Professional Documents

Culture Documents

Fabrication Equipment Ppe 1

Uploaded by

Oladimeji Taiwo0 ratings0% found this document useful (0 votes)

51 views2 pagesThis document describes the fabrication process, associated hazards and controls

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes the fabrication process, associated hazards and controls

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

51 views2 pagesFabrication Equipment Ppe 1

Uploaded by

Oladimeji TaiwoThis document describes the fabrication process, associated hazards and controls

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

INTRODUCTION TO FABRICATION EQUIPMENT

Metal fabrication is the building of metal structures by cutting, bending,

rolling, assembling process:

There are various equipment used in the shop floor for fabrications. They are

cutting machine, bending machines, welding machine, grinding machine etc.

Cutting is done by sawing, shearing or chiseling (all with manual and

powered variants), tourching with hand-held tourches (such as one-fuel

tourches or plasma tourches), and via numerical control (CNC) cutters.

Bending is done by hammering (Manual or powered) or via press brakes and

similar tools. Modern metal fabrications utilize press brakes.

Introduction to various structural steel section and sheet mater.

Today, the company is producing steel products from simple lorry bodies to

more sophisticated structures for industrial building and factories and

agricultural equipments, using inputs as steel flat sheets (i.e 30m, 25m,

20m, 6m, etc.) steel sections ( I beam, H-beam, U-channel etc) and other

components.

Welding work

Welding is a process for joining metals by melting and fusing the base metals

being joined and the filler metal applied.

Welding process

The welding process that is common in ARMECO include;

Shielded metal Arc welding (SMAW) also called manual metal Arc or

stick welding.

Oxy-acetylene welding

Submerged Arc welding (SAW)

Gas Metal Arc Welding (GMAW)

Gas Tungsten Arc Welding (GTAW)

Joints type

Edge joint

Tee joint

Butt joint

Lap joint

Corner joint

Welding positions

- Flat position

Horizontal position

Vertical position

Overhead position

Health, Safety & Environment (HSE) Policy

ARMECO believes that good HSE performance is an integral part of efficient

and profitable business management and therefore committed to executing

its activities to ensure safe and healthy working environment for all

employees and the safety of persons living in the vicinity of the installation.

The companys goal of no major incident in every project will be achieved by

maintaining proactive HSE programs designed to prevent Accidents and

Incidents. To achieve this, ARMECO is guided by the following principles;

- HSE is of equal importance as other business activities

- No activity shall be carried out unless considered safe

- Safeguard the health and safety of all employees, contractors and third

parties

- Minimize the impact of activities on the environment.

- Maintain good relationship with host communities and all stakeholders.

- Enhance security of life and equipment

- Belief that Every job could be safely done

- Effective communication of HSE requirements and results to all

stakeholders

- Compliance with all relevant HSE legislations and requirements.

Continual improvement of the HSE system

Some Control Measures

Follow work instructions/procedures ask, if in doubt

Recognize hazards in the work place

Ensure proper housed keeping keep away flammable materials, clear

rights of way

Report malfunctioning equipment promptly

Keep your head away from fumes during welding

Properly maintained fire extinguishers

Wear appropriate personal protective equipment (PPE) correctly

Active supervision by the supervisors

Above all, top management support needed to provide safe working

environment.

You might also like

- 1 IntroductionDocument9 pages1 IntroductionOladimeji TaiwoNo ratings yet

- Mandatory RequirementsDocument1 pageMandatory RequirementsOladimeji TaiwoNo ratings yet

- Wps Pqrwelding SCSP COUPON Phpapp02Document14 pagesWps Pqrwelding SCSP COUPON Phpapp02Oladimeji TaiwoNo ratings yet

- Lime Manual PDFDocument60 pagesLime Manual PDFKenny RuizNo ratings yet

- Nigerian Content WorkshopDocument2 pagesNigerian Content WorkshopOladimeji TaiwoNo ratings yet

- Drum 10d51 Nozzles DimDocument1 pageDrum 10d51 Nozzles DimOladimeji TaiwoNo ratings yet

- Customer Satisfaction MonitorDocument1 pageCustomer Satisfaction MonitorOladimeji TaiwoNo ratings yet

- Benchmark ArticleDocument38 pagesBenchmark ArticleMd.Tarik ChowdhuryNo ratings yet

- Diamension Check Listaa 2011Document4 pagesDiamension Check Listaa 2011Oladimeji TaiwoNo ratings yet

- BoQ External Networks DEG REV1bDocument7 pagesBoQ External Networks DEG REV1bOladimeji TaiwoNo ratings yet

- Schedule of Delivery 5000 Ltrs Double Skin TanksDocument1 pageSchedule of Delivery 5000 Ltrs Double Skin TanksOladimeji TaiwoNo ratings yet

- Solar Point - WolabDocument16 pagesSolar Point - WolabOladimeji TaiwoNo ratings yet

- CEL-200 Series: Full Compliance, Great Value Sound Level MetersDocument2 pagesCEL-200 Series: Full Compliance, Great Value Sound Level MetersOladimeji TaiwoNo ratings yet

- Follow Up of Engine Oil ToppingDocument1 pageFollow Up of Engine Oil ToppingOladimeji TaiwoNo ratings yet

- QA/QC Job Cards ChecklistDocument2 pagesQA/QC Job Cards ChecklistOladimeji TaiwoNo ratings yet

- Cygnus Underwater Iss 7Document4 pagesCygnus Underwater Iss 7Oladimeji TaiwoNo ratings yet

- Conference BrochureDocument14 pagesConference BrochureOladimeji TaiwoNo ratings yet

- Audit Related ConcernsDocument11 pagesAudit Related ConcernsOladimeji TaiwoNo ratings yet

- MA UFM3030EEX e 72 0803Document48 pagesMA UFM3030EEX e 72 0803Oladimeji TaiwoNo ratings yet

- Quotation For Ppe Quantum Risk - AremcoDocument1 pageQuotation For Ppe Quantum Risk - AremcoOladimeji TaiwoNo ratings yet

- Corrosion ReportDocument29 pagesCorrosion ReportOladimeji TaiwoNo ratings yet

- Welding Face Shield Jw001Document2 pagesWelding Face Shield Jw001Oladimeji TaiwoNo ratings yet

- AutoEI Exco Minute 2016 AprilDocument2 pagesAutoEI Exco Minute 2016 AprilOladimeji TaiwoNo ratings yet

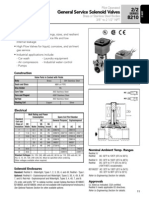

- General Service Solenoid Valves SpecificationsDocument6 pagesGeneral Service Solenoid Valves SpecificationsRicardo RodrigoNo ratings yet

- AutoEI Exco Minute 2016 JulyDocument2 pagesAutoEI Exco Minute 2016 JulyOladimeji TaiwoNo ratings yet

- NSE Kaduna Nigerian Content Committee Meeting MinutesDocument3 pagesNSE Kaduna Nigerian Content Committee Meeting MinutesOladimeji TaiwoNo ratings yet

- AutoEI September 2015 Minutes of General MeetingDocument3 pagesAutoEI September 2015 Minutes of General MeetingOladimeji TaiwoNo ratings yet

- Table of Contents For Strategic PlanDocument1 pageTable of Contents For Strategic PlanOladimeji TaiwoNo ratings yet

- NSE Kaduna Branch Nigerian Content Committee MinutesDocument4 pagesNSE Kaduna Branch Nigerian Content Committee MinutesOladimeji TaiwoNo ratings yet

- Material Input For Steel Mould Extension: 1 PlatesDocument1 pageMaterial Input For Steel Mould Extension: 1 PlatesOladimeji TaiwoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Compact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetDocument4 pagesCompact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetLê ĐạtNo ratings yet

- Butonal NS 175 TDSDocument2 pagesButonal NS 175 TDSPT. PITAGORAS KONSULTANNo ratings yet

- Cap Dev Dimalinao 2023-2027Document4 pagesCap Dev Dimalinao 2023-2027CA T HeNo ratings yet

- Chemical Equation CalculationsDocument6 pagesChemical Equation CalculationsHera RiegoNo ratings yet

- List of Job Specific Safety PPE Used On Site.Document2 pagesList of Job Specific Safety PPE Used On Site.Aejaz MujawarNo ratings yet

- 2008 Annual Debt StatementDocument12 pages2008 Annual Debt StatementEwing Township, NJNo ratings yet

- Everything You Need to Know About Gas Metal Arc Welding (GMAWDocument31 pagesEverything You Need to Know About Gas Metal Arc Welding (GMAWAhmetDuranCeyhanNo ratings yet

- English Based On Latest PatternDocument13 pagesEnglish Based On Latest PatternAtish ToppoNo ratings yet

- 20190904020842HI Kobelco Tier 4 Final SK140SRL BrochureDocument2 pages20190904020842HI Kobelco Tier 4 Final SK140SRL BrochureAkhmad SebehNo ratings yet

- Process Industry Practices Structural: PIP STC01015 Structural Design CriteriaDocument16 pagesProcess Industry Practices Structural: PIP STC01015 Structural Design CriteriaHarjasa AdhiNo ratings yet

- DC72D MK2 Genset Controller User Manual V1.5Document61 pagesDC72D MK2 Genset Controller User Manual V1.5Cristobal AvecillaNo ratings yet

- ITC's diverse businesses: cigarettes, packaging, hotels, paperboards, stationery, matches, incense sticks, retail, food, exportsDocument1 pageITC's diverse businesses: cigarettes, packaging, hotels, paperboards, stationery, matches, incense sticks, retail, food, exportsShashank JainNo ratings yet

- 1 s2.0 S0149763418301957 MainDocument24 pages1 s2.0 S0149763418301957 MainjackNo ratings yet

- The Dukan Diet by Dr. Pierre Dukan - ExcerptDocument8 pagesThe Dukan Diet by Dr. Pierre Dukan - ExcerptCrown Publishing Group15% (20)

- Prof. J.L. HumarOffice: HP 3051Phone: 613-520-2600 ext. 3051Email: jhumar@cmail.carleton.caOffice Hours: Tuesdays and Thursdays, 2:00-3:00 pmDocument2 pagesProf. J.L. HumarOffice: HP 3051Phone: 613-520-2600 ext. 3051Email: jhumar@cmail.carleton.caOffice Hours: Tuesdays and Thursdays, 2:00-3:00 pmBhind NijjarNo ratings yet

- SITHCCC018 Assessment 2Document9 pagesSITHCCC018 Assessment 2Taimoor Ahmed0% (1)

- Basseri TribeDocument3 pagesBasseri TribeMaddah HussainNo ratings yet

- The Positive and Negative Syndrome Scale PANSS ForDocument5 pagesThe Positive and Negative Syndrome Scale PANSS ForditeABCNo ratings yet

- Fault Location of Overhead Transmission Line With Noncontact Magnetic Field MeasurementDocument10 pagesFault Location of Overhead Transmission Line With Noncontact Magnetic Field MeasurementJkNo ratings yet

- Periodic Table of Personality ElementsDocument1 pagePeriodic Table of Personality Elementslilian_vera_1No ratings yet

- Z160-250 Instruction ManualDocument182 pagesZ160-250 Instruction ManualNMA Industrial ServicesNo ratings yet

- Marital Rape in IndiaDocument8 pagesMarital Rape in IndiaSHUBHANK SUMANNo ratings yet

- Viscometer Toki Sangyo - TV25 - 35Document12 pagesViscometer Toki Sangyo - TV25 - 35Eddy CurrentNo ratings yet

- Schematic 1280 - So Do Nokia 1 PDFDocument18 pagesSchematic 1280 - So Do Nokia 1 PDFanh3saigon0% (1)

- HPC ReportDocument316 pagesHPC ReportmamansgNo ratings yet

- QCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)Document41 pagesQCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)lwin_oo2435No ratings yet

- Ethylene Glycol PDFDocument2 pagesEthylene Glycol PDFAngela0% (1)

- 10893259-PIB 背钳弹簧保持架垫片落物事件Document2 pages10893259-PIB 背钳弹簧保持架垫片落物事件xlzyydf2015No ratings yet

- TN EpasssDocument2 pagesTN EpasssStephenrajNo ratings yet

- Kovach 1987Document10 pagesKovach 1987Quyen ta thi nhaNo ratings yet