Professional Documents

Culture Documents

1979-Hahn-On Transient Analysis of Fluid-Structure Systems

Uploaded by

Euge CompagnoniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1979-Hahn-On Transient Analysis of Fluid-Structure Systems

Uploaded by

Euge CompagnoniCopyright:

Available Formats

cwtn & s-m Vol. 10. pp. ?a?

-391

@Pa@mmPmLad.,1979. RintcdinGra~Bri&in

ON TRANSIENT ANALYSIS OF FLUID-STRUCTURE SYSTEMS

K.J. BATHEand W. F. HAHN

Department

of

Mechanicai

Engineering,

Massachusetts

(Reck&d

Institute of Technology,

12 May

G&ridge,

MA 02139, U.S.A.

1978)

Ab&aet-Finite

element procedures fur the dynamic analysis of fluid-structure

systems are presented and

evaluated. The fluid is assumed to be inviscid and compressible and is described using an updated &ran@an

formulation. Variable-number-nodes

isopammetric two- and threedimensional

elements with hmtped or consistent

mass idealization are employed in the finite element discretization, and the incremental dynamic equilibrium

equations are solved using explicit or implicit time integration. The solution prucedures are applied to the analysis

of a number of fluid-structure problems including the nonlinear transient analysis of a pipe test.

1. MI11ow%I1oN

The

restricted to two-dimensionalanalysis, and, in general,

acctnatcand efficient transient analysis of fluid- lack versatility with regard to explicit and implicit time

structme problems has during recent years attracted

much research effortjl-51. ~uid-sake

problems need

to be considered in various e~~g

disciplines, and

to a great deal in reactor safety &ll~~ns[l].

In this

paper we consider the response of fluid-structure

systems in which the fluid can be idealized as being

inviscid and compressible, and we focus particukr

attention on the analysis of problems in which the fled

transmits a significant amount of energy in a relatively

short tune duration (such as might occur under accident

conditions).

An obvious approximate procedure to analyze a fluidstructure problem is to perform the complete analysis in

two steps: first, the fluid response is calcukted assuming

that the structure is rigid; and then the suuctuml

response is predicted that is due to the calculated fluid

pressures. In most cases this analysis approach will

Qmbably) yield

a conservative estimate of the structural

deformations. Thus, a drawback of this decouplingof the

fluid and the structural analysis is that a substantial

overdesign may be reached. On the other hand, this

procedure of analysis may yield an unsound design if

significantresonance between the fluid and the structure

OCCWS.

A decoupled analysis of the fluid and the structural

response is somewhat a natural engineering solution,

because, historically, finite difference analysis procedures are employed for analysis of fluid response and

finite element procedures are usedfor structurai analysis.

Ibus, it is natural to employ a finite d~er~~-~~

computer program to perform the fluid analysis and a

finite element program to predict the structural response.

Recog&& the serious deficiency of a decoupled

analysis, emphasis has been directed in recent years

towards the development of solution algorithmsthat can

be employed to directly analyze the coupled response of

fluid-structure systems. In the search for effective solution procedures the versatility and generality of the finite

element method for structural analysis and the close

relationship between tinite difference and finite element

procedures suggest that it be very effective to include

fluid elements in the finite element programs. These

elements can then be directly employed together with

structural elements to model fled-s~ct~e systems. At

present, some solution ~pab~ities are available, but the

programs use only lower-order Auid elements, are

integration and Imped

and consistent mass

~~ns[l].

The objective of this paper is to report on our recent

~vel~~n~

of solution capabilities for fl~-~

interaction problems. in the paper, fnst the Lagmng&

formulation of the inviscid and compressible variabknumber-nodes 3-8 two-dimensional and 4-21 threedimensional isopmametric fluid elements is briefly

summa&d[6]. YItese elements have been implemented

in the computer program ALXNA[71.The elements can

undergo large dkpkcements, they can be employed with

implicit (Newmark or Wilson-f) methods) or explicit

(central difference method) time integration schemes,

and lumped or consistent mass ideal&ions. Next, the

ekments, time integration schemes and modeling considemtions that lead to either a lumped or consistent mass

idea&at& are discussed- F%tally,a near

of demonstrative sampk soh&ns are presented. Here, the analy~sofa~~s~~~kap~~

and kading to ekstic-pkstic structural response is discussed in detail with regard to the finite element modeling and the time integration scheme employed.

IcAuxJLAxsoNoppuRDslNlTxELw(&Ms

The objective in this work was to develop a fluidstructure analysis capability that can be employed in the

analysis of problems in which no gross fluid motion

occurs. For these types of probkms a Lagrangian

fade

is effective. Ihe &rid elements can than be

ern~y~ in ~nju~

with structural elements that

~e~~~~~~~~.~f~~

two basic assumptionshave been used in the formuktion

of the fluid ekments:

1. The fluid is compressible and inviscid.

2. Interaction between mechanical and thermal processes is negligible;thus only the mechanical equations

are needed to describe the fluid response.

Using a I+mngkn formulation, in principle, a total or

updated Lagn&an formulation can be employed, but

considering the numerical operations required for fluid

systems, an updated Lagra&n (U.L.1 formulation is

more effe&e [S].

2.1 ~ntinuu~ mec~nics fo~~at~~

Consider a body of guid undergoing large deformations and assume that the solutions are known at all

383

K. J. BATHE and W. F.

384

discrete time points 0, At, 2At,. . . t. The basic aim of the

formulation is to establish an equation of virtual work

from which the unknown static and kinematic variables

in the con~g~ation at time t + At can be solved. Since

the displacement-basedfinite element procedure shall be

employed for numerical solution, we use the principle of

virtual displacements to express the equilibrium of the

fluid body. In explicit time integration equilibrium is

considered at time t [6]

HAHN

Tablei. UpdatedLagrangian

formulation

of fluid

elements

(1)

whereas in implicit time integration ~~jb~urn is considered at time t + At,

In eqn (1) p is the pressure at time t, de,, is a virtual

variation of the volumetric strain at time t,

&e,r8-$-

(sumoni)

(9

V is the vofume at time t and Se is the external

~~~,~i~~s~

vilWal work

e&t of body, surface and in&al forcesbf. TIN quantities in eqn (2) are defined analogously.

EQuatiolH(1) and (2) contain the any

balance

and cafe

equations used in analytical B&I

mechanics(9]. in addition we also use the constitutive

relation

p =: - a AV/Vi,

(4)

where AV is the total volume change of a being

volume V0 and *a is a variable that my bc pressure

depcdnt. Using eqn (4) we can directly employ eqn (1)

in transient analysis. For static analysis or implicit time

integration we liize

eqn (2) as summa&& in Table I

and obtaint8,9f,

2.2 Fur&e element discmtimtion

Using isoprtpmetric i%titeelement discretization, the

bask assum@ons for an eiement are [S]

where

p is evaluated using eqn (4) and a

is the tangent

fluid bulk modulus.

The linearization used to arrive at eqn (5) introduces

e~inthesolutionwhichmrmybe~ifthittimestcp

is relatively large. In order to reduce solution errors and

in some cases instabilities (see sampk problem 4.4)

equilibrium iterations are used. In this case, we employ

the f~owi~ eq~n

to solve for the incremental

displacements[ 101

.I-W

s

SKA&&e,,dv t+yjj

fw

p66,7&dv

oatp-J~~,,~~-JJ:+~dvJk-JJ

+

I t+AfV(k-1)

k=1,2,...

where

+Au;k

=

l+Arutk-l>+AUI(k)

and eqn (6) reduces to eqn (5) when k = 1.

(6)

x, = 8, hlr5,

i = 1,2,3dependingon

one, two or three& = &zth&uc* dimensionalanalysis,

respectively

N

Aul = &xJhk A&

_

(71

where N is the number of nodes of the element considered, the k are the elemcut interpolationfunctions, and

the %, U: and hu: are the coordinates, displacements

and incrementaldisp&zementsof nodal point k at time t.

~~

the reletioas in eqn (7) into eqns (I) and

(6) and in&d&

the effect of inertia forces, we obtain

the governing tite element equations in explicit time

integration,

M&=R-:F

and in implicit time integration

(8)

On transient analysis of fluid-structuresystems

where the fist iteration,i = 1, corresponds to the solution of eqn (5).

In eqns (8) and (9) we have

M = time independent lumped or consistent mass

matrix

:KL, :K, = linear, nonlinear strain (tangent) stiffness

matrixinthecon8gurationattimef

..

a, +*%= vector of nodal point accelerations in the

contigurationat time t, f + At

Aa = vector of incremental nodal point displacements

R +&R= vector of external loads at time t, t + AI

:F, :I%F= vectorof nodal point forces at time t, t + At

and

the superscript (i) indicates itb iteration.

Table

3. Linear

385

and nonhear straindisplacement transformation matrices

Two-dimawiwtaI

analysis

Watationdispkcement transformation vector:

where

N

I-

x, =

Fh,x ,.

-1

Nonlinear stmindispkccment transformation matrix:

The matrices in eqns (8) and (9) are defined in Table 2

for a single element using the followingnotation:

Ii = displacementtransformationmatrix

HS = surfacedisplacementtransformation

matrix

:V = dilatation-displacement transformation

IIMtliX

:BNL= nonlinear

straindisplacement

formation matrix

+*&+*Af= tractionand body force vectors.

tINIS-

h, . .

5 IS included only in axisymmetric anaIysis

>

Thnx-dimakonal analysis

Diktationdispkcement transformation vector

The displacement transformation matrices and force

vectors are defined as usual[6,IO],and Tabk 3 gives the

matrices 3 and :B,.,a for the two and three dimensional

fluid elements.

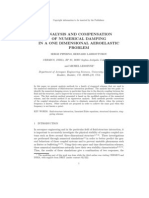

Using the above formulation, the 4-8 and 8-21 variable-number nodes elements (shown in Fig. 1[6]) with

tb.,

0

0

,hu

0

0

. . .

&NJ

lumped or consistent mass assumptions have been imth,3 0 0 ,hu 0 0 . . . ,hNJ

ifiN

=

piemented in ADINA for two- and three-dimensional

h

0

0

h

0

0

. . .

hN3

analysis, respectively. The lumped mass matrix of. an

element is calculated by simpiy allocating l/N times the

total element mass (where N = number of nodes) to the

displacements reduce tbe accuracy of a finite element

nodal degrees of freedom.

We may note that the continuum mechanics equations sohttion. In order to preserve solution accuracy rezoning

of motion (eqns 1 and 2) are valid for general displace- wouldhave to be used whichis not consideredin this study.

ments. However, consideringthe finite element equations

of motion severe mesh distortions that are due to large

2.3 Analysis of pvid finite elewwnts

The variable-number-nodes thiid elements shown in

Fig. 1 are compatible with the solid elements available in

Table 2. Finite ekment matrices

ADINA. This compatiiity is important because higherIntegral

Matrix evaluation

order koparametric solid elements have proven to be

significantlymore effective than lower-order elements in

analysis of problems with sign&ant bending response

and would naturally be employed with high-order fluid

elements. However, to modelthe completefluiddomain

appropriately,the basic characteristicsof the fluid ele,+A,

r+Ar&

=

B=

Iist+A~toda

A&,Su,oda

ments need to be hnown.

I 0.4

0.4

The basic characteristics of a fluid element are displayed by the element eigenvahres and eigenvectors[6].

+

Hf+A;fodn

ov oP+A&5&odv

SOP

Figure2s ummarizs the eigensystemof a Cnode twoI

dimensionalekment..Thefigureshows that, as reported

earlier, using reduced Gauss integration (1 point iniILL8 =

U 1

tegration)for the 4-node elementthe hourglasspatterns

correspondto zero eigenvalues.Various attemptshave

been made to remove the instabilityof the hourglass

deformationmodeswithoutincreasingthe computational

expense signifkantly,but it is believedto be best to use

-P&dv

:F= -p:Vdv

2 x 2 Gauss integration.Indeed, the formulation-consisI

tent removal of the hourglass instability using 2 x 2

K. J. BATHE and W. F. HAHN

D

_A,

II

TYPICAL ELEMENTS

01 TWO-DIYENSIONAL

FLUID

AXlsvYYETRIC

cwDlTIoNS

ELEMENTS

FOR PLANAR

OR

A6:A,'0

IN

I POINT GAUSS

CUAORATURE

(HOURGLASS

MODESI

(01

x/

TYPICAL

bl THIifE~0lYENSIONAl

EIGENVALUES

AND EIGENVECTORS

OF l-NODE

PLANE FLUID ELEMENT, EXACT INTEGRATION

TWO-DIMENSIONAL

ELEMENTS

FLU10 ELEMENTS

(bl

Fig. I. Fluid elements in ADINA.

Fii.

Gauss quadrature is an advantage of a finite element

formulation over a hnite difference anaiysis.

Figure 2 also gives the number of zero eigenvalues of

the&nodetwodimensionaiand8and2O-n&threedimensionalelements. As for the Qnode two-dimensional

element, reduced hUegraM introduces additional zero

eigenvalws that can result in solution instabWies in the

analysis of a fluid-structuresystem.

Of particular interest is the analysis of fluid-Wed

pipes. If the geome&y and loading are axisymmetric,

these thud-structure systems can be mod&d using the

axisymme&ic elements, and the question is whether

higher or lower-order elements should be employed. It is

well-known that in axisymmetric analysis of solids,

hiqher-order isoparonletric elements need be employed

for accurate pruWion of stresses. The same concht!Jion

is reached for the fluid elements. Figure 3 shows the

NUMBER OF ZERO STRAIN ENERGY

(INCLUOING

RIGID BODY ~130~5)

2. Eigcnsyatcms

J.

-~,M+Ps~-&

-- --

two and

elements.

FOR FLUID

threedimensional

SOLID ELEMENTSiRADIAL STRESSI

-4

FLUID

ELEMENTS

IPRESSURE

APPLIED EXTERNAL FflESSURE 2 IW 1 IO PSI

- -

-60

-loot

- - ANALYTICAL SDLUTMll

FINITE ELEMENT SOLIJMWS IEXACT lNTECRAl0N

A-NOOE ELEYENTS MC9EL

6-wODE ELEUENR MOOEL

USEDI

CZOIN-,

Fig. 3. Analysis of axisymmetric

ELEMENTS

fluid

stresses calculated in axisymmetric plane strain fluidsdid models with a varying bulk modulus in the fluid and

compares the results with theoretical values.

The use of higher-order fluid and solid elements in

transient analysis requires that a distinct choice be made

on the use of a lumped or consistent mass idealization.If

Qnode twodimensional elements (and 8-node threedimensionalelements) are employed it is probably most

effective to use a lumped mass model. Not only is the

comprdotional expense less when using a lumped mass

matrix but the similarity between the finite element

equations and the finite difference equations (in some

cases these are the equations used in the method of

characteristics) requires the use of a lumped mass

matrix for best solution accuracy [ 111.On the other hand,

-~,.IIFJPSI

of

MODES

plane strain fluid-structure

model, Cnode vs 6-node elements.

On transient analysis of fluid-structuresystems

387

considering the use of hiier-order elements, a lumped step pressure applied at its free end. Lumped and

mass characterization leads to spurious oscillations that consistent mass idealizations were employed in this

arise because a lumped mass distribution does not analysis, and the objective was to study the accuracy

represent a consistent loadingon the elements. Since it is with which the response of the water column is prethe objective to employ as few higher-order elements as dicted.

possible to model the fhrid-structuredomain, a consistent

Figure 4 shows the calculated longitudinal displacemass idealizationis in most cases desirable.

ments at the free end of the column and compares these

displacements with the analytical solution. It is seen that

3..TB(El?r!EGithTlou

using implicit time integration (Newmark method) the

In ADINA, the centraldiffers methodis employed free-end displacements in the ~nsis~nt mass analysis

in explicit time in~~t~n and the Newmark method or were predicted accurately for a time period that include

the Wdson-6 method can be used in implicit time 6 wave reflections, whereas the lumped mass analysis

integration[6]. Using implicit time integration a lumped results are inaccurate.

or consistent mass matrix can be employed, but in

Ekcause of the simplicity of the problem the method

explicit time integration only a lumped mass idealization of characteristics shows that in this analysis the exact

can be specified. Table 1 in [7] summarizesthe complete solution can be calculated using the central difference

solution algorithm employed.

explicit solution method[ 111.To obtain the exact solution

lbe stability and accuracy characteristics and the the pressure and lumped mass idealizationsmust be such

computational details of using these techniques in linear that the displacements are uniform over the column

analysis have been summarized in 161. Considering cross section aud At = AL&, where c is the wave velogeneral nonlinear analysis the main difficulty is to assure city and AL.is the length of an element.

the stability of a time integration solution. In explicit

time in~~n

the sohttion is simply marched forward, 4.2 Static analysis of an asse~&ge of co~cent~c ftuidand it may be back to identify an insect

that ~~ caged

Five concentric flu~-~l~ cylinders were analyzed for

manifests itself only as a silt

error turn-on

over a few time steps. On the other hand, using an a load applied on a stiff cap. This same problem was

implicit time integration method, in each time step the studied by Munro and Piekarski[12]. Figure 5 shows the

incremental equilibriumequations are solved and equili- finite element model employed and the predicted fluid

brium iterations can be performed on the solution quan- pressures. The finite ekment solution is compared with

tities. These equilibrium iterations arc equivalent to an the approximate analysis results of Munro and Piekarski.

energy balance check and can be very important to

assure a stable and accurate solution (see sample prob- 4.3 Transient analysis of a water-filled copper tube

The dynamic response of a water-filled copper tube

lem 4.4).

subjected to an impact loading was analyzed. The struccsMPLE~oNs

ture, the loading and the finite ekment model employed

The sample analyses presented in this section have are shown in Fig. 6. This problem was also analyzed by

governing

been performed using the computer program ADINA in Walker and P~~i~[l3], who es~blis~

which the fluid elements discussed in this paper have ~cfen~

equations based on a number of ~s~ptions

and solved these equations using the method of characbeen implemented.

teristics.

4.1 Analysis of rigidly-containedwafer column

Two finite element analyses were performed: a lumped

A simple axisymmetric water cohunn idealii using mass and a consistent mass idealization was used. The

&node elements as shown in Fig. 4 was analyzed for a mass allocation employed in the lumped mass analysis is

-05

r

TIME

75

I (SE01 lO-5_9

loo

124

\,I54

175

---!

IO AxISYYYETRlc

FLUID ELEMENTS

I5

200

ANALYTI~L

2&5

SOLUTWN

\

i

NEWMARK

IllWE

lo)

FINITE

ELEMENT

MODEL

STEP

METHGDi

NODES

HALF

OF MA%OF

t 81110-5SECl

PERIPHERAL

NODES1

IMASS OF CENTER

NODES SAME

AG MASS OF P!ZRIPHERAL

NODES

PERlfflERV

DISPLACEMENT IPOINT 81

CENTER DISPLACEUENT

(POINT AI

LUMPED Y=

25 !-

- =-

CO~SISlEN?

-*

ibl

L~GITUDINAL

DISPL~EME~T

- FREE

END

MASS

BSPULWMENT

OF RIGIDLY

CONTAINED

IPOINT A 6 9)

WATER COLUMN

Fig. 4. Longitudinaldisplacementof free end of rigidly contained water column under pressure step load.

388

K. J. BATHE and W. F. HAHN

TOTPL LOAD 2 2 04 I ION

AMRAGE CYLINWR WLL TNtCKlESS JO cm

----

00

-

ANALmcAL sauYwN

FINlIE ELENENT SOLUYNIl

-aosu---------I

CYLINDER RADIUS (cm)

lb)

PRESSURE IN FLUtDS Am, RAVYL

Fig. 5. Static analysis of fluid-f&i

APPLIED LOAD:

( T = 65 pstcl

TGE

0 I_vz

for

for

concentric cylinders.

oitT

tso,t>T

MATERIAL PROPERTIES

TX

(COPPER)

ELASTIC ,MDwLUS:

;;fSY

RATIO:

ELwp (WATER)

BULK MODULUS :

DENSITY :

E = 172 1 IO6 PSI

Y = ,355 _4 sL,6_F,

p, 631:lO

7

I

(01 PROBLEM STATEMENT

31On

193 ELEMENTS)

-----=I

Y+ lb) FINITE ELEMENT MODEL OF FLWD-FILLED TUBE

Fig. 6. Analysis of water-filkd

copper tube.

STRESS IN CWNOERS

Ou

trmsientaaalysisof fluid-stmcturc

systems

shown in Fig. 6. This distributionof mass corresponds to

the assumption used by Walker and Phillips. It should be

noted that a thin layer of elements was used at the tube

wall in order to release the axial displacements of the

fluid.

In both finite ekment analyses the Newmark method

was employed with a time step 1gsec, i.e. 65 time steps

correspond to the pulse length. The length of the elements (axial aeon)

was about l/l~ of the pulse

length. The aspect ratio of the elements was very high

(1:34).

Piis

7 and 8 show the response of the system at

2 = Sin (see Fig. 6) as predicted in this study and by

Walker and Phillips. It is seen that for t < 100ksec the

finite element solutions correspond reasonably well with

the results of Walker and Phillips, but relatively large

solution discrepancies are observed at larger times.

These solution discrepancies are due to the different

assumptions employed in the analyses. Si

no

experimental or exact analytical results are available,

it is difhcult to assess the actuaI accuracy of the different

models. However, consideringthe finite element solution

results it is seen that the consistent mass model predicts

a somewhat smoother response for the hoop strain than

does the lumped mass model and gives also results that

389

compare somewhat better with the response predicted in

1131.

4.4 Nonlinear transient analysis of 0 pipe test

The experience gained in the above analysis was used

to analyze the water-filled straight piping configuration

show in Fe. 9 subjected to a pressure pulse at its end.

The ela&-pla&c response of this pipe was experimentally assessed as mported in 1141.Figure 9 shows

also the finite ekment model employed in the analysis.

in this analysis, a consistent mass matrix was

employed and the time integration was carried out using

the Newmark method. The time step was changed to half

its size at the time the pulse entered the nickel pipe so

that the pulse front would pass thruugh a solid element in

about three time steps. The effective stiffness matrix

used in this analysis was reformed only at time t = 1.905,

2.302,and 3.435msec. However, to take into account the

elastic-plasticresponse of the pipe, ~1~~

iterations

wereusedateactrtimestcponokthepufJeteachedttre

nickel pipe. The ~~t~~

iteratiuns (energy balance

check) were found to be necessary for a stable solution,

although an average of only 1 to 2 iterations per time

step were carried out.

Figure 10 shows the calculated pressures and hoop

NEWMARK METHOD

o HOOP STRAIN lB

x PRESSURE P

----WALKER

8 PHILLIPS

Fig.

7. Responseof water-tilted

coppertubeto halfsinepulseof 65j~secduration.

----WALKER

Fii.

8 PMlIPS

8. Responseof water-t&dcoppertubeto half sinepulseof 65JSCCduration.

K. J. BATHE and W. F. HAHN

390

3-Inch

3-Inch

(al

MATERIAL

IO RIGID

30x(06

ET-TANGENT

MODULUS

Y -POISSONS

RATIO

P, - DENSITY

#o-YlELD

STRESS

NI 200 PIPE

PIPE

STRAIGHT PIPE TEST CONFIGURATION

PROPERTIES

NICKEL 200

E-YOUNGS

MODULUS

FLEXIBLE

2500PST

73.7 110

2000 -

PSI

6.31r;~4~

l2.8~IOSPSI

5

2

g

E

1500,ooo

g

WI\TER

I(- BULK MODULUS

32110

&-DENSITY

9.36 1 IO-) v

PSI

500

OO

IO

20

30

401

TIME IMSECI

lb) PRESSURE PULSE INPUT IN FINITE

40 AXISYMUETRIC

I61 AXISYYMETRIC

(cl

FINITE

ELEMENT

SOLtO ELEMENTS

FLUID ELEMENTS

MODEL

-5

TIME STEP

At

INTEGRATION

ORDER.

i ;;#i,

,,&j; _ ; ;_ ;I$; ;E;

SOLID ELEMENTS.

FLUID ELEMENTS.

313

22

666

956

ELEMENT ANALYSS

NODES

DEGREES OF FREEDOM

EOUlLl6RlUW ITERATION

l?2092YSEC

FOR

EVERY STEP

STIFFNESS REFORMED AT RESTARTS ONLY

(I e , t = I 905, 2.3Q2, and 3.435 YSECI

P AT VARIOUS AXIAL LOCATIONS OfTAlNE

BY AVERAGING PRESSURES AT INTEGRATION POINTS

ADJACENT ELEMENTS (e.g. P4 2f Pa, l PR 112 WHERE P4 IS THE PRESSURE AT 1.5 IN. INlD NICKEL PIPE)

H P TRAIN t

IN THE NICKEL RPE AT VARIOUS AXIAL LOCATIONS OBTAINED BY E : u/r WHERE

RA IAL DISPLACEMENT OF A MIDSIDE NODE AND r IS THE INITIAL RADI$L LOCATION

+d-TrI

OF THE HIDSIDE NODE k.p&

: I?YI.5325 HOOP STRAIN I.5 IN INTO NICKEL PIPE)

PRESSURE

LOAO APPLIED

TO NODES

I AND

CONSISTENT

Fig. 9. Finite element model of straight

strains at various locations along the pipe as a function

of time and compares the ADfNA results with the

experimental data. It is noted that in general the calculated response compares well with the experimentally

observed response.

5. CB

The transient analysis of fluid-structure systems

presents a great deal of diflkulties because an appropriate @Mural and fluid representation together

with effective numerical procedures must be employed.

In this paper, the fluid is assumed to be inviscid and

compressible, an updated Lagangian formulation is used

to describe the fluid motion, isoparametric finite element

discretization is employed with lumped or consistent

mass idealizations and the incremental equilibrium equa-

MASS

NEWYARK lNTEGRATlQ&

SMALL DISPLACEMENTS

pipe test.

tions are solved using explicit or implicit time integration. The solution capabilities have been implemented in the ADINA computer program, and the solution

results of various sampie analyses are presented.

The study performed here indicates that higher-order

isoparamatric finite elements can be effective in the

representation of the fluid. Depending on the discretization used, the elements may have to be employed

with a consistent mass idealization and implicit time

integration.

Considering nonlinear analysis, it can be important

that equilibrium iterations be performed in order to

prevent sohuion instability. In some analyses only very

few iterations are needed to greatly improve the solution

accuracy (see Section 4.4).

Since there does not exist a single analysis approach

On transient analysis of fluid-structuresystems

200-

- *Mw*

....EXPCRlYtNlAl

- AWI

so-

....

EXPERWWIIL

6070 -

175 -

I.1 PIT1Al I2 IN fNw UICKELAK IP31

tbl

PITI AT I5 IN INTONICKEL PIPE fP.1

PI11 A7 60 IN INTO NlCltL PFf

Ill

STRAIN Al 6 IN INTO WXL

Ml

LOINA

....fXPENlufNlAL

ICI

IONI

-.*. EIPEAWNTAL

TIME IMSEC)

Q6 c

TINE IwCl

TIM2 IYSECl

I41 PI11 AT Y IN INTO W46L 8% Ml

Fig. IO. Puke

I@1 S7RAIN IT 15 IN INlD NlCX2L PWf

RPL

propagation

in waterl&d straight

pipesystem.

that is always most eiktive for the analysis of fluids@uctureproblems,it is deemedbest at this timeto have

versatilec43mpuWional

capabilitiesavailable.ibis way,

differentfiniteelementdiscretizations,massidealizations

and time integrationprocedurescan be chosen for an

effective soiution to a particuhrproblem.In this paper

much emphasishas been placed on the use of higherorder isoparamehc finite ehents, consistent mass

idealizationand implicit time integration.However, it

need be noted that these techniqueshave been employed

primarilyin twodimensional analysis and can be prohibitively expensive in ~~~nsio~

response Calculations.

Achowkedgements-The work reported in this paper ba.s been

sgported hncially by tbe Nuclear Regulatory Commission

contract No. AT(49-24)-0366and the ADINA users group. We

would like to acknowl~ gratefully this support.

T. Beiytscbko, Methods and pwgramsfor analysisof fluid-

stnichue systems. 3. Nvcicor J%gng and &sign 42, 41-52

(1977).

T. &1ytscbko, Traasient Analy&, Stractaraf basics

Comprun Progrants (Edited by W. Pilkey et al.), pp. 255275.university Press of Virginia(1974).

1. hf. Kennedy xnd T. Belytscbko, Ettergy source and fluid

representation in a strucnval response code-STRAW.

Argonne Natl Lab. Rep. ANL-8140(May 1975).

U. W. Cbang and 1. Gvildys. REXCGHEP: A twodiinsional computer c4Mefor calculating the primary system

infast reactom. ArgotmeNxtl Lxb. Rep. ANL-7519(Justel9?5).

5. R. Hofnutm, SIEALTH, A Lquqian

expli

finite

difference code for sol&, stru&ual and thermohydraulii

analysis. EJsctric Power Res. II&. Vol. l-4, Palo Alto,

Cxlifomis~(June 1976).

6. K. J. Bathe and E. L. Wilson, Nnmerical Methods in Rnitc

Elmtml Analysis. Prentice-Hall, Ehgkwood Cliffs, New

Jersey (1976).

I. K. J. Bube, ADINA-Af&e ekmeat pogun for automxtk

dynmaici neremental nonlinear analysis. AcoMics and

Vii

Lab., uep. 82448.1, Dcp8rwMt of I&&u&al

Et@ae&g, M.LT.(Sept. 19fS.revised May 1977).

8. ~J.~,~~rn~E.~~,~~e~t

otmuhth for large off

d~ic

anrdysis. kt. 1.

ikn. l&h. Eugng 9 353-386(1975).

9. L E Malvem Intro&ion to the Mechanics of a Conrinuens Medium. Prentice-Hall, Englewood Cliffs, New Jersey

(1969).

10. K. J. Batbe, Static and dynamic ~metric and material

nonlinear at@ysis uaiql ADINA. Acoustics and Vibration

Lab., Rep. 82448-2,Dept.of MechanicalEngng, M.I.T. (May

1976,revised hixy 1977).

11. S. H. hadxll, EngineetingAnalysis-A .Suvey of Numerical

Pmcedms. hkGraw-Hill, New York (1956).

12. kl. Mtmro and K. Pi&a&i, Struhduced radial pressure

grxdknts in ~-~~

multiple concentric cyliirs. i.

App. Mech. 44Q) 218-221(1977).

13. J. S. Walker sad J. W. Phillips, Pulse propagation in fluidfilled tubes. J. Appt. Me& 44(l), 31-3s (1977).

14. C. M. Room&r, D. J. Caglhstro and A. L. Plorence,

Expehents on the response of fkxii piph systems to

intannl pressure pulses. SRI Prujec~ PVD-1960, Stanford

ResearchInsthe, Menlo Park, California (April 1976).

respond

You might also like

- Bathe (1975) - FE Formulations For Large Deformation Dynamic AnalysisDocument34 pagesBathe (1975) - FE Formulations For Large Deformation Dynamic AnalysisFrancesco SturlaNo ratings yet

- Material-Balance-Time During Linear and Radial Flow: Petroleum SocietyDocument16 pagesMaterial-Balance-Time During Linear and Radial Flow: Petroleum SocietyAmr HegazyNo ratings yet

- Advanced Fluid Mechanics: Lecture Notes Module-IVDocument20 pagesAdvanced Fluid Mechanics: Lecture Notes Module-IVMikeNo ratings yet

- Flash Calculation Stability PDFDocument12 pagesFlash Calculation Stability PDFAndre BecNo ratings yet

- MM302 6 Lecture Notes (Dimensional Analysis) PDFDocument17 pagesMM302 6 Lecture Notes (Dimensional Analysis) PDFdragons123x100% (1)

- N-S Equations: Deriving Pressure Poisson EquationDocument3 pagesN-S Equations: Deriving Pressure Poisson EquationSaumya SinhaNo ratings yet

- Issa 1986Document17 pagesIssa 1986andersson benito herreraNo ratings yet

- Steady State Stokes Flow Interpolation For Fluid Control: TMPS03 MTPS04Document4 pagesSteady State Stokes Flow Interpolation For Fluid Control: TMPS03 MTPS04kevin ostos julcaNo ratings yet

- The Current Finite To Fluid: On State of and Structures CouplingDocument12 pagesThe Current Finite To Fluid: On State of and Structures CouplingonderaliNo ratings yet

- Applied Mathematics and MechanicsDocument10 pagesApplied Mathematics and Mechanicsinam vfNo ratings yet

- Spe 140556 MS PDocument13 pagesSpe 140556 MS PelmacanonprietoNo ratings yet

- Voskov2017 (OBL Isotermico. Add No Referencial Teorico)Document30 pagesVoskov2017 (OBL Isotermico. Add No Referencial Teorico)Igor LacerdaNo ratings yet

- Pseudotime Calculation in Low Permeability Gas ReservoirsDocument9 pagesPseudotime Calculation in Low Permeability Gas ReservoirsJorge Leopoldo VeraNo ratings yet

- Multi Scale Mixed Finite Element Modeling of Coupled Wellbore Near-Well FlowDocument9 pagesMulti Scale Mixed Finite Element Modeling of Coupled Wellbore Near-Well Flowpetar_damyanovNo ratings yet

- An Introduction To Fluid-Structure Interaction: Application To The Piston ProblemDocument21 pagesAn Introduction To Fluid-Structure Interaction: Application To The Piston Problemsudhindra_sudhiNo ratings yet

- Time-Averaged Governing Equations For Turbulence: From Thermal-FluidspediaDocument5 pagesTime-Averaged Governing Equations For Turbulence: From Thermal-FluidspediaAnand JaiswalNo ratings yet

- Computation of Hydration Free Energies A Parameterized Continuum Model: Equilibrium Geometries and Reactive Processes Water SolutionDocument8 pagesComputation of Hydration Free Energies A Parameterized Continuum Model: Equilibrium Geometries and Reactive Processes Water SolutionLata DeshmukhNo ratings yet

- Finite Element Analysis of Navier-Stokes EquationsDocument28 pagesFinite Element Analysis of Navier-Stokes EquationsSatyen RamaniNo ratings yet

- The Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenDocument21 pagesThe Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Fluid Structure Interaction Based Upon A Stabilied (ALE) Finite Element MethodDocument20 pagesFluid Structure Interaction Based Upon A Stabilied (ALE) Finite Element MethodBella Tran100% (1)

- Ship Vessel ABAQUSDocument12 pagesShip Vessel ABAQUSamir_siddiq0% (1)

- A Space-Time Coupled P-Version Least Squares Finite Element Formulation For Unsteady Two-Dimensional Navier-Stokes EquationsDocument26 pagesA Space-Time Coupled P-Version Least Squares Finite Element Formulation For Unsteady Two-Dimensional Navier-Stokes EquationsMateus Costa PinheiroNo ratings yet

- Galerkin EFGM Method Computational MechanicsDocument9 pagesGalerkin EFGM Method Computational MechanicsMohit PantNo ratings yet

- Dimensional Analysis - P..1Document45 pagesDimensional Analysis - P..1Ali Shehryar100% (1)

- PMS Experiment 1-Gravity Flow TankDocument17 pagesPMS Experiment 1-Gravity Flow Tank815 PAVANNo ratings yet

- Aeroelasticity Calculations Using Finite Element MethodDocument7 pagesAeroelasticity Calculations Using Finite Element Methodr1733No ratings yet

- International Journal of C Numerical Analysis and Modeling Computing and InformationDocument15 pagesInternational Journal of C Numerical Analysis and Modeling Computing and InformationUrmi AkterNo ratings yet

- Analysis of Flow of Viscous Fluids by The Finite-Element MethodDocument10 pagesAnalysis of Flow of Viscous Fluids by The Finite-Element MethodPeri Pitriadi CaralozNo ratings yet

- Rate Based Vs Equilibrium ModelDocument12 pagesRate Based Vs Equilibrium Modelzorro21072107No ratings yet

- 10.1515 - Pac 2016 1107Document47 pages10.1515 - Pac 2016 1107MajidJgrNo ratings yet

- Transiant Analysis of Dam-Reservoir Interaction: A.H. Akhaveissy and M. MalekshahiDocument5 pagesTransiant Analysis of Dam-Reservoir Interaction: A.H. Akhaveissy and M. MalekshahiengineersruleNo ratings yet

- Optimization of A Static Mixing Device Using The Continuous Adjoint To A Two-Phase Mixing ModelDocument22 pagesOptimization of A Static Mixing Device Using The Continuous Adjoint To A Two-Phase Mixing ModelMichael MedinaNo ratings yet

- A Computational Model For Suspended Large Rigid Bodies in 3D Unsteady Viscous Flows XiaoDocument32 pagesA Computational Model For Suspended Large Rigid Bodies in 3D Unsteady Viscous Flows XiaowatersakanaNo ratings yet

- ATOMIZAÇÃO phd8Document9 pagesATOMIZAÇÃO phd8eustaccoNo ratings yet

- KK Sir 8Document7 pagesKK Sir 8harshalsparksNo ratings yet

- Modelling evaporation from a capillaryDocument36 pagesModelling evaporation from a capillaryDiego JesusNo ratings yet

- Role of Reservoir Geomechanics N The Integrity of Oil Wells - Part I IDocument8 pagesRole of Reservoir Geomechanics N The Integrity of Oil Wells - Part I IAbo Hanif Al EmranNo ratings yet

- Water 10 01652 PDFDocument19 pagesWater 10 01652 PDFArun GangwarNo ratings yet

- Numerical Simulation of Single Phase Flow With Eulerian ModelDocument3 pagesNumerical Simulation of Single Phase Flow With Eulerian ModelBeatriz BarbozaNo ratings yet

- GEC223 - FLUID MECHANICS IDocument8 pagesGEC223 - FLUID MECHANICS IdoghorNo ratings yet

- Methods For FluidsDocument37 pagesMethods For FluidsPau L. RiquelmeNo ratings yet

- Dimensional AnalysisDocument42 pagesDimensional Analysismyint myat zawNo ratings yet

- Analysis and CompensationDocument25 pagesAnalysis and Compensationshaho1946No ratings yet

- Investigation of Hydrodynamic Effects On Linear and NonlinearDocument12 pagesInvestigation of Hydrodynamic Effects On Linear and NonlinearDanielRoblesTorresNo ratings yet

- Computer Methods in Chemical EngineeringDocument247 pagesComputer Methods in Chemical Engineeringkris010100% (1)

- Dynamic Numerical Simulation of Gas-Liquid Two-Phase Flows Euler/Euler Versus Euler/LagrangeDocument16 pagesDynamic Numerical Simulation of Gas-Liquid Two-Phase Flows Euler/Euler Versus Euler/Lagrangeamin_zargaranNo ratings yet

- Wave Plan MethodDocument43 pagesWave Plan Methodchu42100% (1)

- Spe 79709 Pa P PDFDocument9 pagesSpe 79709 Pa P PDFtomk2220No ratings yet

- Modal Time History AnalysisDocument14 pagesModal Time History AnalysisGraham Roberts100% (1)

- A Nonlinear Test Case For The Finite Element Method in Two-Phase FlowDocument5 pagesA Nonlinear Test Case For The Finite Element Method in Two-Phase FlowchrissbansNo ratings yet

- Numerical Solution of Flood Routing Model Using Finite Volume MethodsDocument9 pagesNumerical Solution of Flood Routing Model Using Finite Volume MethodsBoris GreenNo ratings yet

- Research ArticleDocument10 pagesResearch ArticleMuhammed Ali CangürNo ratings yet

- Numerical Solu Tio 00 S NidDocument112 pagesNumerical Solu Tio 00 S Nidmanuelperezz25No ratings yet

- A Review On The Numerical Inversion Methods of Relative Permeability CurvesDocument6 pagesA Review On The Numerical Inversion Methods of Relative Permeability Curvesjsotofmet4918No ratings yet

- ZYSW15Document18 pagesZYSW15Juasadf IesafNo ratings yet

- Numerical Modeling Approach of An Air-Launched AUV Initially Impacting On WaterDocument5 pagesNumerical Modeling Approach of An Air-Launched AUV Initially Impacting On Watermaitoravi78No ratings yet

- Computational Methods for Nonlinear Dynamical Systems: Theory and Applications in Aerospace EngineeringFrom EverandComputational Methods for Nonlinear Dynamical Systems: Theory and Applications in Aerospace EngineeringNo ratings yet

- Factorization of Boundary Value Problems Using the Invariant Embedding MethodFrom EverandFactorization of Boundary Value Problems Using the Invariant Embedding MethodNo ratings yet

- Stochastic Methods for Flow in Porous Media: Coping with UncertaintiesFrom EverandStochastic Methods for Flow in Porous Media: Coping with UncertaintiesNo ratings yet

- Stochastic Dynamics. Modeling Solute Transport in Porous MediaFrom EverandStochastic Dynamics. Modeling Solute Transport in Porous MediaNo ratings yet

- C Impcpc 9929577 20200623 1814221 1302751752000000 20200623 PDFDocument1 pageC Impcpc 9929577 20200623 1814221 1302751752000000 20200623 PDFEuge CompagnoniNo ratings yet

- C.S. Tsai Et All-Experimental Study For Multiple FPSDocument12 pagesC.S. Tsai Et All-Experimental Study For Multiple FPSLevente SikoNo ratings yet

- Dynamic Pressures on Accelerated Fluid ContainersDocument22 pagesDynamic Pressures on Accelerated Fluid ContainersEuge CompagnoniNo ratings yet

- Fmatter PDFDocument11 pagesFmatter PDFEuge CompagnoniNo ratings yet

- Hous NerDocument296 pagesHous NerEuge CompagnoniNo ratings yet

- WCE2012 pp1716-1721 PDFDocument6 pagesWCE2012 pp1716-1721 PDFEuge CompagnoniNo ratings yet

- Fmatter PDFDocument11 pagesFmatter PDFEuge CompagnoniNo ratings yet

- T-1981-Kumar-studies of Dynamic and Static Response of Cylindrical Liquid-Storage TanksDocument196 pagesT-1981-Kumar-studies of Dynamic and Static Response of Cylindrical Liquid-Storage TanksEuge CompagnoniNo ratings yet

- 1951-Jacobsen-Hydrodynamic Experiments With Rigid Cylindrical Tanks Subjected To Transient MontionsDocument34 pages1951-Jacobsen-Hydrodynamic Experiments With Rigid Cylindrical Tanks Subjected To Transient MontionsEuge CompagnoniNo ratings yet

- 1934-HOSKINS-Water Pressure in A Tank Caused by A Simulated EarthquakeDocument32 pages1934-HOSKINS-Water Pressure in A Tank Caused by A Simulated EarthquakeEuge Compagnoni100% (1)

- Case StudyDocument2 pagesCase StudyBunga Larangan73% (11)

- Malware Reverse Engineering Part 1 Static AnalysisDocument27 pagesMalware Reverse Engineering Part 1 Static AnalysisBik AshNo ratings yet

- Kami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Document3 pagesKami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Anna HattenNo ratings yet

- DIN Flange Dimensions PDFDocument1 pageDIN Flange Dimensions PDFrasel.sheikh5000158No ratings yet

- S5-42 DatasheetDocument2 pagesS5-42 Datasheetchillin_in_bots100% (1)

- Pre Job Hazard Analysis (PJHADocument2 pagesPre Job Hazard Analysis (PJHAjumaliNo ratings yet

- Experiences from OJT ImmersionDocument3 pagesExperiences from OJT ImmersionTrisha Camille OrtegaNo ratings yet

- CAS-GEC04 Module11 Food-SecurityDocument6 pagesCAS-GEC04 Module11 Food-SecurityPermalino Borja Rose AnneNo ratings yet

- Decision Maths 1 AlgorithmsDocument7 pagesDecision Maths 1 AlgorithmsNurul HafiqahNo ratings yet

- Yellowstone Food WebDocument4 pagesYellowstone Food WebAmsyidi AsmidaNo ratings yet

- Survey Course OverviewDocument3 pagesSurvey Course OverviewAnil MarsaniNo ratings yet

- Portfolio Artifact Entry Form - Ostp Standard 3Document1 pagePortfolio Artifact Entry Form - Ostp Standard 3api-253007574No ratings yet

- Last Clean ExceptionDocument24 pagesLast Clean Exceptionbeom choiNo ratings yet

- JurnalDocument9 pagesJurnalClarisa Noveria Erika PutriNo ratings yet

- Modified Syllabus of Control SystemDocument2 pagesModified Syllabus of Control SystemDigambar PatilNo ratings yet

- To Introduce BgjgjgmyselfDocument2 pagesTo Introduce Bgjgjgmyselflikith333No ratings yet

- M8-2 - Train The Estimation ModelDocument10 pagesM8-2 - Train The Estimation ModelJuan MolinaNo ratings yet

- Obstetrical Hemorrhage: Reynold John D. ValenciaDocument82 pagesObstetrical Hemorrhage: Reynold John D. ValenciaReynold John ValenciaNo ratings yet

- Insider Threat ManagementDocument48 pagesInsider Threat ManagementPatricia LehmanNo ratings yet

- HCW22 PDFDocument4 pagesHCW22 PDFJerryPNo ratings yet

- Do You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Document1 pageDo You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Mary Rose BaluranNo ratings yet

- BPL Millipacs 2mm Hardmetrics RarDocument3 pagesBPL Millipacs 2mm Hardmetrics RarGunter BragaNo ratings yet

- En dx300lc 5 Brochure PDFDocument24 pagesEn dx300lc 5 Brochure PDFsaroniNo ratings yet

- CMC Ready ReckonerxlsxDocument3 pagesCMC Ready ReckonerxlsxShalaniNo ratings yet

- Google Dorks For PentestingDocument11 pagesGoogle Dorks For PentestingClara Elizabeth Ochoa VicenteNo ratings yet

- Bank NIFTY Components and WeightageDocument2 pagesBank NIFTY Components and WeightageUptrend0% (2)

- Resume of Deliagonzalez34 - 1Document2 pagesResume of Deliagonzalez34 - 1api-24443855No ratings yet

- Electronics Ecommerce Website: 1) Background/ Problem StatementDocument7 pagesElectronics Ecommerce Website: 1) Background/ Problem StatementdesalegnNo ratings yet

- ABP - IO Implementing - Domain - Driven - DesignDocument109 pagesABP - IO Implementing - Domain - Driven - DesignddoruNo ratings yet

- Column Array Loudspeaker: Product HighlightsDocument2 pagesColumn Array Loudspeaker: Product HighlightsTricolor GameplayNo ratings yet