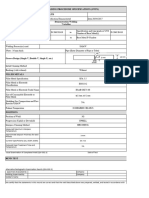

Form WL 100. The following is a description of each entry required on form WL 100 . The

paragraph numbers correspond to the circled numbers shown on the sample form in FIG. 3.1.

Identification: Enter the AWS-SFA classification of the electrode or an abbreviation of the

trade name of the electrode. See Table 3.3 for typical AWS-SFA classifications and

abbreviations.

If the WPS is for submerged arc welding (SAW), both the AWS-SFA classification of the wire

and the number (I.D.) of the flux should be given. Example: WPS EM 12K/860.

Enter the Contract Number or Standard I.D. for CB&I Standard WPS's.

Product: Give general description for all structures.

Customer: Enter the customer's name.

Page No.: Enter the page number and total number of pages included in the WPS. The total

includes form WL 100, WL 100A, WL100S, and the Standard Parameter Sheet for the

specific electrode(s).

Rev. No.: Enter the revision number.

By: Fill in initials of person making the revision or original.

Date: Enter the date the WPS is written or the date the revision is made.

Enter the initials of all welding process used on the WPS. See Table 2.0 for the GWPS's

available.

Enter the number of the Procedure Qualification Record (PQR) used to qualify the WPS. This

PQR must be reviewed to assure that it complies with ASME Section IX and that it fulfills

customer, code and CBI requirements. More than one PQR may be listed to qualify different

thickness ranges, use of preheat, post weld heat treatment, other position, etc.

If a PQR is used that has been post weld heat treated, enter the PQR number and then the

letters PWHT in parenthesis.

Enter the position(s) welded to qualify each PQR.

Enter the thickness range qualified by each PQR in accordance with ASME Section IX.

Enter the welding positions qualified to be used on the specific contract.

Enter the thickness range the PQR will be used on the specific contract. Code impact, preheat

and post weld heat treatment requirements, as well as CBI requirements, must be complied

with.

Enter the Code Edition and Addenda that the WPS is written for. Example: ASME Section IX,

Winter 82.

Enter the page number(s) of the General Welding Technique page or parameter pages that

joint details are shown on.

Give the type of backing required. This may be a tape, consumable insert, flux, strip or strap,

bar, temporary bar, etc. If no backing is to be used, state "None".

Enter the base material(s) by ASME or ASTM grade and whether they are welded together or

to another material. Also list the ASME group number of the base material(s). If a material

does not have an ASME or ASTM type and grade assigned, use proprietary names and state

that the group number is similar to an ASME material(s).

If several materials are to be welded together or to one another with the same electrode, it is

permissible to list all the base materials and their group numbers and state, "These materials

may be welded together or to one another in any combination."

Identify the filler metal to be used by ASME specification number, classification, analysis

number, and group number. Trade names may be referenced but may not be used alone

unless (a) the electrode does not have an ASME specification and/or classification; or (b) a

specific electrode must be used. Also specify the type of consumable insert or type of

supplemental powdered filler metal to be used. If none will be used state, "None" or "N/A"*

If flux is required, give the trade name with the AWS-SFA Flux-Electrode designation

(Classification) in parenthesis. The AWS-SFA Flux-Electrode designation is only applicable

when it is available from the flux manufacturer or from previous CB&I test to AWS A5.17 or

A5.23 Specifications. Alternatively to the complete Flux-Electrode designation being listed in

parentthesis next to the flux trade name, the complete flux-electrode designation

(classification) can be listed for the complelte ASME Classification: as referenced in paragraph

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

4

__________________________________________________________________________________________________________

"19" above. Otherwise, state "None" or "N/A".

Enter the page number of Form WL 100S in the WPS. Refer to Paragraph 4.5 for filling in

form WL 100S. If a preheat paragraph and an inter-pass temperature paragraph are to be

used instead of WL 100S, enter the page number of WL 100A that the paragraphs are

entered on.

22

Enter "Yes" if PWHT is required. Enter "No" if PWHT is not required.

23

If shielding gas is required, give the composition and the range of flow rate. Otherwise state

"None" or "N/A"*

24

If backup gas is required, give the composition and the range of flow rate. Otherwise state

"None" or N/A

25

State the type of current to be used (AC, DC) and whether the electrode will be positive or

negative. The phrases "Reverse Polarity" or "Straight Polarity" should be added in parenthesis

but should not be used alone.

26

Enter the page number(s) of the General Welding Technique page or parameter pages.

27

If impacts are required, state "Yes" and enter page number of Vertical Welding Technique

page for manual welding. For automatic processes list the welding heat input limitations on

form WL 100 A. If impacts are not required, state "No".

28

Enter mode of transfer for GMAW or FCAW. (Spray, Globular, Pulsed, Short Circuit). For other

processes state "N/A" (Not Applicable).

*Note: State N/A (Not Applicable) if subject does not apply to process being used. State None

if subject does apply but is not to be used with that process.

29

This space is used to indicate Form WL 100 A which lists all Customer, Code, and/or CBI

Limitations exceptions, and/or restrictions to the GWPS. See 4.0 for standard paragraphs.

30

Enter the page number(s) of the General Welding Technique sheet or the page number that

a statement for stringer or weave bead is used.

31

Mark the box that applies to the process being used.

32

This space is available for customer approval and may be filled in by the customer.

33

The right side portion will be filled in for all WPS's. The left side normally will only filled in by

QA for Nuclear work.

21

88.LIF

Fig. 3.1 - Form WL 100

Limitation Notes

A change from upward to downward, or from downward to upward, in the progression specified for

any pass of a vertical weld must be shown. Therefore, on WL 100A for the vertical welding specify

uphill or downhill for welding. Following are two examples:

1

A contract that does not have a special hardness requirement: "All passes uphill except the

rootpass or coverpass may be uphill or downhill".

2

A contract that has a special hardness requirement: "All passes uphill except rootpass may

be uphill or downhill".

Contracts that have impact requirements must have special instructions. These instructions are to

control welding heat input to the maximum qualified on the welding Procedure Qualifications

Records (PQR's) referenced to support the Welding Procedure Specification (WPS). The welding heat

input control requirements per ASME Section IX, QW-409.1 are listed below. The maximum allowed

heat input in KJ/in or maximum bead size including vertical weld pass/bead size sketch shall be

included, as applicable, on WL100 A See the CB&I heat input control requirements below. Multiple

pages of WL100 A form may be required to include all of the limitation requirements for some

Welding Procedure Specifications.

CB&I controls welding heat input per the following, except when special contract requirements apply:

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

5

__________________________________________________________________________________________________________

l

Welding Heat input shall be controlled per paragraph QW-409.1 "a" (control of Voltage, Amperage

and Travel Speed) for machine/automatic welding processes, such as when the Automatic Girth

Welder (AGW) or Automatic Vert Welder is used.

Welding Heat input shall be controlled per paragraph QW-409.1 "b" (control of Volume of Weld

Metal) for manual and semiautomatic welding processes, such as SMAW, GMAW/FCAW and GTAW.

The Volume of Weld Metal control that CB&I uses is bead size.

QW-409.1 states a change in the type of current or polarity, or an increase in heat input, or an

increase in volume of weld metal deposited per unit length of weld, over that qualified. The increase

may be measured by either of the following:

a) Heat Input (J/in.) =

Voltage x Amperage x 60

Travel Speed (in./min.)

b) Volume of Weld Metal = An increase in bead

size, or a decrease in length of weld bead per unit

length of electrode.

l

l

For automatic welding, the maximum heat input allowed on the WPS must have a PQR with that heat

input or greater.

For manual welding the maximum bead size allowed on the WPS must have a PQR with that bead

size or larger.

Form WL 100Q can be used for processes not listed in Table 3.3 or when special instructions are

required for impact work.

For the SAW process, the electrode spacing when multiple electrodes are used is a nonessential

variable and must be specified on the WPS.

3.2

3.3

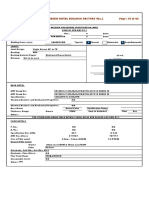

Form WL 100 A. The entries required on form WL 100 A as shown in Fig. 3.2 are:

thru :

same as for WL 100 described in paragraph 3.1 above.

Standard Parameter Sheets available are listed in Table 3.3. These contain amperage and

voltage ranges, travel speeds, burn-off rates and/or other pertinent data. Most of the

parameter sheets have typical joint detail sketches included on the form. WL 100Q is a blank

form to provide special joint details when necessary. All of the parameter pages, WL 100E to

WL100U, provide reference to the specific contract drawings for the applicable joint details

and dimensions for application of the specific WPS.

Form WL 100R is to be used for stud welding. The operating parameters and other essential

variables are to be listed for each size of stud and each position to be welded. Damper setting

and equipment specifications should be stated in the body of the WPS.

Applicable parameter sheets for automatic submerged arc welding are provided in the following Red

Book Standards: 814-2-2 , 814-2-5 ,814-2-6 ,814-3-2 , 814-3-3 . The general

welding parameters (amps, volts and travel speed ranges can be listed on form WL 100Q with

the specific welding parameter provided to the CB&I Welding and QC manager as a separate

attachment. The standard pages are considered proprietary infomramation and should not be

sent to customers when Welding Procedure Specifications are sent for review and approval. In

special cases the parameter sheets can be attached to form WL 100A and state stringer

beads as a general note on each parameter page.

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

6

__________________________________________________________________________________________________________

The entries required on Standard Parameter Sheets as shown in Fig. 3.3 are:

as for WL 100 described in paragraph 3.1 above.

thru :same

Where necessary, enter the electrode classification or name. Usually this will be the same as

the classification or name in .

Table 3.3 Standard Parameter Sheets

Form

WL

WL

WL

WL

100A

100B

100C

100D

Description

Typical No.

WPS Blank Pages

Unassigned

Unassigned

Unassigned

WL 100E

Parameters for E6010

or E7010 electrodes

WPS-E6010

WL 100F

Parameter for E6012

electrodes

WPS-E6012

WL 100G

Parameters for EXX18

electrodes

WPS-E7018

WL 100H

Parameters for Lincoln

innershield NR431

electrode (EGW

Process)

WPS-NR431

WL 100I

Parameters for McKay

Speedalloy

66 or 86 electrodes

WPS-SA66

WL 100J

Parameters for E71T-1

electrodes and E81T1-X

electrodes

WPS-E71T-1

WL 100K

Parameters for E300

series stainless

electrodes

WPS-E308

WL 100L

Parameters for E7024

or E7024-1 electrodes

WPS-E7024-1

WL 100M

Parameters for

ENiCrMo-6 electrodes

WPS-ENiCrMo6

WL 100N

Parameters for GTA

welding

WPS-ER308-GTA

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

7

__________________________________________________________________________________________________________

WL 100P

Parameters for GMA

welding with ER 300

series stainless steel

electrodes

WPS-ER308-GMA

WL 100Q

Standard Parameter

Sheet. (To be used

when other forms listed

do not apply.)

WL 100R

Standard Parameter

Sheet for Stud Welding

WL 100S

Welding Procedure

Specifications Preheat

Chart (Information)

WL 100T

Parameters for E70T-1

electrodes

WPS-E70T-1

WL 100U

Parameter sheet for

E3XXLT1-1 or

E3XXLT1-4 stainless

steel FCAW electrodes

WPS-E316LT1-4

WPS-STUD

8301.LIF

Page 1 - Fig. 3.2 - Form WL 100A

Page 2 - Fig. 3.3 - Form WL 100G (Example for all Parameter Pages)

4.0 STANDARD PARAGRAPHS FOR USE ON FORM WL 100A.

The following paragraphs are standard paragraphs and should be used to insure uniformity of

welding procedure specifications on a company-wide basis. Most of these paragraphs are CBI

limitations, exceptions, and/or requirements. Code and/ or customer limitations, exceptions

and/or requirements vary a great deal and therefore will have to be handled on an individual

basis; however, they should be patterned after the following paragraphs.

4.1

1

2

3

4

Limitations to the General Welding Procedure Specification. The following are typical

limitations to the GWPS:

E6010 and E7010 electrodes: "Normally this electrode is for use on materials less than

3/8" thick."

E6012, E6024, and E7024 electrodes: "Limit the use of this electrode to fillet and lap

welds."

AVW welding: "Normally this process is used on materials 3/8" thick and greater."

Low hydrogen type welding of impact tested material in the vertical and overhead

position: Limit bead size to that shown in the appropriate table in 813-1-3 , 813-1-4 ,

813-1-4-1

,813-1-5 , Attach a copy of the appropriate table as another page to the

WPS on form WL 100 A and complete per 3.1.

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

8

__________________________________________________________________________________________________________

4.2

1

2

4.3

1

2

3

4

5

6

Exceptions to the General Welding Procedure Specification. The following are typical.

Materials on which no flame burning is allowed: "No flame burning shall be permitted

on______________ material."

Materials where no arc gouging is permitted: "No arc gouging is permitted on

______________material."

Miscellaneous requirements. The following paragraphs may be required in certain

applications.

Where welding shall be performed from one side with a single pass: "All

____________ joints shall be welded from one side with a single bead."

Where joints shall be finished uphill: "All ____________________ joints over

__________________ inch shall be finished uphill."

Where stainless steel brushes must be used: "Use only stainless steel brushes on

______________________ material."

Where all passes are deposited downhill: "All passes shall be deposited downhill."

Where all passes are deposited uphill including the root pass. "All passes shall be

deposited uphill."

For stainless and nickel welding where customer specifications address stress corrosion or

when CBI is concerned about stress corrosion: "Remove all visible traces of anti-spatter

compound after welding and before PWHT."

4.4

Combination of processes or electrodes: In some instances, two or more processes or

electrodes may be needed to weld a joint. When this happens, the dominant process or

electrode may be written as one WPS while the subordinate process or electrode may be

written as another WPS, with the subordinate WPS referenced on the dominant WPS. This

may be used in lieu of a combination of processes of electrodes on one WPS.

The following are typical paragraphs to use:

1

AGW: "Refer to WPS-E7018 for welding of the root pass on joints 1 1/8" and over."

2

AVW: "Refer to WPS-E7018 or WPS-E70T-1 for welding of the second side of joints less than

or equal to 1" thick."

If one PQR is used to qualify two processes or electrodes and the subordinate one is not used for

any other welding, reference the same PQR on both WPS. On the dominate WPS give the

thickness range qualified by the PQR and on the subordinate WPS state that only one

application is qualified; i.e., "Root pass only is qualified" or "Second side only is qualified", etc.

4.5

Preheat requirements. Refer to Standard 895 for CBI minimum preheat requirements.

Pertinent code and customer preheat requirements must also be addressed.

For standard CBI preheat requirements, use pertinent information directly from 895 tables for the P

and Group numbers of materials,

4.5.1 Form WL 100S The following is a description of each entry required on form WL 100S.

The paragraph numbers correspond to the circled numbers shown on the sample form in Fig. 4.7.

1

List maximum interpass temperature.

2

List P number, Group number, material type, and if material is PWHT. Example: Preheat

requirement for P-1 Gp-1 materials (A36, A283C) PWHT.

3

Use ambient temperature requirement. Example: 32F and above.

4

Use thickness range of materials. Spell out; do not use symbols. Example: Less than or equal

to 1 1/4".

5&6

List preheat temperature and referencing notes, Notes to be used are listed below.

Example: 100F Note-2.

Notes:*

1

Preheat for removing moisture may be used.

2

100F is considered warm to hand. (Use this note whenever 100F is

specified).

3

Preheat within 3" of the point of welding and maintain 3" ahead of arc.

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

9

__________________________________________________________________________________________________________

Maintain uniform heat over entire joint.

4.5.2 Preheat requirements for various welding processes are given in standard 895. Do not

confuse preheat requirements for different processes.

4.5.3 Normally preheat charts will be used for SMAW, GMAW, and GTAW.

4.5.4 In lieu of tables, preheat statements may be used for limited preheat requirements. Examples

are listed below.

Materials P-1 - Group 1

Maximum t 1 1/4" with or without PWHT: "No preheat is required except as an aid for removing

moisture or unless the ambient temperature falls below 32F. When the ambient temperature

falls below 32F, the plate shall be preheated warm to the hand within 3" of the point of

welding and maintain 3" ahead of arc.

Materials P-1 - Groups 2 and 3 ambient temperature 50F:

Maximum t 1 1/4" with or without PWHT: "No preheat is required except as an aid for removing

moisture."

Materials P-1 - Groups 2 and 3 ambient temperature < 50F:

Maximum t 1 1/8" with or without PWHT: "No preheat is required except as an aid for removing

moisture or unless the ambient temperature falls below 50 F. When the ambient temperature

falls below 50 F, preheat within 3" of the point of welding and maintain 3" ahead of arc.

*

The use of these notes shall be dictated by the notes in Standard 895, code, and the customer

requirements.

93.LIF

Fig. 4.7 - Form WL 100S

Non-ferrous or austenitic welding: "No preheat is required except as an aid for removing

moisture or unless the ambient temperature falls below 0F. When the ambient temperature falls

below 0F, a preheat of warm to the hand (approx. 100F) is required within 3" of the start of

welding."

5.0

DISTRIBUTION OF THE WELDING PROCEDURE SPECIFICATIONS

See Table 5.0a and 5.0b. In all cases the completed WPS should be checked before distribution to

assure that it complies with code, customer, and/or CBI limitations, exceptions, and/or restrictions

and that it is correct and complete. The checker must initial and date the WPS in space 33 of form

WL 100.

The procedure qualification records (see 831-1 ) must also be checked to assure that they meet

customer, code and CBI requirements and comply with ASME Section IX, but do not provide more

data than necessary. Unless specifically required, impact data, dropweight data, chemistries, or

other special information should not be included.

When hardness data is required, it should be reported on form WL 1 or WL 10, as applicable. Form

WL 120, Hardness Test Report, should not be sent out.

Table 5.0a

Distribution of Welding Procedure

Red Book # 830-1

Chicago Bridge & Iron Company. For Internal Use only.

10

__________________________________________________________________________________________________________

Specification for All Structures Except

Those Built to ASME Section III (Nuclear)

Cover Letter

Title Page

All WPS's

Referenced GWPS

Referenced PQR

RBS Attachments

Special Instructions

CB&I Organization

Local Welding & QC Originating

Manager

Department (1)

Original

1 Copy

Original (2)

1 copy

Original (2)

1 copy

1 copy

On File

1 copy

On File

1 copy

On File

Original (2)

1 copy

Notes:

(1)

(2)

Customer or Owner

Copies as Required

Copies as Required

Copies as Required

Copies as Required

Copies as Required

Not to be Sent

Not to be Sent

Originating Department will be CWT or assigned WEE Group.

Documents will be sent to contract file.

Documents may be saved in electronic format in Lotus Notes.

Table 5.0b

Distribution of Welding Procedure Specification

for Vessel Built to ASME Section III (Nuclear)

CB&I Organization

Local Welding & QC Originating

Manager

Department (1)

Cover Letter

Title Page

All WPS's

Referenced GWPS

Referenced PQR

RBS Attachments

Special Instructions

Customer or Owner

As Required by Contract Requirements

*******

Chicago Bridge & Iron Company, 2006. All Rights Reserved. For Internal Use Only.

NOTICE: THIS DOCUMENT, AND ALL TEXT, DRAWINGS, DETAILS AND DATA SHOWN HERETO, IS THE SOLE PROPERTY OF

CHICAGO BRIDGE & IRON COMPANY, AND SHALL NOT BE REPRODUCED IN ANY MANNER OR USED FOR ANY PURPOSE

WHATSOEVER EXCEPT BY EXPRESS WRITTEN PERMISSION OF CHICAGO BRIDGE & IRON COMPANY.

You might also like

- Welding Log BookDocument1 pageWelding Log Booksamsurendran_mech4020No ratings yet

- WeldingProcedurePreparation PDFDocument122 pagesWeldingProcedurePreparation PDFAlecioSM100% (1)

- WPS Uide PDFDocument32 pagesWPS Uide PDFmuthuswamy77No ratings yet

- SSPC SP16 Brush-Off Blast CleaningDocument5 pagesSSPC SP16 Brush-Off Blast Cleaninglonglong300394% (16)

- Concept of Operations DRAFT v1Document84 pagesConcept of Operations DRAFT v1Ramesh dodamaniNo ratings yet

- 02-18-11 ATT-002-290-502 Presentation Rev 5Document111 pages02-18-11 ATT-002-290-502 Presentation Rev 5dentler6969100% (1)

- Fabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)Document58 pagesFabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)johnknight000No ratings yet

- 250 42aECDocument35 pages250 42aECniknenadNo ratings yet

- Astm D610 PDFDocument6 pagesAstm D610 PDFAmbarNo ratings yet

- Astm D610 PDFDocument6 pagesAstm D610 PDFAmbarNo ratings yet

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Document6 pagesRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriNo ratings yet

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNo ratings yet

- 121 T BW FPDocument4 pages121 T BW FPA. ΒρατσισταNo ratings yet

- Welding Insection ReportDocument4 pagesWelding Insection ReportRanjeet MouryaNo ratings yet

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 pagesTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- Astm E1003 PDFDocument3 pagesAstm E1003 PDFJairo Wilches80% (5)

- Iso+9000 3 1997Document38 pagesIso+9000 3 1997api-19846338No ratings yet

- Jotafloor Easy Painting Guide For Concrete Floors Tcm29 5703Document8 pagesJotafloor Easy Painting Guide For Concrete Floors Tcm29 5703Riski FebriantoNo ratings yet

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- IIAR ProcedimientodeSoldadura PDFDocument12 pagesIIAR ProcedimientodeSoldadura PDFmelator100% (3)

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocument50 pagesASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNo ratings yet

- Revised RCSC Specification-Simplified, Clarified, Andimproved PDFDocument5 pagesRevised RCSC Specification-Simplified, Clarified, Andimproved PDFfarhadmrt6923No ratings yet

- Tube-to-tubesheet weldingDocument8 pagesTube-to-tubesheet weldingManjadi Maverick100% (1)

- Course Module 4Document6 pagesCourse Module 4Makise AghataNo ratings yet

- Welding Inspector Roles and ResponsibilitiesDocument22 pagesWelding Inspector Roles and ResponsibilitiesKevin ArmandoNo ratings yet

- Wopq Format Asme Qw-360Document1 pageWopq Format Asme Qw-360Anonymous S33n8gNo ratings yet

- Materials and Qualification Procedures For Ships: Book ADocument15 pagesMaterials and Qualification Procedures For Ships: Book AJavier del AngelNo ratings yet

- Closure Weld Mag ProcedureDocument1 pageClosure Weld Mag ProcedurehellionxNo ratings yet

- STS EDAC WELD REPAIR PROCEDUREDocument51 pagesSTS EDAC WELD REPAIR PROCEDUREmohd as shahiddin jafriNo ratings yet

- Gtaw+smaw 3G 566Document2 pagesGtaw+smaw 3G 566YASAR ALINo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- WPSPQRDocument11 pagesWPSPQR0502raviNo ratings yet

- 08 PawDocument30 pages08 PawAnupam KushwahaNo ratings yet

- SPL - PQR-WPS-SWPS SmawDocument7 pagesSPL - PQR-WPS-SWPS Smawgopuvinu4uNo ratings yet

- WIC-WPS-01 Rev. 00 - FCAW - 1.2Document2 pagesWIC-WPS-01 Rev. 00 - FCAW - 1.2murshid badshahNo ratings yet

- STT Pipe Welding Reduces Spatter & SmokeDocument3 pagesSTT Pipe Welding Reduces Spatter & SmokeahmedNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document1 pageDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocument5 pagesWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNo ratings yet

- Dilution in Single Pass Arc Welds: As+As,, Asm EtaDocument9 pagesDilution in Single Pass Arc Welds: As+As,, Asm EtadayalramNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- 2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFDocument59 pages2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFGeorge JhonsonNo ratings yet

- 3.3.1-Basics of Weld Joint Design-9th Mar 21Document60 pages3.3.1-Basics of Weld Joint Design-9th Mar 21Vivek kmNo ratings yet

- World Lecture Hall: Useful Links For EngineersDocument9 pagesWorld Lecture Hall: Useful Links For Engineerssandi1111No ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Weldingdefects 150915053459 Lva1 App6892Document22 pagesWeldingdefects 150915053459 Lva1 App6892Star GlacierNo ratings yet

- MT Sample ProcedureDocument7 pagesMT Sample ProcedureAgustine SetiawanNo ratings yet

- A234A234M-15 Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Service PDFDocument9 pagesA234A234M-15 Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Service PDFRony YudaNo ratings yet

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- WI-02 Thermal CuttingDocument16 pagesWI-02 Thermal CuttingPrakash RajNo ratings yet

- PFMEA Process Failure AnalysisDocument1 pagePFMEA Process Failure AnalysisasderbvaNo ratings yet

- PQR - WPQ Witness ReportDocument1 pagePQR - WPQ Witness Reportsdkeskar40No ratings yet

- Welder Id SampleDocument1 pageWelder Id SampleArputharaj Maria LouisNo ratings yet

- SV Engineerings: Work InstructionDocument5 pagesSV Engineerings: Work InstructionPrakash RajNo ratings yet

- 1 en 1090 1 QuestionnaireDocument5 pages1 en 1090 1 QuestionnaireJohn PirretNo ratings yet

- Declaration of Perormance-Le-ZnDocument4 pagesDeclaration of Perormance-Le-ZnDavid SeeNo ratings yet

- Astm A 234 A234m-15Document9 pagesAstm A 234 A234m-15Mohammed AliNo ratings yet

- RSW WOPQ REV. 2010a Interactive FormDocument1 pageRSW WOPQ REV. 2010a Interactive FormcosmicbunnyNo ratings yet

- Welding Specification for Austenitic, Duplex and Superduplex PipeworkDocument45 pagesWelding Specification for Austenitic, Duplex and Superduplex Pipeworkmurugesan0% (1)

- EN 15085 Update: Important Changes to Railway Welding Standard Effective April 2021Document2 pagesEN 15085 Update: Important Changes to Railway Welding Standard Effective April 2021Boran YelkenciogluNo ratings yet

- Write WPS ISO 15614Document10 pagesWrite WPS ISO 15614Hoang LamNo ratings yet

- Approved Weld Procedure SpecificationsDocument38 pagesApproved Weld Procedure SpecificationsJohan0001No ratings yet

- The New Declaration of Performance (Description)Document39 pagesThe New Declaration of Performance (Description)Bogdan MuresanNo ratings yet

- Portfolio Storage&Drying Control ProcedureDocument4 pagesPortfolio Storage&Drying Control Procedurelaz_kNo ratings yet

- Set-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1Document1 pageSet-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1sbmmlaNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- Tol Geom Ansi y 14.5Document33 pagesTol Geom Ansi y 14.5Rebecca TurnerNo ratings yet

- Welding Procedure Specification (WPS) & Procedure Hp-Bolir Esr0040020qmo4279a-2507 - 0BXDocument62 pagesWelding Procedure Specification (WPS) & Procedure Hp-Bolir Esr0040020qmo4279a-2507 - 0BXkingstonNo ratings yet

- WPQRDocument3 pagesWPQRDimitris NikouNo ratings yet

- Tank Welding Details1Document5 pagesTank Welding Details1Dilip PatilNo ratings yet

- SurfacePrepGuide PDFDocument2 pagesSurfacePrepGuide PDFPercyFloresNo ratings yet

- Bridges - HPS - Guide Spec For Highway Bridge Fab With HPS Steel - Nov 2012 FinalDocument16 pagesBridges - HPS - Guide Spec For Highway Bridge Fab With HPS Steel - Nov 2012 Finalwookie1977No ratings yet

- Visualacuityform PDFDocument1 pageVisualacuityform PDFPercyFloresNo ratings yet

- SurfacePrepGuide PDFDocument2 pagesSurfacePrepGuide PDFPercyFloresNo ratings yet

- 1169 - 40 CFR 122 Doc - 20140808Document16 pages1169 - 40 CFR 122 Doc - 20140808Thaibinh NguyenNo ratings yet

- Preparacion de PQR S PDFDocument6 pagesPreparacion de PQR S PDFPercyFloresNo ratings yet

- 1169 - 40-CFR 112-Doc - 20140808 PDFDocument24 pages1169 - 40-CFR 112-Doc - 20140808 PDFPercyFloresNo ratings yet

- 49 CFR 195 Transportation of Hazardous Liquids by PipelineDocument18 pages49 CFR 195 Transportation of Hazardous Liquids by PipelineThaibinh NguyenNo ratings yet

- 49 CFR 192 Api 1169 PDFDocument17 pages49 CFR 192 Api 1169 PDFkblaxtonNo ratings yet

- Contoh Teaching OutlineDocument4 pagesContoh Teaching OutlineNorazzah AbdullahNo ratings yet

- E37447Document180 pagesE37447Bryan BowmanNo ratings yet

- PROCESS COSTING PRODUCTION REPORTSDocument3 pagesPROCESS COSTING PRODUCTION REPORTSjozsefczNo ratings yet

- Samsung Single DVD-Player Intro Standard & Karaoke ModelsDocument60 pagesSamsung Single DVD-Player Intro Standard & Karaoke ModelsparascoliNo ratings yet

- Word File XM AfcsDocument14 pagesWord File XM AfcsAnik MiaNo ratings yet

- (WRC-SouthAfrica-2001-R. McKenzei) PRESMAC User GuideDocument80 pages(WRC-SouthAfrica-2001-R. McKenzei) PRESMAC User GuideStephenson Xavier Molina ArceNo ratings yet

- Sizing a Flare Stack and Calculating Flame Distortion from Wind VelocityDocument49 pagesSizing a Flare Stack and Calculating Flame Distortion from Wind VelocityBayu AjipNo ratings yet

- Apis PHP enDocument265 pagesApis PHP enAMORSIKO.EXENo ratings yet

- Assignment-1 EE-2101: Name:-Hage Nobin Roll no.-B/19/EE/036 Date of Submission-30/10/2020Document4 pagesAssignment-1 EE-2101: Name:-Hage Nobin Roll no.-B/19/EE/036 Date of Submission-30/10/2020x caliber10No ratings yet

- Power and Eff WorksheetDocument6 pagesPower and Eff WorksheetYu ErinNo ratings yet

- Service Manual Acer Aspire 1710Document118 pagesService Manual Acer Aspire 1710Quique FerNo ratings yet

- Surface Vehicle Recommended Practice: Recommended Practices For Hydraulic Hose AssembliesDocument22 pagesSurface Vehicle Recommended Practice: Recommended Practices For Hydraulic Hose AssembliesIgor BastosNo ratings yet

- CableConduits InterflexDocument132 pagesCableConduits InterflexSEO BDMNo ratings yet

- Ddrcs Unit 4Document22 pagesDdrcs Unit 4siva shanmukhaNo ratings yet

- Terex TSL 210 Compact Track Loader - Ebook SpecsDocument2 pagesTerex TSL 210 Compact Track Loader - Ebook SpecsMico EquipmentNo ratings yet

- Test-4 SomDocument42 pagesTest-4 SomVivekMishraNo ratings yet

- Generator BrochureDocument32 pagesGenerator BrochuresudiNo ratings yet

- Kwa FORM RA2Document7 pagesKwa FORM RA2Anand Vamadevan0% (1)

- PCR for Keyboard EPDDocument20 pagesPCR for Keyboard EPDNurul Haerani Mohamad100% (1)

- Understanding Pressure: Units, Measurements, and CalculationsDocument2 pagesUnderstanding Pressure: Units, Measurements, and Calculationsirma elNo ratings yet

- Sizing Criteria For Cylinders and Servocylinders: F (P A - P A) 10 (N) F (P A - P A) 10 (N) F (P - P) A 10 (N)Document5 pagesSizing Criteria For Cylinders and Servocylinders: F (P A - P A) 10 (N) F (P A - P A) 10 (N) F (P - P) A 10 (N)Mohammed bakrimNo ratings yet

- ISO and EN standards for securing cargo in vehicles and containersDocument35 pagesISO and EN standards for securing cargo in vehicles and containersMuharrem BeyogluNo ratings yet

- Drilling Catalog 2013 Kyocera PDFDocument106 pagesDrilling Catalog 2013 Kyocera PDFTuấn NguyễnNo ratings yet