Professional Documents

Culture Documents

Parker Re15196 - 2013-12

Uploaded by

Ashley DeanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parker Re15196 - 2013-12

Uploaded by

Ashley DeanCopyright:

Available Formats

Radial piston motors for industrial applications

MCR-D

MCR-E

RE 15196

Edition: 12.2013

MCR-D

Frame size MCR3, MCR5, MCR10

Displacement 160 cc to 1340 cc

Dierential pressure up to 450 bar

Torque output up to 8530 Nm

Speed up to 875 rpm

Open and closed circuits

MCR-E

Frame size MCR5

Displacement 380 cc to 820 cc

Dierential pressure up to 450 bar

Torque output up to 5220 Nm

Speed up to 570 rpm

Open and closed circuits

Features

Contents

Compact robust construction

Functional description

High volumetric and mechanical eciencies

Ordering code

Front case mount

Technical data

Parallel shaft with key

Eciencies

High reliability

Permitted loading on drive shaft

Low maintenance

Dimensions

10

Smooth running at very low speeds

Selection guide

16

Low noise

Bi-directional

Sealed tapered roller bearings

Freewheeling possible

Available with:

Holding brake (multi-disc)

Bi-directional two speed

Integrated ushing valve

Speed sensor

RE 15196/12.2013, Bosch Rexroth AG

MCR-D and MCR-E | Radial piston motors for industrial applications

Functional description

Functional description

6

8 53

5

3

D 7

Hydraulic motors of the type MCR-D, MCR-E are radial

Torque generation

piston motors with front case mounting and parallel shaft

with key. MCR-D and MCR-E have the same type of rotary

group and rear case assembly but dier in the front case

mounting. These motors are intended for open or closed

circuit operations as drive motors for various industrial

Working

stroke

Return

stroke

applications.

Construction

Feed

Two part housing (1, 2), rotary group (3, 4, 8), cam (5),

Return

drive shaft (6) and ow distributor (7)

The number of working and return strokes corresponds to

Transmission

the number of lobes on the cam multiplied by number of

The cylinder block (4) is connected to the shaft (6) by

pistons in the cylinder block.

means of splines. The pistons (3) are arranged radially in

the cylinder block (4) and make contact with the cam (5)

Flow paths

via rollers (8).

The ports A and B, which are located in the rear case, carry

oil through the distributor to the cylinder chambers (E).

Bearings

Tapered roller bearings capable of transmitting high axial

and radial forces are tted as standard.

Freewheeling

In certain applications there may be a requirement to freewheel the motor. This may be achieved by connecting ports

A and B to zero pressure and simultaneously applying a

pressure of 2bar to the housing through port L. In this

condition, the pistons are forced into the cylinder block

which forces the rollers to lose contact with the cam thus

allowing free rotation of the shaft.

Bosch Rexroth AG, RE 15196/12.2013

Radial piston motors for industrial applications | MCR-D and MCR-E

Functional description

Two speed operation (2W)

Flushing valve

In mobile applications where vehicles are required to ope-

In a closed circuit, the same hydraulic uid continuously

rate at high speed with low motor loads, the motor can be

ows between the pump and the motor. This could there-

switched to a low-torque and high-speed mode. This is

fore lead to overheating of the hydraulic uid.

achieved by operating an integrated valve which directs

The function of the ushing valve option is to replace hyd-

hydraulic uid to only one half of the motor while conti-

raulic uid in the closed circuit with that from the reservoir.

nuously re-circulating the uid in the other half. This redu-

When the hydraulic motor is operated under load, either in

ced displacement mode reduces the ow required for a

the clockwise or anti-clockwise direction, the ushing valve

given speed and gives the potential for cost and eciency

opens and takes a xed ow of uid through an orice from

improvements. The motor maximum speed remains

the low pressure side of the circuit. This ow is then fed to

unchanged.

the motor housing and back to the reservoir normally via a

Bosch Rexroth has developed a special spool valve to allow

cooler. In order to charge the low pressure side of the

smooth switching to reduced displacement whilst on the

circuit, cool uid is drawn from the reservoir by the boost

move. This is known as soft-shift and is a standard fea-

pump and is fed to the pump inlet through the check valve.

ture of 2W motors. The spool valve requires either an addi-

Thus the ushing valve ensures a continuous renewal and

tional sequence valve or electro-proportional control to

cooling of the hydraulic uid. The ushing feature incorpo-

operate in soft-shift mode.

rates a relief valve which is used to maintain a minimum

boost pressure and operates at a standard setting of 14bar

Schematic

(other options available on request).

L

B A

Dierent orice sizes may be used to select varying ows of

ushing uid. The following table gives ushing rate values

based on a boost / charge pressure of 25bar.

15 bar

Schematic

A (B)

12 bar

B (A)

Flushing ow rates

Orice size

Flow (l/min) at 25 bar1)

(mm)

min

max

F1

2.2

2.7

F2

1.5

5.0

6.1

F7

1.7

6.4

7.8

F4

8.2

10.7

F6

2.3

8.8

11.4

Flushing code

1)

0.6 mm Shim (Standard), Cracking pressure = 113 bar

RE 15196/12.2013, Bosch Rexroth AG

MCR-D and MCR-E | Radial piston motors for industrial applications

Functional description

Holding brake (multi-disc brake)

Speed sensor

A Hall-eect speed sensor (16) may be tted as an option,

Mounting

giving a two-channel output of phase-displaced square

By way of rear housing (2) and brake shaft (14).

waves, and enabling detection of speed and direction. A

toothed target disc (17) is tted to the motor cylinder block

Brake application

(4), and the sensor, tted to a port in the rear case, produ-

As a safety requirement in mobile applications a parking

ces a pulse on each channel as each tooth passes in front

brake may be provided to ensure that the motor cannot

of it. The frequency of the pulses is proportional to the

turn when the machine is not in use. The parking brake

rotational speed.

provides holding torque by means of discs (11) that are

Versions are available for use with regulated supplies 10 V

compressed by a disc spring (10). The brake is released

(CodeP1) and for direct connection to a 12V or 24V

when oil pressure is applied to brake port Z and the

unregulated supply (CodeP2).

pressure in the annular area (9) compresses the disc spring

The motor can also be supplied tted with a target disc and

using brake piston (12) thus allowing the brake discs (11)

with a speed sensor port machined, but covered and sealed

to turn independently.

with a blanking plate (CodeP0). These sensor-ready

motors may be tted with a sensor at a later date.

Note

This brake is provided solely for static use - not to be

used dynamically.

Schematic diagrams

Motor

without brake

Motor

with holding brake

17

16

Manual release of holding brake

The brake may also be released manually by loosening

Direction of shaft rotation with ow

screws (13).

(viewed from drive shaft)

2

9

12

14

11

10

13

Ordering code ... 1L ... or ... 2WL ...

Bosch Rexroth AG, RE 15196/12.2013

Radial piston motors for industrial applications | MCR-D and MCR-E

Ordering code

Ordering code

01

02

03

04

05

06

MCR

07

08

09

10

11

12

13

14

15

16

33

Radial piston motor

01 Radial-piston type, low-speed, high-torque motor

MCR

Frame size

02 Frame size

MCR-D

MCR-E

10

10

Housing type

03 Front case square mounting ange - SAE 4 o holes

Front case mounting - 4 o M16 tapped holes

Nominal size, displacement Vg in cm3/rev

04 Frame size 3 (only for MCR-D)

Low displacement: motors use standard cylindrical pistons

LD

High displacement: motors use stepped pistons

HD

Frame size 5

Low displacement: motors use standard cylindrical pistons

LD

High displacement: motors use stepped pistons

HD

Frame size 10 (only for MCR-D)

160

225

255

280

325

365

400

380

470

520

565

620

680

750

820

780

860

940

1120 1250 1340

Low displacement: motors use standard cylindrical pistons

LD

High displacement: motors use stepped pistons

HD

Drive shaft

05 Parallel keyed shaft

40 mm only for MCR3D

L40

50 mm available for MCR5D and MCR5E

L50

60 mm only for MCR10D

L60

Through shaft

06 Without through shaft

Series

07 Series 33

33

Brake

08 Without brake

Hydraulic release spring applied multi-disc holding brake

MCR3

MCR5

MCR10

A0

2200 Nm

B2

4400 Nm

B4

7000 Nm

B7

Seals

09 NBR (nitrile rubber)

FKM (uoroelastomer / Viton)

M

V

Single/two-speed operation

10 Single speed, standard direction of rotation

Bi-directional two speed, standard direction of rotation

1L

2WL

Ports

11 Tapped with UNF thread (SAE J514)

Tapped with UNF thread (SAE J514) (A and B ports SAE split ange metric bolt holes)

= Available

12

42

= Not available

RE 15196/12.2013, Bosch Rexroth AG

MCR-D and MCR-E | Radial piston motors for industrial applications

Ordering code

01

02

03

04

MCR

05

06

07

08

09

10

11

12

13

14

15

16

33

Studs

12 Without studs (no code)

Speed sensor

13 Without sensor (no code)

Sensor ready

P0

Sensor without regulator

P1

Sensor with regulator

P2

Flushing

14 Without ushing (no code)

With ushing (see table on page 3)

F1-F8

Special order

15 Special feature

SOXXX

Other

16 Mark in text here

Footer from page 7

1) Not available for E-Type

2) Ensure motor case is lled with oil prior to start-up. See instruction manual 15215-B.

3) For installation and maintenance details, please see instruction

manual 15215-B.

4) For use with environmentally acceptable uids HEES, HEPG, HETG,

uoroelastomer / Viton seals must be specied.

5) Extension of the allowable temperature range may be possible depending on specication. Please consult Bosch Rexroth Engineering Department in Glenrothes for further details.

6) Maximum values should only be applied for a small portion of the

duty cycle. Please consult Bosch Rexroth Engineering

Department in Glenrothes for motor life calculations based on particular operating cases.

7) When operating motors in series, please consult Bosch Rexroth

Engineering Department in Glenrothes.

8) For continuous operation at speeds <5 rpm please consult Bosch

Rexroth Engineering Department in Glenrothes.

9) Based on nominal no-load p of 20 bar in full-displacement mode.

10) Warning! During the running in period of the motor (min. 20 hrs) it

should not be run unloaded at >100 rpm.

11) Guide values for up to 5000 hours of motor operation

(ISO VG46 at 50 C).

12) Maximum pressure is restricted according to maximum torque

Bosch Rexroth AG, RE 15196/12.2013

Note

Motor performance values are based on theoretical

calculations.

Eciencies are not taken into consideration for theoretical calculations.

Brake torque accounts for tolerances. Values are based

when used with standard mineral oil (HLP).

Please refer the related foot notes for more details.

Radial piston motors for industrial applications | MCR-D and MCR-E

Technical data

Technical data

MCR31) MCR5

Frame size

MCR101)

Type of mounting

Flange mounting, face mounting

Pipe connections2)3)

Threaded per SAE J514; Flanged per SAE J518

Shaft loading

see page 9

Weight

MCR3D MCR5D MCR5E MCR10D

Single speed (1L)

kg

21

39

36

62

Two speed (2WL)

kg

27

47

44

67

Hydraulic uid4)

Fluid cleaniness

ISO 4406, Class 20/18/15

Fluid viscosity range

min/max

mm/s

10 to 2000

Fluid temperature range5)

min/max

-20 to +85

Low displacement

High displacement

Operating pressure

pnom

bar

250

250

Maximum dierential pressure6)7)

pmax

bar

450

400

Maximum pressure at port A or B6)7)

pmax

bar

470

420

Maximum case drain pressure

pcase max

bar

10

10

Vg

cm3/rev

160

225

255

280

325

365

400

Nm/bar

Tmax

Nm

1146

1500

1500

1500

1500

1500

1500

Pressure

Motor performance MCR3

Displacement

Specic torque

Maximum torque6)12)

8)

Minimum speed for smooth running

nmin

rpm

0.5

0.5

0.5

0.5

0.5

0.5

0.5

Maximum speed (1L)9)10)

nmax

rpm

670

475

420

385

330

295

270

Maximum speed (2WL)9)10)

nmax

rpm

875

620

550

500

430

385

350

kW

11.64

15.34

15.17

17.48

11.61

11.38

14.99

Vg

cm3/rev

380

470

520

565

620

680

750

820

Nm/bar

10

11

12

13

10)

Continuous operating power

Motor performance MCR5

Displacement

Specic torque

Maximum torque6)12)

Tmax

Nm

2722

3000

3000

3000

3000

3000

3000

3000

Minimum speed for smooth running8)

nmin

rpm

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

Maximum speed (1L)9)10)

nmax

rpm

475

385

350

320

290

265

240

220

Maximum speed (2WL)

nmax

rpm

570

465

420

385

350

320

290

265

Continuous operating power10)

kW

38.01

38.14

37.86

42.42

26.52

25.85

24.42

31.98

Vg

cm3/rev

780

860

940

1120

1250

1340

Nm/bar

12

14

15

18

20

21

Maximum torque6)12)

Tmax

Nm

4800

4800

4800

4800

4800

4800

Minimum speed for smooth running8)

nmin

rpm

0.5

0.5

0.5

0.5

0.5

0.5

Maximum speed (1L and 2WL)9)10)

nmax

rpm

215

195

180

150

135

125

Continuous operating power10)

kW

50.21

55.67

52.82

38

42.34

38.81

9)10)

Motor performance MCR10

Displacement

Specic torque

Brake

MCR3D

MCR5D, MCR5E MCR5D, MCR5E MCR10D

Holding brake (disc brake)

B2

B2

B4

B7

Minimum holding torque

tmin/max

Nm

2200

2200

4400

7000

Release pressure (min)

prel min

bar

11

11

11

11

Release pressure (max)

prel max

bar

15

15

15

15

Maximum pressure at brake port Z

pmax

bar

40

40

40

40

Oil volume to operate brake

Vrel

cm3

23

23

46

36

Footer on page 6

RE 15196/12.2013, Bosch Rexroth AG

MCR-D and MCR-E | Radial piston motors for industrial applications

Eciencies

Eciencies

Mechanical eciency

Charge pressure

14

Minimum charge pressure [bar]

Mechanical eciency [%]

100

80

60

40

20

10

8

6

4

2

0

0.2

0.4

0.6

0.8

1.0

Volumetric eciency

120

100

80

60

40

20

0

0

0.2

0.4

0.6

0.8

1.0

Speed n/nmax [rpm]

100 bar / 1450 psi

300 bar / 4350 psi

Note:

For specic performance information or operating conditions contact the Engineering Department at Bosch Rexroth, Glenrothes.

Bosch Rexroth AG, RE 15196/12.2013

0.2

0.4

0.6

Speed n/nmax [rpm]

Speed n/nmax [rpm]

Volumetric eciency [%]

12

0.8

1.0

Radial piston motors for industrial applications | MCR-D and MCR-E

Permitted loading on drive shaft

Permitted loading on drive shaft

Drive shaft ...3D L40...

Drive shaft ...10D L60...

Maximum radial load FR max (with axial load Fax = 0)

Maximum radial load FR max (with axial load Fax = 0)

70

140

120

Radial load FR [kN]

Radial load FR [kN]

60

50

40

30

20

100

80

60

40

20

10

0

200 160 120

80

40

-40

-80 -120 -160 -200

0

200 160 120

Oset x mm from shaft end face

80

40

-40

-80 -120 -160 -200

Oset x mm from shaft end face

Maximum axial load Fax max (with radial load FR = 0):

Maximum axial load Fax max (with radial load FR = 0):

Fax max = 30200N +

Fax max = 78700N +

Fax max = 27000N

Fax max = 63400N

Drive shaft ...5D L50...5E L50...

Maximum radial load FR max (with axial load Fax = 0)

Note:

These values and graphs are for initial guidance only

For actual motor life calculations under typical or specied

duty cycles, contact Bosch Rexroth Engineering Department in

Glenrothes

70

Radial load FR [kN]

60

50

40

30

20

10

0

200 160 120

80

40

-40

-80 -120 -160 -200

Oset x mm from shaft end face

Maximum axial load Fax max (with radial load FR = 0):

Fax max = 50000N +

Fax max = 32000N

RE 15196/12.2013, Bosch Rexroth AG

10

MCR-D and MCR-E | Radial piston motors for industrial applications

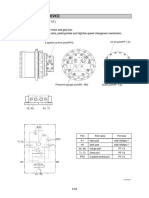

Dimensions

Dimensions

MCR-D

L1

L3

L2

L5

L6

L7

L4

L10

L8

L9

L17

A, B

L16

D6

D5

D3

D1

D2

D4

L15

X

F

S1

Speed sensor

S2

View Z

L11

L14

D7

D8

L12

L13

Before nalizing your design, request a binding installation drawing.

Dimensions in mm.

Bosch Rexroth AG, RE 15196/12.2013

Radial piston motors for industrial applications | MCR-D and MCR-E

Dimensions

11

Single speed (1L)

Motor

D1

D2

D3

D4

D5

D6

D7

D8

L1

L2

L3

L4

L5

L6

MCR3

40

125

134

180

14

160

281.3

114.4

167

84.5

133

MCR5

50

152.4

189

225

223

225

22

229

304

96

197

82

181

10.5

MCR10

60

152.4

189

264

262

262

20.5

229

407

123

259

105

223

10.5

Motor

L7

L8

L9

L10

L11

L12

L13

L14

L15

S1

S2

MCR3

112

70

14

113

43

140

12

66.5

63.5

90

MCR5

145

70

18

162

53.5

200

14

76

75

45

MCR10

182

80

19

162

64

200

18

98

89

45

Two speed (2WL)

Motor

D1

D2

D3

D4

D5

D6

D7

D8

L1

L2

L3

L4

L5

L6

MCR3

40

134

180

14

160

341

114.4

226.7

84.5

105.7

MCR5

50

152.4

189

225

223

225

22

229

343

96

237

82

159

10.5

MCR10

60

152.4

189

264

262

262

20.5

229

432

123

283.5

105

247.5

10.5

Motor

L7

L8

L9

L10

L11

L12

L13

L14

L15

L16

L17

S1

S2

MCR3

112

70

14

113

43

140

12

67.5

26

65

63.5

30

MCR5

70

18

162

53.5

200

14

105

23.5

78

75

45

MCR10

180.5

80

19

162

64

200

18

88

25

107

89

45

Ports

Motor

Designation

Port function

Code

Size

pmax [bar]

State2)

MCR3

A, B

Inlet, outlet

SAE J514

7/8-4 UNF

470/4201)

Case drain

SAE J514

9/16-18 UNF

10

Filler port

SAE J514

3/4-16 UNF

10

2 speed port

SAE J514

9/16-18 UNF

35

MCR5

MCR10

1)

2)

3)

O

1)

A, B

Inlet, outlet

SAE J514

1 1/16-12 UNF

470/420

Case drain

SAE J514

3/4-16 UNF

10

Filler port

SAE J514

3/4-16 UNF

10

2 speed port

SAE J514

9/16-18 UNF

35

A, B

Inlet, outlet

SAE J5183)

3/4 in

470/4201)

Case drain

SAE J514

3/4-16 UNF

10

Filler port

SAE J514

3/4-16 UNF

10

2 speed port

SAE J514

9/16-18 UNF

35

Depends on nominal size

O = Must be connected (plugged on delivery)

X = Plugged (in normal operation)

Only dimensions according to SAE J518

(Code 62 - high pressure series)

RE 15196/12.2013, Bosch Rexroth AG

12

MCR-D and MCR-E | Radial piston motors for industrial applications

Dimensions

Dimensions

MCR-E

L1

L3

L2

L4

L8

L6

L5

L7

L13

L

A, B

L12

D5

D4

D1

D2

D3

L11

X

F

S1

Speed sensor

S2

View Z

A1

L9

D6

L10

Before nalizing your design, request a binding installation drawing.

Dimensions in mm.

Bosch Rexroth AG, RE 15196/12.2013

Radial piston motors for industrial applications | MCR-D and MCR-E

Dimensions

13

Single speed (1L)

Motor

D1

D2

D3

D4

D5

D6

D7

L1

L2

L3

L4

L5

MCR5

50

160

222.5

223

225

200

M16

304

122

182

155

Motor

L6

L7

L8

L9

L10

L11

A1

S1

S2

MCR5

82

70

8.5

14

53.45

76

45

75

45

Two speed (2WL)

Motor

D1

D2

D3

D4

D5

D6

D7

L1

L2

L3

L4

L5

MCR5

50

160

222.5

223

225

200

M16

343

122

221

134.4

Motor

L6

L7

L8

L9

L10

L11

L12

L13

A1

S1

S2

MCR5

82

70

8.5

14

53.45

76

23.5

78

45

75

45

Ports

Motor

MCR5

1)

2)

3)

Designation

Port function

Code

Size

1 1/16-12 UNF

pmax [bar]

1)

470/420

State2)

A, B

Inlet, outlet

SAE J514

Case drain

SAE J514

3/4-16 UNF

10

Filler port

SAE J514

3/4-16 UNF

10

2 speed port

SAE J514

9/16-18 UNF

35

Depends on nominal size

O = Must be connected (plugged on delivery)

X = Plugged (in normal operation)

Only dimensions according to SAE J518

(Code 62 - high pressure series)

RE 15196/12.2013, Bosch Rexroth AG

14

MCR-D and MCR-E | Radial piston motors for industrial applications

Dimensions

Holding brake (multi-disc brake)

L18

L19

Reference brake interface

D9

Housing type D

Housing type E

Motor

Brake

L18

L19

D9

MCR3

B2

67.3

22

174

B2

67.3

22

174

B4

80.7

26.5

215

MCR10

B7

97.8

29

251

Motor

Designation

Port function

Code

Size

pmax [bar]

State1)

MCR3

Brake port

SAE J515

9/16-18 SAE

30

MCR5

Brake port

SAE J515

9/16-18 SAE

30

MCR10

Brake port

SAE J515

9/16-18 SAE

30

MCR5

1)

O = Must be connected (plugged on delivery)

Bosch Rexroth AG, RE 15196/12.2013

Before nalizing your design, request a binding installation drawing.

Dimensions in mm.

Radial piston motors for industrial applications | MCR-D and MCR-E

15

RE 15196/12.2013, Bosch Rexroth AG

16

MCR-D and MCR-E | Radial piston motors for industrial applications

Selection guide

Data sheet Motor type

Application

15198

15200

15195

15199

15221

15223

15214

15197

15196

MCR-F

Wheel drives

MCR-W

Heavy duty

wheel drives

MCR-A

Frame integrated drives

MCR-H

Integrated drives

MCR-T

Track drives

MCR-R Series 40

Hydraulic drive assist

MCR-X

Slew drives

MCR-C

Compact drives

MCR-D

Industrial applications

MCR-E

Industrial applications

Bosch Rexroth Limited

Vieweld Industrial Estate

Glenrothes, Fife

Scotland, KY6 2RD

UK

Phone +44 15 92 631 777

Telefax +44 15 92 631 936

info.ma@boschrexroth.de

www.boschrexroth.com

Bosch Rexroth AG, RE 15196/12.2013

Frame size

3

10

160..400 cc

380..820 cc

820..920 cc

780..1340 cc

15

20

1130..2150 cc 1750..3000 cc

This document, as well as the data, specications and other information

set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be

reproduced or given to third parties without its consent.

The data specied above only serve to describe the product. No statements

concerning a certain condition or suitability for a certain application can be

derived from our information. The information given does not release the

user from the obligation of own judgment and verication. It must be

remembered that our products are subject to a natural process of wear and

aging.

You might also like

- W3C Service Manual 3-7-13Document54 pagesW3C Service Manual 3-7-13angel017100% (1)

- Robot 150 013314Document254 pagesRobot 150 013314jbarcelocamacho100% (1)

- CPU3.2 Service Manual and User GuideDocument61 pagesCPU3.2 Service Manual and User GuideDiego Alejandro Gomez100% (3)

- Minigador 465 New HollanDocument903 pagesMinigador 465 New HollanOscar Losada100% (1)

- NH 87659705 PreviewDocument51 pagesNH 87659705 PreviewYesenia Gpe Vega100% (1)

- Rexroth MCR-FDocument14 pagesRexroth MCR-FAbhishek Kadam100% (1)

- Motor MCR 15207-RDocument24 pagesMotor MCR 15207-RDavid AltarribaNo ratings yet

- Wire Rope User GuideDocument40 pagesWire Rope User GuideMaey Akim100% (3)

- Bobcat 310 313 Skidsteerloader Service Sec WatDocument150 pagesBobcat 310 313 Skidsteerloader Service Sec Watvaleriu szabados100% (1)

- Shackle WUL 63581 Rev ADocument2 pagesShackle WUL 63581 Rev AList EngineeringcompanyNo ratings yet

- Group 4 Travel Device: TYPE 1 (31N3-40010)Document35 pagesGroup 4 Travel Device: TYPE 1 (31N3-40010)АлексейNo ratings yet

- 20 GPM Stack Valve Catalog INDEXDocument82 pages20 GPM Stack Valve Catalog INDEXMauricio Ariel H. OrellanaNo ratings yet

- 'Wa200 5l ShopDocument960 pages'Wa200 5l ShopHerbert Honorato100% (1)

- MCR 5Document18 pagesMCR 5adyro100% (1)

- 6 75491-Linked PDFDocument849 pages6 75491-Linked PDFCooporacion Hidrodiesel Sac100% (1)

- OMEW Repair InstructionsDocument16 pagesOMEW Repair Instructionsjose manuel barroso pantojaNo ratings yet

- Vickers PVB MVB Piston PumpDocument29 pagesVickers PVB MVB Piston Pumppablo cofreNo ratings yet

- Cylindrical Roller Bearings SL04 in Rope SheavesDocument46 pagesCylindrical Roller Bearings SL04 in Rope SheavesAshley DeanNo ratings yet

- Spec Pump Hd2-4000Document24 pagesSpec Pump Hd2-4000SAKDA MAPRADITKUL100% (2)

- Job Description - Mechanical Integrity - Project Engineer (1713975)Document3 pagesJob Description - Mechanical Integrity - Project Engineer (1713975)Bil KaNo ratings yet

- New Holland l180 (Early) Skid SteerDocument906 pagesNew Holland l180 (Early) Skid SteerCristhian Sullon Sosa100% (1)

- BMHDocument7 pagesBMHAnonymous WOdE3Y100% (1)

- Re 15228 Radial Piston Hydraulic Motor With A Fixed DisplacementDocument36 pagesRe 15228 Radial Piston Hydraulic Motor With A Fixed Displacementraj8378100% (1)

- Formación TécnicaDocument250 pagesFormación Técnicajesus100% (1)

- Sp-Spv40-46-E 2-41701 2000-01-21Document132 pagesSp-Spv40-46-E 2-41701 2000-01-21Aan TeeNo ratings yet

- Torque-Hub Planetary Final Drive S12A4 & 6 Series Service ManualDocument58 pagesTorque-Hub Planetary Final Drive S12A4 & 6 Series Service Manualrafasel otubo guatia100% (1)

- 06 632Document12 pages06 632Fernando Sabino100% (1)

- Ross Motors & Steering Index2Document228 pagesRoss Motors & Steering Index2Eng-Mohammed Salem100% (2)

- Eaton Series e Modelos Product Branded PDF 56e2cff9633ec 75Document945 pagesEaton Series e Modelos Product Branded PDF 56e2cff9633ec 75Marcos Vinicius100% (1)

- Wire Rope Forensics Letter PDFDocument50 pagesWire Rope Forensics Letter PDFAshley DeanNo ratings yet

- Kubota Excavator: Workshop ManualDocument766 pagesKubota Excavator: Workshop ManualNavigation Laptops100% (1)

- 13A Pop Can Hero Engine Lesson PlanDocument6 pages13A Pop Can Hero Engine Lesson PlanEbenEzer Mengistu100% (1)

- 37222090-Huawei-WCDMA-HSDPA-Parameters Huawei)Document68 pages37222090-Huawei-WCDMA-HSDPA-Parameters Huawei)Faizal Jamaludeen100% (2)

- Proyecta Catalogo de PartesDocument138 pagesProyecta Catalogo de PartesErik Jose Chacon YupanquiNo ratings yet

- M25 Axial Piston Pump: Series 40Document20 pagesM25 Axial Piston Pump: Series 40Miguel100% (1)

- K3VG-Datasheet Letter Cc19 191008 Final-NRDocument40 pagesK3VG-Datasheet Letter Cc19 191008 Final-NRcatur vallentNo ratings yet

- Relief Cartridge ValvesDocument16 pagesRelief Cartridge Valvesvivek_11111987No ratings yet

- Bomba de PistonDocument22 pagesBomba de PistonAlexSora100% (1)

- Series 42 4T: Axial Piston Tandem PumpsDocument56 pagesSeries 42 4T: Axial Piston Tandem PumpsRachid KerdidiNo ratings yet

- C014 Assembly Manual GuideDocument21 pagesC014 Assembly Manual Guidewillyan100% (2)

- L20 Series: Service and Repair ManualDocument28 pagesL20 Series: Service and Repair ManualJoe CorreaNo ratings yet

- p1 PD XL Service Lte 00062 3 C 0707 075 100 140Document42 pagesp1 PD XL Service Lte 00062 3 C 0707 075 100 140Bernardo Orozco LariosNo ratings yet

- Operators Manual TB235 2 Ae9e002 SN 123600005Document321 pagesOperators Manual TB235 2 Ae9e002 SN 123600005bilwdavisNo ratings yet

- Activa I User ManualDocument75 pagesActiva I User ManualSandy Sury100% (2)

- LowSpeed Failure MotorsDocument23 pagesLowSpeed Failure MotorsMichel Brassard AppliedNo ratings yet

- 11068682Document48 pages11068682manjappahNo ratings yet

- ICVD 01 GB 0319 - WebDocument20 pagesICVD 01 GB 0319 - WebintecelNo ratings yet

- Great Plains Parts Manual NTA607HD & NTA2007HDDocument176 pagesGreat Plains Parts Manual NTA607HD & NTA2007HDa04205No ratings yet

- Radial Piston Motor (Multi-Stroke) MCR10: RE 15207/07.10 1/16 Replaces: 02.98Document16 pagesRadial Piston Motor (Multi-Stroke) MCR10: RE 15207/07.10 1/16 Replaces: 02.98juanchis650No ratings yet

- Re 15190Document24 pagesRe 15190Ahmed Abd ElhakeemNo ratings yet

- Manual Solar Controler SR868C8Document44 pagesManual Solar Controler SR868C8Pedro PereiraNo ratings yet

- Service Parts Manual: Series 40 M25 Axial Piston Tandem PumpDocument40 pagesService Parts Manual: Series 40 M25 Axial Piston Tandem Pumpjose manuel barroso pantojaNo ratings yet

- Manual Motor de Pistones Radiales CB Bosch RexrothDocument48 pagesManual Motor de Pistones Radiales CB Bosch RexrothDavid Jimenez100% (1)

- Concrete Pump 6903713 SM 12-07Document143 pagesConcrete Pump 6903713 SM 12-07Victor MozoNo ratings yet

- Astm e 1226Document12 pagesAstm e 1226João Pedro Bravo100% (1)

- 1600 SERIES: Gear Pumps and MotorsDocument16 pages1600 SERIES: Gear Pumps and Motorscoulibalyoumar100% (1)

- Tractor Hydraulics in Line with TrendsDocument10 pagesTractor Hydraulics in Line with TrendsNelson PaicoNo ratings yet

- 32 McNeilus Mixer Parts Section Revised 1 PDFDocument59 pages32 McNeilus Mixer Parts Section Revised 1 PDFLuis Cuentas100% (1)

- 45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Document56 pages45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Sasko Dimitrov100% (2)

- Pilot Oil Supply: Type: MHSTE5G L1X/350 MHSTE5G L1X/100Document9 pagesPilot Oil Supply: Type: MHSTE5G L1X/350 MHSTE5G L1X/100anandsubbiahNo ratings yet

- Handok Hydraulic - Co: Flow Rate ControlDocument1 pageHandok Hydraulic - Co: Flow Rate Controlanon_485665212No ratings yet

- SCZ Cheetah Manual Book 03363Document87 pagesSCZ Cheetah Manual Book 03363rob sullivan100% (1)

- 520L0813 S40 M25 Variable Pump SPM PDFDocument20 pages520L0813 S40 M25 Variable Pump SPM PDFjose manuel barroso pantojaNo ratings yet

- Spare Parts Catalogue: Series 2000Document96 pagesSpare Parts Catalogue: Series 2000pascukintaNo ratings yet

- Field Testing of A Closed Loop PumpDocument4 pagesField Testing of A Closed Loop Pumpmagarmat1980No ratings yet

- Excava e PDFDocument22 pagesExcava e PDFFaserphi SacNo ratings yet

- Everything You Need to Know About External Gear PumpsDocument7 pagesEverything You Need to Know About External Gear PumpsPrince ShanNo ratings yet

- Application Center Fork-Lift TrucksDocument10 pagesApplication Center Fork-Lift TrucksQXNNo ratings yet

- PVK Pump Features SummaryDocument99 pagesPVK Pump Features SummarySebastiao DuarteNo ratings yet

- Re15200 - 2023 05 26Document18 pagesRe15200 - 2023 05 26Giovane CrestaniNo ratings yet

- Bridon Crane and IndustrialDocument93 pagesBridon Crane and Industrialadh3ckNo ratings yet

- Rotex Tipo Zs DKM H InglesDocument1 pageRotex Tipo Zs DKM H InglesAshley DeanNo ratings yet

- Rated Loads For Grade 80 (System 8) Alloy Steel Chain SlingsDocument5 pagesRated Loads For Grade 80 (System 8) Alloy Steel Chain SlingsAshley DeanNo ratings yet

- Manilha Da 838 YokeDocument1 pageManilha Da 838 YokeAshley DeanNo ratings yet

- GLRB Catalogue ReducedDocument112 pagesGLRB Catalogue ReducedAshley DeanNo ratings yet

- Bridgestone Cell FenderDocument53 pagesBridgestone Cell FenderAshley Dean100% (1)

- Dura RampDocument8 pagesDura RampAshley Dean100% (1)

- Smart shape container lock corrosion protectionDocument2 pagesSmart shape container lock corrosion protectionAshley DeanNo ratings yet

- Superlift MetricDocument2 pagesSuperlift MetricAshley DeanNo ratings yet

- FADesignManual v2 12 SPDocument88 pagesFADesignManual v2 12 SPmichael17ph2003No ratings yet

- USL Issue 2Document3 pagesUSL Issue 2Ashley DeanNo ratings yet

- A New Method For Detecting Wire Rope Defects PDFDocument8 pagesA New Method For Detecting Wire Rope Defects PDFAshley DeanNo ratings yet

- Space Mountain wire rope test machineDocument18 pagesSpace Mountain wire rope test machineAshley DeanNo ratings yet

- An Empirical Model To Predict The Lifetime of Braided HMPE Handling Ropes Under Cyclic Bend Over Sheave (CBOS) LoadingDocument20 pagesAn Empirical Model To Predict The Lifetime of Braided HMPE Handling Ropes Under Cyclic Bend Over Sheave (CBOS) LoadingAshley DeanNo ratings yet

- Adjustment range for 22/130 rail clipDocument2 pagesAdjustment range for 22/130 rail clipAshley Dean100% (1)

- Wire Connects the WorldDocument47 pagesWire Connects the WorldAshley DeanNo ratings yet

- An Empirical Model To Predict The Lifetime of Braided HMPE Handling Ropes Under Cyclic Bend Over Sheave (CBOS) LoadingDocument20 pagesAn Empirical Model To Predict The Lifetime of Braided HMPE Handling Ropes Under Cyclic Bend Over Sheave (CBOS) LoadingAshley DeanNo ratings yet

- Differences in Reference Standards for Wire Rope EMTDocument7 pagesDifferences in Reference Standards for Wire Rope EMTAshley DeanNo ratings yet

- E MOLO MC001 E6 - Disc - CDocument121 pagesE MOLO MC001 E6 - Disc - CthailanNo ratings yet

- Emg Eldro enDocument20 pagesEmg Eldro enAshley DeanNo ratings yet

- Bridon Crane and IndustrialDocument93 pagesBridon Crane and Industrialadh3ckNo ratings yet

- Brochure PDFDocument47 pagesBrochure PDFAshley DeanNo ratings yet

- External Retaining Rings (A) DIN 471: D Up Thru Ø 5Document18 pagesExternal Retaining Rings (A) DIN 471: D Up Thru Ø 5Ashley DeanNo ratings yet

- Smart shape container lock corrosion protectionDocument2 pagesSmart shape container lock corrosion protectionAshley DeanNo ratings yet

- Sprockets Information 1Document8 pagesSprockets Information 1Ashley DeanNo ratings yet

- BR-MAGDR-0109 - Enrolador Cabo Motorizado - MAG DRIVE PortuguesDocument20 pagesBR-MAGDR-0109 - Enrolador Cabo Motorizado - MAG DRIVE PortuguesAshley DeanNo ratings yet

- Supported Media Formats Guide for BlackBerry DevicesDocument53 pagesSupported Media Formats Guide for BlackBerry Devices!ofiuco2000No ratings yet

- Sla Practices PDFDocument43 pagesSla Practices PDFsanty_princeNo ratings yet

- CDMDocument16 pagesCDMrusdiabubakar1001No ratings yet

- ABI 4.0 SpecDocument96 pagesABI 4.0 SpecSushant KulkarniNo ratings yet

- IP Packet Switching: COS 461: Computer Networks Spring 2006 (MW 1:30-2:50 in Friend 109)Document35 pagesIP Packet Switching: COS 461: Computer Networks Spring 2006 (MW 1:30-2:50 in Friend 109)ajazahmednet3946No ratings yet

- P14D CortecDocument8 pagesP14D CortecimhalidaNo ratings yet

- Fuel Saving Operation Guide Koamtsu PDFDocument42 pagesFuel Saving Operation Guide Koamtsu PDFyudha wicaksonoNo ratings yet

- ABC AccessoriesDocument15 pagesABC Accessorieshd2000bwNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- MSS Pooling ActivationDocument4 pagesMSS Pooling ActivationKumaraguru SathiyaseelanNo ratings yet

- Metric Dowel PinsDocument1 pageMetric Dowel PinszainudinNo ratings yet

- Big Boss Corporation Ltd. Electrical Safety Inspection ReportDocument8 pagesBig Boss Corporation Ltd. Electrical Safety Inspection ReportYaser AkarNo ratings yet

- HySpan 6500 CatalogDocument16 pagesHySpan 6500 CatalogdragasaniNo ratings yet

- Ppap 1Document2 pagesPpap 1atulrathor828No ratings yet

- Igo My Way Android 240x320 Apk Download TorrentDocument3 pagesIgo My Way Android 240x320 Apk Download TorrentMladen MarkovicNo ratings yet

- Cyberoam Next-Gen Security for EnterprisesDocument7 pagesCyberoam Next-Gen Security for EnterprisesksibinpaulNo ratings yet

- XG-X Series: Communications Control ManualDocument928 pagesXG-X Series: Communications Control ManualDeaNo ratings yet

- Guidelines For AbstractDocument4 pagesGuidelines For AbstractYoga Alfian NoorNo ratings yet

- TP201.1E Leak Rate and Cracking Pressure of Pressure-Vacuum Vent Valves PDFDocument8 pagesTP201.1E Leak Rate and Cracking Pressure of Pressure-Vacuum Vent Valves PDFCésar Oswaldo Aguilera OjedaNo ratings yet

- Services Provided by The InternetDocument29 pagesServices Provided by The InternetSahil NagpalNo ratings yet

- Power Factor CorrectorDocument16 pagesPower Factor CorrectorMichalis AltousNo ratings yet

- Pump Comparision - Sheet1 PDFDocument5 pagesPump Comparision - Sheet1 PDFAnonymous 5nKsxGrGToNo ratings yet

- 119 Vol25 ATR72-212A600 MP Version1.50 1nov2017Document179 pages119 Vol25 ATR72-212A600 MP Version1.50 1nov2017Jnr Rastah MarksmahnNo ratings yet

- DCFDocument47 pagesDCFJordan Yun-Chiang KungNo ratings yet