Professional Documents

Culture Documents

Qualification Soudeur PDF

Uploaded by

r_racOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qualification Soudeur PDF

Uploaded by

r_racCopyright:

Available Formats

~\..

E TEC1y-\<:

~"'

'".

:i'Q

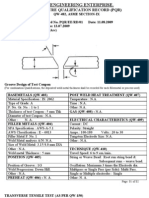

WELDER PERFORMANCE QUALIFICATION (WPQ)

IN ACCORDANCE WlTH ASME SECTION IX

(QW-484)

~o~{>~

-s>'fJ. ~'V

"lXINOU

'" $~~

: B 267 324

CNSS

: 180 192 710

Identification Nr.

B/SB-209 Gr 5083 H22

...::

..

-~

C/DIV/QW/OUH/409/14

GTAW/AL

Specification of base metal

.-., '""'7':"" --

W3006

TEST DESCRIPTION

identification of W PS followed

SCIF *

W elder name : ELAIDI KHADDIOUI

CIN N

Test coupon

Production w eld

4 mm

Thickness

TESTING CONDITIONS AND QUALIFICATION LIMITS

ACTUAL VALUES

RANGE QUALIFIED

Welding process/es

Type (manual, semiautomatic, etc.)

GTAW

Manual

GTAW

Manu al

Backing (metal, weld metal, double welde, etc.) (QW 402)

Without

With or without

Filler metal classification (QW 404)

Plate

PN 25

AS.10

ER 5355

Filler metal (F-Number) (QW 404)

FN 22

Ali FN21 to FN25

NA

NA

WELDING VARIABLES (QW-350)

Plate

Pipe (enter diam.) (QW 403)

Base metal P or S number to P or S Number (QW 403)

Filler metal specification (SFA) (QW 404)

Consumable insert (GTAW, PAW) (QW 404)

Deposit thickness. For each process (QW 404)

lnert gaz backing (GTAW- GMAW)

Transfer mode (Spray/ globular or pulse to short circuit) (GMAW) (QW409)

GTAW : Current type/ polarity (AC, DCEP, DCEN) (QW409)

RESULTS

Visual examination of completed weld (QW-302.4)

SATISFACTORY

D Transverse root and face (QW 462.3a)

D Bend test

Macro test

Type

Maxi 8 mm

1G

GROOVE :Plate and Pipe over

24in : F /Pipe :::24 in: F

F ILLET: F

/

ARCAL21

NA

/

/

lnert qaz

NA

/

D Side (QW 462.2)

1

D Pipe bend specimen, corrosion- resistant overlay

(QW 462.5c)

D Plate bend specimen, corrosion- resistant

overlay (QW 462.5d)

Result

Macro test for fusion

Result

Type

73 mm

PN21 To PN 25

D Longitudinal root and face

(QW 462.3b)

Macro test for fusion

Position qualified (2G, 6G, 3F, etc.) (QW 405)

Vertical progression (uphill or downhill) (QW 405)

Plate and Pioe 0

Nt<

Type

Result

Alternative radiooraohic examination results (QW 191) : C/CND/RT/AMM/294/14 Accepted

Fillet weld - fracture test (QW 180 )

Macro examination (QW 184)

I

1 Fille! size

Lenght and percent of defects

(mm)

1 Concavity I Convexity

Other test

M.TANAGHITE

Film or specimens evaluated by

Mechanical test conducted by

Welding supervised by

M.TANAGHITE

1 Company

- ~-

C.T.T.I

~-~ tJ.._

/,..'l.r .J.

1

~( J,;_

~V,.> ~

~

Test nr

~tl

... 1t:... /

I7~ 1#. - agr

"' ,, "" .1_:;

"'

'1

'ur

<

...

'

,..

- - . . ' ~

.!!::-._~~ _:_

_._,,,

We certify that the statements in this record are correct and that the test coupon were prepared, welded , and tested in accordance with the requirements of

section IX of the ASME Boiler and pressure vessel code.

Company :

Date

SCIF

17/11/2014

Organization

By

C.T.T.I

M.TANAGHITE

- -- -

sc'1F*

WELDER PERFORMANCE QUALIFICATION (WPQ)

IN ACCORDANCE WITH ASME SECTION IX

(QW-484)

~-.

,-:- --

W elder name : TAOUAL AZIZ

GIN N

: B 527 970

CNSS

: 119 846 156

Identification Nr.

W977

C/DIV/QW/OU H/408/14

TEST DESCRIPTION

GMAW/AL

identification of WPS followed

B/SB-209 Gr 5083 H22

Specification of base metal

Test coupon

Production weld

4 mm

Thickness

TESTING CONDITIONS AND QUALIFICATION LIMITS

WELDING VARIABLES (QW-350)

ACTUAL VALUES

RANGE QUALIFIED

GMAW

GMAW

Semi-automatic

Semi-auto matie

Backing (metal, weld metal, double welde, etc.) (QW 402)

W ithout

W ith or without

Plate

Plate and P ipe 0 ~ 73 mm

PN21 To PN25

Filler metal classification (QW 404)

PN25

A5.10

ER 5355

Filler metal (F-Number) (QW 404)

FN22

Ali FN21 to FN25

NA

NA

Deposit thickness. For each process (QW 404)

Position qualified (2G, 6G, 3F, etc.) (QW 405)

1G

Maxi 8 mm

GROOVE :Plate and Pipe over

24in : F /Pipe ~24 in: F

FILLET: F

Welding process/es

Type (manual, semiautomatic, etc.)

Plate

Pipe (enter diam.) (QW 403)

Base metal P or S number to P or S Number (QW 403)

Filler metal specification (SFA) (QW 404)

Consumable insert (GTAW, PAW) (QW 404)

Vertical progression (uphill or downhill) (QW 405)

lnert gaz backing (GTAW- GMAW)

ARCAL21

lnert qaz

NA

NA

Transfer mode (Spray/ globular or pulse to short circuit) (GMAW) (QW409)

GTAW: Current type/ polarity (AC, DCEP, DCEN) (QW409)

RESULTS

Visual examination of completed weld (QW-302.4)

SATISFACTORY

O Transverse root and face (QW 462.3a)

0 Bend test

O Pipe bend specimen, corrosion- resistant overlay

(QW 462.5c)

Macro test

Type

Result

Type

0 Side (QW 462.2)

1

0 Plate bend specimen, corrosion- resistant

overlay (QW 462.5d)

Macro test for fusion

0 Longitudinal root and face

(QW 462.3b)

Macro test for fusion

Result

Nt<

Type

Result

Alternative radiographie examination results (QW 191 ) : C/CND/RT/AMM/294/14 Accepted

Fille! weld - fracture test (QW 180 )

Lenght and percent of defects

Macro examination (QW 184)

Fille! size (mm)

Other test

Film or specimens evaluated by

,,

Mechanical test conducted by

Welding supervised by

M.TANAGHITE

""-

Concavity / Convexity

Company

C.T.T.I

I i'1'..

M.TANAGHITE

"-=

V

We certify that the statements in this record are correct and that the test coupon were prepared, welded, and tested in accordance with the requirements of

section IX of the ASME Boiler and pressure vesse! code.

Company:

Date

SCIF

17/11/2014

Organization

By

C.T.T.1

M.TANAGHITE

Examen Radiographique/Radiographie Examination

Conditions d'cution/ Operating Conditions

lnterpretations de Radiogrammes/ lnterpretation of Radiographs

!LIEU D'EXECUTION I Place of execution: ATELIER SCIF AIN SEBAA

SCIF

EPROUVETTES

REPERE D'IDENTIFICATION I dentification mark :

Before :

AH480

After :

ATELIER SCIF AIN SEBAA

LIEU DE FABRICATION I Fabrication place:

ASME IX ' QW191

Rev:

SOURCE DE RAYONNEMENT : dsignation de l'appareil :

Radiation source: equipment description

QUALIFICATION DES SOUDEURS

Affaire I Job :

TRAITEMENT THERMIQUElheat traitement:

5083 H22

MATIERE I Materia/ :

Etendue de contrle/Control Area

100%

CONDITION D'EXECUTION SUIVANT/Conditions of execution to:

Rayon gamma - IR 192

REQUEST N: I

RAPPORT/ REPORT N: C/CND/RT/AMM/294/14

CLIENT :

Page/Sheet:1/1

Dimentions, foyer ou radiolment:

3.0X3.00mm

Focal spot size

34.84

en Ci

[il ou TBq

Traitement radiogramme/Film processing : Manuel/Manua1[8J Automatique/Automatic

Rx D

1 max: /

mA V max: ................ .

Observations/N~~.~:.............................................................

Caractristiques des films. crans renforateurs, filtres et IQI utiliss - conditions de prises de vue

Characteristics of films intensifvina screens filters ans JQl's- Operatina conditions

::>

Repre pice/Repre soudure

i~

~

Ci

~

Worl<pte marl< I Weld mark

;:::

(ii

w

!i 0 0z "'t::

0

o. (/) ' n.

:::> Ci

z

Sl "'~ (ii

"' w (..) :l><w

zw g

"'w

~ ~~ ~

"'Ci ~

>-

>~

"'

GTAW

D7

1

1

G'riA.w 01 x

.........

0.10

0.10

0.10

......... .........

ASTM

1A

.........

ASTM 1A

0.10

Film

Film

4,0

4,0

(/)

n.

::<

w

"'E

""~

"'"'

8.

dl

>--

4,0 400

.........

......... .......... ...........

4,0

400

12 AUTRE :

--.

INTERPRETATIONS DE RADIOGRAMMES SUIVANT:

lnteroretation of radioaraohs following

....................................................... ~~~~..~~..~.9~~~~

RESULTATS

Results

NAlURt: DES Dt:t-AUTS

Tvoe of defect

Repre lment

examin

OBSERVATIONS

Checked item mark

Remarks

GTAW 1G W3006

..~!~.. .. ~. ........... ...... .

GMAW 1G W977

2,3

~===::: :

r--_

......... ... .... ... ... ..................... ... ... .... .... ........ .. ...... .... ... ......... ........ ::::-::,,,. ~ ................................................ .

r--~-= ..

1---r-- ~-=

.......................................................................

............................................................. .

i---_

......... ................................................................................................. ~-~

Effectuer par

Execute by

M.TANAGHITE

17/11/2014

-- r,

~

I

:}rl1

f!/.

E

agl'

,rt l?T

Approuv par

Aprouved by

Client

Custrner

You might also like

- 4) WQT Certificate For (SPT-02) (4''x8.56)Document1 page4) WQT Certificate For (SPT-02) (4''x8.56)JithuJohnNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- 161 Gmaw Zug Asme (Beni Kantona 3g) WPQDocument2 pages161 Gmaw Zug Asme (Beni Kantona 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Dodsal Pte Ltd Q-Chem Project Doha Qatar Welder QualificationDocument1 pageDodsal Pte Ltd Q-Chem Project Doha Qatar Welder QualificationproxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Loading Unloading Temperature Welding ProgressionDocument5 pagesLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- Dodsal Pte Ltd Q-Chem Project Doha Qatar Welder Qualification TestsDocument1 pageDodsal Pte Ltd Q-Chem Project Doha Qatar Welder Qualification Testsrohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha Qatar Job No 7979 Welder Qualification RecordDocument1 pageDodsal Pte Ltd Q-Chem Project Doha Qatar Job No 7979 Welder Qualification Recordproxywar100% (1)

- DQR Project Quality Control Form for Welder PerformanceDocument1 pageDQR Project Quality Control Form for Welder PerformanceminhnnNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document2 pagesQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document2 pagesQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha Qatar Job No 7979 Welder Qualification RecordDocument1 pageDodsal Pte Ltd Q-Chem Project Doha Qatar Job No 7979 Welder Qualification RecordproxywarNo ratings yet

- Welder Cirt TotalDocument78 pagesWelder Cirt TotalNguyễn ChâuNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document2 pagesQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- WPQ 282Document1 pageWPQ 282proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification RecordDocument1 pageDodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification Recordravi00098No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Emissioni convogliate in atmosfera: Sistemi di monitoraggio in continuo delle emissioni SMEDocument25 pagesEmissioni convogliate in atmosfera: Sistemi di monitoraggio in continuo delle emissioni SMEr_racNo ratings yet

- Emissioni convogliate in atmosfera: Sistemi di monitoraggio in continuo delle emissioni SMEDocument25 pagesEmissioni convogliate in atmosfera: Sistemi di monitoraggio in continuo delle emissioni SMEr_racNo ratings yet

- En 1090Document47 pagesEn 1090Darren Thoon100% (5)

- Conveyor Belt Design and Calculation GuideDocument161 pagesConveyor Belt Design and Calculation Guider_rac91% (11)

- Guide-DIN-EN-12464-1 - 2011Document44 pagesGuide-DIN-EN-12464-1 - 2011carlosmandopinto100% (7)

- Guide-DIN-EN-12464-1 - 2011Document44 pagesGuide-DIN-EN-12464-1 - 2011carlosmandopinto100% (7)

- TERRENA - Resume Non Technique PDFDocument18 pagesTERRENA - Resume Non Technique PDFr_racNo ratings yet

- En 1090Document47 pagesEn 1090Darren Thoon100% (5)

- UT Arabic BookDocument58 pagesUT Arabic BookSana AlzakiNo ratings yet

- Injection Moulding MachineDocument35 pagesInjection Moulding MachineRajesh Kumar88% (8)

- EXPORT POTENTIAL OF STEEL BILLETS AND HOT ROLLED COIL IN MENA AND SOUTH EAST ASIAN REGION at SAIL (Steel Authority of India)Document100 pagesEXPORT POTENTIAL OF STEEL BILLETS AND HOT ROLLED COIL IN MENA AND SOUTH EAST ASIAN REGION at SAIL (Steel Authority of India)haidersyed06No ratings yet

- Inventory Optimization Produces Operational and Cost EfficiencyDocument2 pagesInventory Optimization Produces Operational and Cost EfficiencyfyfyNo ratings yet

- 7 11 JapanDocument27 pages7 11 JapanMuhammad Mazhar HussainNo ratings yet

- Pipe Class & Thickness Guide for ShipbuildingDocument19 pagesPipe Class & Thickness Guide for ShipbuildingfarhanNo ratings yet

- Bucket ElevatorsDocument6 pagesBucket Elevatorskingathur26681No ratings yet

- Hydrogen Plant 2520Location&Layout.Document7 pagesHydrogen Plant 2520Location&Layout.SabyasachiGoswami100% (1)

- Shop floor best practices guideDocument19 pagesShop floor best practices guidesridharchebrolu50% (2)

- FDocument19 pagesFFrans van der MerweNo ratings yet

- Nukote Polyurea Systems: Constructive SolutionsDocument6 pagesNukote Polyurea Systems: Constructive Solutionslilik riyantiNo ratings yet

- OROCADocument6 pagesOROCAMelvin MateoNo ratings yet

- Titanium&Titanium AlloysDocument4 pagesTitanium&Titanium Alloysnike_y2kNo ratings yet

- DB80 Concrete Barrier v8 PDFDocument2 pagesDB80 Concrete Barrier v8 PDFshery3670No ratings yet

- LEI 1 1 e 10 150dpiDocument4 pagesLEI 1 1 e 10 150dpiheart1985No ratings yet

- Piping Isometrics ExplainedDocument16 pagesPiping Isometrics ExplainedDinesh Kumar Jd100% (1)

- Bs Steel CodeDocument14 pagesBs Steel CodeA.K.A. HajiNo ratings yet

- Of RISK MANAGEMENT OIL AND GAS CONSTRUCTION PROJECTS IN NIGERIADocument29 pagesOf RISK MANAGEMENT OIL AND GAS CONSTRUCTION PROJECTS IN NIGERIAPratick TibrewalaNo ratings yet

- Why Dissimilar Metal Welding Is Needed, and How To Select Proper Filler MetalsDocument1 pageWhy Dissimilar Metal Welding Is Needed, and How To Select Proper Filler Metalsnasir1141No ratings yet

- Presented By: Deepti Goyal Devanshu Rajesh Nayandeep Kaur Ridhi PoddarDocument9 pagesPresented By: Deepti Goyal Devanshu Rajesh Nayandeep Kaur Ridhi PoddarsaxenaNo ratings yet

- Kanban: David Chen IMS, University Bordeaux 1Document23 pagesKanban: David Chen IMS, University Bordeaux 1Óscar Eduardo Acevedo AponteNo ratings yet

- Barreras Hormigón in SituDocument4 pagesBarreras Hormigón in SituTuza KutuzaNo ratings yet

- DepartDocument2 pagesDepartansharbalapNo ratings yet

- WM ScenariosDocument6 pagesWM ScenariosVishnu Kumar SNo ratings yet

- Crosby Shackles G-2130 PDFDocument2 pagesCrosby Shackles G-2130 PDFBolarinwaNo ratings yet

- Operational Requirements NCO NCC SPODocument19 pagesOperational Requirements NCO NCC SPOloicfrevilleNo ratings yet

- My life as a human speed bump - struggling without a car after 17 yearsDocument1 pageMy life as a human speed bump - struggling without a car after 17 yearsMaría Ofelia SaundersNo ratings yet

- Kinamatic GEA - 18864 Brochure (GE Catalog)Document6 pagesKinamatic GEA - 18864 Brochure (GE Catalog)Joako TorresNo ratings yet

- Cold Hot Working AnnealingDocument40 pagesCold Hot Working AnnealingNikesh KoliNo ratings yet

- Wire DrawingDocument4 pagesWire DrawingSolomon NgussieNo ratings yet

- 1 3 4 A AirtrafficcontrolDocument4 pages1 3 4 A Airtrafficcontrolapi-254646214No ratings yet