Professional Documents

Culture Documents

Will Tape

Uploaded by

QuariousValentinoHutabaratOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Will Tape

Uploaded by

QuariousValentinoHutabaratCopyright:

Available Formats

technical sheet

load-bearing wall type I

Dfinition

A vertical load-bearing structure of worked stone

masonry consisting of a single wall, with the possible addition of an insulating coating or lining to

the interior face. This wall is classified as type I.

Load-bearing wall, type I

Flat or weathering

joint

Choice of materials

Stonework

Stone should be selected in accordance with its

capillarity, frost resistance and compressive

strength (see standard XP B 10-601).

Minimum thickness

30 to 40 cm

CSTB sketch

Slenderness

Slenderness =

The reference document is DTU 20-1 "Small

masonry unit walls". The diagrams below are taken

from DTU 20-1.

They are only given as examples and are to be

adapted in accordance with specific plans for

works to which they relate.

vertical Distance between floors

overall thickness of the load-bearing wall

CAPILLARITY

(as per NFB 10-502)

The minimum thickness is calculated according to

the capillarity measured perpendicular to the face.

When stones have capillarity factors between two

values on the table given below, the thickness of

the wall is obtained by linear interpolation.

Slenderness conditions the safety coefficient used in

calculating the allowable compressive stresses. DTU

20-1 imposes a maximum slenderness ratio of 20.

20

= 40

= 60

= 80

100

Worked stone

Thickness in cm

for type I wall

30

30

30

35

40

Worked ashlar

Thickness in cm

for type I wall

30

30

30

35

40

Rough ashlar

Thickness in cm

35

35

35

40

45

1

Version 2000

load-bearing wall type I

Cornice with overhang

3 cm and drip

Springer

Lintel course formed

with arch stones

Elevation

Springing course

Sting course with

overhang 3 cm and drip

Elevation

Handrail

Springing course

Solid balcony

slab

String course with

overhang 3 cm and drip

Balusters

Console

Elevation

> 15 cm

Sill

Base

Pavement tiles

2

Version 2000

load-bearing wall type I

Residence in Beverly Hills USA. ARCHITECTS: THE MUNSELLE PARTNERSHIP INC. USA AND PIERRE BARBE PARIS.

Joints

Joints between stones

According to the traditional method, the plaster is

poured after the faces and contours have been filled

(the cup method). For the economical method,

stones are laid on a mortar bed with the vertical

joints being filled as the installation is performed.

Grouting is finished afterwards with a compatible

mortar.

Thickness of joints: from 0.8 cm to 1.5 cm.

Construction: joints between stones must be filled

or poured through the entire thickness of the

masonry and up to the reference plane of the facade without recesses or projections.

Htel de Rgion du Limousin Limoges. Architects: C. Langlois, J.L. Dufour, L. Arsne

Henry, P. Sangenberger.

Expansion and contraction joints

Important

recommendations

Expansion and contraction joints are spaced approximately 20 m to 35 m apart depending on the region.

Load-bearing piers should be greater than 80 cm in

width although may be less if justified.

Stones should be shaped so that the quarry faces

are perpendicular to the compression stress and

installed with staggered joints.

Stones should be selected according to their characteristics (see standard XP B 10-601) and position in the facade and the geographic location

where they are to be installed.

Ebisu Garden Place Tokyo. Architects: Cossin, Sanville, Kume Sekei.

You might also like

- Wo 8 Nov 2016Document3 pagesWo 8 Nov 2016QuariousValentinoHutabaratNo ratings yet

- ResiDocument1 pageResiQuariousValentinoHutabaratNo ratings yet

- Wo 8 Nov 2016Document3 pagesWo 8 Nov 2016QuariousValentinoHutabaratNo ratings yet

- Mengapa SemuanyaDocument4 pagesMengapa SemuanyaQuariousValentinoHutabaratNo ratings yet

- Mengapa SemuanyaDocument4 pagesMengapa SemuanyaQuariousValentinoHutabaratNo ratings yet

- CDDocument1 pageCDQuariousValentinoHutabaratNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Eula Microsoft Visual StudioDocument3 pagesEula Microsoft Visual StudioqwwerttyyNo ratings yet

- Ntah Lah Apa Ini SemuanyaDocument16 pagesNtah Lah Apa Ini SemuanyaQuariousValentinoHutabaratNo ratings yet

- Eula Microsoft Visual StudioDocument3 pagesEula Microsoft Visual StudioqwwerttyyNo ratings yet

- Makalah Penelitian Tentang LingkunganDocument1 pageMakalah Penelitian Tentang LingkunganDedi IrhandiNo ratings yet

- Hosts UmbrellaDocument1 pageHosts UmbrellaFabsor SoralNo ratings yet

- SE W550 SchematicsDocument22 pagesSE W550 SchematicsQuariousValentinoHutabaratNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Assembly Analysis of Piston, Connecting Rod & CrankshaftDocument5 pagesAssembly Analysis of Piston, Connecting Rod & Crankshaftbis-2009100% (1)

- Group Technology Implementation and BenefitsDocument24 pagesGroup Technology Implementation and BenefitsChamoda liyanageNo ratings yet

- Section 6 TroubleshootingDocument4 pagesSection 6 TroubleshootingRached DouahchuaNo ratings yet

- Organization Chart For SMS9 Batching Plant: SMCC Philippines, IncDocument4 pagesOrganization Chart For SMS9 Batching Plant: SMCC Philippines, IncE-dwayne S. FernandezNo ratings yet

- Instrument Air SupplyDocument8 pagesInstrument Air SupplyMohammad Amini100% (1)

- Banking & Government Exam Preparation BooksDocument425 pagesBanking & Government Exam Preparation Booksnaveenbabu19100% (1)

- CV Curriculum Vitae OptimizationDocument7 pagesCV Curriculum Vitae OptimizationAdi M. MutawaliNo ratings yet

- Wrapflex - EN-sell Sheet PDFDocument2 pagesWrapflex - EN-sell Sheet PDFIvanNo ratings yet

- Software CrisisDocument4 pagesSoftware CrisisJee AlmanzorNo ratings yet

- Power Quality Improvement Using Statcom: Dr. R N RayDocument28 pagesPower Quality Improvement Using Statcom: Dr. R N RayRajkiranNo ratings yet

- Engineering Risk Survey Reports - An Insight For UnderwritersDocument14 pagesEngineering Risk Survey Reports - An Insight For UnderwritersAli Mahgoub Ali TahaNo ratings yet

- Ecoshield PDocument2 pagesEcoshield PBaugh Graphic DesignNo ratings yet

- PHP O6 TC VoDocument42 pagesPHP O6 TC VoAahana RayNo ratings yet

- Classification of Engineering ServicesDocument24 pagesClassification of Engineering ServicesPaul Vincent De GuzmanNo ratings yet

- Integrals Ex SchedulesDocument7 pagesIntegrals Ex SchedulesChukzdeNo ratings yet

- Introduction To Reinforced ConcreteDocument29 pagesIntroduction To Reinforced ConcreteDarlene Kate MonterdeNo ratings yet

- Online Acces of Grades - RevisedDocument17 pagesOnline Acces of Grades - RevisedJennelie jandusayNo ratings yet

- 0.11 Job Docket - Enel India 2018 - 22052018Document19 pages0.11 Job Docket - Enel India 2018 - 22052018Balaji_Rajaman_2280No ratings yet

- Overview of TSDDocument7 pagesOverview of TSDMuhammad Abdul RaufNo ratings yet

- Engineering Drawing ManualDocument128 pagesEngineering Drawing Manualadnan100% (6)

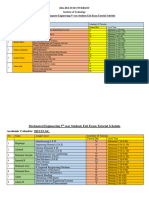

- 7th Sem Time Table PDFDocument40 pages7th Sem Time Table PDFUmesh KsNo ratings yet

- 1.6 Process Alarm Management: M. S. Mannan, H. H. WestDocument5 pages1.6 Process Alarm Management: M. S. Mannan, H. H. WestkangsungjinNo ratings yet

- Abdul Shakoor: Electrical Power EngineerDocument2 pagesAbdul Shakoor: Electrical Power EngineerAnonymous NWSu4UNo ratings yet

- UNIFLAIR ACCESS FLOOR QUOTEDocument2 pagesUNIFLAIR ACCESS FLOOR QUOTEBaba HansNo ratings yet

- API-580, RBI, QB+ans-2 PDFDocument3 pagesAPI-580, RBI, QB+ans-2 PDFaleemudin86No ratings yet

- Distribution System Grounding FundamentalsDocument17 pagesDistribution System Grounding FundamentalsJose Alberto RodriguezNo ratings yet

- BS5070-1Document20 pagesBS5070-1iamtanjoshtanNo ratings yet

- IOT Exit Exam ScheduleDocument6 pagesIOT Exit Exam ScheduleabdulazizNo ratings yet

- String Quartet - Violin IDocument4 pagesString Quartet - Violin IMartin NardoNo ratings yet

- General Requirements For Alloy and Stainless Steel PipeDocument11 pagesGeneral Requirements For Alloy and Stainless Steel Pipergi178No ratings yet