Professional Documents

Culture Documents

Marine Engineering Study Materials: Wall Paints in HD Shades

Uploaded by

Bhupender RamchandaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marine Engineering Study Materials: Wall Paints in HD Shades

Uploaded by

Bhupender RamchandaniCopyright:

Available Formats

5/1/2015

Marine Engineering Study Materials - Page 55 of 89 - www.marineengineeringonline.com

Marine Engineering Study Materials

Search

www.marineengineeringonline.com

Home

General Engineering Knowledge

Downloads

Forums

Contact Us

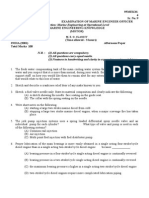

Pressure Vacuum (PV) Valve

Categories

May 1, 2014 1:05 pm | Leave a Comment | Frozee

Categories

Select Category

Wall Paints in

HD Shades

Get That Perfect Look for Your Wall with

Nerolac High Definition Paints

nerolac.com/High-Definiton-Colours

Moderate pressures of 0.24 bar acting on large surfaces in liquid cargo tanks are sufficient to cause

damage and rupture. The pressure on each unit of area multiplied by the total area gives a large

loading on the underside of the top of a tank or other surface, which may then buckle or the metal

plate may be torn. Similarly, pressure drop within a tank can cause damage due to greater

atmospheric pressure on the outside.

Follow Us

Jab Froze

Follow

Marine Engineering

Online

Like 3,302

Recent Posts

http://marineengineeringonline.com/page/55/

1/7

5/1/2015

Marine Engineering Study Materials - Page 55 of 89 - www.marineengineeringonline.com

Scavenge Port Inspection onboard

Ships

Operation of Freshwater Generator with

Jacket Cooling Water

Shell and Tube Freshwater Generator

Testing of Water Mist Fire Fighting

System onboard Ships

Maintenance of Water Mist Fire Fighting

System

Water Mist Fire Fighting System

Alexa Rank

Categories

Air Conditioning Boilers

Diesel

Engines Fire Detectors

Compressors

Fire Fighting Forms

http://marineengineeringonline.com/page/55/

2/7

5/1/2015

Marine Engineering Study Materials - Page 55 of 89 - www.marineengineeringonline.com

Pressure / vacuum valves in the ventilation system will prevent either over or under pressure. They

are set usually so that tank pressure of about 0.14 bar will lift the main valve (The smaller valve will lift

along with it) and release excess pressure. The vapour passes to atmosphere through a gauze flame

trap. Drop in tank pressure compared with that of the outside atmosphere will make the small valve

open downwards to equalize internal pressure with that outside.

Pressure vacuum valves can relieve moderate changes in tank pressure due to variations in

temperature and vapour quantity. A drop towards vacuum conditions as the result of the

condensation of steam will also be handled by the valve. Rapid pressure rise due to an explosion

would not be relieved.

The fast rate at which a tank is filled while loading produces a very rapid expulsion of the previous

and Checklists

General

Engineering

Knowledge Heat

Exchangers Hydraulics Inert Gas

System Instrumentation

and

Control Lubricating Oil Marine

Electrical Technology

MEO

Examination

Study Materials

neither should the tank hatch be left open. The latter method of venting can cause an accumulation

Motor Engineering

Knowledge Naval

of flammable vapours at deck level. Tanks should be vented while filling, through mast head vents or

through special high velocity vents.

Architecture and Ship

Construction Pumps

contents (vapour and inert gas). The pressure vacuum valve is not designed as a filling vent and

Refrigeration Safety

and

Environmental Protection

Sewage Treatment Turbochargers

References

General Engineering Knowledge by H.D. McGeorge

May 2015

M

http://marineengineeringonline.com/page/55/

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3/7

5/1/2015

Marine Engineering Study Materials - Page 55 of 89 - www.marineengineeringonline.com

Apr

share it...

Posted in: Inert Gas System | Tagged: inert gas system, marine engineering study materials, pressure vacuum

valve, pv valves

Soot Blower

May 1, 2014 1:00 pm | Leave a Comment | Frozee

Pallet Trucks

Online Shop

Top Brands - Stiller, Rana & More. Best Price

Warranty, Free Shipping

industrybuying.com/Pallet-Trucks

Between periodic boiler cleaning the gas surfaces of the boiler tubes should be kept as clean as

http://marineengineeringonline.com/page/55/

4/7

5/1/2015

Marine Engineering Study Materials - Page 55 of 89 - www.marineengineeringonline.com

practicable. To facilitate this, soot blowers, steam or air operated, are often fitted. They enable the

tube surfaces to be cleaned of loose sooty deposits rapidly without shut down of the boiler.

Figure below shows a typical soot blower arrangement fitted to a Scotch type boiler.

Working

With steam supplied to the blower and the steam supply line thoroughly drained. Rotation of the

blower hand wheel causes the supply tube and nozzle to move towards the combustion chamber.

Nozzle and tube are rotated as they move inwards by means of a scroll cut in the nut and a stationary

http://marineengineeringonline.com/page/55/

5/7

5/1/2015

Marine Engineering Study Materials - Page 55 of 89 - www.marineengineeringonline.com

pin A in the body assembly that runs in the scroll. Ports in the tube communicate the steam supply

line with the nozzle.

The arrangement enables rotating, fine, high pressure jets of steam to be discharged to the tube

plate over a considerable area.

When not in use, the retractable nozzle of the blower is well within the housing tube and is therefore

protected from overheating, which could cause burning and distortion of the nozzle.

Too frequent use of the blower should be avoided as this could cause wastage of the tube plate. It is

advisable to operate the blower regularly even if the boiler tubes are clean (in this case without steam

supply to the blower) to ensure the blower unit is free and in operable order.

References

General Engineering Knowledge by H.D. McGeorge

share it...

Posted in: Boilers | Tagged: boiler soot blower, marine engineering, marine engineering study materials, soot

blower

Previous

53

http://marineengineeringonline.com/page/55/

54

55

56

57

89

Next

6/7

5/1/2015

Copyright 2014 - Marine Engineering Online

http://marineengineeringonline.com/page/55/

Marine Engineering Study Materials - Page 55 of 89 - www.marineengineeringonline.com

Theme by WPJournals WordPress

7/7

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Storage Tank Vents & Fire SystemsDocument24 pagesStorage Tank Vents & Fire SystemsMohammad Rawoof100% (2)

- Marine Engineering Study Materials: Videocon d2h HD OfferDocument7 pagesMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniNo ratings yet

- Air Start ExplosionDocument12 pagesAir Start ExplosionsahilimuNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Emergency For Internal Pressure - MorovichDocument34 pagesEmergency For Internal Pressure - MorovichrodrigoperezsimoneNo ratings yet

- 800 Fire and Safety DesignDocument31 pages800 Fire and Safety Designjhon smith100% (1)

- 800 - Fire and Safety DesignDocument32 pages800 - Fire and Safety DesignShinji46No ratings yet

- 2017-12-20-Prevention of Accidents in Distribution and Power TransformersDocument5 pages2017-12-20-Prevention of Accidents in Distribution and Power TransformersNeeraj GuptaNo ratings yet

- Eliminate Cavitation in Overboard Dump ValvesDocument3 pagesEliminate Cavitation in Overboard Dump ValvesekabudiartiNo ratings yet

- Deck SealDocument7 pagesDeck SealAlamin Siddique100% (1)

- Marine Engineering Study Materials: Videocon d2h HD OfferDocument6 pagesMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniNo ratings yet

- Turbine Bypass ValvesDocument6 pagesTurbine Bypass ValvesadehriyaNo ratings yet

- Valva MechanismDocument38 pagesValva MechanismAnkitSingh100% (1)

- Term Report 2Document9 pagesTerm Report 2Faizan FareedNo ratings yet

- Oil Well Completion and Work Over GuideDocument29 pagesOil Well Completion and Work Over GuideDavid LutmangNo ratings yet

- VALVES OVERCOME CHALLENGES IN OIL SAND EXTRACTIONDocument4 pagesVALVES OVERCOME CHALLENGES IN OIL SAND EXTRACTIONAnonymous ntK705RtNo ratings yet

- Factors Influencing Well Completion DesignDocument6 pagesFactors Influencing Well Completion DesignMahesh sinhaNo ratings yet

- Answer:-T Is A Known Fact That Every Running Machine Has A Tendency To VibrateDocument92 pagesAnswer:-T Is A Known Fact That Every Running Machine Has A Tendency To VibrateSri VasanNo ratings yet

- Stress Analysis of Storage Tank PipingDocument36 pagesStress Analysis of Storage Tank PipingTree Tawee100% (1)

- Applying Controlled Air Transfer Tech to PipelinesDocument14 pagesApplying Controlled Air Transfer Tech to PipelinesRui ApolinárioNo ratings yet

- Proper Sizing of Steam Header Drains Prevents Water InductionDocument7 pagesProper Sizing of Steam Header Drains Prevents Water InductionmhdsolehNo ratings yet

- Sb2125 - Valve Head Cracking BreakageDocument2 pagesSb2125 - Valve Head Cracking BreakageahmedalgaloNo ratings yet

- Oil & Gas Production and Surface Facilities: Presented by Eng. Mohamed Ibrahim 6 March 2015Document51 pagesOil & Gas Production and Surface Facilities: Presented by Eng. Mohamed Ibrahim 6 March 2015HariNugrohoNo ratings yet

- The Design and Operation of Offshore Relief - Venting SystemsDocument24 pagesThe Design and Operation of Offshore Relief - Venting SystemsMichael HaiseNo ratings yet

- EPRI Combined CycleDocument34 pagesEPRI Combined CycleRaden Mas100% (1)

- TD Vs IB TrapDocument5 pagesTD Vs IB TrapKailas NimbalkarNo ratings yet

- 1.6 Inert Gas SystemDocument8 pages1.6 Inert Gas SystemAbcdNo ratings yet

- DesuperheatersDocument6 pagesDesuperheaterskparthypan100% (1)

- Method Statement For Valve InstallationDocument11 pagesMethod Statement For Valve InstallationKhang Hồ Lê100% (1)

- Push Valve ExperienceDocument13 pagesPush Valve ExperienceIan Mann100% (1)

- Reduce Boiler Tube Leakages Through Proper MaintenanceDocument7 pagesReduce Boiler Tube Leakages Through Proper MaintenanceNorman IskandarNo ratings yet

- Surge DamageDocument12 pagesSurge DamageRajat WadhwaniNo ratings yet

- Flowserve PI-07-02Document4 pagesFlowserve PI-07-02mariasofiarossiNo ratings yet

- Design of Petroleum Refining Equipment-1Document20 pagesDesign of Petroleum Refining Equipment-1sherifelbayoumy266No ratings yet

- Nitrogen Handling PurgingDocument9 pagesNitrogen Handling PurgingJeet Singh100% (1)

- Research On Air Valve of Water Supply Pipelines: SciencedirectDocument8 pagesResearch On Air Valve of Water Supply Pipelines: SciencedirectKenNo ratings yet

- Coc Oral Boiler Safety Valve13 PDFDocument6 pagesCoc Oral Boiler Safety Valve13 PDFshamratNo ratings yet

- Tech Data 11Document8 pagesTech Data 11Varun SanganiNo ratings yet

- Losses in steam turbines explainedDocument6 pagesLosses in steam turbines explainedMohamed Abashar MusmarNo ratings yet

- Cause and Effect Analysis of Head Compression Leak of A Tractor EngineDocument4 pagesCause and Effect Analysis of Head Compression Leak of A Tractor EngineSarita HuriaNo ratings yet

- Assignment #3: To: Ma'Am Saima AliDocument9 pagesAssignment #3: To: Ma'Am Saima AliEsmatullah BegzadNo ratings yet

- Advances in Automated Subsea ValvesDocument3 pagesAdvances in Automated Subsea ValvesSyko GuyNo ratings yet

- DE - Ch9 - Piping Design and SpecificationsDocument9 pagesDE - Ch9 - Piping Design and SpecificationsMy TvNo ratings yet

- Sample ProcessUtilitiesPlantDocument6 pagesSample ProcessUtilitiesPlantgplese0100% (2)

- Aviation Storage TanksDocument6 pagesAviation Storage Tanksram71990No ratings yet

- Reservoir Design Solutions for Mobile EquipmentDocument7 pagesReservoir Design Solutions for Mobile EquipmentSympatyagaNo ratings yet

- Proper Tank DsignDocument3 pagesProper Tank DsignEugenioNo ratings yet

- Proper Piping For Vacuum SystemsDocument5 pagesProper Piping For Vacuum SystemsDowni Oader100% (1)

- 05 CHARGE AIR COOLER MaK - 9M20CDocument14 pages05 CHARGE AIR COOLER MaK - 9M20Ccamilo.provoste.manNo ratings yet

- Simulacro Sábado 13 de NoviembreDocument20 pagesSimulacro Sábado 13 de NoviembreNo HernaNo ratings yet

- Miscellaneous TopicsDocument6 pagesMiscellaneous TopicsNyoman RakaNo ratings yet

- WEIR - Technical Bulletin - Hazards of Blocked PipesDocument6 pagesWEIR - Technical Bulletin - Hazards of Blocked PipesWesley MendesNo ratings yet

- Title: Effects of Valve Trim Geometry in Flashing ServiceDocument7 pagesTitle: Effects of Valve Trim Geometry in Flashing ServiceRamy KamalNo ratings yet

- H2 Safety VentDocument5 pagesH2 Safety Ventmsantosu000No ratings yet

- Comparative Study Between Hydraulic and Electric Bop Regarding ReliabilityDocument8 pagesComparative Study Between Hydraulic and Electric Bop Regarding ReliabilityGeugomes Higino1997No ratings yet

- Assignment #3: To: Ma'Am Saima AliDocument9 pagesAssignment #3: To: Ma'Am Saima AliEsmatullah BegzadNo ratings yet

- Exhaust Valve EverythingDocument1 pageExhaust Valve EverythingAjim MokashiNo ratings yet

- Group Oil Lub Stern TubeDocument25 pagesGroup Oil Lub Stern TubevivekNo ratings yet

- Ship security levels and duties guideDocument10 pagesShip security levels and duties guideBhupender RamchandaniNo ratings yet

- P 57Document7 pagesP 57Bhupender RamchandaniNo ratings yet

- 95MEP-4 Exam of Marine Engineer Officer Maintenance & RepairDocument2 pages95MEP-4 Exam of Marine Engineer Officer Maintenance & RepairBhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument2 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- Marine Engineering Study Materials: Videocon d2h HD OfferDocument6 pagesMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No2Document2 pages95 MEKM4 SR No2Bhupender RamchandaniNo ratings yet

- ArticrlDocument9 pagesArticrlBhupender RamchandaniNo ratings yet

- Marine Engineering Study Materials: EFC InternationalDocument5 pagesMarine Engineering Study Materials: EFC InternationalBhupender RamchandaniNo ratings yet

- ArticlDocument11 pagesArticlBhupender RamchandaniNo ratings yet

- Marine engineering exam questionsDocument3 pagesMarine engineering exam questionsBhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument2 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument2 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- 95MEKM-4 Marine Engineer Officer Exam QuestionsDocument3 pages95MEKM-4 Marine Engineer Officer Exam QuestionsBhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No5Document3 pages95 MEKM4 SR No5Bhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No5Document3 pages95 MEKM4 SR No5Bhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No4Document3 pages95 MEKM4 SR No4Bhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument3 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No.7Document3 pages95 MEKM4 SR No.7Bhupender RamchandaniNo ratings yet

- Marine engineering exam questionsDocument3 pagesMarine engineering exam questionsBhupender RamchandaniNo ratings yet

- Examination of Marine Engineer Officer - MotorDocument3 pagesExamination of Marine Engineer Officer - MotorBhupender RamchandaniNo ratings yet

- 95 MEKM SR No.3Document3 pages95 MEKM SR No.3Bhupender RamchandaniNo ratings yet

- 95MEKM4 SrNo8Document3 pages95MEKM4 SrNo8Bhupender RamchandaniNo ratings yet

- Marine Engineer Exam QuestionsDocument4 pagesMarine Engineer Exam QuestionsBhupender RamchandaniNo ratings yet

- Marine Engineer Exam QuestionsDocument4 pagesMarine Engineer Exam QuestionsBhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument3 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- 95MEKM4 SrNo10Document3 pages95MEKM4 SrNo10Bhupender RamchandaniNo ratings yet

- 95MEKM4 SrNo6Document3 pages95MEKM4 SrNo6Bhupender RamchandaniNo ratings yet

- 95MEKM4 SrNo2Document3 pages95MEKM4 SrNo2Bhupender RamchandaniNo ratings yet

- Résumé For Arjun JayaramanDocument1 pageRésumé For Arjun JayaramanArjun JayaramanNo ratings yet

- Intro To FmdtoolsDocument38 pagesIntro To FmdtoolsSmurf Account1No ratings yet

- Advanced Excel Data Management & AnalysisDocument3 pagesAdvanced Excel Data Management & AnalysisGaurav Shankar MullickNo ratings yet

- Rayos X Odont Cranex - S - M PDFDocument206 pagesRayos X Odont Cranex - S - M PDFDaniel Parada VanegasNo ratings yet

- Giddings & Lewis Sect10 MaintenanceDocument10 pagesGiddings & Lewis Sect10 MaintenanceAngel AdautaNo ratings yet

- SL Nx-OsDocument676 pagesSL Nx-Osa_salesmanNo ratings yet

- AI Sentiment Analysis of YouTube CommentsDocument18 pagesAI Sentiment Analysis of YouTube CommentsRey NeshNo ratings yet

- SRS SampleDocument31 pagesSRS SampleAbhishek DuttaNo ratings yet

- ANALYSISTABS Sample Dashboard Sales DataDocument232 pagesANALYSISTABS Sample Dashboard Sales Datapuran1234567890No ratings yet

- FR 17Document3 pagesFR 17Nagaraja MVNo ratings yet

- Data Communications & Computer Networks Signal Encoding TechniquesDocument23 pagesData Communications & Computer Networks Signal Encoding TechniquesahbendNo ratings yet

- 1737 - MAR - NucliSENS EasyMAG - Stepper PCB FuseDocument5 pages1737 - MAR - NucliSENS EasyMAG - Stepper PCB FuseKaraboNo ratings yet

- Total Quality Management ManualDocument55 pagesTotal Quality Management ManualjaminkwadNo ratings yet

- All about computersDocument18 pagesAll about computersOrevelNo ratings yet

- Calculate volume and number of tilesDocument8 pagesCalculate volume and number of tilesRichard Antoni GosnoNo ratings yet

- It SecurityDocument285 pagesIt SecuritySUSOVAN GARAINo ratings yet

- Sustainable Architecture - Martina Keitsch EditorialDocument5 pagesSustainable Architecture - Martina Keitsch EditorialAren RoukemaNo ratings yet

- Vba Codes ExcelDocument46 pagesVba Codes ExcelKen Matsuda100% (1)

- CFD Bim PDFDocument8 pagesCFD Bim PDFCristina PaduanoNo ratings yet

- B, 40,41, Case 2 Goodyear, Jea, Osumc and MonsantoDocument10 pagesB, 40,41, Case 2 Goodyear, Jea, Osumc and MonsantoSuhel PathanNo ratings yet

- Low Voltage Alternator - 4 Pole: 1100 To 1640 kVA - 50 HZ / 1250 To 2000 kVA - 60 HZ Electrical and Mechanical DataDocument12 pagesLow Voltage Alternator - 4 Pole: 1100 To 1640 kVA - 50 HZ / 1250 To 2000 kVA - 60 HZ Electrical and Mechanical DataBart VyveyNo ratings yet

- cpp5gs PDFDocument2 pagescpp5gs PDFmohammadNo ratings yet

- BPB31103 Production & Operations Management ch7Document60 pagesBPB31103 Production & Operations Management ch7Anis TajuldinNo ratings yet

- Awp Serv Embedded 7-0-50 RLDocument12 pagesAwp Serv Embedded 7-0-50 RLOscar Alberto ZambranoNo ratings yet

- Chapter 3!: Agile Development!Document21 pagesChapter 3!: Agile Development!Irkhas Organ SesatNo ratings yet

- Oracle 1z0-497 exam guide with 91% successDocument65 pagesOracle 1z0-497 exam guide with 91% successprem kumarNo ratings yet

- EE021 - Sub-Station Earth Grid DesignDocument4 pagesEE021 - Sub-Station Earth Grid DesignbhavikNo ratings yet

- F5 Training Lab GuideDocument11 pagesF5 Training Lab GuideBrayan Anggita LinuwihNo ratings yet

- SV-Is5 User Manual - 100224Document205 pagesSV-Is5 User Manual - 100224Kỹ Sư Tđh100% (1)

- Leica Geosystems TPS Comparison Chart 1120 en LRDocument1 pageLeica Geosystems TPS Comparison Chart 1120 en LRChristian Guillmar Huanca OscoNo ratings yet