Professional Documents

Culture Documents

Toolbox4Planning - Working With Progress S-Curve For A Project or Turnaround Work

Uploaded by

m_verma21Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toolbox4Planning - Working With Progress S-Curve For A Project or Turnaround Work

Uploaded by

m_verma21Copyright:

Available Formats

Toolbox4Planning: Working with Progress S-curve for a Project or Tur...

1 of 3

http://www.toolboxforplanning.com/2010/12/working-with-progress-s-...

Toolbox4Planning

Where Planning Resources and Techniques are

Home

About

Download

Tutorials

Subscribe to Primavera P6 and Project Controls

Articles by Email:

Search This Site...

Like

Working with Progress S-curve for a Project or Turnaround

work

E-mail Adress:

ARCHIVES

INDEX

Baseline

Constraint Date

Construction Planning

Construction schedule

EPC planning

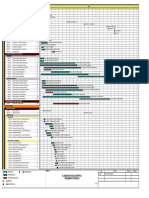

Progress S-curve can be developed from various

sources. It can be produced directly project

management software such as primavera, MS

project, etc. It can also be developed in the excel

spreadsheet. How ever, the concept and working

procedures are the same no matter which tools

are utilized. The two processes called developing

and updating are required when working with

Progress S-curve. Normally in a project, progress

curve is used to measure the project status and

report to client as well as internal stakeholders who

will take remedial action in the event of project

delay occurs.

Project Plan

Template

1

Share

Download this Project Plan

Template - right here!

32

Excel Tutorial

Lookahead Schedule

Maintenance Planning

Maintenance schedule

Planner's Resources

Primavera P6

Primavera P6 Tutorial

Primavera Tutorial

Progress Calculation/Measurement

Sample Layout

The following steps should be taken when the

progress curve is developed.

1. Collect project requirements/scope

2. Develop WBS

3. Develop baseline schedule

4. Assigns planned hours (man-hours and/or equipments hours or budgeted cost) in each activity or each

deliverables such as engineering documents and so on

5. Calculate the relative weight

Sample WBS

Sample Work Activity

Schedule Control

6. Distribute the percent completion over the time line.

7. Develop progress calculation procedure for each WBS

schedule design

Schedule development

Schedule Options

Schedule Report

The following steps should be taken when the progress curve is updated.

1. Update actual physical progress for each activity or deliverables

2. Calculate percent completion

Tank Construction

Normally in an EPC project, Engineering, Procurement and Construction Progress Curve and Overall progress

curve are produced and used to monitor the project performance. The three WBS element ( Engineering,

Procurement and Construction ) are WBS level 1. Overall is a project level WBS called level 0.

Assume that a project scope includes design, procurement and construction of pump station and additonal

pipelines for a refinery plant.

Engineering Progress S-curve

According to that project scope, the following documents could be produced for engineering stage.

1. Basic Engineering Data

2. P&ID drawings

3. Line list

4. Piping MTO list

5. Piping GA drawings

6. Pump GA drawings

7. Mechanical Seal drawing

8. Structure GA drawings

9. Pump Foundation drawings

10. Electrial drawings

11. Instrument drawings

12. Construction Requisition and so on

POPULAR POSTS

How to Get Resource Loading Histogram/S

Curve in Primavera P6

Develop engineering schedule based on the agreed deliverable list. Assign the planned man hour on each activity

to be produced engineering documents. Suppose the total man hour to be spent for engineering is 11,500 hrs and

the schedule is 6 month. Engineering planned percent complete can be calculated by dividing man hour

distribution over time line and total engineering man hour. Man hour distribution would be different according to

work load.

Example; man hour distribution over the time line is as follows;

50 hrs (in 1st week), 100 hrs (in 2nd week), 150 hrs (in 3rd week) and so on.

Therefore percent complete for 1st week ; 50/11,500= 0.4%

2nd week; 100/11,500=0.9%

3rd week; 150/11,500=1.3%

-----

16-05-2015 09:39

Toolbox4Planning: Working with Progress S-curve for a Project or Tur...

2 of 3

WBS ( Work Breakdown Structure ) for

Engineering and Construction

http://www.toolboxforplanning.com/2010/12/working-with-progress-s-...

----Final week; 120/11,500=1% and percent complete for total weeks should be 100%.

Then, progress s-curve can be produced using charting tool in excel. See creating progress S-curve

When the actual work is started, the actual progress data should be calculated. Update the physical percent

complete on each activity/step for each document. Multiply document progress and document weightage. Finally,

total percent complete can be calculated by doing sum-up the weightage progress for each document.

Tutorial-How to generate S curve/histogram

from Primavera, P6 - Part I

Procurement Progress S-curve

The planned procurement progress data can be produced as follows;

Ads by Google

Excel Project Management

Maintenance Schedule

Plant Maintenance

Ads by Google

Project Engineering

Project Resource Planning

Project Report

Ads by Google

Construction Contract

Earned Value Formula

Project Resource Planning

Find us on Facebook

Toolbox4Planning

1. Sum-up the material and equipment cost

2. Develop and get the approved baseline procurement schedule

3. Distribute the cost over the time line

4. Calculate the percent complete by dividing the distributed cost over time line and total material and

equipment cost. The distributed cost (planned cost) would be different depending on procurement step

and work load. Assume the total cost is 200,000 and schedule is 4 months.

Example; planned cost over the time line is as follows;

1

2,000 (in 1st week), 3,000 (in 2nd week), 5,000(in 3rd week) and so on.

Share

Therefore percent complete for 1st week ; 2,000/200,000 = 1%

2nd week; 3,000/200,000 = 2%

3rd week; 5,000/200,000 = 3%

32

The accumulated percent complete up to three week is 6 percent. Then the percent complete for total week

should be also 100%.

When the actual work is started, update the physical progress on each procurement step for each

equipment. Multiply the physical progress of equipment/material and its weightage (equipment cost/total

equipments cost) . Finally, total percent complete can be calculated by doing sum-up the weightage progress for

each equipment/material.

Like

480 people like Toolbox4Planning.

Construction Progress S-curve

The planned construction progress data can be produced as follows;

1. Develop and get the approved baseline construction schedule

2. Assign the planned man hour on each activity

3. Distribute the man hour over the time line

Facebook social plugin

FOLLOWERS

with Google Friend Connect

Members (172) More

4. Calculate the percent complete by dividing the distributed hour over the time line and the total construction

hours ( man hour and equipment hour) . The distributed hours would be different depending on work load in

a time frame. Assume the total construction hour is 160,000 and schedule is one and half years.

Example; planned hour over the time line is as follows;

4,000 hrs (in 1st week), 4,500 hrs (in 2nd week), 5,000 hrs (in 3rd week) and so on.

Therefore percent complete for 1st week ; 4,000/160,000 =2.5%

2nd week; 4,500/160,000 =2.8%

3rd week; 5,000/160,000 =3.1%

The accumulated percent complete up to three week is 8.4 percent. Then the percent complete by the end of the

project is 100%.

Update the physical construction progress when the actual work is started. Update the actual percent complete on

each work step for each activity.Multiply the physical progress of each activity and its weightage (activity hour/total

construction hour) . Finally, total percent complete can be calculated by doing sum-up the weightage progress for

each activity.

Already a member? Sign in

WELCOME

Hi, my name is Min Oo. Thank you for visiting my site and

welcome to my blog. I have been working in different roles

in projects, maintenance planning & scheduling and

engineering in the oil & gas and petrochemical industry

over the last 12 years. The greatest value of

Toolbox4Planning is sharing ideas, tool & techniques and

best practices that can be applied in industries involved in

engineering, construction, manufacturing, maintenance and

research. You can find tutorials and templates related to

planning & scheduling and project control at

Toolbox4Planning which would help you improve your

planning knowledge and skills. Grab a cup of your favourite

beverage, browse the blog, share your thoughts / leave

comments. Email: admin@toolboxforplanning.com

Overall progress S-curve

The overall progress data (planned and actual) can be calculated as follows;

1. Calculate Engineering , Procurment and Construction cost

2. Calculate relative weightage for Engineering, Procurement and Construction. example; for engineering

weightage - total engineering cost/total project cost

3. Get engineering weightage progress by multiplying engineering physical progress and engineering

weightage

4. Get procurement weightage progress by multiplying procurement physical progress and procurement

weightage

5. Get construction weightage progress by multiplying construction physical progress and construction

weightage

6. Sum-up all weightage progress (EPC)

Then, use the charting tool in excel to produce progress curve. See creating progress s-curve.

A CRM That Drive Sales

Easy To Use, Close More Deals. Start Your Free 30-Day Trial Now!

You might also like:

Progress

Calculation

Procedure for

Developing

Resource

Curve/Progress

Working with

Baseline Plan in

Planning and

16-05-2015 09:39

You might also like

- How To Generate S Curve Histogram From Primavera P6-Part IDocument5 pagesHow To Generate S Curve Histogram From Primavera P6-Part Ijoaquin_guaco80380% (1)

- TCF Variance Report for Reggane Nord Development ProjectDocument19 pagesTCF Variance Report for Reggane Nord Development ProjectAbhiyan Anala ArvindNo ratings yet

- Negative FloatDocument5 pagesNegative Floatroyal3311No ratings yet

- How To Export Resource Assignment Data To Excel From P6Document9 pagesHow To Export Resource Assignment Data To Excel From P6artletNo ratings yet

- Total PrimaveraDocument60 pagesTotal PrimaveraSmart SaadNo ratings yet

- Retained Logic OptionDocument15 pagesRetained Logic Optionsharad kumarNo ratings yet

- P6 Tricks of the Trade GuideDocument4 pagesP6 Tricks of the Trade Guideabuelazm2132No ratings yet

- 283 Lookahead Schedule 25 Oct 17Document2 pages283 Lookahead Schedule 25 Oct 17adnanNo ratings yet

- Primavera P6 Lookahead Filters in 40 StepsDocument8 pagesPrimavera P6 Lookahead Filters in 40 StepshichemokokNo ratings yet

- Project Scheduling: Project Cost Management (Mbem-202)Document15 pagesProject Scheduling: Project Cost Management (Mbem-202)Sripadma SanjivNo ratings yet

- Construction Planning and SchedulingDocument11 pagesConstruction Planning and SchedulingAWAKSEORANGNo ratings yet

- Lecture 6fDocument30 pagesLecture 6fhiteshNo ratings yet

- MONTHLY PROGRESS REPORT Mar-12Document78 pagesMONTHLY PROGRESS REPORT Mar-12shareyhouNo ratings yet

- Creating Filters in PrimaveraDocument14 pagesCreating Filters in PrimaveraARP MEILNo ratings yet

- Resource Dependent Activity Type in P6Document7 pagesResource Dependent Activity Type in P6MuhammadIqbalMughalNo ratings yet

- Steps in Preparation of WorkplanDocument12 pagesSteps in Preparation of WorkplanMuhammad ZubairNo ratings yet

- Two Maridien Revised Program.10.11.16Document33 pagesTwo Maridien Revised Program.10.11.16Aldrin MacaraegNo ratings yet

- Actual Progress Schedule With EVMDocument5 pagesActual Progress Schedule With EVMunseenladdNo ratings yet

- PROJECT STANDARD and SPECIFICATIONS Progress Measurement Procedure Rev01 WebDocument6 pagesPROJECT STANDARD and SPECIFICATIONS Progress Measurement Procedure Rev01 WebAkangAtetNo ratings yet

- Section 2A. Schedule DevelopmentDocument1 pageSection 2A. Schedule DevelopmentSucher EolasNo ratings yet

- Earned ValueDocument17 pagesEarned ValueBlanche PhlaumNo ratings yet

- Automation Line Refit Progress Updating WorkshopDocument13 pagesAutomation Line Refit Progress Updating WorkshophodubanjoNo ratings yet

- Progress Tracking Sheet-Tie-in InstallationDocument2 pagesProgress Tracking Sheet-Tie-in InstallationRedouane MerabteneNo ratings yet

- Industrial TrainingDocument59 pagesIndustrial TrainingSatnam SinghNo ratings yet

- How To Generate S Curve From Primavera-P6Document6 pagesHow To Generate S Curve From Primavera-P6Lai QuocNo ratings yet

- Percent Complete Fields in Primavera P6Document41 pagesPercent Complete Fields in Primavera P6TAHER AMMAR100% (1)

- Benefit To Compensation Ratio CalculationsDocument6 pagesBenefit To Compensation Ratio CalculationsRamkishor PandeyNo ratings yet

- AGM REPORT Construction Excel Revised 2.22.12Document7 pagesAGM REPORT Construction Excel Revised 2.22.12niroNo ratings yet

- Planner S CurveDocument23 pagesPlanner S CurveMd ShariqueNo ratings yet

- Mid-Atlantic Operations Schedule Analysis TechniquesDocument45 pagesMid-Atlantic Operations Schedule Analysis TechniquesYossi Habibie100% (1)

- Different Duration Types in Primavera p6 r8Document3 pagesDifferent Duration Types in Primavera p6 r8Adnan AhmedNo ratings yet

- Project Control System ManualDocument20 pagesProject Control System Manualdeltahawk61No ratings yet

- FGP WPMP OverviewDocument15 pagesFGP WPMP OverviewyazardNo ratings yet

- Proj Desc 1768 29may2018 PDFDocument31 pagesProj Desc 1768 29may2018 PDFKungu Teddy NjorogeNo ratings yet

- P6 Training AberdeenDocument3 pagesP6 Training AberdeenNnamdiNo ratings yet

- Al Mussafah A Al Mussafah Ahalia Hospital Al Mussafah Ahalia HospitalDocument4 pagesAl Mussafah A Al Mussafah Ahalia Hospital Al Mussafah Ahalia HospitalChâu TúNo ratings yet

- Notes For PrimaveraDocument11 pagesNotes For PrimaveraSmart FunboyNo ratings yet

- P6 Professional Fundamentals R8.3 PDFDocument5 pagesP6 Professional Fundamentals R8.3 PDFAbdelmuneimNo ratings yet

- Baselines, Floats, Constraints ComparedDocument24 pagesBaselines, Floats, Constraints ComparedS.m.sajjad Haider NaqviNo ratings yet

- Create Professional Gantt Charts and Timelines in PowerPoint from ExcelDocument10 pagesCreate Professional Gantt Charts and Timelines in PowerPoint from ExceltakreemkhanNo ratings yet

- PM Handbook TeaserDocument22 pagesPM Handbook TeaserFarid FaridNo ratings yet

- Enhanced resource planningDocument53 pagesEnhanced resource planningBogdanloeNo ratings yet

- Daily Activity Report from Wafa Field HSEQ DepartmentDocument1 pageDaily Activity Report from Wafa Field HSEQ DepartmentSalim Muftah100% (1)

- STO300 V 8.2 r1Document8 pagesSTO300 V 8.2 r1faheem2005rajaNo ratings yet

- PDS Milk of LimeDocument2 pagesPDS Milk of Limenachiappan_rameshNo ratings yet

- Procurement Process in Larsen & Toubro Epc: by Deepak Bhatt 063015Document14 pagesProcurement Process in Larsen & Toubro Epc: by Deepak Bhatt 063015Deepak BhattNo ratings yet

- Al Ramah Residental C Al Ramah Residental Complexes (Infrastructure)Document5 pagesAl Ramah Residental C Al Ramah Residental Complexes (Infrastructure)anoopvvvNo ratings yet

- 4.1 EOT Workshop Sub Contractors Claim Analysis Solution v3Document7 pages4.1 EOT Workshop Sub Contractors Claim Analysis Solution v3dhaferjabNo ratings yet

- MPR Month YearDocument58 pagesMPR Month YearSanthosh PalaniappanNo ratings yet

- Toolbox4Planning - How To Get Resource Loading Histogram - S Curve in Primavera P6Document14 pagesToolbox4Planning - How To Get Resource Loading Histogram - S Curve in Primavera P6Anish MMNo ratings yet

- Lecture # 5 Cost Estimation IDocument35 pagesLecture # 5 Cost Estimation IBich Lien Pham100% (1)

- KEC - Price List CablesDocument8 pagesKEC - Price List CablesSCM ASA BHANUNo ratings yet

- Man Hours HistogramDocument1 pageMan Hours HistogramMostafa Elkadi0% (1)

- Actural Jan-00 Pipeline Installation Work Progress ReportDocument2 pagesActural Jan-00 Pipeline Installation Work Progress ReportGomathyselviNo ratings yet

- Engineering ProductivityDocument15 pagesEngineering ProductivityGeetha_jagadish30No ratings yet

- Planners and EPC ScopeDocument7 pagesPlanners and EPC ScopeRoshin99No ratings yet

- Earned Value: Looking For An Easy Way To Implement It: PMI Virtual Library © 2013 Williams ChirinosDocument5 pagesEarned Value: Looking For An Easy Way To Implement It: PMI Virtual Library © 2013 Williams Chirinosumairbaig33No ratings yet

- Planning and PrimaveraDocument6 pagesPlanning and PrimaveraSyamraj JayarajanNo ratings yet

- TMP3413 Software Engineering Lab: The Development PlanDocument31 pagesTMP3413 Software Engineering Lab: The Development PlanNurfauza JaliNo ratings yet

- Filter media selection for cement production processesDocument4 pagesFilter media selection for cement production processesm_verma21No ratings yet

- 3M Whole House Filtration Systems PDFDocument4 pages3M Whole House Filtration Systems PDFm_verma21No ratings yet

- JETFLEX Burner BrochureDocument8 pagesJETFLEX Burner Brochurenagendra51No ratings yet

- Baghouse 101 Seminar 2005Document67 pagesBaghouse 101 Seminar 2005ssmith2007No ratings yet

- Welcome To All: Basics of Dedusting (Nuisance) FilterDocument109 pagesWelcome To All: Basics of Dedusting (Nuisance) Filterm_verma21100% (2)

- इंटरनेट मानक के लिए IS 8598 स्पेसिफिकेशनDocument11 pagesइंटरनेट मानक के लिए IS 8598 स्पेसिफिकेशनm_verma21No ratings yet

- World Cement Dust PipesDocument4 pagesWorld Cement Dust PipesBen FriskneyNo ratings yet

- KHD Comflex PDFDocument4 pagesKHD Comflex PDFm_verma21No ratings yet

- International Bag FilterDocument4 pagesInternational Bag FilterRAJAMANICKAMNo ratings yet

- Air SlidesDocument2 pagesAir Slidesm_verma21100% (2)

- Sizes & Weights of Seamless Pipes As Per ASTM A 106/53 Gr.A/BDocument3 pagesSizes & Weights of Seamless Pipes As Per ASTM A 106/53 Gr.A/BMontuJoshiNo ratings yet

- Air Slide Working ManualDocument20 pagesAir Slide Working ManualKrishnadas Gopalakrishnan100% (3)

- VSK SeparatorDocument3 pagesVSK Separatorm_verma21No ratings yet

- Is 808 1989Document20 pagesIs 808 1989713e5db8No ratings yet

- B 1716Document16 pagesB 1716m_verma21No ratings yet

- Beumer Apron Conveyor enDocument8 pagesBeumer Apron Conveyor enm_verma21No ratings yet

- Is 15560 - 2005Document12 pagesIs 15560 - 2005kalpanaadhiNo ratings yet

- Chain Pull CalculationsDocument39 pagesChain Pull Calculationsmech_abhi100% (2)

- Vibration Severity StandardDocument2 pagesVibration Severity Standardm_verma21No ratings yet

- Is 7054 1973Document16 pagesIs 7054 1973m_verma21No ratings yet

- KHD Comflex April 2012Document4 pagesKHD Comflex April 2012m_verma21No ratings yet

- Brochure - Loading Spout - Pubc-0499-AulDocument2 pagesBrochure - Loading Spout - Pubc-0499-Aulm_verma21No ratings yet

- Is 3746 1966Document14 pagesIs 3746 1966m_verma21No ratings yet

- Gulab Jamun Recipe, How To Make Gulab Jamun, Easy Recipe Step by StepDocument10 pagesGulab Jamun Recipe, How To Make Gulab Jamun, Easy Recipe Step by Stepm_verma21No ratings yet

- Tableau Incoterms 202000Document5 pagesTableau Incoterms 202000souleymane sow100% (6)

- A 7 Day Weight Loss Plan PDFDocument4 pagesA 7 Day Weight Loss Plan PDFm_verma21No ratings yet

- Jupiter - The Planet Jupiter - Jupiter For Kids PDFDocument4 pagesJupiter - The Planet Jupiter - Jupiter For Kids PDFm_verma21No ratings yet

- Belt Conveyor Counter Weight CalculationDocument1 pageBelt Conveyor Counter Weight Calculationm_verma2180% (5)

- Using Styles and Templates in Microsoft Word 2003: Guide 11Document0 pagesUsing Styles and Templates in Microsoft Word 2003: Guide 11m_verma21No ratings yet

- FQP SurveyDocument1 pageFQP Surveyrajiv71No ratings yet

- Manual HPDocument44 pagesManual HPMiguel Angel Limon MonasterioNo ratings yet

- Review Questions For: Physiology II-1Document26 pagesReview Questions For: Physiology II-1ngphm70% (1)

- Sheet Metal Forming PDFDocument8 pagesSheet Metal Forming PDFAlpha WolfNo ratings yet

- JSA ProjectDocument4 pagesJSA ProjectbrantasNo ratings yet

- Fastener TheoryDocument4 pagesFastener TheoryAnonymous OFP2ygPIdNo ratings yet

- NFPA Fire Design GuidanceDocument6 pagesNFPA Fire Design Guidancerashal100% (1)

- Mot-An-S en 20160403Document9 pagesMot-An-S en 20160403DARIONo ratings yet

- Capitol Steel Corporation-RSB PDFDocument1 pageCapitol Steel Corporation-RSB PDFeg choloNo ratings yet

- WPS RB GM 01Document12 pagesWPS RB GM 01hetpinNo ratings yet

- Pullout Strength of Hardened Concrete - C900 - 15Document10 pagesPullout Strength of Hardened Concrete - C900 - 15Ahmad ThaherNo ratings yet

- An Experimental Investigation of Single-Phase Forced Convection in MicrochannelsDocument7 pagesAn Experimental Investigation of Single-Phase Forced Convection in MicrochannelsAmit JhaNo ratings yet

- T0 - Space Syntax MethodologyDocument118 pagesT0 - Space Syntax Methodologyquraisha shaNo ratings yet

- Janet - Harbord Excentric Cinema Giorgio AgambenDocument272 pagesJanet - Harbord Excentric Cinema Giorgio Agambenmlauralattanzi100% (1)

- On October 15 2017 Oil Products Co Purchased 4 000 BarrelsDocument1 pageOn October 15 2017 Oil Products Co Purchased 4 000 BarrelsAmit PandeyNo ratings yet

- Gauge: Relevance and Non-Relevance To Performance What Affects Film Thickness Test Principles Related TerminologyDocument43 pagesGauge: Relevance and Non-Relevance To Performance What Affects Film Thickness Test Principles Related TerminologyMohamed SaiedNo ratings yet

- 47 (3) 0190Document16 pages47 (3) 0190prisciliano1No ratings yet

- Chapter 2 Study GuideDocument2 pagesChapter 2 Study Guideapi-330077886No ratings yet

- Psychology For UX Study GuideDocument11 pagesPsychology For UX Study GuideS. D.No ratings yet

- Class 4 Social Science Important QuestionsDocument3 pagesClass 4 Social Science Important Questionsanokhee aminNo ratings yet

- Still RX60-16,18,20 Parts CatalogueDocument678 pagesStill RX60-16,18,20 Parts CatalogueПетр100% (1)

- Universal Conjuring Circle@Document93 pagesUniversal Conjuring Circle@dolunay1990100% (3)

- Refleksi Kasus Dengan EBMDocument44 pagesRefleksi Kasus Dengan EBMidris setyadi lubisNo ratings yet

- Empowered EbookDocument13 pagesEmpowered EbookMarian HalapiNo ratings yet

- EchoLife HG520s Home Gateway Quick StartDocument14 pagesEchoLife HG520s Home Gateway Quick StartAdi CatanescuNo ratings yet

- Sam McCoy MFG - Catalogue 2004 - 2Document29 pagesSam McCoy MFG - Catalogue 2004 - 2Sam McCoy ManufacturingNo ratings yet

- 2022 08 29 04 44Document31 pages2022 08 29 04 44Iftekharul IslamNo ratings yet

- Bio Edit 2008Document26 pagesBio Edit 2008kumbharbajarang9092No ratings yet

- Dwnload Full Chemical Engineering Design 2nd Edition Towler Solutions Manual PDFDocument35 pagesDwnload Full Chemical Engineering Design 2nd Edition Towler Solutions Manual PDFandrewduffydckjxfspnq100% (10)

- Baterías AlphaDocument2 pagesBaterías Alphadisanty94No ratings yet