Professional Documents

Culture Documents

010-PREWPS FOR SS304 (2.5 - 11 MM) PDF

Uploaded by

Köksal PatanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

010-PREWPS FOR SS304 (2.5 - 11 MM) PDF

Uploaded by

Köksal PatanCopyright:

Available Formats

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.305.134

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No :

Project Rev.: O

Page 2 of 6

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

19.10.08

Issued for Review

HG

AB

AG

IFR

23.09.08

Issued for Review

BC

AB

AG

IFR

22.09.08

Issued for Review

BC

AB

AG

IFR

22.09.08

Issued for Internal Review

BC

AB

AG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

PREWPS FOR SS304 (2.5-11 mm )

LINDE ENGINEERING AG

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

WPS

QAC

GTL

010

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.305.134

Vendor Code

Rev No: O

TABLE OF CONTENTS

1.

2MH127/WPS/004

T-4.305.134 Rev. O

Page 4 of 6

WELDING PROCEDURE SPECFICATIONS (WPS)

Code of Reference : ASME B31.3 ,ASME Sec IX,T-13.377.441

Client :

SHELL or its PMC

Project Name:

Contractor :

LINDE ENGINEERING AG

C2 ASU PEARL GTL PROJECT- RAS LAFFAN INDUSTRIAL CITY

Company Name :

GAMA QATAR

WPS No:

2MH127/WPS/004

Rev:

PQR No:

2MH127/PQR/004

Rev:

Welding Process :

GTAW

Date:

Date:

Type(s):

MANUAL

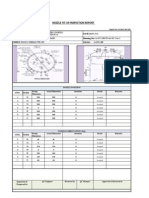

JOINTS ( QW - 402)

Joint Design :

ALL

Backing (Yes/ No):

Backing Material (Type ):

NO

N/A

37.5 2.5

1.6

0.8mm

3.2

0.8mm

Base Metals ( QW - 403)

P -No.

Group No.

To

P-No

Group No.

OR

Specification Type and Grade:

ASTM A312,Gr TP 304 L

Specification Type and Grade:

ASTM A312,Gr TP 304/316/321 L

To

OR

Chem.Analysis and Mech. Prop:

N/A

Chem.Analysis and Mech. Prop:

N/A

To

Thickness Range :

Groove :

2.5 to 11mm

Fillet:

ALL

Diameter Range

Groove :

ALL

Fillet:

N/A

Others:

FILLER METALS(QW - 404)

F No:

Other:

N/A

A- No

Other:

N/A

Spec No. (SFA):

5.9

AWS No. (Class):

ER 308 L

Size Of Filler Metals :

2,2.4(GTAW)

Max.Deposited Weld Metal Thick. :

Electrode-Flux (Type):

N/A

Trade Name:

ESAB

Consumables Insert :

N/A

POSITION(S)(QW - 405)

POST WELD HEAT TREATMENT(QW - 407)

Positions Of Groove:

ALL

Temperature Range :

N/A

Welding Progression:

UPHILL

Time Range:

N/A

Position(s) of fillet:

ALL

Rate of heating:

Rate of Cooling:

N/A

N/A

GAMA REP

Prepared By

Checked By

LINDE REP

QSGTL or its PMC

Page 1

Test coupon: 6" SCH XXS

Weld Sequence

WELDING PROCEDURE SPECIFICATIONS (WPS)

Code of Reference : ASME B31.3 ,ASME Sec IX,T-13.377.441

WPS No: 2MH127/WPS/004

Rev . No:

Date:

PRE- HEAT (QW - 406)

GAS (QW - 408)

Pre Heat Min:

Ambient Temp.

(Preheat to 50 C if metal temp< 5 C)

Interpass temp :

170 C Max.

Shielding Gas(es):

Percent Composition(Mixture):

Shielding gas flow Rate:

Method of Heating:

Backing Gas(es):

Torches(Propane)

Argon

99.99%

13-20 lt/min.

Argon (99.99% & FL 14-18

lt/min)

Trailing shielding gas

composition:

Temp Monitoring Method: Pyrometer/Infrared termometer

N/A

Temp Indicator Stick

ELECTRICALCHARACTERISTICS(QW - 409)

Current AC or DC

DC

Polarity

Amps Range

Min 80 Amps- Max 120 Amps

Tungsten Electrode Size and Type

2,2.4 EWTh-2

Mode of Metal Transfer GMAW

N/A

Electrode Wire Feed Speed Range

N/A

DCEN(GTAW)

Voltage range Min 9V - Max13V

TECHNIQUE(QW - 410)

String or Weave Bead :

String-Root Pass,Weave-Fill&Cap

Orifice or Gas Cup Size :

6/8/11 mm

Initial and Interpass Cleaning :

Grinding/Wire Brushing (Stainless Steel)

Method of Back gouging:

N/A

Oscillation

N/A

Contact Tube To Work Distance

N/A

Multiple Or Single Pass (per side)

Multiple Passes

Multiple or Single Electrodes

Single Electrode

Travel Speed(Range)

OTHERS :

Piping Class :

Service :

PQR Impact Test Temperature :

AA1L06,AA1M06,AA6S06,AACM06

-196 C

Filler Metal

Weld Pass

Root

Hot

Fill

Cap

Current

Process

GTAW

GTAW

GTAW

GTAW

Class

Dia mm

Polarity

Amps

Range

ER 308L

ER 308L

ER 308L

ER 308L

2,2.4

2,2.4

2,2.4

2,2.4

DCEN

DCEN

DCEN

DCEN

80-100

80-110

95-120

95-110

Volts Range

Travel Speed

mm/min

Heat Input

KJ/mm (Max.)

9-13

9-12

10-12

10-12

Notes :-

GAMA REP

Prepared By

Checked by

LINDE REP

QSGTL or its PMC

Page-2

You might also like

- Juk Lu-562 563Document24 pagesJuk Lu-562 563RHoskaNo ratings yet

- Ch8. Welding Symbols PDFDocument66 pagesCh8. Welding Symbols PDFMEHMET SIDDIK TEKDEMİRNo ratings yet

- 07 SMAW 332 18 532 332 E7018 Prequalified WPSsDocument82 pages07 SMAW 332 18 532 332 E7018 Prequalified WPSsErick VazquezNo ratings yet

- 016-CIVIL - MS Anchor Bolt Installation PDFDocument14 pages016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 043-ITP FOR Water Proofing (Buildings) PDFDocument13 pages043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- RT Pipeline Crawler PDFDocument12 pagesRT Pipeline Crawler PDFAnonymous 5qPKvmuTWCNo ratings yet

- Astm A 833Document2 pagesAstm A 833AHMED ALJAAFARNo ratings yet

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pages045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 014-MS For General Scaffolding PDFDocument33 pages014-MS For General Scaffolding PDFKöksal Patan100% (2)

- Assessing Pipeline Girth Weld FlawsDocument48 pagesAssessing Pipeline Girth Weld FlawsLuigi Rizzi100% (1)

- PAUT - Phased Array and ToFD - V - Radiography PDFDocument14 pagesPAUT - Phased Array and ToFD - V - Radiography PDFdarouichNo ratings yet

- 013-MS For Mass Concrete Works PDFDocument26 pages013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 015-Method Statement For Painting Works (Building) PDFDocument21 pages015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- Aws d1.1 Tubular Vs Non TubularDocument1 pageAws d1.1 Tubular Vs Non TubularrendraNo ratings yet

- Pipeline Welding Qualification TestsDocument2 pagesPipeline Welding Qualification TestsKali AbdennourNo ratings yet

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocument17 pages010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanNo ratings yet

- Pws Convention PresentationDocument93 pagesPws Convention Presentationbenj100% (1)

- 041 - ITP For Painting (Building) PDFDocument12 pages041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pages050-Itp For Installation of Air Intake Filter PDFKöksal PatanNo ratings yet

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocument16 pages012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- Welding Consumable Storage and Handling ProceduresDocument27 pagesWelding Consumable Storage and Handling ProceduresKannan MurugesanNo ratings yet

- SOP-030 - Rev0 Mic10 Mic20Document2 pagesSOP-030 - Rev0 Mic10 Mic20Stephen LewellenNo ratings yet

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocument10 pages044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 003-WPS For CS & Itcs With PWHT (C.S-19-40MM) (Itcs-20-44mm) PDFDocument7 pages003-WPS For CS & Itcs With PWHT (C.S-19-40MM) (Itcs-20-44mm) PDFKöksal PatanNo ratings yet

- 015-MS For Night Works PDFDocument16 pages015-MS For Night Works PDFKöksal Patan80% (5)

- 4 5847992272976611240 PDFDocument8 pages4 5847992272976611240 PDFAyyappanSubramanianNo ratings yet

- TSPP9Document90 pagesTSPP9Ian NaylorNo ratings yet

- Cigweld-Deposited Rates PDFDocument7 pagesCigweld-Deposited Rates PDFNam_HitechNo ratings yet

- WPS Development For Non-Welding Engineers - Jan 2021Document79 pagesWPS Development For Non-Welding Engineers - Jan 2021Juan Felipe Murillo Alzate100% (1)

- Smaw g11 1st ExamDocument3 pagesSmaw g11 1st ExamNeil Alcantara Masangcay91% (33)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocument23 pages014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNo ratings yet

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- QPR0150 Flushing Proc.Document3 pagesQPR0150 Flushing Proc.ZackTeeKeatTeongNo ratings yet

- Mentor UT Configuration Guide: Probe/Scanner/Software/Accessory Part Number GuideDocument24 pagesMentor UT Configuration Guide: Probe/Scanner/Software/Accessory Part Number GuideFethi BELOUISNo ratings yet

- Weld DiscontinuityDocument61 pagesWeld DiscontinuityEKKACHAI PRABNAKORN0% (1)

- 009-Civil-Ms Concrete Works PDFDocument27 pages009-Civil-Ms Concrete Works PDFKöksal PatanNo ratings yet

- CV-NDTL3 TPI-NavDocument22 pagesCV-NDTL3 TPI-NavShanmuga NavaneethanNo ratings yet

- 048-Itp For Installation of Hvac Unit PDFDocument8 pages048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pages011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocument18 pages017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pages008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNo ratings yet

- 005-WPS For Carbon Steel (1.6-4.6MM) PDFDocument7 pages005-WPS For Carbon Steel (1.6-4.6MM) PDFKöksal Patan0% (1)

- 038-Itp For Coldboxes PDFDocument25 pages038-Itp For Coldboxes PDFKöksal PatanNo ratings yet

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pages007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNo ratings yet

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocument28 pages047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNo ratings yet

- 040-ITP For Repair of Steam Distribution Manifold PDFDocument11 pages040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNo ratings yet

- 040-ITP For Repair of Steam Distribution Manifold PDFDocument11 pages040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNo ratings yet

- Radiography Testing - NDT Inspection - TWIDocument5 pagesRadiography Testing - NDT Inspection - TWIKolusu SivakumarNo ratings yet

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocument18 pages046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNo ratings yet

- AUT Pipeline CRA Weld Inspection BrazilDocument13 pagesAUT Pipeline CRA Weld Inspection BrazilMajeed RumaniNo ratings yet

- Welding Qualification As Per AWS D1.1Document19 pagesWelding Qualification As Per AWS D1.1Ouni AchrefNo ratings yet

- Phased Array in Lieu of RadiographyDocument4 pagesPhased Array in Lieu of RadiographyreiazhNo ratings yet

- 008-CIVIL-MS Backfilling Works PDFDocument16 pages008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- API 1169 - Prep Test #3: Written by Dale Honn, P.E., P.L.SDocument45 pagesAPI 1169 - Prep Test #3: Written by Dale Honn, P.E., P.L.SHeartyscorpionNo ratings yet

- 010-MS For Grouting PDFDocument33 pages010-MS For Grouting PDFKöksal PatanNo ratings yet

- 009-Method Statement - Main Erection Sequence For Acc PDFDocument68 pages009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- As 2452.1-2004 Non-Destructive Testing - Determination of Thickness Determination of Wall Thickness of Pipe BDocument7 pagesAs 2452.1-2004 Non-Destructive Testing - Determination of Thickness Determination of Wall Thickness of Pipe BSAI Global - APACNo ratings yet

- 013-MS Utilization of Hilti DX 76 PDFDocument51 pages013-MS Utilization of Hilti DX 76 PDFKöksal PatanNo ratings yet

- Equipment Catalogue 2014 - ENDocument48 pagesEquipment Catalogue 2014 - ENIonut SaucaNo ratings yet

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- European Standard EN 288-1: 1992 + A1: 1997 Has The Status of A DIN StandardDocument9 pagesEuropean Standard EN 288-1: 1992 + A1: 1997 Has The Status of A DIN StandardSanjay C BhattNo ratings yet

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocument18 pages012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- 039-Itp For Embedded Plate PDFDocument7 pages039-Itp For Embedded Plate PDFKöksal PatanNo ratings yet

- 011-PREWPS FOR SS304 (6.3 - 18.7 MM) PDFDocument9 pages011-PREWPS FOR SS304 (6.3 - 18.7 MM) PDFKöksal PatanNo ratings yet

- What'S in Your Coiled Tubing?: Roderic K. Stanley, PH D, I. EngDocument30 pagesWhat'S in Your Coiled Tubing?: Roderic K. Stanley, PH D, I. EngAriel TerrensNo ratings yet

- Flare Stack ITP Inspection PlanDocument3 pagesFlare Stack ITP Inspection Planlailatul kodriNo ratings yet

- QP-010, Quality Manual For Process Piping Inspection StandardDocument14 pagesQP-010, Quality Manual For Process Piping Inspection StandardIksan Adityo Mulyo100% (1)

- CV - Fabio Madeira en - 082018Document3 pagesCV - Fabio Madeira en - 082018inspetorfabiomadeiraNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- Radiography 2 ProcedureDocument9 pagesRadiography 2 ProceduresheikmoinNo ratings yet

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- ASME Sec VIII - Temper Bead TechniqueDocument1 pageASME Sec VIII - Temper Bead TechniquezanlogNo ratings yet

- Saferad ProcedureDocument19 pagesSaferad ProcedureExsan OthmanNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- PDS Na GTS65 PDFDocument2 pagesPDS Na GTS65 PDFMoaatazz NouisriNo ratings yet

- API 570 Pipeline Inspection PDFDocument1 pageAPI 570 Pipeline Inspection PDFKhalidMoutarajiNo ratings yet

- Weld Defects in RTDocument102 pagesWeld Defects in RTSaad Al Katrany100% (1)

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- Astm A335 p91 PipeDocument1 pageAstm A335 p91 PipeBhagwati SteelageNo ratings yet

- IRTS Pulsed Eddy Current Testing Work ProcedureDocument10 pagesIRTS Pulsed Eddy Current Testing Work ProcedurePeterNo ratings yet

- PipingDocument8 pagesPipingRajkumar ANo ratings yet

- 12 MT ProcedureDocument17 pages12 MT ProcedureThân KhaNo ratings yet

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiNo ratings yet

- 2018 Uk Cswip Exam FeeDocument7 pages2018 Uk Cswip Exam FeeMostafaRockNo ratings yet

- Silverwing B Scan ReportDocument46 pagesSilverwing B Scan ReportpjhollowNo ratings yet

- Operating Manual CrxvisionDocument45 pagesOperating Manual CrxvisionChandrashekhar ThiramdasuNo ratings yet

- Procedure Demonstration RecordDocument5 pagesProcedure Demonstration RecordSantanu SahaNo ratings yet

- GE Mentor EM Weld BrochureDocument6 pagesGE Mentor EM Weld BrochuredimachampionNo ratings yet

- Assessing linearity of phased array instrumentsDocument20 pagesAssessing linearity of phased array instrumentsKevin HuangNo ratings yet

- Radiography Test Procedure Part - 1Document21 pagesRadiography Test Procedure Part - 1Ahmed Lepda100% (1)

- Comparison of Automated Ultrasonic Inspection and Radiographic Inspection for WeldsDocument12 pagesComparison of Automated Ultrasonic Inspection and Radiographic Inspection for WeldsgorkembaytenNo ratings yet

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- Ometry of Bolted Connections:: Hole Spacing and Code FormulaDocument17 pagesOmetry of Bolted Connections:: Hole Spacing and Code FormulaSimi NagyNo ratings yet

- Proc SopDocument90 pagesProc SopJohn Dolan100% (1)

- Feritescope MP30 TrainingDocument20 pagesFeritescope MP30 Trainingafnene1No ratings yet

- Case Study - PresentationDocument4 pagesCase Study - PresentationNurin irdina ZainuddinNo ratings yet

- Cross Sectional Assembly Drawing With Part ListDocument33 pagesCross Sectional Assembly Drawing With Part Listhuynhthanhtamga1981No ratings yet

- CITY # 100274628 0800.05000-A: ConnectorDocument2 pagesCITY # 100274628 0800.05000-A: Connectorzbigniew prenetaNo ratings yet

- Turbine Handover List EquipmentDocument22 pagesTurbine Handover List Equipmentjindal powerNo ratings yet

- File3 PDFDocument119 pagesFile3 PDFikkemijnnaam0% (1)

- Boq Mei Isbl Refinery Glycerine Plant - For TenderDocument64 pagesBoq Mei Isbl Refinery Glycerine Plant - For TenderIsnanto AjaNo ratings yet

- Northern Zambales College, Inc. Checklist of Tools, Equipment, Supplies and Materials, and FacilitiesDocument3 pagesNorthern Zambales College, Inc. Checklist of Tools, Equipment, Supplies and Materials, and Facilitiesjerome24diassanNo ratings yet

- PHOENIX Conectores de Passagem PDFDocument160 pagesPHOENIX Conectores de Passagem PDFHaldirLeaoNo ratings yet

- Plugs, Sockets and Adaptors Technical Data - 621471 - ClipsalDocument52 pagesPlugs, Sockets and Adaptors Technical Data - 621471 - ClipsalalibinabubakarNo ratings yet

- Aws z49-1 PDFDocument58 pagesAws z49-1 PDFTaylorNo ratings yet

- Especificacion de Torque EnglishDocument4 pagesEspecificacion de Torque EnglishpetercuriNo ratings yet

- Itp EvaporatorDocument10 pagesItp EvaporatorChinni KrishnaNo ratings yet

- WQT Enrolment Form TWIT-WQ-F1 Rev 1Document1 pageWQT Enrolment Form TWIT-WQ-F1 Rev 1reezmanNo ratings yet

- Patrick Miguel Cos Sande: Institute/University:TESDA MASBATE CITYDocument1 pagePatrick Miguel Cos Sande: Institute/University:TESDA MASBATE CITYMark Jasper BadillosNo ratings yet

- Registry Re Request For NTTC (May 16-26,2017)Document22 pagesRegistry Re Request For NTTC (May 16-26,2017)manzNo ratings yet

- Analisis Kekuatan Tarik, Kekerasan, Dan Struktur PengelasanDocument10 pagesAnalisis Kekuatan Tarik, Kekerasan, Dan Struktur PengelasanNurkholis NurkholisNo ratings yet

- GS TRANCHE 23 SPARE PARTS LISTINGDocument33 pagesGS TRANCHE 23 SPARE PARTS LISTINGdoganhisar tvNo ratings yet

- Fundamentals of WeldingsDocument96 pagesFundamentals of WeldingsBurag HamparyanNo ratings yet

- Sivakumar Service CertificatesDocument21 pagesSivakumar Service CertificatesAbdul SirajNo ratings yet

- Weidmuller Screw Connection Terminal AccessoriesDocument30 pagesWeidmuller Screw Connection Terminal AccessoriesPeralta FcoNo ratings yet

- Welder Semester 1 NSFQ Books Compressed 1 100 74f282f1Document100 pagesWelder Semester 1 NSFQ Books Compressed 1 100 74f282f1Md Eklakh Md EklakhNo ratings yet

- Methode Statement Weld & Fitup of PipeDocument14 pagesMethode Statement Weld & Fitup of PipeRio Cristovan MantiriNo ratings yet

- ISSUE 367 QUIZ-Charpy Impact Test Reduction Temperature For CVN VIII.2-ANSWERDocument9 pagesISSUE 367 QUIZ-Charpy Impact Test Reduction Temperature For CVN VIII.2-ANSWERcpchonburiNo ratings yet