Professional Documents

Culture Documents

Model FC

Uploaded by

LeandroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model FC

Uploaded by

LeandroCopyright:

Available Formats

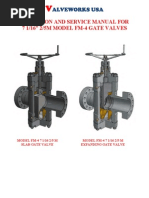

VALVEWORKS USA

OPERATION AND SERVICE MANUAL FOR

MODEL FC GATE VALVES

MODEL FC 3000-15000 PSI W.P

FLOATING SLAB GATE VALVES

VALVEWORKS USA

Model FC Operation Manual

INTRODUCTION

In appreciation to our customer for purchasing our product, we have prepared this Operation Manual to assist

you in the Operation, Maintenance, Assembly and Installation of the Valveworks USA API 6A Model FC Gate

Valves. We encourage you to follow recommendations in this booklet to attain the best possible service from

our product, which is designed and proven to offer the service one can expect of a quality product. If you need

to contact a representative for more specific information pertaining to a special problem, you should contact:

EMAIL:

WEBSITE:

VALVEWORKS USA

1650 SWAN LAKE RD.

BOSSIER CITY, LA 71111

PHONE: 318-425-0266

FAX# 318-425-0934

TOLL FREE: 888-425-0266

SALES@VALVEWORKSUSA.COM

WWW.VALVEWORKSUSA.COM

CONTENTS

APPLICATIONS ......................................................................................................................................................... 3

TEMPERATURE RATING ....................................................................................................................................... 3

TRIM CHART ............................................................................................................................................................. 3

ORDERING INFORMATION .................................................................................................................................. 4

OPERATION ............................................................................................................................................................... 4

ASSEMBLY INSTRUCTIONS .................................................................................................................................. 5

BODY SUB-ASSEMBLY .................................................................................................................................................. 5

BONNET SUB-ASSEMBLY ..............................................................................................................................................7

FINAL ASSEMBLY .......................................................................................................................................................... 8

BACK SEATING PROCEDURE ...................................................................................................................................... 10

ASSEMBLY DRAWING .......................................................................................................................................... 11

BILL OF MATERIALS .......................................................................................................................................... ..12

PHYSICAL DIMENSIONS ...................................................................................................................................... 14

PERIODIC MAINTENANCE.................................................................................................................................. 15

MAINTENANCE TOOLS ............................................................................................................................................... 15

STEM BEARING LUBRICATION ................................................................................................................................... 15

STEM PACKING ........................................................................................................................................................... 16

PROCEDURE TO VENT OR DRAIN ......................................................................................................................16

MAINTAINANCE INTERVALS ..................................................................................................................................... 17

TROUBLESHOOTING ............................................................................................................................................ 17

REPLACING SHEAR PIN .............................................................................................................................................. 18

TEST PROCEDURE................................................................................................................................................. 18

HYDROSTATIC BODY TEST ......................................................................................................................................... 20

HYDROSTATIC SEAT TEST .......................................................................................................................................... 21

VISUAL INSPECTION ............................................................................................................................................ 22

FIELD HOOK UP INSTRUCTIONS ...................................................................................................................... 23

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FC Operation Manual

APPLICATIONS

Valveworks USA Model FC valves can be applied to the following sizes and working pressures.

Size (inches)

1 13/16

2 1/16

2 9/16

3 1/8

3 1/16

4 1/16

Working Pressures

(PSI)

10000 15000

5000 10000 15000

5000 10000 15000

3000 5000

10000 15000

3000 5000 10000

The Model FC valves covered in this manual are suitable for performance requirement levels 1 and 2, PR1 and

PR2 respectively.

TEMPERATURE RATING

Temperature

classification

Operating Range

C

Min.

-60

-46

-46

-29

-18

-18

-18

2

K

L

N

P

S

T

U

V

Max.

82

82

60

82

60

82

121

121

Min.

-75

-50

-50

-20

0

0

0

35

(F)

Max.

180

180

140

180

140

180

250

250

Note: For special applications involving other sizes and pressure ratings, temperatures, materials, etc., please

contact Valveworks USA.

TRIM CHART

Minimum Material Requirements

Material class

AA - General service

BB - General service

CC - General service

DD - Sour service a

EE - Sour service a

FF - Sour service a

HH - Sour service a

a

b

Body, bonnet, end and

outlet connections

Carbon or low-alloy steel

Carbon or low-alloy steel

Stainless steel

Carbon or low-alloy steel b

Carbon or low-alloy steel b

Stainless steel b

CRAs b

Pressure-controlling parts,

stems and mandrel hangers

Carbon or low-alloy steel

Stainless steel

Stainless steel

Carbon or low-alloy steel b

Stainless steel b

Stainless steel b

CRAs b

As defined by NACE MR 0175.

In compliance with NACE MR 0175.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FC Operation Manual

ORDERING INFORMATION

The following information should be provided with any request for quote or order placement of Valveworks

USA Model FC gate valves:

Model of Valve

Size of Valve

Pressure Rating (maximum)

API 6A Requirements (PR-PSL)

API 14D Requirements (Class of Service)

Temperature Rating (API 6A)

Material (API 6A)

Any Special Test Requirements

Any Special Material Requirements

Any Special Coating or Protection Requirements

Other Specifications and/or Certifications

OPERATION

The Valveworks USA Model FC gate valves are handwheel operated valves. The gate of the MODEL FC

valve is a one piece slab gate that uses two floating seats to generate a highly reliable seal. The slab gate

eliminates the chance of trapping pressure within the body cavity which can cause pressure locking.

Below are some steps which have to be followed at all times.

1. Fully open the valve before installing or shipping. The sealing area of the gates, in the full open position,

is protected by the body and is less likely to be damaged.

2. Do not remove the molybdenum disulfide coating from internal parts. This coating serves as a lubricant

and corrosion inhibitor.

3. To hydrostatically test the valve body to full API test pressure, the valve must be in a partially open

position. When testing the valve in the closed position (seat test) do not exceed the working pressure

stamped on the valve identification plate.

4. During storage always leave the valve in the fully opened or fully closed position. This will tightly

wedge the gate against the seats and prevent damage to the sealing area of both the gate and seats.

5. Always remove the valve from service before work is performed on the stem bearings.

6. When lubricating the body do not exceed the maximum API working pressure stamped on the

identification plate.

7. The valve should be fully closed or fully opened during lubrication of the body or seats.

8. Seat lubrication pressures should not exceed the maximum allowable API test pressure.

This method of operation will prevent damage to the sealing surfaces of the gate and seats, and will increase the

life of the valve.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FC Operation Manual

ASSEMBLY INSTRUCTIONS

BODY SUB-ASSEMBLY

Picture showing parts of

Model FC.

Insert both the greased seal ring side of the

body bushings into the body as shown.

Insert the greased seal ring side of the retainer plate into

the body and onto the body bushing. The picture above

shows both the retainer plates placed in the body.

Grease the seal ring side of the body bushing

with Red Bentone grease.

Insert seats into each retainer plate and

grease the seal ring side of it as shown.

Insert the gate into the body, between

the retainer plates.

NOTE: Beveled side of the retainer plate should be placed against the body cavity wall.

Model FC slab gates are bidirectional and can be inserted with either side facing

the flow.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FC Operation Manual

Insert the gate guides as shown.

Slide the gate guides completely into the body.

Insert the bonnet seal ring into the bonnet seal

ring groove. Make sure it rests in the groove.

Apply anti-seize compound to the

threads in the bonnet stud holes.

Screw the studs into the body by

hand.

Using a stud tightening bolt and a

certified torque wrench, tighten the studs

into the body.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FC Operation Manual

BONNET SUB-ASSEMBLY

The bonnet assembly parts for Model FC are shown.

Insert the stem through the bottom of the bonnet.

Place the packing over the stem.

Push the packing inside the bonnet as shown.

Apply anti-seize compound to the inside threads of bonnet

and screw in the packing gland until the stem is visible.

Place the bearing-race set over the top and

bottom of the stem adapter.

Grease the bearing-race sets as shown.

Apply anti-seize to the bottom bearing of the

stem adapter.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FC Operation Manual

Place the stem adapter and bearing-race sets

onto the stem and insert a shear pin through the

stem adapter and the stem.

Apply 2 Alemite grease fittings into the

bearing cap.

Screw the bearing cap until tight on the

bonnet as shown.

FINAL ASSEMBLY

Grease the bottom of the stem with red

Bentone grease.

Place the bonnet onto the studs with the grease

fitting pointing to the front of the valve.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Place the handwheel on top of the stem adapter and

turn it clockwise to screw the stem into the gate.

Model FC Operation Manual

Screw the nuts onto the studs after screwing

the stem into the gate.

Screw the 1/2 NPT body grease fitting and

tighten it with a certified impact wrench.

Tighten the nuts to the studs using a

certified impact wrench.

Insert the handwheel back on the stem

adapter, insert and tighten the nut as shown.

Screw the grease fitting cap, and the

final valve assembly is complete.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

VALVEWORKS USA

Model FC Operation Manual

BACK SEATING PROCEDURE

Turn the handwheel until the gate is in open position (In case of Direct Operating gate).

Loosen the bearing cap using a pipe wrench by approximately 3.5-4 turns.

Over run the close position such that the gate hits the bottom, stem rises up and jams the back seat area.

An illustration of the bearing cap placed on

the bonnet is shown.

WARNINGS

The back seat is only intended to be used in an emergency situation to stop packing leakage.

One of the features of the back seat is to change the stem packing under pressure on well, even though it is not

promoted. It is always recommended that the valve be removed from service before packing is changed unless

an emergency.

By backseating the valve it is possible the gate will not seal the bore line.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

10

VALVEWORKS USA

Model FC Operation Manual

ASSEMBLY DRAWING

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

11

VALVEWORKS USA

Model FC Operation Manual

BILL OF MATERIALS

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

PART NO.

290-22XY

291-22XY

096-0000

319-22XY

109-0002

101-0000

340-22XY

350-22XY

346-22XY

032-0000

384-0000

344-0000

370-22XY

301-22XY

354-22XY

360-22XY

378-22XY

032-0000

320-22XY

334-0000

330-22XY

032-0000

380-0000

400-0002

DESCRIPTION

BODY

BONNET

STUDS & NUTS

BONNET SEAL RING

GREASE ALEMITE FITTING

BODY GREASE FITTING

STEM

PACKING

STEM ADAPTER

STEM ADAPTER O-RING

SHEAR PIN

PACKING GLAND

TORRINGTON BEARINGS

GATE, SLAB

GATE GUIDE

RETAINER PLATE

BEARING CAP

BEARING CAP O-RING

SEAT

SEAT SEAL

BODY BUSHING

BODY BUSHING SEAL

HAND WHEEL

HANDWHEEL NUT

HANDWHEEL BOLT

GREASE

QTY.

1

1

16

1

2

1

1

1

1

1

1

1

2

1

2

2

1

1

2

1

2

1

1

1

1

FILL

The last two digits in the part nos vary with X - Material Type and Y Coating. The table below gives the

different available material types and coatings. Please refer to the valve tag to see the material type and coating

on the valve parts.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

12

VALVEWORKS USA

Model FC Operation Manual

MATERIAL

TYPE

COATING

1

1A

1B

1C

1D

1E

1F

2

2A

3

3A

4

4A

4B

5

6

6A

6B

7

8

8A

8B

8C

8D

8E

9

9A

9B

4130

4140

1040

1018

1020

SA285-C

1026

410SS FORGED

S42400

174SS

NITRONIC 50

316SS

316/304SS

304SS

BRONZE

INCONEL 718

INCONEL 725

INCONEL X750

MONEL

A487-4D

A487-4C

CA15

CF8M

CF3M

CA6NM

STELLITE #6

PLASTIC

STELLITE #3

NONE;

PHOSPHATE,

MOLY, STANDARD

PAINT/COATING,

POWDER COAT

NITRIDE QPQPHOSPHATE;

EXCEPTION - FC

BODY BUSHING DO NOT NITRIDE

HARDFACESTELLITE #6

SPRAY & FUSE

HARDFACE TUNGSTEN

CARBIDE

HARDFACE COLMONOY #5

ELECTROLIS

NICKEL

WELD ON

HARDFACE

ZINC PLATE

XYLAN COATING

(4130) INCONEL

625 CLAD

(4130)SS-316-RING

GROOVE

4

5

6

7

8

9

9A

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

13

VALVEWORKS USA

Model FC Operation Manual

PHYSICAL DIMENSIONS

10000 FLANGED END DIMENSIONS (In Inches)

Nominal Size

1 13/16 2 1/16

A End to End

B Nominal Bore

C Center Line to Bottom

D Center Line to Top

E Handwheel Diameter

F Extreme Body Width

Weight - lbs

Flange Ring Joint

Bonnet Stud Size (# of Studs)

No. of Turns (Full Open to Full Close)

Amount of Grease (Lbs. Appx.)

2 9/16

3 1/16

4 1/16

18 1/4

20 1/2

22 1/4

1 13/16 2 1/16

2 9/16

5 3/4

5 3/4

6 3/4

20 5/8

20 5/8

21 3/8

16

16

20

9

9

9 1/2

270

275

485

BX151 BX152

BX153

1 1/8 (8) 1 1/8 (8) 1 1/4 (8)

24 3/8

3 1/16

7 3/4

21 5/16

23

10 5/8

680

BX154

1 3/8 (8)

26 3/8

4 1/16

10 1/8

28 3/4

24

13

950

BX155

1 5/8 (8)

12 1/2

12 1/2

15 1/4

18 1/4

23 1/4

2.75

4.25

2 9/16

3 1/16

15000 FLANGED END DIMENSIONS (In Inches)

Nominal Size

1 13/16 2 1/16

A End to End

B Nominal Bore

C Center Line to Bottom

D Center Line to Top

E Handwheel Diameter

F Extreme Body Width

Weight - lbs

Flange Ring Joint

Bonnet Stud Size (# of Studs)

No. of Turns (Full Open to Full Close)

Amount of Grease (Lbs. Appx.)

18

19

21

23 9/16

1 13/16 2 1/16

2 9/16

3 1/16

6 1/8

6 1/8

7 1/2

9 1/8

20 5/8

20 5/8 22 13/16 25 7/16

16

16

20

23

9 1/2

9 1/2

11 7/16

13 3/8

275

350

800

1065

BX151 BX152

BX153

BX154

1 1/4 (8) 1 1/4 (8) 1 1/2 (8) 1 1/4 (12)

12 1/2

12 1/2

15 3/4

15 1/4

2.00

2.25

2.75

3.25

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

14

VALVEWORKS USA

Model FC Operation Manual

PERIODIC MAINTENANCE

The Model FC gate valves are non-lubricated sealed valves, which do not require the injection of lubricants or

sealants to effectively seal. However, to prevent corrosion, excessive wear and ensure continued operation, a

normal amount of lubrication is recommended to extend the life and serviceability of the valve.

MAINTENANCE TOOLS

To perform normal maintenance and lubrication, the following tools are recommended:

1) Grease pump with adapter

and coupling.

2) Safety pressure releasing tool.

Valveworks USA API Gate Valves, 2000 PSI W.P. thru 10,000 PSI W.P. are supplied with 1/2" NPT body

fitting connections. Body fittings on 15,000 PSI W.P. valves are 1 1/8 12 UN threads.

STEM BEARING LUBRICATION

Valveworks USA API gate valves are equipped with alemite hydraulic type 1/8" NPT bonnet grease fittings.

Stem bearing lubrication is accomplished through this fitting using a standard type grease gun. Any good No. 3

grease is recommended for lubrication purpose. Stem bearings normally do not require high amounts of grease.

If too much lubrication should occur, excess grease will flow around the stem to the atmosphere.

An example of using a grease gun to grease

the stem bearings.

CAUTION: If bearings need to be changed, the valve must be removed from service. During

pressurized valve body lubrication, pressure applied to the valve body with the grease gun must not

exceed the maximum working pressure of the valve being lubricated.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

15

VALVEWORKS USA

Model FC Operation Manual

STEM PACKING

Most products contain a certain amount of water, lime scale, sediment and other foreign matter which tend to

accumulate in the valve body. A regular draining program will increase the life of a valve against damage

caused by:

1) Water freezing in the body cavity, causing damage to the body.

2) An accumulation of foreign matter in the lower part of the body, which could prevent the valve from fully

closing, resulting in a throttling action which may cause inefficient sealing.

3) Foreign matter trapped in the body may become lodged between the sealing surfaces of the gate and seats,

resulting in scored or damaged sealed.

4) Venting a Model FC valve is a positive method of checking the sealing ability of the gate and seats. If the

body vents down to zero pressure with the valve in fully closed position, this is definite indication that sealing

surfaces are in good condition.

PROCEDURE TO VENT OR DRAIN

1. Place the valve gate in a fully opened or fully closed position.

2. Remove the safety cap from either body grease fitting and attach the pressure release tool.

CAUTION: Remove the safety cap slowly to allow the ball check to sufficiently seal, to avoid

uncontrolled venting. Should the ball check fail to seal properly, pressure will continue to blow through

the safety cap orifices. You should then retighten the safety cap screw and vent through the other body

grease fitting. Once the body pressure is bled to zero you should then attempt to repair the leaking ball

check.

3. Screw the stem of the releasing tool into the fitting forcing the ball check off its seat. The valve will vent and

drain once the ball check is unseated. A program of regular draining and body venting is the most positive way

to prevent problems caused by foreign matter in the valve. However, if a regular draining program cannot be

followed, it is recommended that valves be drained after the following operations:

1) After a well has come in and has been cleaned up.

2) After a mudding operation.

3) After a cementing operation.

4) Anytime the valve seems hard to operate by hand and will not fully open or close by the required number of

handwheel turns.

5) When the valve is hard to operate from the fully open or fully closed position because it is "pressure locked"

or "Iced-up".

"Pressure locked" is a condition that may exist with any dual seat expanding type gate valve when body

pressure greatly exceeds line pressure. It occurs only in fully closed position and is a positive indication that

sealing surfaces are in good condition.

"Iced-up" is a condition caused by a restriction in the flow or a differential in the pressure of gas flow at high

pressure, which produces extremely low temperatures. These restrictions or differentials in pressure may be

caused by throttling through a valve, by leakage of a closed valve or by Leakage through the stem packing.

Valves in service on gas containing hydrates or in fresh water service, exposed to low external temperatures

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

16

VALVEWORKS USA

Model FC Operation Manual

may also "iced-up". In this case it is advisable to inject alcohol or glycol into the valve body through the drain

fitting to combat these conditions. The same procedures are used for injecting alcohol or glycol as are used for

valve body lubrication. Do not operate the valve immediately after injecting as these fluids should be retained in

the body to perform the Antifreeze effect.

IDENTIFICATION PLATE

Identification plates are attached to all Valveworks USA API Production Gate Valves. They are located on the

bonnet of each valve and warrants that all products are manufactured to design and quality control

specifications of industry standards. The information listed on the identification plate should be referred to

when ordering replacement parts.

INTERVALS OF MAINTENANCE

Procedure

Recommended Interval

Vent or Drain

See Page 8

Cycle Open to Close

Semi-Annually

Disconnect & Test

Annually

These are just recommended intervals of maintenance. Depending on the level of usage, your valve(s) may

require more or less maintenance than this manual suggests. For more information, contact Valveworks USA.

TROUBLESHOOTING

Problem

Cause

Leakage when closed

Seats

Leakage when open thru

body/bonnet connection

Leakage when partially open thru

top of bonnet

Bonnet Seal

Ring

Leakage at flange

Handwheel spins freely

Packing

Flange Seal

Ring

Broken Shear

Pin

Solution

Disconnect from service and replace

the seats.

Disconnect from service and replace

the bonnet seal ring.

Disconnect from service and replace

the packing.

Disconnect from service and replace

the flange seal ring.

Replace broken shear pin as explained

below.

For extra assistance with these or any other problems, please contact Valveworks USA

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

17

VALVEWORKS USA

Model FC Operation Manual

REPLACING BROKEN SHEAR PIN (WHILE IN SERVICE)

1) Remove hand wheel

2) Attempt to remove Bearing Cap.

a) If Bearing Cap tries to remove the packing gland hit the stem adapter firmly to break any gunk build up.

b) If the Bearing Cap will not remove without the packing gland from unthreading. Pressure must be

removed from the valve or the valve MUST be back seated.

c) Once Bearing Cap is free or Valve is back seated go to step 3.

3) Once Bearing Cap is removed replace damaged shear pin.

4) Retighten packing gland with pipe wrench (~100 ft*lbf)

a) Debur with sandpaper if needed.

5) Reassemble Bearing Cap (See Bonnet Sub-Assembly Section for details)

6) Tighten Bearing Cap with pipe wrench (~100 ft*lbf)

a) Debur with sandpaper if needed.

NOTE: NEVER REMOVE PACKING GLAND WHILE VALVE IS UNDER PRESSURE UNLESS THE

PRESSURE HAS BEEN ISOLATED.

TEST PROCEDURE

1. Grease and insert the ring joint

into one of the body flanges.

2. Make sure that the test flange has a tightened

grease fitting, all of its studs, and a hex nut on each

stud with the hex nuts on the grease fitting side as

shown.

NOTE: YOU CAN FIND THE FLANGE RING JOINT SIZE IN THE PHYSICAL

DIMENSIONS SECTION OF THIS MANUAL.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

18

VALVEWORKS USA

Model FC Operation Manual

3. Align and place the test flange on the

valve flange with all of the studs going thru

the valve flange holes as shown.

4. Screw the each hex nut on the vacant side

of a stud and tighten them with a certified

impact wrench.

5. A finished flange should appear as shown.

REPEAT STEPS 1-5 FOR THE OPPOSITE FLANGE.

Remove the safety cap from one of the test

flange grease fittings and attach a pressure

release tool as shown above.

Remove the grease fitting cap from the

opposite test flange and attach the flow

line as shown above.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

19

VALVEWORKS USA

Model FC Operation Manual

HYDROSTATIC BODY TEST

With the pressure release tool and flow line connection tight, open the valve partially, and apply the test

pressure for at least three (3) minutes.

Bleed off the pressure until its reduced to zero, and close the pressure release tool.

Raise the pressure back up to the test pressure for the secondary pressure-holding period of at least three (3)

minutes.

Bleed off the pressure until its reduced to zero. Then, close the pressure release tool and the valve.

The hydrostatic body test pressure shall be determined by the rated working pressure of the equipment.

Hydrostatic test pressures shall be as given in table below.

HYDROSTATIC BODY TEST PRESSURE, PSI (MPa)

Working

Pressure

Rating - PSI (Mpa)

2,000

(13,8)

3,000

(20,7)

5,000

(34,5)

10,000

(69,0)

15,000

(103,4)

20,000

(138,0)

End and

Outlet

Connections - PSI (Mpa)

4,000

(27,6)

6,000

(41,4)

7,500

(51,7)

15,000

(103,4)

22,500

(155,2)

30,000`

(207,0)

Line Pipe

and Tubing

Threads - PSI (Mpa)

4,000

(27,6)

6,000

(41,4)

7,500

(51,7)

15,000

(103,4)

-

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

20

VALVEWORKS USA

Model FC Operation Manual

HYDROSTATIC SEAT TEST

With the valve closed, apply the rated working pressure.

Hold and monitor at that pressure for at least three (3) minutes.

Open the valve, and bleed off the pressure until its reduced to zero. Then, close the valve and the

pressure release tool.

Repeat steps specified above.

Switch the sides of your flow and pressure release connections, bleed off the new pressure release side, and

repeat steps to perform a seat test on the new flow side.

The valve is acceptable if no leakage is visible during the holding period.

While holding the hex nuts on the body flange,

loosen each of the test flange hex nuts with an

impact wrench.

Pass a drift mandrel through the valve bore

after the valve has been assembled,

operated, and pressure tested.

After removing the body flange hex nuts, you

can remove the test flange, its studs, and their

hex nuts.

Remove the bonnet grease fitting cap and attach a

flow line from the grease pump to the bonnet

grease fitting. Grease until any remaining water

from testing drains from the valve.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

21

VALVEWORKS USA

Model FC Operation Manual

VISUAL INSPECTION

Before installing a Valveworks USA Model FC valve in the field, here are a few items to visually inspect:

1. Make sure the bonnet grease

fitting cap is on and tight.

3. Make sure the Handwheel Nut is tight

2. Make sure the Alemite fittings are

on and tight

Make sure the gate is in the open position

NOTE: THE GLAND BACKSEAT WILL BE SCREWED INTO THE FINISHED

VALVE.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

22

VALVEWORKS USA

Model FC Operation Manual

FIELD HOOK UP INSTRUCTIONS

1. Grease and insert the ring joint into

one of the body flanges.

2. Align the service flange holes with the body

flange holes. Push a stud thru each aligned hole

until there is a stud thru each hole. Screw a hex

nut on both sides of each stud by hand.

NOTE: YOU CAN FIND THE FLANGE RING JOINT SIZE IN THE PHYSICAL

DIMENSIONS SECTION OF THIS BOOKLET.

3. Tighten the service flange nuts using a

certified impact wrench until they are tight.

4. A finished flange should appear as

shown.

REPEAT STEPS 1-4 FOR THE OPPOSITE FLANGE.

Proprietary Booklet of Valveworks USA. Do not reproduce without explicit permission.

Address: 1650 Swan Lake Road, Bossier City, LA-71111. Ph # 888-425-0266. Fax # 318-425-0934

23

You might also like

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- API 6A and 6D Ball ValvesDocument27 pagesAPI 6A and 6D Ball ValveszayerirezaNo ratings yet

- Model fm1Document30 pagesModel fm1LeandroNo ratings yet

- GV-040 Cameron Model Gate ValvesDocument1 pageGV-040 Cameron Model Gate ValvesSuresh BalrajNo ratings yet

- MTR's SO# 1009605Document20 pagesMTR's SO# 1009605ksi meritosNo ratings yet

- Engineering Bulletin - EB 99013-A: Multiple Position Lock System UpgradeDocument3 pagesEngineering Bulletin - EB 99013-A: Multiple Position Lock System UpgradeJean Dubois0% (1)

- API 6A Hydraulic Actuator Operation InstructionDocument7 pagesAPI 6A Hydraulic Actuator Operation InstructionSrikanth Bammhide100% (1)

- Mj-1645-Us Expanding Gate Valve MJDocument16 pagesMj-1645-Us Expanding Gate Valve MJgm_revankar3942No ratings yet

- Gate Valve Torque Cal - GuideDocument1 pageGate Valve Torque Cal - GuideTracy PatelNo ratings yet

- Choke Valve MSPDocument26 pagesChoke Valve MSPabbas1368No ratings yet

- Summary of Choke Valve API 6A 21 EditionDocument52 pagesSummary of Choke Valve API 6A 21 EditionInChy Rencarnation Poseidon100% (1)

- Fabritech Globular® GBOP User Manual REV.1Document50 pagesFabritech Globular® GBOP User Manual REV.1Joel S100% (1)

- Hydril Annular BOP1Document2 pagesHydril Annular BOP1Abde EsselamNo ratings yet

- API Gate Valve - WKM Maintenance ManualDocument8 pagesAPI Gate Valve - WKM Maintenance ManualsambhajiNo ratings yet

- Choke ParveenDocument3 pagesChoke ParveenYM Edwin Gil BeltranNo ratings yet

- 04 Samss 050Document10 pages04 Samss 050Saeed KazemiNo ratings yet

- Introduction To The Oil Field (Drilling)Document37 pagesIntroduction To The Oil Field (Drilling)Ahmed SelmyNo ratings yet

- API6A Trim Material RatingsDocument5 pagesAPI6A Trim Material RatingsAneez MhdNo ratings yet

- Drawn by Date RevisionDocument10 pagesDrawn by Date RevisionИван ВасильевNo ratings yet

- 1529 Fz6821u Ram BopDocument37 pages1529 Fz6821u Ram BopAsif JalgaonkarNo ratings yet

- Danfoss Safety Relief Valves For Industrial Refrigeration PDFDocument66 pagesDanfoss Safety Relief Valves For Industrial Refrigeration PDFHyeong-Ho KimNo ratings yet

- Tests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water LevelDocument6 pagesTests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water Levelahmed121No ratings yet

- 2P36606 Spring Loaded ERVDocument42 pages2P36606 Spring Loaded ERVYM Edwin Gil BeltranNo ratings yet

- Bop Pressure Test ReportDocument1 pageBop Pressure Test ReportsamNo ratings yet

- Catalog C v5 PDFDocument80 pagesCatalog C v5 PDFAshokNo ratings yet

- Adjustable Choke Valve PDFDocument3 pagesAdjustable Choke Valve PDFabbas1368No ratings yet

- Test Pump WindlassDocument40 pagesTest Pump WindlassMd.farman Ali AhmedNo ratings yet

- QCI 2010 BrochureDocument11 pagesQCI 2010 BrochureFabricio Vega EstrellaNo ratings yet

- WellheadDocument2 pagesWellheadRicardo Paz SoldanNo ratings yet

- 01-Choke Manifold - Data HeaderDocument11 pages01-Choke Manifold - Data HeaderRio IndokniveziaNo ratings yet

- Recommendation For Elimination of Lead Filling in Target FlangesDocument10 pagesRecommendation For Elimination of Lead Filling in Target FlangesYoung Su KoNo ratings yet

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Document21 pagesTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoNo ratings yet

- VGS 23.1.4 Rev 3 (UT of Weld Overlay For Equinor)Document18 pagesVGS 23.1.4 Rev 3 (UT of Weld Overlay For Equinor)Rod RoperNo ratings yet

- Design CalculationsDocument4 pagesDesign CalculationsEDWIN M.P50% (2)

- BOP Control Unit FlyerDocument2 pagesBOP Control Unit Flyeraliabd1989 alzubidiNo ratings yet

- WEIR Product ListDocument4 pagesWEIR Product ListSaurabhNo ratings yet

- Summary of Choke Valve API 6A 21st EditionDocument52 pagesSummary of Choke Valve API 6A 21st EditionInChy Rencarnation Poseidon100% (2)

- Section 10Document53 pagesSection 10Palmério CarvalhoNo ratings yet

- Wire LineDocument54 pagesWire LineJOUININo ratings yet

- CAMERON INTERNATIONAL CORP 10-K (Annual Reports) 2009-02-25Document147 pagesCAMERON INTERNATIONAL CORP 10-K (Annual Reports) 2009-02-25http://secwatch.com100% (2)

- ACF Tender Dossier BoreholeDocument30 pagesACF Tender Dossier BoreholeAcción Contra el HambreNo ratings yet

- SUBSEA TREE DESIGN DATA (Includes Wellhead/Downhole) No. System Design Requirements CommentsDocument3 pagesSUBSEA TREE DESIGN DATA (Includes Wellhead/Downhole) No. System Design Requirements CommentsMartinus LuckyantoNo ratings yet

- Parveen: Technical ManualDocument16 pagesParveen: Technical ManualDEATH ASSASSIN GAMERNo ratings yet

- Api 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim MccabeDocument11 pagesApi 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim Mccabesaeed65No ratings yet

- Pumptools - BOP CanDocument1 pagePumptools - BOP Cancasda73No ratings yet

- 1522 FZ54-35U Ram BOPDocument42 pages1522 FZ54-35U Ram BOPAsif JalgaonkarNo ratings yet

- D392005428-MKT-001 6012 Bop PDFDocument2 pagesD392005428-MKT-001 6012 Bop PDFMitul PatelNo ratings yet

- API Vs ANSI FlangesDocument1 pageAPI Vs ANSI FlangesAKSHAY BHATKARNo ratings yet

- Cameron EB 205 D Rev C1 - Pilot Operated Check Valve - Hydraulic Locking DeviceDocument2 pagesCameron EB 205 D Rev C1 - Pilot Operated Check Valve - Hydraulic Locking DeviceCanrig RamdeNo ratings yet

- SC-90 Conventional Surface Wellhead System PDFDocument12 pagesSC-90 Conventional Surface Wellhead System PDFErcan YilmazNo ratings yet

- API 6A Gate ValvesDocument12 pagesAPI 6A Gate ValvesLee Sweningson100% (1)

- Manual Adjustable ChokeDocument36 pagesManual Adjustable ChokeWill CastellanosNo ratings yet

- Clamp Connections: Bearing Ring Load Ring Nut Washer DetailDocument2 pagesClamp Connections: Bearing Ring Load Ring Nut Washer DetailНикита ПромиснкийNo ratings yet

- Workover Bops PDFDocument5 pagesWorkover Bops PDFBeni N SoloNo ratings yet

- Engineering Bulletin - EB 99009A: Hydraulic Operating FluidDocument1 pageEngineering Bulletin - EB 99009A: Hydraulic Operating FluidJean DuboisNo ratings yet

- Parker HTR ActuatorDocument22 pagesParker HTR ActuatorYorkistNo ratings yet

- Operation and Service Manual For Model M & MSG: Alveworks USADocument26 pagesOperation and Service Manual For Model M & MSG: Alveworks USAAshok SureshNo ratings yet

- Model fm4Document25 pagesModel fm4LeandroNo ratings yet

- Choke E Series MasterFloDocument14 pagesChoke E Series MasterFloianherzogNo ratings yet

- API 6A ValveDocument12 pagesAPI 6A Valveedo_tapia_ur100% (1)

- Omega 600S ManualDocument36 pagesOmega 600S ManualLeandroNo ratings yet

- FB1600 Part Numbers NatOilDocument1 pageFB1600 Part Numbers NatOilLeandroNo ratings yet

- Catalog PDFDocument222 pagesCatalog PDFLeandro100% (1)

- Bolt Head Stress Concentration Factors in Cylindrical Pressure VesselsDocument6 pagesBolt Head Stress Concentration Factors in Cylindrical Pressure VesselsLeandroNo ratings yet

- Stress Concentration Factors in T-HeadDocument27 pagesStress Concentration Factors in T-HeadLeandroNo ratings yet

- Model fm4Document25 pagesModel fm4LeandroNo ratings yet

- MCM Oil Tools: 10422 W. Gulf Bank RD., Houston, Texas 77040Document29 pagesMCM Oil Tools: 10422 W. Gulf Bank RD., Houston, Texas 77040LeandroNo ratings yet

- QFC Valve ManualDocument27 pagesQFC Valve ManualLeandro100% (1)

- Gate Valve Parts CatalogueDocument12 pagesGate Valve Parts CatalogueLeandroNo ratings yet

- Ad00912v Wkmsaf T SealDocument36 pagesAd00912v Wkmsaf T SealJulia WadeNo ratings yet

- Amca 211Document62 pagesAmca 211Raji PanickerNo ratings yet

- Stoody 104Document1 pageStoody 104JUAN DAVID ESPITIANo ratings yet

- Unit-4 Control of Gaseous PollutantsDocument40 pagesUnit-4 Control of Gaseous Pollutantspthangarasu sctengNo ratings yet

- Chem Lab Report 9:26:18Document3 pagesChem Lab Report 9:26:18Andrew SmithNo ratings yet

- Camion 789DDocument14 pagesCamion 789Ddinny blanco rojasNo ratings yet

- Testeo Transmisión 966HDocument9 pagesTesteo Transmisión 966HVictorNo ratings yet

- Life Cycle Costing - HVACDocument103 pagesLife Cycle Costing - HVACDaniel Henrique100% (1)

- SN200Document111 pagesSN200tajinder231280% (5)

- Reinforcing Bar Couplers-UK-IRE-Edition June 2014 - Version 3Document28 pagesReinforcing Bar Couplers-UK-IRE-Edition June 2014 - Version 3Federico.IoriNo ratings yet

- Daikin Presentation - Chiller SystemDocument112 pagesDaikin Presentation - Chiller Systemlucio ruiz jr100% (1)

- Sika RaintiteDocument3 pagesSika RaintiteHoneyNo ratings yet

- D 2938 - 95Document3 pagesD 2938 - 95Humberto Diomedi MirandaNo ratings yet

- Rate AnalysisDocument9 pagesRate AnalysisRajesh JujareNo ratings yet

- RB - Specifications Piping MaterialsDocument21 pagesRB - Specifications Piping MaterialsFalcon PeregrinusNo ratings yet

- After Ultra CoolantDocument8 pagesAfter Ultra CoolantEmrah KutluNo ratings yet

- Cryomax Jan2016Document8 pagesCryomax Jan2016arielNo ratings yet

- Thermal StressDocument104 pagesThermal Stressmanishtopsecrets100% (1)

- Installation Instructions: - Split System Air ConditionerDocument45 pagesInstallation Instructions: - Split System Air ConditionerpejdewitNo ratings yet

- Advance Manufacturing Technology 26100720014Document10 pagesAdvance Manufacturing Technology 26100720014matrika adhikariNo ratings yet

- Valassky Piskovec Sharpening StoneDocument17 pagesValassky Piskovec Sharpening StoneMikail RNo ratings yet

- David Brown in International MiningDocument9 pagesDavid Brown in International MiningKroya HunNo ratings yet

- Minimum Pipe Spacing Chart For Petrochemical & Refinery Plants PDFDocument4 pagesMinimum Pipe Spacing Chart For Petrochemical & Refinery Plants PDFRamesh KumarNo ratings yet

- Coek - Info - Acorga Znx50a New Selective Reagent For The SolvenDocument16 pagesCoek - Info - Acorga Znx50a New Selective Reagent For The SolvenGeorgi SavovNo ratings yet

- Super HDB Turbo 15W-40Document1 pageSuper HDB Turbo 15W-40izzybjNo ratings yet

- Silicon Wafer Wetability On Metal Thin Film MorphologyDocument8 pagesSilicon Wafer Wetability On Metal Thin Film MorphologyLee chong looNo ratings yet

- SCHNEIDER Flusarc 36 36kV Gas Insulated - enDocument72 pagesSCHNEIDER Flusarc 36 36kV Gas Insulated - enjopsesNo ratings yet

- Generic PID DefinitionsDocument4 pagesGeneric PID DefinitionsNicoara Stoica Paul FlorinNo ratings yet

- Phosphonics Catalogue 2011 FullDocument80 pagesPhosphonics Catalogue 2011 Fullapi-94537271No ratings yet

- Distillation of Ethanol-Water Solution Using Enthalpy-Concentration DiagramDocument16 pagesDistillation of Ethanol-Water Solution Using Enthalpy-Concentration DiagramChiara PatrianaNo ratings yet

- ExtruderDocument6 pagesExtruderSamuel AbebawNo ratings yet