Professional Documents

Culture Documents

Combined Gearbox

Uploaded by

kats2404Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Combined Gearbox

Uploaded by

kats2404Copyright:

Available Formats

United States Patent 1191

[11]

4,106,603

Walter

[45]

Aug. 15, 1978

[54] ARRANGEMENT FOR DRIVING A

WORKING SHAFT BY TWO COMBUSTION

ENGINES

[75] Inventor:

[73]

[21]

[22]

[30]

Jiirgen Walter, Wanne-Eickel, Fed.

Rep. of Germany

Assignee: Vulkan Kupplungs -und Getriehebau

Bernhard Hackforth, Wanne-Eickel,

Fed. Rep. of Germany

Appl. No.: 669,879

Filed:

Mar. 24, 1976

Foreign Application Priority Data

Mar. 29, 1975 [DE]

Fed Rep. of Germany ..... .. 2514029

[51]

Int. c1.1 ........................................... .. 13631-1 23/30

[52]

us. c1. ............................... .. 192/85 AB; 74/661;

[58]

Field 01'' Search ............... .. 74/661, 665 R, 665 A,

192/55; 192/1061; 192/DIG. 2

74/665 B, 665 K; 192/55, 85 AB, 88 A, 106.1,

110 B, DIG. 2

[56]

A transmission system for transmitting drive from at

least two internal combustion engines to a single shaft

comprises a clutch associated with each engine, an in

termediate shaft connected to the hub part of each

clutch and, in use, connected to its associated engine

through a ?exible coupling, a hollow shaft connected

co-axially to the housing of each clutch, the intermedi

ate shaft extending along and through its associated

hollow shaft so that each clutch is remote from its asso

ciated engine. Each hollow shaft passes through a com

mon gear housing and carries a gear wheel, the gear

wheels on the hollow shafts meshing with a gear train in

the gear housing to drive the driven shaft. The movable

friction surfaces of each clutch are connected yieldingly

to the hub parts of each clutch so that they are movable

in all directions with respect to the hub parts of each

clutch, and the hub- parts of each clutch are centered

substantially non-yieldingly in a radial direction on the

References Cited

clutch axis by a rolling bearing having its inner ring

U.S. PATENT DOCUMENTS

?xed to one of the clutch parts and its outer ring having

an axially curved outer surface engaging the other

clutch part through a thin resilient cushion, so that, in

1,492,862

1,896,968

5/1924

2/1933

Smith .............................. .. 192/1061

Paton ................................... .. 192/55

3, 196,7 1 4

7/1965

Lundstrom ...................... .. 74/665 R

3,460,656

3,669,230

8/1969

Swanson .............................. .. 74/661

6/1972

Burkhardt et al. .................. .. 74/661

3,777.865

4,022,083

12/1973

5/1977

Walter et a1. ................. .. 192/85 AB

Pollak-Banda et a1. ......... .. 74/665 B

FOREIGN PATENT DOCUMENTS

232,682

Primary Examiner-Stephen C. Bentley

Attorney, Agent, or FirmToren, McGeady and Stanger

[57]

ABSTRACT

5/1959

Australia ............................. .. 192/1061

use, movements of the intermediate shaft through a

small solid angle with respect to the hollow shaft are

permitted. This system overcomes the misalignments,

particularly those caused by thermal expansion and

contraction, where two engines are mounted side by

side.

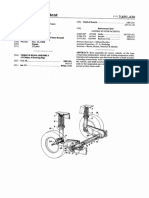

10 Claims, 3 Drawing Figures

U. S. Patent

Aug. 15,1978

AUXILIARY

~APPARATUS

Sheetl of 3

4,106,603

U. S. Patent

Aug. 15, 1978

Sheet2 of 3

FIG. 2

4,106,603

U. S. Patent

Aug. 15, 1978

Sheet 3 of 3

4,106,603

% AUXILIARY

APPARATUS

44mm.

llI

1

- bI

1

I[6

2|

|l %_|l

\

Tl.Il

vvvk.

I'l1|

1.

all8I

12

4,106,603

intermediate shafts of bearing constraint by connecting

ARRANGEMENT FOR DRIVING A WORKING

SHAFI BY TWO COMBUSTION ENGINES

The invention relates to a transmission system for

transmitting drive from at least two internal combustion

them through pivot joints, at one end to the ?exible

coupling and at the other end by a self-aligning bearing

in the hollow shaft. The results of these attempts have

not been satisfactory. A dif?culty is that a self-aligning

bearing, located in the hollow shaft does not have ready

engines to a driven shaft.

access to the usual lubrication system, and cannot there

A convenient way of arranging the drive from at least

two internal combustion engines, particularly if the

engines are arranged side by side, is one in which the

fore be supplied with lubricant easily. Furthermore

drive going from each engine is taken through a ?exible

since the far end of the intermediate shaft, which

projects out beyond the self-aligning bearing, and

coupling to an intermediate shaft and thence to a clutch.

which is connected to the hub part of the clutch, makes

an angle with the geometric axis of the hollow shaft and

The output from each clutch is taken through a hollow

shaft to which is ?xed a driving gear wheel. The driving

it becomes necessary to use a yielding clutch which is

gear wheels on each shaft are enclosed in a gear housing

forms a gyrating movement about the axis of the clutch

and its axis describes a conical surface whose apex is in

the centre of the self-aligning bearing, that is to say not

and mesh with a gear train itself taking drive to the

driven shaft. The intermediate shaft leading to each

clutch is arranged so that it extends through the hollow

costly in construction. The hub part of the clutch per

in the clutch. The ?exible couplings take the resulting

shaft leading away from that clutch with the clutch

radial stresses only when the clutch is engaged. When

20 the clutch is disengaged the parts of the clutch which

remote from the engine.

In transmission systems of this kind the ?exible cou

move during engagement and disengagement of the

plings have a number of functions. In the ?rst place they

clutch share the gyrating movement of the hub part and

help to damp out fluctuations in the torque which are

consequently rub against the clutch housing friction

unavoidable in the operation of internal combustion

surfaces.

engines and they help absorb the impact loads which 25 Attempts have been made to do without the self

occur during engagement and disengagement of the

aligning bearing by connecting the hollow shaft to the

clutch. They also compensate for changes in the lengths

clutch housing through a hypoid-tooth coupling, to act

of shafts which are coaxially coupled together during

changing operating conditions. They also compensate

for parallel displacements of the hollow driving shafts,

which are usually supported in bearings in opposed

walls of the gear housing, due to changes in the temper

as a pivot joint. This does relieve the intermediate shaft

and the hub part of the clutch from transverse loads, but

it becomes necessary to use a clutch whose hub parts

are centred unyieldingly on the axis of the clutch hous

ing to take the weight of the intermediate shaft. The hub

part can, for example, be a multi-disc arrangement. This

The clutches allow the individual engines to be en 35 increases, in conjunction with the hypoid-tooth cou

pling between the clutch housing and the hollow shaft,

gaged and disengaged while the engines are running, so

both

bulkiness and cost.

that the driven shaft, that is to say the working shaft,

The invention in the present invention, starting out

can be driven by either of the two engines or by both. In

from the device mentioned at the beginning, is to pro

most previous systems each clutch is positioned just

behind the ?exible coupling, that is to say in between 40 vide a support for the intermediate shaft which allows a

ature of the gear housing or any ?exing resulting from

operating conditions.

the engine and the gear housing. But, particularly in

propeller drives for ships, the requirement for the great

simple kind of clutch to be used and makes it unneces

sary to use a pivot joint of any kind between the clutch

est possible compactness and the best utilization of the

available space makes it preferable to locate the clutch

housing and the hollow shaft.

According to this invention, a transmission system

gine as described above. To make this possible the driv

bustion engines comprises a clutch associated with each

engine, an intermediate shaft connected to the hub part

of each clutch and, in use, connected to its associated

engine through a ?exible coupling, a hollow shaft con

nected co-axially to the housing of each clutch, the

intermediate shaft extending along and through its asso

on the far side of the gear housing, away from the en 45 for transmitting drive from at least two internal com

ing gear wheel of the gear train is mounted on a hollow

shaft which passes through the gear housing and is

supported by two bearings in the walls of the gear hous

ing. The intermediate shaft which passes through the

interior of the hollow shaft has previously been sup

ported by two bearings in the hollow shaft.

Technological developments have constantly in

creased the power which has to be transmitted, and

consequently the drive components have increased in

size with a resulting increase in the distance between the

shafts of the two engines. Similarly the distance be

tween the hollow shafts has increased, with the result

' that thermal effects produce greater variation in this

distance, by parallel displacement of the hollow shafts,

tending to put the hollow shafts, and consequently the

intermediate shafts which they contain, out of align

ciated hollow shaft so that each clutch is remote from

its associated engine, each hollow shaft passing through

a common gear housing and carrying a gear wheel, and

the gear wheels on the hollow shafts meshing with a

gear train in the gear housing to drive the driven shaft,

the movable friction surfaces of each clutch being con

nected yieldingly to the hub part of each clutch so that

they are movable in all directions with respect to the

60 hub part of each clutch, and the hub part of each clutch

being centred substantially non-yieldingly in a radial

direction on the clutch axis by a rolling bearing having

its inner ring ?xed to one of the clutch parts and its

outer ring having a curved outer surface engaging the

65 other clutch part through a thin resilient cushion, so

adequately.

that, in use, movements of the intermediate shaft

Attempts to reduce the radial stressing of the flexible

through a small solid angle with respect to the hollow

couplings and the bend stressing of the intermediate

shaft are permitted.

shafts have taken the form of attempts to relieve the

ment with the engine shafts. These variations are such

that the ?exible couplings can no longer compensate

4, 106,603

This centring of the hub on the clutch axis prevents

the hub part from shifting radially, when the clutch is

disengaged, due to the weight of the long and conse

quently heavy intermediate shaft, and ensures constant

spacing of the movable clutch members from the hous

ing, only a small gap being now required. The arrange

ment nevertheless still permits small angular move

ments of the hub part relative to the axis of the clutch.

Supporting the intermediate shaft only at its two ends

has the result that parallel relative displacement of the

axes of the ?exible coupling and clutch merely has the

effect that the intermediate shaft adopts a slightly slant

ing attitude with respect to the hollow shaft. As the

intermediate shaft is quite long the angle of slant is only

a fraction of a degree and this can easily be taken up by

the ?exible couplings and the connection between the

hub and the housing of the clutches themselves. The

same thing applies to the resilient cushion mounted on

the domed outer surface of the outer roller bearing ring.

The pendulum-like oscillations due to the slant of the

intermediate shaft produce only axial stresses in the

cushion, which can therefore be quite thin and conse

quently practically unyielding radially.

Hub parts 20, 2a of the ?exible couplings 2, 2 are

connected rigidly to hub parts 3a, 3a of the clutches 3,

3' by the intermediate shafts 7, 7. Each intermediate

shaft passes through the middle of a hollow shaft 4d,

4'0, without touching it. Each hollow shaft passes

through the gear housing 40 and is supported in bearings

in opposite walls of the gear housing 40. Each hollow

shaft has one of the gear wheels 4b and 4'b ?xed to it

which meshes with the gear wheel 40 ?xed to the

driven shaft 5. Furthermore, each hollow shaft is di

rectly ?xed to the housing 30, 3c of the clutch 3 or 3.

FIG. 2 shows an example of a clutch which can be

used in the system of FIG. 1. This is a pneumatically or

hydraulically actuated double-cone friction clutch of a

type known per se. Its hub part 3a is connected through

metal spring plates 8 to axially movable clutch members

9 having conical outer surfaces which cooperate with

conical inner surfaces of the clutch housing 30. One of

the clutch members 9 is screwed to an annular piston 10,

the other to an annular disc 11 which has an annular

groove 11a, the structure forming an annular piston and

cylinder. The annular groove 11a communicates

through partly ?exible and partly rigid line 12 with a

source (not shown) of hydraulic or pneumatic ?uid

For the purposes of the present invention there can

for example be used a clutch of simple construction and 25 under pressure, through a control valve (also not

comparatively small size, of a basic type known per se,

shown).

The clutch differs from normal double-cone friction

whose axially moving friction surfaces are connected to

clutches in that the hub part 30, one end of which is

the hub part through radially stiff and elastically ?exible

attached to one end of the intermediate shaft 7, has a

stressed elements, which not only move axially, during

central bore 13. A hollow pin 15 which is attached to

actuation of the clutch, but also permit the hub part to

the other end of the hub part 30 by an end plate 14 ?xed

move through small angles relative to the stressed ele

to the clutch housing 3c penetrates into the bore 13. The

ments and relative to the clutch housing. The clutch

hub part 3a is supported on the hollow pin 15, and

friction surfaces move on straight lines axially whereas

therefore indirectly on the clutch housing 3c, by a roller

the outer edges of the stressed elements follow curved

bearing 16 whose inner ring 16a is mounted on the

paths. These different movements are permitted in that

hollow pin 15 and whose outer ring 16b has a domed

the clutch members are connected to the stressed ele

outer surface which is formed by an equatorial band of

ments by rubber bodies which are yielding in all direc

a sphere and which supports a ?exible cushion 17 made,

tions. It should be observed that this basic type of clutch

for example, of rubber. The inner surface of the hub part

is intended to function only if its hub part is connected

3a rests in contact with the outer surface of the cushion

to a shaft rotating in bearings and centred positively on

the axis of the clutch housing, the fact that in the present

17. The cushion is quite thin, compared to its axial

case the hub part is not so connected makes it necessary

length. The effect obtained is that when the hub part 3a

oscillates pendulum-fashion, due to the other end of the

to provide the arrangements of the present invention, to

prevent the radial displacement of the movable friction

surfaces.

Two examples of transmission systems in accordance

with this invention are represented diagrammatically in

the drawings, in which:

FIG. 1 is a diagram of a transmission system for driv

in g a propeller shaft of a ship from two internal combus

intermediate shaft 7 moving sideways with the engine 1

45 so that the intermediate shaft 7 assumes a slanting atti

tude with respect to the shaft 4d, the hub part 30 is

supported practically unyieldingly in radial directions

through the thin cushion 17 against the hollow pin 15

and thus against the clutch housing 30.

The clutch shown in FIG. 3 differs from the clutch of

FIG. 2 in that in the clutch shown in FIG. 3 the hub

part consists of two parts 23a and 23b which are spaced

FIG. 2 is a radial section taken along the axis of a ?rst

apart axially but ?xed to each other rigidly by a core

example of a clutch arranged to be used with the pres

shaft 24. Each hub part 2311 and 23b is connected

ent invention; and,

FIG. 3 is a diametric section taken along the axis of a 55 through annular spring discs 28 to an axially movable

clutch member 29 which has an annular piston 20 coop

second example of a clutch arranged to be used with the

erating with an annular cylinder consisting of an annu

present invention.

lar disc 21, ?xed to the hub part 230 or 23b and having

In the system shown in FIG. 1 two internal combus

an annular groove 210. An annular plate 19 is ?xed to

_ tion engines 1, 1 which drive a driven shaft 5 through

a transmission system comprising engine shafts 1a, l'a, 60 the clutch housing 23 and interposed between the two

tion engines positioned side by side;

?exible couplings 2, 2', intermediate shafts 7, 7,

clutches 3, 3', gear wheels 4b, 4'b and a gear wheel 4a

situated in a gear housing 4c. The driven shaft 5 in this

example is a propeller shaft of a ship and has a propeller

6 ?xed to its end remote from the engines. The driven

shaft 5 can be driven selectively by either or both of the

two engines. The clutches 3, 3' are located at the side of

the gear housing 40 opposite from the engines 1 and 1'.

hub parts 230 and 23b. Each hub part is thus supported

radially through the core shaft 24 and the roller bearing

16, against the annular plate 19 and thus against the

clutch housing 23c. The inner ring 16a of the roller

bearing is mounted on the core shaft 24 and the outer

ring 16b is supported through the cushion 17. The outer

ring 1612 again has a domed outer surface formed like an

equatorial band from a sphere. The cushion 17 is sand

4,106,603

wiched between the domed outer surface of the ring 16b " whereby each clutch is remote from its associated en

gine, a'gear housing, each of said hollow shafts passing

and the inner surface of a cylinder ring 18 attached to

throughsaid gear housing, a gear wheel ?xed to each

the annular plate 19.

'

hollow sh'aft, a gear train in said gear housing connected

The example of the clutch shown in FIG. 3 enables

the hub part 23 to be connected to the driving shaft.25

to said single vdriven shaft, said gear wheels on said

of an auxiliary apparatus which is constantly driven by vhollow shafts meshing with said gear train, the improve

one of the engines. This connection is preferably made 'me'ntv wherein said movable friction elements of each

through a ?exible coupling 26.

'

This gives far greater freedom of choice in the ar

rangement of the auxiliary driven devices, and a consid

erable saving of space, when compared to conventional

practice in which the auxiliary device is driven from the

intermediate shaft through a special drive train located

in the gear housing.

I claim:

clutch are connected yieldingly to said hub part so that

they are movable in all directions with respect to said

hub part of each clutch, each of said hollow shafts being

connected rigidly and co-axially on said respective

housings, a rolling bearing in each of said clutches hav

ing their inner rings ?xed to one of said clutch parts, an

axially curved surface on their outer rings, thin resilient

15 cushions covering said curved surfaces and said curved

1. In a transmission system for transmitting drive

from at least two internal combustion engines to a single

driven shaft, a single clutch associated with each said

outer surfaces engaging the other clutch parts through

said thin resilient cushions, whereby said hub parts of

each clutch are centered substantially non-yieldingly in

engine, each said clutch having a hub part and a housing

a radial direction on their respective clutch axes so that

20 movements of said intermediate shafts through a small

part, said housing part carring ?xed friction elements,

an intermediate shaft connected to said hub part of each

clutch and, in use, connected to its associated engine

through a ?exible coupling, a hollow shaft connected to

said housing part of each clutch, said intermediate shaft

extending along and through its associated hollow shaft

whereby each clutch is remote from its associated en

gine, a gear housing, each of said hollow shafts passing

through said gear housing, a gear wheel ?xed to each

hollow shaft, a gear train in said gear housing connected

to said single driven shaft, said gear wheels on said

hollow shafts meshing with said gear train, the improve

ment wherein said movable friction elements of each

clutch are yieldingly connected to said hub part so that

they are movable in all directions with respect to said

hub part, each of said hollow shafts being rigidly and

co-axially connected on said respective housings, a

solid angle with respect to said hollow shafts are permit

ted, said friction elements of each clutch being axially

movable to engage and disengage each of said clutches

and including resilient members which are radially stiff

and capable of axial movement to connect said friction

elements to said hub parts of each of said clutches, said

members permitting actuation of each of said clutches

and also allowing small angular movements of said hub

parts relative to said clutch housing, a bore being pro

vided in each of said hub parts, a hollow pin extending

into each of said bores, each of said pins being ?xed to

said clutch housings remote from its associated interme

diate shaft, and said inner rings of said rolling bearings

being mounted on said pin and said curved outer sur

faces of said outer rings engaging the wall of said bore

through said cushions.

rolling bearing in each of said clutches, each rolling

5. The transmission system of claim 2, wherein said

bearing having inner rings ?xed to one of said clutch

hub part of each of said clutches consists of two por

tions which are mirror images of each other, a core

parts, each rolling bearing having outer rings, an axially

curved surface on said outer rings, thin resilient cush 40 shaft ?xing said two portions together in each clutch,

annular plate springs connecting said axially movable

ions covering said curved surface, and said curved outer

friction elements to each portion, said plate springs

surface engaging the other clutch parts through said

?xed to said hub parts, said core shaft of each of said

thin resilient cushions, whereby said hub parts of each

clutches being ?xed to said inner rings of said rolling

clutch are centered substantially non-yieldingly in a

radial direction on their respective clutch axes to permit 45 bearings and, an annular plate ?xed to said housing part

of each of said clutches engaging said curved surface of

small angular movements of said intermediate shafts

said outer rings of said rolling bearings through said

with respect to said hollow shafts.

thin resilient cushions.

2. The transmission system of claim 1, wherein said

friction elements of each clutch move axially to engage

and disengage each of said clutches and including resil

ient members which are radially stiff and capable of

axial movement to connect said friction elements to said

hub parts of each of said clutches, said members permit

ting actuation of each of said clutches and also allowing

small angular movements of said hub parts relative to

said clutch housing.

'

6. The transmission system of claim 5, wherein a

driving shaft of an auxiliary device is connected to said

hub part of one of said clutches forming an extension of

said intermediate shaft.

7. The transmission system of claim 6, wherein a

?exible coupling is interposed between said driving

shaft of said auxiliary device and said hub part of said

one clutch.

8. In a clutch for use in a transmission system, having

a hub part and a housing part, including movable fric

tion elements yieldingly connected to said hub part to

4. In a transmission system for transmitting drive

from at least two internal combustion engines to a single 60 be movable in all directions with respect to said hub

part, ?xed friction elements carried by said housing

driven shaft, a clutch having a hub part carrying the

part, and actuating means for moving said movable

movable friction elements and a housing part carrying

friction elements with respect to said ?xed friction ele

the ?xed friction elements associated with each engine,

ments to engage and disengage said friction elements,

an intermediate shaft connected to said hub part of each

clutch and, in use, connected to its associated engine 65 the improvement wherein said clutch includes a rolling

bearing having its inner ring ?xed to one of said clutch

through a ?exible coupling, a hollow shaft connected to

parts, each rolling bearing having an outer ring, an

said housing part of each clutch, said intermediate shaft

axially curved surface on said outer ring, and a thin

extending along and through its associated hollow shaft

3. The transmission system of claim 2, wherein said

_ resilient members are formed by annular plate springs.

4,106,603

said clutch, said annular plate springs permitting axial

resilient cushion engaging said curved outer surface,

said curved outer surface engaging said other clutch

movement of said movable friction elements and per

mitting small angular movements of said hub part with

respect to said housing part.

10. The clutch of claim 9, wherein said actuating

part through said thin resilient cushion, whereby small

angular movements of said hub part with respect to said

housing part are permitted.

9. The clutch of claim 8, having two conically shaped

friction elements, annular plate springs connected be

means is an annular ?uid pressure-operated piston and

cylinder assembly arranged to move said movable fric

tion surfaces in an axial direction.

tween said movable friction elements and said hub part,

said actuating means moving axially during actuation of

10

15

20

25

35

45

50

55

65

it

You might also like

- Clutch DesignDocument12 pagesClutch Designmos3ad2006No ratings yet

- ClutchDocument5 pagesClutchyudhisthar0110% (1)

- Boite Seamless XtracDocument13 pagesBoite Seamless Xtracdudule01No ratings yet

- DoME Report (009 & 019)Document9 pagesDoME Report (009 & 019)Muhammad WaleedNo ratings yet

- Unit 3 ClutchesDocument54 pagesUnit 3 Clutchesswapnil pandeNo ratings yet

- TM 9-1750 Power Train Unit, Three-Piece Differential Case, For Medium Tanks, M3, M4, and Modifications 1942Document117 pagesTM 9-1750 Power Train Unit, Three-Piece Differential Case, For Medium Tanks, M3, M4, and Modifications 1942RobertLockieNo ratings yet

- Frame Saw Manual 1902Document111 pagesFrame Saw Manual 1902wolf143No ratings yet

- PRESENTION 2 MPPDocument28 pagesPRESENTION 2 MPPKhairul SyahreelNo ratings yet

- Mechanics of Textile Machinery ContentDocument59 pagesMechanics of Textile Machinery ContentPARAMASIVAM SNo ratings yet

- United States Patent: Primary Examiner-Benjamin W. WycheDocument5 pagesUnited States Patent: Primary Examiner-Benjamin W. WycheMarc GlebNo ratings yet

- Friction Clutch: 1.single Plate Clutch (Disc Clutch)Document5 pagesFriction Clutch: 1.single Plate Clutch (Disc Clutch)Ashok PradhanNo ratings yet

- Ae Unit 2Document25 pagesAe Unit 2Iyyappan SivalingamNo ratings yet

- Us3443375 PDFDocument3 pagesUs3443375 PDFRamos GabeNo ratings yet

- Automobile Clutch: Aim To Study and Prepare Report On The Constructional Details, Working Principles andDocument4 pagesAutomobile Clutch: Aim To Study and Prepare Report On The Constructional Details, Working Principles andசிவ சங்கர்No ratings yet

- Mass College ProjectDocument68 pagesMass College ProjectGLOBAL INFO-TECH KUMBAKONAMNo ratings yet

- Wheel Set AssemblyDocument7 pagesWheel Set AssemblysumantlNo ratings yet

- Easychair Preprint: Siddharth Boon, R. C. Singh and Rajiv ChaudharyDocument8 pagesEasychair Preprint: Siddharth Boon, R. C. Singh and Rajiv ChaudharyayushNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2010/0105516 A1Document11 pagesPatent Application Publication (10) Pub. No.: US 2010/0105516 A1KrozeNo ratings yet

- ClutchesDocument32 pagesClutchesWeins GemerlapNo ratings yet

- Report of Cam ShaftDocument85 pagesReport of Cam ShaftkotoyayNo ratings yet

- CrankshaftDocument9 pagesCrankshaftmuchamad luthfi aliNo ratings yet

- Shafting SystemDocument9 pagesShafting SystemKariem ZakiNo ratings yet

- UntitledDocument44 pagesUntitledWondwosen FriewNo ratings yet

- MCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Document19 pagesMCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Fahim ShahrierNo ratings yet

- Engine ConstructionDocument89 pagesEngine ConstructionVinod Cf Cruz100% (2)

- TUGASDocument2 pagesTUGASselviana safitriNo ratings yet

- United States Patent (19) : Harris (451 Oct. 21, 1975Document10 pagesUnited States Patent (19) : Harris (451 Oct. 21, 1975FernandoNo ratings yet

- Unit-2-Automobile EnggDocument23 pagesUnit-2-Automobile EnggPrashant BhumireddyNo ratings yet

- Stress Analysis of Crankshaft: Mechanics of Materials (Lab Project)Document18 pagesStress Analysis of Crankshaft: Mechanics of Materials (Lab Project)Baran ShafqatNo ratings yet

- Automobile Systems: Unit - IIDocument30 pagesAutomobile Systems: Unit - IISasankBabuNo ratings yet

- Fabrication of Multi Nut Tighter or Remover Mechanical ProjectDocument6 pagesFabrication of Multi Nut Tighter or Remover Mechanical ProjectBhuvnesh MehtaNo ratings yet

- AT6501 UwDocument132 pagesAT6501 UwAjithNo ratings yet

- Connecting RodDocument8 pagesConnecting RodSubham Badhyal50% (2)

- Galgotias University: Laboratory ManualDocument52 pagesGalgotias University: Laboratory ManualAgnivesh SharmaNo ratings yet

- Automobile Engineering Lab (ME-314-F) List of ExperimentsDocument48 pagesAutomobile Engineering Lab (ME-314-F) List of ExperimentsTapas Kumar SahooNo ratings yet

- Us 3601426 RearDocument4 pagesUs 3601426 Rearanup tiwariNo ratings yet

- Power Units and TransmissionDocument42 pagesPower Units and TransmissionAmarjeet RaiNo ratings yet

- Project ReportDocument5 pagesProject ReportAshley Sam100% (1)

- Transmission SystemDocument51 pagesTransmission SystemPethurajNo ratings yet

- Antonio Sanchez Hybrid Engine PDFDocument60 pagesAntonio Sanchez Hybrid Engine PDFAntonio Sánchez100% (2)

- Unit 2-At6402 Automotive ChassisDocument20 pagesUnit 2-At6402 Automotive ChassisSathis KumarNo ratings yet

- Tm. VC: May 13, 1969 E. F. CielaszykDocument3 pagesTm. VC: May 13, 1969 E. F. CielaszykjoycebaylonNo ratings yet

- Engine Parts: Laboratory Exercise 3Document5 pagesEngine Parts: Laboratory Exercise 3Milx Jyms AvilaNo ratings yet

- WL 00200 5 T7-8 de enDocument20 pagesWL 00200 5 T7-8 de enrwva20No ratings yet

- Clutch Working and PropertiesDocument41 pagesClutch Working and Propertiessarath100% (1)

- Safety Features For Reduction of Failure in Stacker Cum Reclaimer For Thermal Power PlantDocument3 pagesSafety Features For Reduction of Failure in Stacker Cum Reclaimer For Thermal Power PlantIjsrnet EditorialNo ratings yet

- The Piston Cylinder Assembly in Piston MachinesDocument13 pagesThe Piston Cylinder Assembly in Piston Machinesbee140676No ratings yet

- Factsheet - Rear Axle Rt2310Hv: Features and BenefitsDocument2 pagesFactsheet - Rear Axle Rt2310Hv: Features and BenefitsJoãoPauloSouzaNo ratings yet

- Factsheet Rearaxle PDFDocument2 pagesFactsheet Rearaxle PDFJoãoPauloSouzaNo ratings yet

- Automotive Transmission NewDocument147 pagesAutomotive Transmission NewhodvmkvecautoNo ratings yet

- Ijess Volume3, Issue6 ISSN: 2249-9482 Operation and Maintenance of Stacker Cum Relaimer in Coal Handling Plant in Thermal Power PlantDocument7 pagesIjess Volume3, Issue6 ISSN: 2249-9482 Operation and Maintenance of Stacker Cum Relaimer in Coal Handling Plant in Thermal Power Plantramanujam59No ratings yet

- Tugas DeckyDocument2 pagesTugas Deckyselviana safitriNo ratings yet

- NOV-9, 1943. A. Ca. Schneider: Planetary Turbine TransmissionDocument6 pagesNOV-9, 1943. A. Ca. Schneider: Planetary Turbine Transmissionbelchior alvaroNo ratings yet

- Design and Analysis of CrankshaftDocument35 pagesDesign and Analysis of CrankshaftAbijit Guda50% (6)

- Crank Shaft: Software Used-Catia V5R20 Submitted To Submitted byDocument47 pagesCrank Shaft: Software Used-Catia V5R20 Submitted To Submitted byYaman Saluja0% (1)

- Propeller Shaft & Universal JointDocument22 pagesPropeller Shaft & Universal JointaaraNo ratings yet

- Slider Crank Mechanism Term Project ReportDocument16 pagesSlider Crank Mechanism Term Project ReportAnis Badshah88% (24)

- Lecture 8 Transmission PDFDocument6 pagesLecture 8 Transmission PDFabdul quadirNo ratings yet

- Auto Module 01Document13 pagesAuto Module 01p_cheta11No ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- M240 MountDocument2 pagesM240 Mountkats2404No ratings yet

- EDF ComparisonDocument1 pageEDF Comparisonkats2404No ratings yet

- Thin Gap Brochure 2015 WebDocument12 pagesThin Gap Brochure 2015 Webkats2404No ratings yet

- Heat ExchangersDocument8 pagesHeat Exchangerskats2404No ratings yet

- F135 Engine SpecificationDocument2 pagesF135 Engine Specificationkats2404100% (1)

- Helio ServicesDocument68 pagesHelio Serviceskats2404No ratings yet

- Gas Metering System-Woodward - SwiftDocument4 pagesGas Metering System-Woodward - Swiftkats2404No ratings yet

- Silicone MoldingDocument6 pagesSilicone Moldingkats2404No ratings yet

- Constant Speed PropellerDocument16 pagesConstant Speed Propellerkats2404100% (1)

- IC 900 IC 910 Ignition ControllerDocument50 pagesIC 900 IC 910 Ignition Controllerkats2404No ratings yet

- Adjustable OvenDocument3 pagesAdjustable Ovenkats2404No ratings yet

- Variable Pitch Constant Speed Propellers For Light AircraftDocument72 pagesVariable Pitch Constant Speed Propellers For Light Aircraftkats2404100% (1)

- Horizontal and Vertical OvensDocument2 pagesHorizontal and Vertical Ovenskats2404No ratings yet

- QuikCONE PerformanceDocument1 pageQuikCONE Performancekats2404No ratings yet

- Designer's Guide For Laser Hermetic SealingDocument11 pagesDesigner's Guide For Laser Hermetic Sealingkats2404No ratings yet

- Fused Silica DatasheetDocument2 pagesFused Silica Datasheetkats2404No ratings yet

- BEL - 6D Through Conduit GateDocument2 pagesBEL - 6D Through Conduit Gateasoka.pwNo ratings yet

- Compiled By: Sir Sumair: KinematicsDocument6 pagesCompiled By: Sir Sumair: KinematicsHasan NawazNo ratings yet

- En EQP17 ALIVA-263-285 GB 0607Document3 pagesEn EQP17 ALIVA-263-285 GB 0607Gonçalo Duarte AntunesNo ratings yet

- ELECTRIC MOTORS IN Explosion PDFDocument43 pagesELECTRIC MOTORS IN Explosion PDFanisNo ratings yet

- Experiment No.9 FrictionDocument13 pagesExperiment No.9 Frictionredhotchick84100% (7)

- (Hyundai Sonata 2005-2011, (Kia Forte 2009-2010, K5 2010-2011, Lotze 2010)Document4 pages(Hyundai Sonata 2005-2011, (Kia Forte 2009-2010, K5 2010-2011, Lotze 2010)marran almarranyNo ratings yet

- Datasheet Crx-10iaDocument1 pageDatasheet Crx-10iaGuillaume RICHARDNo ratings yet

- Chapter - 7 Part I STDDocument75 pagesChapter - 7 Part I STDBelkacem Achour100% (1)

- Design of Forming ToolsDocument22 pagesDesign of Forming ToolskunwarNo ratings yet

- PMSM 2012Document62 pagesPMSM 2012Sreerag Kunnathu Sugathan100% (3)

- Standard Specification For Standard Specification For: Designation: A 1018/A 1018M - 01a Designation: A 1018/A 1018M - 01aDocument5 pagesStandard Specification For Standard Specification For: Designation: A 1018/A 1018M - 01a Designation: A 1018/A 1018M - 01arahil shahNo ratings yet

- Thermodynamics: AllenDocument9 pagesThermodynamics: AllenronakNo ratings yet

- Screws Self-DrillingDocument22 pagesScrews Self-DrillingSamra DukićNo ratings yet

- CP2 2000 Installation, Operation and Maintenance of Electric Passenger and Goads LiftsDocument52 pagesCP2 2000 Installation, Operation and Maintenance of Electric Passenger and Goads Liftskhant kyaw khaingNo ratings yet

- 29 V3800dit 26Document2 pages29 V3800dit 26Hector Dongo ArrayanNo ratings yet

- Determination of Blockage Correction in Open-Jet Wind TunnelDocument6 pagesDetermination of Blockage Correction in Open-Jet Wind Tunnelmoro1381100% (1)

- 02 The Wind Turbine-0001Document16 pages02 The Wind Turbine-0001vodasanket100% (1)

- Catalog MotoreductoareDocument20 pagesCatalog MotoreductoareNitzu Holhorea CornelNo ratings yet

- BTech 1st Sem: Mechanical Science: Stress & StrainDocument10 pagesBTech 1st Sem: Mechanical Science: Stress & StrainTechno India Group100% (1)

- Mecanica MotoareDocument45 pagesMecanica MotoareAutogrederNo ratings yet

- Scheda Autoclave VT - Med ResDocument2 pagesScheda Autoclave VT - Med Resengomar nadyNo ratings yet

- KinematicsDocument7 pagesKinematicsNicole WheelerNo ratings yet

- AssignmentME LawDocument2 pagesAssignmentME LawMatthew AquinoNo ratings yet

- Syllabus Mechanical Qaqc Course Sdlinc 9600162099Document3 pagesSyllabus Mechanical Qaqc Course Sdlinc 9600162099Sridurgha Lakshmi Inc SDLINC NDT QA QC INSTITUTE100% (3)

- ElectronoobsDocument5 pagesElectronoobsTaufiq QurahmanNo ratings yet

- ME302: Materials Mechanics: Chap. 1 StressDocument16 pagesME302: Materials Mechanics: Chap. 1 StressMat MatttNo ratings yet

- Forging PresentationDocument17 pagesForging PresentationRakesh PuriNo ratings yet

- OSS Hardware SectionDocument72 pagesOSS Hardware SectionglobalindosparepartsNo ratings yet

- SY16 Maintenance ManualDocument148 pagesSY16 Maintenance ManualAndres SorinNo ratings yet

- Suction Pile SpecDocument33 pagesSuction Pile Specriaz16shaik100% (1)