Professional Documents

Culture Documents

Fire Safety 5

Uploaded by

ShahrulNizamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Safety 5

Uploaded by

ShahrulNizamCopyright:

Available Formats

Section 5

Fire Safety

Overview

Section content

This section contains the following topics.

Topic

Page

General Information

5-1

Fire Prevention

5-2

Fire Response and Training

5-3

Firefighting Equipment

5-6

Flammables and Combustibles

5-11

Offshore Operating Guidelines

5-12

Smoking and Smoking Materials

5-13

General Information

General rules

This section provides guidelines regarding fires on Company property. Fires, no

matter how small, must be reported to in-country management immediately. A formal

report should include all known or reasonably surmised details, as additional reports

may be required by governmental agencies.

Fire doors, such as doors to an interior stairwell, should remain closed.

Definitions

Flammable liquids

A liquid having a flash point below 100F and a vapor pressure exceeding 40 psi

absolute at 100F.

Combustible liquids

A liquid having a flash point at or above 100F but less than 200F.

Continued on next page

March 1999

Fire Safety

5-1

General Information, Continued

For more

information

For more information, refer to the ECI OIMS Standard Systems:

Work management

Operating Procedures

Personnel Safety Management

Fire Prevention

Housekeeping

Good housekeeping and equipment maintenance must be followed to minimize fire

hazards.

The area immediately adjacent to a lease, well equipment and storage areas must

be kept free of combustible debris and dry weeds.

Furniture

Furniture must be arranged to avoid contact with heaters.

Space heaters

Open-type space heaters should not be used in gas plant or compressor facilities.

Automotive

equipment and

other ignition

sources

Unless properly permitted, automotive equipment and other ignition sources are

prohibited within the firewall or fenced enclosure of a tank battery or other facilities

designated by field management.

Burning

combustible

materials

Oil and gasoline from leaks should not be burned unless it is being done in

accordance with both the local regulatory requirements and the Esso Waste

Management Guidelines .

In the absence of firewalls or enclosures, automotive equipment and other ignition

sources must be kept a safe distance (generally 50 feet) from these facilities. If it is

not possible or necessary to maintain this 50-foot distance, then a safe distance

must be determined considering wind, weather, terrain, and other conditions.

The burning of waste oil, grass, brush, rubbish, or other combustible material is

prohibited without supervisory authorization and required permits. Extreme care

must be taken when working in dry woods, brush, marshes, and prairies.

Continued on next page

5-2

Fire Safety

March 1999

Fire Prevention, Continued

Ice and paraffin

plugs

Lines containing hydrocarbons or combustible materials under pressure must not be

fired to remove ice or paraffin plugs.

Reporting and

repairing

hydrocarbon

leaks

All hydrocarbon leaks must be reported and, if practical, repaired immediately. If

immediate repair is not possible, adequate warning signs must be posted, and extra

precautions against fires must be instituted.

Testing for gas

leaks

When testing for gas leaks, use soapsuds, an approved leak detector fluid, or an

approved combustible gas meter. Open flames must not be used.

Iron sulfide

Dry iron sulfide will spontaneously ignite when it comes in contact with air, so it must

be kept wet to prevent this problem.

In the event of a significant, unexpected release of hydrocarbons, ignition sources in

the affected area must be shut down immediately.

REFERENCE: Section 3, Chemical and Product Safety

Fire Response and Training

Personnel

requirements

Fighting fires is a dangerous operation. Personnel fighting fires must be properly

trained and equipped. They should understand their responsibilities and limitations.

Basic rules

Personnel expected to respond to initial fires must be trained in the use of portable

extinguishers and other designated equipment.

Fire drills must be held at regular intervals to familiarize personnel with their

responsibilities in the event of a fire.

Personnel assigned to enclosed buildings where automatic extinguishing systems

are employed should be instructed to vacate the building in the event of extinguisher

discharge.

Only designated and trained personnel should attempt to extinguish a fire that has

advanced beyond the initial stage.

Continued on next page

March 1999

Fire Safety

5-3

Fire Response and Training, Continued

Fire response

procedure: Initial

stage

Listed below are the actions for responding to a fire in the initial stage.

Step

Action

Activate an alarm if possible.

Attempt to extinguish Use a portable hand extinguisher or other

designated equipment to control and extinguish the fire.

NOTE: If the fire is not controlled within the first minute, back out and either

get help, or evacuate.

Notify proper personnel Contact the supervisor and provide him or her

with:

The location

The time the fire was observed

Any actions taken to contain the fire

Isolate the fuel source. If necessary and safe to do so, follow local

procedures to isolate the source of fuel to the fire area.

Continued on next page

5-4

Fire Safety

March 1999

Fire Response and Training, Continued

Fire response

procedure:

Beyond

initial stage

Listed below are the actions for responding to a fire that has developed beyond the

initial stage.

Step

Survival

techniques

Action

Activate an alarm if possible.

Notify proper personnel Contact the supervisor and communicate:

The location

The time the fire was observed

Any actions taken to contain the fire

Isolate the fuel source. If necessary and safe to do so, follow local

procedures to isolate the source of fuel to the fire area.

When applicable, assist the fire brigade or outside agencies by identifying

and communicating additional hazards in the fire area.

Fire response In some areas, the fire brigade or outside agency may

handle the response (onshore).

Personnel must be familiar with the following survival techniques if trapped by a fire:

Be aware of the location of designated fire exits.

Understand evacuation procedures at the work location.

Do not use elevators. Use designated exits.

If caught in a smoke-filled area, crawl on the floor and take short breaths through

the nose. If possible, hold a cloth in front of the face.

Before opening a door, touch it to check if it is hot. If it is hot, do not open it.

If unable to safely exit a fire or smoke-filled area:

Proceed to a room with an outside window.

Close the door to isolate the room from the smoke-filled hallway.

Move to a window.

Signal for help.

March 1999

Fire Safety

5-5

Firefighting Equipment

Basic rules

Firefighting equipment is for fire use only and must be kept in its designated place at

all times.

All fire protection equipment must be located in designated areas which are clearly

identified with appropriate markings (e.g., warehouses, canteens, offices, living

quarters, etc.). This equipment should be located near likely fire hazards and must

also be accessible to operating personnel.

Due to the probability of electrostatic charge generation, CO2 extinguishers must not

be discharged into any space containing a flammable atmosphere, unless there is a

fire.

Local standards

The number, type, and location of extinguishers must meet, as a minimum, local

guidelines and standards if guidelines and standards are more stringent than Essoestablished guidelines.

Maintenance and

inspection

A qualified person must perform maintenance and inspection of fire equipment. All

fire hoses and foam stations must be inspected annually or per regulatory and

Company requirements for that work area.

Automatic fire

protection

system

In buildings equipped with an automatic fire protection system, all doors must remain

closed. The automatic louver closure and exhaust fan shutdown system must be

operable.

NOTE: Adapters should be available to connect municipal fire equipment to existing

equipment when applicable.

Continued on next page

5-6

Fire Safety

March 1999

Firefighting Equipment, Continued

Fire extinguisher

codes and uses

The chart below describes the symbols, designation codes, and extinguishing

agents that should be used for the different types of fires.

If the type of fire is...

Then this extinguisher

symbol applies...

and it contains one of

these extinguishing

agents...

Common Combustibles

(wood, cloth, rubber, or

plastic)

Water

Dry chemical

Flammable Liquids

(flammable materials,

combustible liquids, or

gas)

Dry chemical

CO2

Electrical

Dry chemical

CO2

Burning Metals

(magnesium, titanium,

batteries)

Dry powder

Company

vehicles

All assigned Company vehicles must be equipped with an approved fire extinguisher.

The size of the extinguisher should be determined by the anticipated need; however

the minimum size is 5 pounds.

Fire extinguisher

upkeep

All fire extinguisher hose nozzles must be kept free of obstructions at all times. In

areas where insects tend to nest, the nozzle must be protected against plugging.

Welding on the outer shell of a fire extinguisher is prohibited.

Instruction labels on fire extinguishers must be maintained.

Continued on next page

March 1999

Fire Safety

5-7

Firefighting Equipment, Continued

Fire extinguisher

inspections

All portable and semi-portable extinguishers must be inspected monthly to ensure

that they:

Are in their designated places

Have not been tampered with

Have a durable tag securely attached to show the maintenance or recharge date

Have no obvious physical damage, corrosion, or other impairments.

A more thorough inspection should be performed:

Recharging and

replacing fire

extinguishers

Every six months in open buildings or outside

Yearly inside air-conditioned buildings

Fire extinguishers must be recharged, repaired, or replaced as needed.

Partially-used fire extinguishers must be discharged of pressure and then recharged

or replaced immediately.

Fire extinguishers removed from the premises to be recharged must be replaced

immediately with spare extinguishers.

Hydrostatic

testing

If a portable extinguisher shows evidence of corrosion, deterioration, or mechanical

damage, hydrostatic testing at 75% of factory test pressures must be conducted.

Fire extinguisher hoses with shut-off nozzles at the discharge end must be included

in the hydrostatic test.

Nitrogen and CO2 cylinders that have been discharged must be hydrostatically tested

if more than 5 years have elapsed since the last test.

CO2 cartridges used for cartridge type extinguishers should only be filled by Original

Equipment Manufacturers (OEM) qualified personnel following manufacturers'

recommendations.

Prior to recharging portable extinguishers, a visual internal inspection by qualified

personnel should be performed.

Continued on next page

5-8

Fire Safety

March 1999

Firefighting Equipment, Continued

Hydrostatic

testing,

(continued)

The table below describes the intervals in which hydrostatic tests must be conducted.

Type of Extinguisher

Hydrostatic Test

Interval

CO2 extinguisher

Example: A General 15-pound extinguisher.

Stored pressure water/foam extinguisher

Example: An extinguisher with a stainless steel shell.

Pressurized-type, dry-chemical extinguisher

Example: An extinguisher with a mild steel shell such as

the Safety 1st 20-pound extinguisher.

Nitrogen cylinder (wheel units only).

5 years

Powder tank and hose (wheel units).

12 years

CO2 cylinder (fixed system).

12 years

Cartridge dry chemical unit with brazed-brass or mildsteel shells such as Ansul or General.

5 years

5 years

12 years

5** years

** If the retest markings include a five-point star, then the retest interval may be

extended to 10 years.

IMPORTANT: Use of Halon is prohibited.

For more information on hydrostatic testing requirements, refer to the National Fire

Protection Association, NFPA 12-A and Local Regulatory Authority regulations.

Continued on next page

March 1999

Fire Safety

5-9

Firefighting Equipment, Continued

Fixed systems

Firewater

systems

Sprinkler and foam systems must be kept in good operating condition and

periodically inspected in accordance with appropriate Company and government

standards . The following precautions apply to fixed dry-chemical and carbon dioxide

extinguishing systems:

Expellant gas containers must be inspected and checked semi-annually for

pressure and weight against the required minimums.

The complete system, including alarms, shutdowns, and other associated

equipment must be thoroughly inspected and checked for proper operation by a

qualified inspector at least annually.

Dry chemical containers must be sampled annually from the top, at the center,

and near the wall of the container to determine the existence of packing or

deterioration.

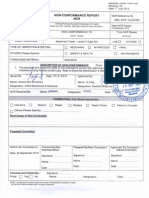

Records of inspections and tests must be maintained. The preventive

maintenance report or a similar form is typically used for this purpose. The

report should be reviewed monthly to ensure that all inspections are being made

and that defective equipment is being promptly repaired or replaced.

Firewater systems, except on some offshore platforms, should have a primary and

secondary power source. They should be remotely located from potential fire hazard

areas. These facilities must be started and operated weekly and appropriate

personnel must be familiar with starting and operating procedures.

Firewater systems must be tested after any maintenance or modifications are made

to the pump, driver, or other associated equipment.

5-10

Fire Safety

March 1999

Flammables and Combustibles

Storage of

flammables and

combustibles

The following flammables and combustibles must not be allowed near stoves,

furnaces, or gas fires:

Containers of oil, kerosene, and solvents

Oily rags

Waste

Debris and

Other combustible items.

REFERENCE: For more information, refer to the National Fire Protection Association,

NFPA 30 and Local Regulatory Authority regulations.

Storing in

buildings

Buildings in which flammables or combustible liquids are handled and stored must

be adequately ventilated. Buildings that store large quantities of flammable liquids

may need design and engineering evaluation.

Storing large

amounts

Storage of greater than 10 gallons of flammable and combustible liquids requires

use of:

Outside storage

Approved storage rooms

Approved cabinets

Warehouses

Glass containers

Gasoline, kerosene, or other flammable/combustible liquids must not be placed in

glass containers unless designated or approved for transportation or storage.

Oil-soaked

clothing

Oil-soaked clothing should be removed and properly disposed of or cleaned.

Oily waste

Oily waste must be disposed of properly because of the possibility of spontaneous

combustion. Approved metal containers must be provided for the disposal of oily

rags and other oil-soaked materials. These containers must be emptied often

enough to keep the premises in a safe, sanitary condition.

Continued on next page

March 1999

Fire Safety

5-11

Flammables and Combustibles, Continued

Flammable/

Combustible

liquids

as cleaning

agents

The use of flammable liquids as cleaning agents is prohibited.

While combustible liquids (such as kerosene, diesel and varsol) may be used in

cleaning machinery, they should not be used on hot metal surfaces or sprayed

around operating machinery where there is a source of ignition.

NOTE: Section 10, Electrical Safety, "Cleaning Electrical Apparatus"

Paint, insect

sprays and

aerosol sprays

Because paint, insect sprays, aerosol sprays and paint removers are usually

flammable, they should not be used near open flames or other sources of ignition.

NOTE: Read the labels on the containers

Offshore Operating Guidelines

Offshore

operating

guidelines

5-12

Offshore platform operations must add the following requirements to the other

guidelines contained in this chapter:

Fire and evacuation drills for each work group must be held in accordance with

governmental regulations and Esso guidelines . A written report of such drills

must be made on the appropriate forms and communicated to management.

In the absence of designated smoking areas, smoking is restricted to the

quarters area. Smoking in bed is prohibited.

Gasoline powered engines and compressors, gasoline fuel, and open fires are

prohibited on offshore platforms without special approval from appropriate

Production Organization Management.

Automatic nozzle water-spray and foam systems must be inspected and tested

at least quarterly.

A fire extinguisher of appropriate size should be located near each room of the

living quarters.

Fire Safety

March 1999

Smoking and Smoking Materials

General rules

Safety tips

The following general safety rules apply:

Cigarette lighters must not be carried onto helicopters or to offshore locations.

Cigarette, cigar, or pipe smoking must be confined to specifically designated

areas.

Attics of all buildings must be designated as "No Smoking" areas, and "No

Smoking" signs must be prominently displayed.

Matches and cigarette lighters must not be carried into an area where a

potentially explosive atmosphere exists.

Cigarette lighters must not be carried into an area where welding or open flame

burning is taking place.

On offshore platforms, smoking must only be allowed in the designated smoking

room inside the living quarters. Smoking must be strictly prohibited in all other

areas.

At drilling and workover locations, designated and posted "No Smoking" areas

must include as a minimum:

The rig floor

Cellar areas

Areas near the shale shaker, mud tanks, and fuel tanks

Never leave a burning cigarette unattended. Where smoking is allowed in buildings

or offices, place cigarettes or cigars well inside of ashtrays to prevent them from

falling out. Never lay cigarettes or cigars on desks, in wastebaskets, or on the floor.

A wastebasket is the worst substitute for an ashtray; even extinguished matches and

tobacco are often hot enough to ignite other materials. Empty the contents of

ashtrays into metal containers used only for this purpose.

Wastebaskets must not be used as ashtrays and ashtrays must not be emptied into

wastebaskets until the ashes have cooled.

Continued on next page

March 1999

Fire Safety

5-13

Smoking and Smoking Materials, Continued

No-smoking

areas

Smoking in operating areas is prohibited except where specifically designated by

management.

Lighted cigarettes, cigars, or pipes are not to be carried on elevators.

Any area subject to contamination by flammable liquids or gas must be designated a

"No Smoking" area by In-country Management. A "No Smoking" sign must be

displayed in the area.

Smoking must be prohibited in the following areas, whether or not a "No Smoking"

sign is displayed:

Formation

fracturing and

high-pressure

pumping

5-14

In records storage or filing areas

In computer rooms while handling computer tapes or paper

Around shale shakers

On or under the floors of drilling and workover rigs

Near tank batteries

Next to oil and gas wells

In any area suspected of containing flammable vapors.

During all phases of the formation fracturing and high-pressure pumping of liquid

hydrocarbons operation, smoking and smoking materials (including matches,

lighters and cigarettes) are prohibited within 100 feet of the well and related

equipment.

Fire Safety

March 1999

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- List of Method Statement - ArchitectDocument1 pageList of Method Statement - ArchitectShahrulNizam100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tugas Fire Safety-FixxxDocument9 pagesTugas Fire Safety-FixxxridhoernandiNo ratings yet

- General and Specific Objectives-Combustion and FlamesDocument2 pagesGeneral and Specific Objectives-Combustion and FlamesSubha Dey75% (4)

- Aztec Owner'S: HandbookDocument52 pagesAztec Owner'S: HandbookFachri AryudaNo ratings yet

- Mbe900opsguide PDFDocument116 pagesMbe900opsguide PDFJavier MontesNo ratings yet

- NCR Electrical 20150915 - 165540Document4 pagesNCR Electrical 20150915 - 165540ShahrulNizamNo ratings yet

- Backcharges To A.GDocument179 pagesBackcharges To A.GShahrulNizamNo ratings yet

- Table Monitoring Progress Finsihing & MEPDocument267 pagesTable Monitoring Progress Finsihing & MEPShahrulNizamNo ratings yet

- Accident Investigation ProcedureDocument3 pagesAccident Investigation ProcedureShahrulNizamNo ratings yet

- F023 - Non-Conformance Report (NCR) - Team 02 - 02Document2 pagesF023 - Non-Conformance Report (NCR) - Team 02 - 02ShahrulNizam100% (1)

- Fogging CompanyDocument15 pagesFogging CompanyShahrulNizam100% (1)

- BODY 1: Biomass Energy Conversion Technologies and ApplicationsDocument5 pagesBODY 1: Biomass Energy Conversion Technologies and ApplicationsHilal AltuntaşNo ratings yet

- Aditya KumarDocument4 pagesAditya KumarAnil B YadavNo ratings yet

- CY6251Document2 pagesCY6251Muthu KrishNo ratings yet

- Non-Consolidating Plugging Material For Wellbore and AnnulusDocument18 pagesNon-Consolidating Plugging Material For Wellbore and AnnulusSLACKENGINEERNo ratings yet

- PerforationDocument45 pagesPerforationCatur Nila Pratiwi75% (4)

- AirbaseDocument48 pagesAirbaseimepsystems100% (1)

- Mahindra QUANTO Repair Manual Part 1 of 4 MAN 00209 Rev 1 PDFDocument145 pagesMahindra QUANTO Repair Manual Part 1 of 4 MAN 00209 Rev 1 PDFS.P ARIMURUGAN83% (6)

- Acid-Catalyzed Preparation of Biodiesel From Waste Vegetable OilDocument3 pagesAcid-Catalyzed Preparation of Biodiesel From Waste Vegetable OilRommelGalvanNo ratings yet

- BFF Manual InglesDocument74 pagesBFF Manual InglesLuisPazPerdomoNo ratings yet

- Fouling Factor TEMADocument2 pagesFouling Factor TEMAIynulF.OmarNo ratings yet

- SRBF8091 ролики 3500Document20 pagesSRBF8091 ролики 3500mohamed hamedNo ratings yet

- Motor Installation and Maintenance ManualDocument23 pagesMotor Installation and Maintenance ManualVenkat CherukuriNo ratings yet

- Fire SafetyDocument37 pagesFire SafetybhaskarNo ratings yet

- 434 4 PDFDocument18 pages434 4 PDFVidaflor Cabada LaraNo ratings yet

- NCJ Oct 2010Document102 pagesNCJ Oct 2010techkasambaNo ratings yet

- De Montfort Mark 9 Incinerator: Summary of CharacteristicsDocument9 pagesDe Montfort Mark 9 Incinerator: Summary of CharacteristicsChathura SrinayakaNo ratings yet

- Scheerer Bearing Oil Industry PDFDocument8 pagesScheerer Bearing Oil Industry PDFcristinelbNo ratings yet

- PDFDocument32 pagesPDFJuan Carlos Cahuasquí IntriagoNo ratings yet

- Taller CombustionDocument1 pageTaller CombustionAlexanderCáceresCalderón100% (1)

- Fuels & Alkanes 4 MSDocument5 pagesFuels & Alkanes 4 MSHayaa KhanNo ratings yet

- Guidelines For Hydraulic Desig of Multiple Pipe Slug CatchersDocument34 pagesGuidelines For Hydraulic Desig of Multiple Pipe Slug CatchersYosmar Guzman75% (4)

- Safety QuestionsDocument6 pagesSafety QuestionsBikas SahaNo ratings yet

- Orkiszewski CorrelationDocument3 pagesOrkiszewski CorrelationLuis Abdul-MelendezNo ratings yet

- Rijal Maulana HaqimDocument8 pagesRijal Maulana HaqimRijal Maulana HaqimNo ratings yet

- Flash and Fire Point TestDocument7 pagesFlash and Fire Point TestAisyah Ibrahim89% (18)

- UNIT 2 Welcome To A Modern Port: The Port of SantanderDocument6 pagesUNIT 2 Welcome To A Modern Port: The Port of SantanderIban Santana HernandezNo ratings yet