Professional Documents

Culture Documents

OCW Drilling Hydraulics Lecture

Uploaded by

freelancer2earnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OCW Drilling Hydraulics Lecture

Uploaded by

freelancer2earnCopyright:

Available Formats

1

SKM 3413 - DRILLING ENGINEERING

Chapter 3 - Drilling Hydraulics

Assoc. Prof. Abdul Razak Ismail

Petroleum Engineering Dept.

Faculty of Petroleum & Renewable Energy Eng.

Universiti Teknologi Malaysia

Contents

Review of flow in pipes (Fluid Mechanics)

Drilling mud flow (circulating) system

Newtonian fluid flow calculations

Bingham plastic fluid flow calculations

p across bit nozzles

p calculation for typical system

Review of flow In Pipes

Real fluid flow is much complex compare to perfect fluid flow.

Between fluid particles

Shear stress

fluid

Between fluid particles

and pipes wall

Energy equilibrium principles are used to solve the problems.

Partial differential equation (Eulers equation) has no general

solution to solve problems.

Results from experiment (analytical) and semi-empirical method

needs to be used to solve flow problems.

There are 2 types of steady flow of real fluid exists:

Laminar flow

Turbulent flow

Dye

This one?

or

Laminar (viscous) flow

this one?

or

Transition flow

this one?

Turbulent flow

All three types of flow actually do occurred in real fluid flow.

Laminar flow v

Turbulent flow v

The problem is: what is v and v .Why we need to know?

This phenomenon was first investigated in 1883 by Osborne

Reynolds in an experiment which has a classic in fluid mechanic.

Laminar flow

Transition flow

Turbulent flow

After a few experiments, he found out a mathematical relationship:

vd

This mathematical relationship can be used to determine the types

of flow.

vd

2000

laminar flow

vd

2000

4000 transition flow

vd

4000

turbulent flow

Subsequently until now, this mathematical relationship is known as

Reynolds number, Re (or NRe ).

vd

Re

dimensionless

laminar flow : Re 2000

transition flow : 2000 Re 4000

turbulent flow : Re 4000

vd

where:

v

d

fluid density

fluid average velocity

pipe inside diameter

fluid absolute viscosity

If kinematic viscosity, , is inserted in the equation:

vd

Re

Fluid velocity profile in a pipe:

Laminar flow

Turbulent flow

vmaks

v vavg 12 vmaks

v vavg

v vavg

Mechanical Energy of a Flowing Fluid

Consider the situation below:

Qin

element ( mg )1 @ Station 1

HL

v1

Turbine

HE

z1

element ( mg )2 @ Station 2

Pump

v2

HA

Control volume

Qout

z2

2

Datum

The energy possessed by a flowing fluid consists of internal energy and energies due to

pressure, velocity, and position

energy at energy energy energy energy at

section 1 added

lost

extracted section 2

This equation, for steady flow of incompressible fluids in which the change in internal

energy is negligible, simplifies to

p1 v12

p2 v22

z

1

A

L

E

2

2g

2g

10

Energy Losses In Pipe

Def.: Any energy losses in closed conduits due to friction, HL.

This types of losses can be divided into 2 main categories:

Major losses, HL-major, and

Minor losses, HL-minor.

From Bernoullis equation:

p1 v12

p2 v22

2 g z1 H A H L H E 2 g z2

Energy added to the system, HA, is frequently due to pump fluid

head, HP, energy extracted, HE, is frequently due to turbine fluid

head, HT, Bernoullis equation can be simplify as:

v12

p2 v22

z1 H P

z2 H T H L major H L minor

2g

2g

p1

11

Major Losses In Pipe

Def.: The head loss due to friction in long, straight sections of pipe.

The losses do happen in pipe, either in laminar or turbulent flow.

a. Laminar flow

Problem solved analytically derived purely from mathematical

relationship

Hagen-Porseuille equation

32 vL

p f

d2

in the forms of head loss, HL

32 vL

HL

d2

Darcy-Weisbach equation

vd

by replacing Re

into Hagen-Porseuille equation

2

64

v

L

HL

Re d 2 g

12

b. Turbulent flow

From Darcy-Weisbach equation for laminar flow

2

64

v

L

HL

Re d 2 g

2

v

L

HL f

d 2g

64

a simple mathematical relationship.

Re

For turbulent flow, f has to be solved empirically experiment need to be done.

In laminar and turbulent flow, f is known as friction coefficient or friction factor.

Where, for laminar flow, f

13

Friction Factor

a.

Laminar flow

Darcy-Weisbach equation

2

HL f L v

d 2g

b.

where f 64

Re

Turbulent flow

In the literature (from 1900s current date), there are many studies that have been

conceded by various researchers.

Blasiuss equation (1913)

von Karmans equation modified by Prandtl

Nikuradses equation (for smooth and rough pipes)

Colebrook-White equation (1940s)

Moody

Barrs equation (1975)

14

Laminar

Friction Factor . (cont. 2)

Transition

f 64

Re

Turbulent

Complete Turbulent

vd

Re vd

Moody Chart

15

Normal practice in determination of f

1. Calculate Re to determine the types of

flow.

2.

HL calculation: used Darcy-Weisbach

equation.

2

L

v

HL f

d 2g

3. For laminar flow: f 64

Re

4. For turbulent flow:

a. Determine pipe relative roughness,

d

Where:

pipes absolute roughness

d pipe internal diameter

e is depend on pipes material, normally

is given in tabular forms.

Material (new)

Riverted steel

Concrete

Wood stave

Cast iron

Galvanized iron

Asphalted cast iron

Commercial steel or wrought iron

Drawn tubing

Glass

Absolute roughness,

ft

mm

0.003 - 0.03

0.001- 0.01

0.0006 - 0.003

0.00085

0.0005

0.0004

0.00015

0.000005

0.0 (smooth)

0.9 - 9.0

0.3 - 3.0

0.18 - 0.9

0.26

0.15

0.12

0.045

0.0015

0.0 (smooth)

b. Obtain f from Moody chart, @ Re,

d

16

Attention

1. In this subject, SKM1043, the f that we are using, is the American friction factor, fAmerican.

2. The value of fAmerican is different to the one that used by the British

f American 4 f British

64

Re

16

Re

needs to refer different Moody Chart

3. Sometimes:

f American 4 f British

17

Since the mud enters the drill string and leaves the annulus

at essentially the same elevation, the only pressure

required is to overcome the frictional losses in the system.

Hence, the discharge pressure at the pump is defined by:

pt p s p p p c pb p ac p ap

....... (3.1)

where:

pt =

ps =

pp =

pc =

pb =

pac =

pap =

pump discharge pressure

pressure loss in surface piping, standpipe, and mud hose

pressure loss inside drill pipe

pressure loss inside drill collars

pressure loss across bit nozzles

pressure loss in annulus around drill collars

pressure loss in annulus around drill pipe

18

The solution of Eq. (3.1) is rather tedious; separate

calculations are needed for each section

There are 4 different types of model used to calculate

frictional pressure losses in mud circulating system:

Newtonian

Bingham plastic

Power-law

API Power-law

Due to the limitation of the syllabus, Power-Law and API

Power-Law models will not be discussed in this subject.

All calculations will be focused on Newtonian and plastic

fluid models.

19

Newtonian Fluid Flow Calculations

Similar to generalized flow system approach, calculation of p for

pipe flow requires a knowledge of which flow pattern pertains to the

specific case, since different equations apply for each situation.

Definition of the existing flow pattern is given by a dimensionless

quantity known as the Reynolds number (NRe ):

N Re

where:

928 vd

N Re = Reynoldss number

v = average velocity of flow, ft/sec

= fluid density, ppg

d = pipe inside diameter, in.

= fluid viscosity, cp

q = circulating volume, gal/min

.......... (3.2)

20

Similar to generalized flow system approach, that if

laminar flow : N Re 2000

transition flow : 2000 N Re 4000

turbulent flow : N Re 4000

The p in laminar flow is given by the Hagan-Poiseuille law; this,

in practical units, is

Lv

.......... (3.3)

p

2

1,500d

where:

p = laminar flow p, lb/in2

L = length of pipe, ft

turbulent flow

For turbulent flow, Fannings equation applies:

f Lv 2

.......... (3.4)

p

25.8 d

where:

p = turbulent flow p, lb/in2

f = Fanning friction factor

21

The friction factor f is a function of and pipe

roughness, and has been evaluated experimentally

for numerous materials (see Fig. 7.1)

p calculation for Newtonian fluid flow systems in

the following manner:

a. Calculate NRe from Equation (3.2).

b. If NRe < 2000, use Equation (3.3) to calculate the

pressure drop.

c. If NRe > 2000, use Equation (3.4). In this case the

friction factor f is obtained from Figure 7.1 or its

equivalent.

22

23

Plastic Fluid Flow Calculations

Drilling fluids is non-Newtonian fluid

Newtonian fluid equations must be altered for application

to typical drilling mud systems

24

Surface Equipment Losses ( ps)

The surface equipment consist of standpipe, hose, swivel, kelly

joint, and the piping between the pump and standpipe.

In practice, there are only four types of surface equipment; each

type is characterized by the dimensions of standpipe, kelly,

rotary hose and swivel. Table 3.1 summarizes the four types of

surface equipment.

Table 3.1: Types of surface equipment & value of constant E

Standpipe

Type

Hose

Swivel, etc.

Kelly

Eq. length,

3.826 ID

ID

Length

ID

Length

ID

Length

ID

Length

40 ft.

2.5

45 ft.

20 ft.

2.25

40 ft.

2,600 ft.

2.5 x 10-4

3.5

40 ft.

2.5

55 ft.

2.5

25 ft.

3.25

40 ft.

946 ft.

9.6 x 10-5

45 ft.

55 ft.

2.5

25 ft.

3.25

40 ft.

610 ft.

5.3 x 10-5

45 ft.

55 ft.

30 ft.

40 ft.

424 ft.

4.2 x 10-5

25

To determine surface equipment losses ( ps):

Use the following formula:

ps E m0.8 q1.8 0.2

p

.......... (3.5)

where:

ps =

q =

m =

E =

p

surface pressure losses, psi

flow rate, gpm

mud density, ppg

a constant depending on type of surface equipment used

mud plastic viscosity, cp

Fluid Flow Inside the Pipe

Shearing stress or pressure

A. Laminar Flow Region

4

144p Yt mv

3

(True laminar flow)

Yb, Bingham yield

Transition from plug to laminar flow

Plug flow

Yt, True yield

Rate of shear or velocity

Fig. 3.1: Flow behavior of plastic and Newtonian fluids.

4

144p Yt mv

3

where:

144p = pressure drop, lb/ft2

4

3

Yt = Yb, lb/ft2

m = L/(1500d2), slope of linear portion (from Eq. (3.3))

26

27

For practical values of v , the behavior of plastic fluids may be

expressed as:

p vL

LYb

p

300d 1500d 2

L

p

300d

where:

pv

Yb

5

d

laminar flow

.......... (3.6)

p = plastic viscosity, cp.

Yb = yield point, lb/100ft2.

Eq. (3.6) may be used in cases where laminar flow exists

Determination of flow characteristic (laminar or turbulent) is

made by comparing the actual velocity with a calculated critical

velocity

28

Average Velocity Calculation

q ft 3 /sec

v

A ft 2

Avg. velocity

inside the pipe

Avg. velocity

in the annulus

1 ft 3

1 min

q gal/min

7.48 gal

60 sec

( /4)(d /12)2

q

....... (3.7a)

v

2

2.45 d

OD

ID

Hole

q

....... (3.7b)

v

2

2

2.45 (d h - d p )

where :

v average velocity, ft/sec.

q = flow rate, gpm

d = diameter, in.

Drill pipe

Annulus

Annulus Area Ah Ap

(d h2 d p2(OD ) )

29

Critical Velocity Calculation

If Eqs. (3.3) and (3.6) are equated, an equivalent Newtonian

viscosity in terms of d , v , p and Yb is obtained:

5dYb

p

v

Substituting the above Eq. for in the Reynoldss number of Eq.

(3.2), equating the resulting equation to 2000, and solving for v

gives:

1.08 p 1.08 p2 9.3 d 2Yb

.......... (3.8)

vc

d

where:

vc = critical velocity, ft/sec, above which turbulent flow

exists and below which the flow is laminar.

Eq. (3.8) assumes that turbulence occurs at NRe = 2000. Therefore,

if:

v vc , flow is laminar

v vc , flow is turbulent

30

B. Turbulent Flow Region

Before Fanning Eq. can be used, alteration to NRe expression have to

be done (after Beck, Nuss & Dunn)

p

.......... (3.9)

t

3.2

where:

t = turbulent viscosity of plastic fluids, cp

Substitution of t, for in the general NRe expression (Eq. (3.2)) gives:

NRe

NRe

928 vd

t

2,970vd

.......... (3.10)

By using Fig. 7.1, determine f

This f may then be used in Eq. (3.4) for calculation of pressure

31

In summary, p calculation for plastic fluid flow systems can

be done as follows:

(1) Calculate the average velocity, v , from Eq. (3.7a) or (3.7b)

(2) Calculate vc from Eq. (3.8)

(3) If v vc flow is laminar, Eq. (3.6) applies

(4) If v vc flow is turbulent, requiring:

a. Calculation of NRe from Eq. (3.10)

b. Determination of f from Fig. 7.1 at the calculated

for the conduit in question

c. Calculation of pressure drop from Eq. (3.4)

32

Example 3.1

Mud is flowing through 4 1/2 inch OD, internal flush drill pipe.

Calculate the frictional pressure drop per 1000 ft of pipe.

Mud properties

Mud density, m

Pipe ID

Bingham yield, Yb

Circulating rate, q

Plastic viscosity, p

=

=

=

=

=

10 lb/gal

3.640 in.

10 lb/100 ft2

400 gal/min

30 cp

33

Solution 3.1

Eq. (3.7a) : v

q

2.45d 2

Eq. (3.8) : v

c

1.08 p 1.08 p2 9.3 d 2Yb

400

12.3 ft/sec

2.45(3.64)2

(1)

(2)

(1.08)(30) (1.08) (30)2 (9.3)(10)(3.64)2 (10)

vc

4.3 ft/sec

(10)(3.64)

(3) Since v vc , flow is turbulent.

(a) N Re

(2,970)(10)(12.3)(3.64)

44,300

30

(b) f 0.0062 from Curve II, Fig. 3.1

(0.0062)(10)(1000)(12.3)2

(c) p p

100 psi/1000 ft

(25.8)(3.64)

34

Hydraulically Equivalent Annulus Diameter

For annular flow, it is necessary to use a hypothetical circular diameter,

da, which is the hydraulic equivalent of the actual annular system

The hydraulic radius is defined as:

hydraulic radius, rh =

cross-sectional area of flow system

wetted perimeter of conduit

Annulus

(r12 r22 ) r1 r2

for an annulus

rh =

2 (r1 r2 )

2

r2 r

for a circular pipe rh =

2 r 2

r2

r

The frictional loss in an annulus is equal to the loss in a circular pipe

having the same hydraulic radius; hence, in general terms:

re = r1 r2

or

de = d1 d2

.......... (3.11)

where re and de are the hydraulically equivalent radius and diameter

r1

35

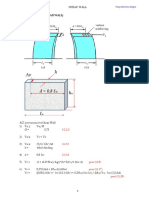

Pressure Drop Across Bit Nozzles

Consider the diagram below for incompressible fluid:

Fig. 3.2: Schematic sketch of incompressible fluid flowing

through a converging tube or nozzle.

Assuming steady state, adiabatic, and frictionless:

v12 p2 v22

2g 2g

p1

where:

p1 , p2 = turbulent flow pressure drop, lb/ft2

v1 , v2

= density, lb/ft3

= velocities at points 1 and 2, ft/sec

.......... ( a)

36

or

p1 v12 p2 v22

w 2g w 2g

.......... (a )

v22 v12

2g

Practically, v22 v12 v22 , therefore:

p

.......... (b)

v22 2 g

The ideal rate of flow, qi A2 v2 . The actual flow rate q is:

.......... (c)

q Cqi

where C is the flow or nozzle coefficient for particular design.

p

37

By substituting Eq. (c) into Eq. (b), and rearranging it, the equation

becomes:

q2

.......... (3.12)

p

2 2

2 gC A2

Altering Eq. (3.12) to practical units for mud flow, we:

q2

pb

7, 430 C 2 d e 4

.......... (3.13)

where de = hydraulically equivalent nozzle diameter, in.

The value of C is around 0.8 0.98.

38

Multiple Nozzles

The calculation of p across a multiple nozzle bit may be simplified

by substituting the sum of the nozzle areas for A in Equation (3.12).

For single nozzle:

q2

p

2 gC 2 A2

For several nozzles, each of area A1:

q12

pm

2 gC 2 A12

39

q

For parallel flow, q1 , where n = number of nozzles.

n

therefore:

pm q12 A2

q12 A2

2 2 2 2 2

p q A1 n q1 A1

Cross sectional area of flow, A, is defined as

A2

1

2 2

n A1

A2 n2 A12

or

A nA1

.......... (3.14)

40

Similarly, for use in Eq. (3.13)

d e nd 2

.......... (3.15a)

If the multiple nozzles vary in size,

where:

de ad12 bd 22 etc. .......... (3.15b)

a = number of nozzles having diameter d1.

b = number of nozzles having diameter d2.

d e = hydraulically equivalent single nozzle diameter, in.

41

Example 3.2

A 10 lb/gal mud is being circulated at the rate of 500 gal/min.

through a tri-cone bit having three 3/8 in. diameter jets. What

is the pressure drop across the bit?

Solution 3.2

Drill string

p1

Hole

Nozzle

vn1

vn2 vn3

p2

de or d 3( 83 )2 0.65 in. (equivalent single nozzle diameter)

Using Eq. (3.13):

(500) 2 (10)

( p1 p2 ) or p

2,100 psi

2

4

(7430)(0.95) (0.65)

42

Pressure Drop Calculations for a Typical Systems

Example 3.3

Operating Data

Depth = 6,000 ft (5,500 ft drill pipe, 500 ft drill collars)

Drill pipe = 4 -in. internal flush, 16.6 lb/ft (ID = 3.826 in.)

Drill collars = 6 in. (ID = 2.813 in.)

Mud density,

m = 10 lb/gal

Plastic viscosity, p = 30 cp

Bingham yield, Yb = 10 lb/100ft2

Bit = 7 7/8-in., 3 cone, jet rock bit

Nozzle velocity required = at least 250 ft/sec through each nozzle (this

value is obtained by a commonly applied rule of thumb). Assume C = 0.95

Surface equipment type = 2

What hydraulic (pump output) horsepower will be required for these conditions?

43

Solution 3.3

Gbr ni tak perlu

ubah

Circulation rate: This is obtained from the

desired annular velocity necessary for

proper hole cleaning (cutting removal).

Assume that this is a fast drilling, soft rock

area and that 180 ft/min (3 ft/sec) upward

velocity based on a gauge hole is required

(i.e. annular velocity around the drill pipe).

5,500 ft.

The flow rate , q is:

q (annulus area) velocity

2.45(d h2 - d p2 )v

7 2

1 2

2.45 7 8 4 2 (3)

307 gpm

500 ft.

Eq. (3.16) ps E m0.8 q1.8 0.2

p

(a) Surface equipment losses ( ps)

Surface equipment type 2

Table 3.1

E 9.6 10-5

ps (9.6 10-5 )(10) 0.8 (307)1.8 (30) 0.2 36 psi

(b) Pressure losses inside drill pipe ( pp)

The average velocity inside the drill pipe:

v

q

307

8.56 ft/sec

2

2

2.45d

2.45(3.826)

The critical velocity:

vc

1.08p 1.08 p2 9.3 m d 2Yb

m d

1.08 (30) 1.08 (30) 2 (9.3)(10)(3.826)2 (10)

(10)(3.826)

4.25 ft/sec

45

v vc turbulent flow (use Eq. 3.4)

NRe

2,970 vd

N Re 32, 400

Curve II

(2,970)(10)(8.58)(3.826)

32, 423 32, 400

30

Fig. 7.1 f 0.0066

Applying Eq. (3.4):

f Lv 2 (0.0066)(10)(5,500)(8.56)2

pp

269 psi

25.8 d

(25.8)(3.826)

46

(c) Pressure losses inside drill collar ( pc)

The average velocity inside the drill collar:

q

307

v

15.84 ft/sec

2

2

2.45d

2.45(2.813)

The critical velocity:

vc

1.08p 1.08 p2 9.3 m d 2Yb

m d

1.08 (30) 1.08 (30) 2 (9.3)(10)(2.813) 2 (10)

(10)(2.813)

4.64 ft/sec

47

v vc turbulent flow (use Eq. 3.4)

NRe

2,970 vd

N Re 44,100

Curve II

(2,970)(10)(15.84)(2.813)

44,112 44,100

30

Fig. 7.1 f 0.0062

Applying Eqn. (3.4):

f Lv 2 (0.0062)(10)(500)(15.84)2

pc

107 psi

25.8 d

(25.8)(2.813)

48

(d) Pressure losses through bit ( pb)

Three nozzles (one for each cone) will be used, hence 1/3 q will flow

through each. For v = at least 250 ft/sec through each nozzle,

q

1

3

q

307 / 3

0.41 in.

2.45v

(2.45)(250)

Nozzle sizes are sell in multiples of 1/32 in.

Therefore, the nearest stock nozzle available is

13/32 in. (i.e. 0.40625 in.):

nozzle diameter of

13

32

in. is chosen

This nozzle allows an actual velocity of:

102

v

252 ft/sec

13 2

2.45( 32 )

1

3

1

3

1

3

49

Eq. (3.15a) d e nd 2

Eq. (3.15b) de ad12 bd 22 etc.

Using Eq. (3.15) or (3.15a), the actual nozzle diameter:

2

d 3 ( 13

)

0.704 in.

32

q 2 m

Eq. (3.13) pb

7, 430C 2 d 4

Pressure drop across the bit, pb :

(307)2 (10)

pb

573 psi

2

4

7, 430(0.95) (0.704)

50

(e) Pressure losses around drill collar ( pac)

The average velocity around the drill collar:

307

v

7.62 ft/sec

7 2

3 2

(2.45) (7 8 ) (6 4 )

The hydraulically equivalent diameter of the annulus:

d a d1 d 2

d 7 78 6 34 1 18 in.

The critical velocity:

vc

1.08 (30) 1.08 (30)2 (9.3)(10)(1 18 )2 (10)

1

8

(10)(1 )

7.26 ft/sec

51

v vc turbulent flow (use Eq. 3.4)

NRe

2,970 vd

(2,970)(7.62)(1 18 )

8, 487 8,500

30

N Re 8, 400

Curve IV (for annuli

in uncased hole)

Fig. 7.1 f 0.0098

Applying Eqn. (3.4):

f Lv 2 (0.0098)(10)(500)(7.62)2

pac

98 psi

1

25.8 d

(25.8)(1 8 )

52

(f) Pressure losses around drill pipe ( pap)

The average velocity around the drill collar (as assume/given earlier):

v 3 ft/sec

The hydraulically equivalent diameter of the annulus:

d a d1 d 2

d 7 78 4 12 3 83 in.

The critical velocity:

vc

1.08(30) 1.08 (30)2 (9.3)(10)(3 83 )2 (10)

v vc

3

8

(10)(3 )

4.39 ft/sec

laminar flow (use Eq. 3.6) p L

300d

5,500

pap

300 (3 83 )

30 (3)

83 psi

10

3

5(3 8 )

pv

Yb

5

d

53

(g) The total pressure drop in the system ( pt)

pt 36 269 107 573 98 83 1,166 psi

(h) Horsepower output at the pump

q p

HP

1,714 v m

.......... (3.17)

where :

q = flow rate, gpm

v = volumetric efficiency

m = mechanical efficiency

Assuming volumetric and mechanical efficiencies of the pump are 90% and 85%

respectively:

HP

307 (1,166)

273 horsepower

1,714(0.90)(0.85)

54

Summary

Bingham Plastic Model: Calculation Steps

pt p s p p p c pb p ac p ap

p

vc

Eq. (3.8)

E q . (3 .1 6 ) o r F ig . 3 .3

v

Eq. (3.7a ) or (3.7b)

de

Eq. (3.15a) or (3.15b)

pb

No

(lam in ar)

p p , pc , pac , pap

Eq. (3.6)

if

v vc

(Eqn. 3.13)

Yes

(tu rb u len t)

N Re

Eq. (3.2)

f

(Fig. 7.1)

p p , pc , pac , pap

Eq. (3.4)

55

p

p pu

9.5 3.2(3)

Example 3.4

Using a data as in Example 3.3, calculate the circulating pressure required.

Solution 3.4

From Example 3.3: q = 307 gpm, bit = 3 13/32 in. nozzles

(a) Surface equipment losses ( ps)

q = 307 gpm

Curve type 2

Fig. 7.3

pu 27 psi

0.14

10 30

ps 27

33 psi

9.5 3.2(3)

(b) Pressure losses inside drill pipe ( pp)

q = 307 gpm

Fig. 7.5 (for 4.5 d/p)

Curve 7

(assume ID = 3 )

10 30

p p 176

9.5 3.2(3)

32

pu

5,500 176 psi

1,000

0.14

217 psi

0.14

56

p

p pu

9.5 3.2(3)

(c) Pressure losses inside drill collar ( pc)

q = 307 gpm

Curve 2 bore

Fig. 7.7

(assume ID = 2 )

10 30

pc 75

9.5 3.2(3)

13 "

32

93 psi

Fig. 7.9

nozzle

pb 550

15

500 75 psi

100

0.14

(d) Pressure losses through bit ( pb)

q = 307 gpm

pu

(no viscosity effect)

10

579 psi

9.5

p pu

pu 550 psi

m

9.5

0.14

57

p

p pu

9.5 3.2(3)

(e) Pressure losses around drill collar ( pac)

q = 307 gpm

6 drill collar

Fig. 7.10

(bit size = 7 7/8)

10 30

pac 125

9.5 3.2(3)

25

500 125 psi

100

pu

0.14

154 psi

(f) Pressure losses around drill pipe ( pap)

q = 307 gpm

4 drill pipe

Fig. 7.10

(bit size = 7 7/8)

10 30

pap 77

9.5 3.2(3)

pu

1.4

5,500 77 psi

100

0.14

95 psi

(g) The total pressure drop in the system ( pt)

pt 33 217 107 579 154 95 1,185 psi

0.14

58

Comparison of p Calculation Methods

System

component

Plastic flow calculation

(psi)

Hughes Tools Co. charts

(psi)

Surface connections, ps

36

33

Inside drill pipe, pp

269

217

Inside drill collar, pc

107

107

Bit nozzles, pb

573

579

Outside drill collar, pac

98

154

Outside drill pipe, pap

83

95

1,166

1,185

Total circulating

pressure, pt

59

Additional Information

Besides Newtonian and Bingham Plastic Models, there are

several other model used to predict pressure losses in mud

circulating systems.

Generally, each model is based on a set of assumptions which

cannot be completely fulfilled in any drilling situation.

Power law, Herschel-Bulkley (Yield Power Law @ API Power

Law) models are the most widely used in the oil industry.

Table 3.3 shows a summary of pressure loss equations

You might also like

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Drilling Hydraulics ADocument63 pagesDrilling Hydraulics Asryn89100% (3)

- Drilling HydraulicsDocument39 pagesDrilling HydraulicsAllbert Einstein100% (1)

- Chapter 3 - Hydraulics and Hole Cleaning 2015Document86 pagesChapter 3 - Hydraulics and Hole Cleaning 2015Shalihan Mustafa0% (1)

- WellBore Planner HLB Landmark ManualDocument416 pagesWellBore Planner HLB Landmark ManualECP Maria P - Respaldo100% (1)

- Hole Volume Mu-135aDocument8 pagesHole Volume Mu-135afadli.lpgNo ratings yet

- Drilling HydraulicsDocument78 pagesDrilling HydraulicsKarlos Rdgz100% (1)

- Primary Cementing CalculationsDocument40 pagesPrimary Cementing CalculationsMostafa ElghifaryNo ratings yet

- IRP 22 - Underbalanced Drilling & Managed Pressure Drilling Operations Using Jointed Pipe - Oct 17 - 2018 PDFDocument158 pagesIRP 22 - Underbalanced Drilling & Managed Pressure Drilling Operations Using Jointed Pipe - Oct 17 - 2018 PDFJohnny BreuerNo ratings yet

- CH4-3 Drilling Hydraulics Optimization Criteria (Practical Example)Document13 pagesCH4-3 Drilling Hydraulics Optimization Criteria (Practical Example)Haseen KaurNo ratings yet

- Rahimov, MPDDocument102 pagesRahimov, MPDYassir HindiNo ratings yet

- Torque and Drag CalculationsDocument67 pagesTorque and Drag CalculationsStalin ChugchilánNo ratings yet

- LD2 Drilling Practices & Lessons Learned - A.boubeniaDocument8 pagesLD2 Drilling Practices & Lessons Learned - A.boubeniaAli BoubeniaNo ratings yet

- Best Practices Drilling 26 inDocument6 pagesBest Practices Drilling 26 inmanuelperdomotNo ratings yet

- Well PlanDocument450 pagesWell PlanazeazeazeNo ratings yet

- How To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred GrowcockDocument16 pagesHow To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred Growcockrıdvan duranNo ratings yet

- Drilling Fluid PDFDocument68 pagesDrilling Fluid PDFShiela ONo ratings yet

- CASING DESIGN CRITERIA CALCULATIONSDocument59 pagesCASING DESIGN CRITERIA CALCULATIONSahoua100% (1)

- Mud LoggingDocument15 pagesMud Loggingspydaman4uNo ratings yet

- Under-Balanced Drilling FluidsDocument74 pagesUnder-Balanced Drilling Fluidsflyerrunner100% (1)

- Round Trip Ton-Miles CalculationDocument2 pagesRound Trip Ton-Miles CalculationKenaouia BahaaNo ratings yet

- Drill Bench 5Document12 pagesDrill Bench 5Abdalla Magdy DarwishNo ratings yet

- Mud Engineer User ManualDocument48 pagesMud Engineer User ManualstevebeardsleyNo ratings yet

- Mud FactsDocument91 pagesMud FactsShamia EssamNo ratings yet

- Drilling Dynamics Sensors Opt BR PDFDocument16 pagesDrilling Dynamics Sensors Opt BR PDFhamed1725No ratings yet

- Discover How Slant Drilling Techniques Revolutionized Heavy Oil RecoveryDocument184 pagesDiscover How Slant Drilling Techniques Revolutionized Heavy Oil RecoveryWeatherford75267% (3)

- Offshore Drilling IntroductionDocument56 pagesOffshore Drilling IntroductionnaefmubarakNo ratings yet

- Maximizing Hydraulics PerformanceDocument36 pagesMaximizing Hydraulics PerformancedohlalaNo ratings yet

- Circulation and Well ControlDocument16 pagesCirculation and Well ControlAmirhosseinNo ratings yet

- GTSC Simulator Profile Offers 10 Training OptionsDocument14 pagesGTSC Simulator Profile Offers 10 Training OptionsDurga PrasadNo ratings yet

- Well Plan PDFDocument280 pagesWell Plan PDFTanaNo ratings yet

- Casing Setting Depth DesignDocument26 pagesCasing Setting Depth Designehsan100% (1)

- 2well Control - ExerciseDocument140 pages2well Control - ExercisemmmmjjNo ratings yet

- Squeeze Cementing JobDocument1 pageSqueeze Cementing JobstevebeardsleyNo ratings yet

- Old - WELLPLAN Software Release 5000.1.13Document338 pagesOld - WELLPLAN Software Release 5000.1.13HassaanAhmed100% (1)

- Convential Drilling Vs MPD StodleDocument83 pagesConvential Drilling Vs MPD StodleSyed Irtaza100% (1)

- EX-0035 Drilling - English API Forumla SheetDocument4 pagesEX-0035 Drilling - English API Forumla Sheetmohamed abbasNo ratings yet

- SDU Ver142beta1 - Demo Print 1 PDFDocument12 pagesSDU Ver142beta1 - Demo Print 1 PDFreza khNo ratings yet

- Surface BOP Stack Operations API - Deviated Well Kill SheetDocument0 pagesSurface BOP Stack Operations API - Deviated Well Kill Sheetjosesito_amoroso2005No ratings yet

- Stuck Pipe and Filter CakeDocument14 pagesStuck Pipe and Filter CakeKolawole AdisaNo ratings yet

- Well PlanningDocument4 pagesWell PlanningSibte Hassan ButtNo ratings yet

- Drilling Hydraulics LectureDocument36 pagesDrilling Hydraulics LectureAlen Yu Ni100% (1)

- HPHT Offset Well Data ExampleDocument23 pagesHPHT Offset Well Data ExampleWaleed Barakat MariaNo ratings yet

- Remedial Cementing TechniquesDocument4 pagesRemedial Cementing TechniquesColor RougeNo ratings yet

- Drilling & Oilwell DevelopmentDocument362 pagesDrilling & Oilwell DevelopmentAhmed AmerNo ratings yet

- 1 Casing DesignDocument73 pages1 Casing DesignHasril Fauzul AziNo ratings yet

- LOSS OF CIRCULATION Guide PDFDocument82 pagesLOSS OF CIRCULATION Guide PDFMateus OrnaiNo ratings yet

- Balanced Cement Plug CalculationDocument7 pagesBalanced Cement Plug CalculationAlejandro ViscarraNo ratings yet

- Casing Design GuideDocument484 pagesCasing Design GuideClOudyo Virgílio100% (1)

- CSG Design by AmrDocument19 pagesCSG Design by AmrSudish BhatNo ratings yet

- Casing ExerciseDocument9 pagesCasing ExerciseYesar Bin Mustafa AlmalekiNo ratings yet

- Optimization of Rig Hydraulics & Hole CleaningDocument60 pagesOptimization of Rig Hydraulics & Hole CleaningAbhinav Goyal100% (4)

- Drilling String CalculationDocument3 pagesDrilling String CalculationriobmNo ratings yet

- Mud Factors for Drilling OperationsDocument91 pagesMud Factors for Drilling OperationsRomadona Yoga PutratamaNo ratings yet

- Drill String Design 4.11Document23 pagesDrill String Design 4.11Ryan Tan Ping YiNo ratings yet

- Drilling EquipmentDocument63 pagesDrilling EquipmentYudha negaraNo ratings yet

- Applied Drilling Circulation Systems: Hydraulics, Calculations and ModelsFrom EverandApplied Drilling Circulation Systems: Hydraulics, Calculations and ModelsRating: 5 out of 5 stars5/5 (4)

- Vimagineering Flyer PDFDocument1 pageVimagineering Flyer PDFfreelancer2earnNo ratings yet

- Machine Learning and Deep Learning Crash CoursesDocument1 pageMachine Learning and Deep Learning Crash Coursesfreelancer2earnNo ratings yet

- Modeling IPRDocument19 pagesModeling IPRfreelancer2earnNo ratings yet

- How To Recognize "Double-Porosity" Systems From Well Tests: Alain C. GringartenDocument3 pagesHow To Recognize "Double-Porosity" Systems From Well Tests: Alain C. GringartenRafiZafiNo ratings yet

- Machine Learning and Deep Learning PDFDocument1 pageMachine Learning and Deep Learning PDFfreelancer2earnNo ratings yet

- Ideo Coding Technique Using Swarm Intelligence in 3-D Dual Tree Complex Wavelet Transform, 2010Document5 pagesIdeo Coding Technique Using Swarm Intelligence in 3-D Dual Tree Complex Wavelet Transform, 2010freelancer2earnNo ratings yet

- Modeling ICDs in Gas Condensate ReservoirsDocument96 pagesModeling ICDs in Gas Condensate Reservoirsfreelancer2earnNo ratings yet

- EclipseDocument43 pagesEclipseBảo Toàn NguyễnNo ratings yet

- Gas Injection DesignDocument161 pagesGas Injection DesignSarkodie KwameNo ratings yet

- FishboneDocument116 pagesFishbonefreelancer2earnNo ratings yet

- YE ZHANG, Introduction To GeostatisticsDocument36 pagesYE ZHANG, Introduction To Geostatisticsmesquida1993No ratings yet

- VariogramsDocument20 pagesVariogramsBuiNgocHieu92% (13)

- PRECAST ELEMENTS AND SYSTEMS EXPLAINEDDocument9 pagesPRECAST ELEMENTS AND SYSTEMS EXPLAINEDRegine Ignacio SobremonteNo ratings yet

- 01 Introduction To Earthquake EngineeringDocument50 pages01 Introduction To Earthquake EngineeringAnonymous LcR6ykPBTNo ratings yet

- DeckDocument9 pagesDeckSamuel AntobamNo ratings yet

- Reinforced Concrete Slab Punching Shear StrengthDocument8 pagesReinforced Concrete Slab Punching Shear StrengthRaju ShresthaNo ratings yet

- Masterflow 715 PDFDocument2 pagesMasterflow 715 PDFMd. Shahadat HossainNo ratings yet

- M3c Hazen WilliamsDocument8 pagesM3c Hazen WilliamsTariq AfridiNo ratings yet

- Reinforced Concrete Footing Design SpreadsheetDocument5 pagesReinforced Concrete Footing Design SpreadsheetJamil AlhamatyNo ratings yet

- Allowable Foundation Settlement For Different StructuresDocument2 pagesAllowable Foundation Settlement For Different StructuresMohammad Abu Al-ToyourNo ratings yet

- Punching Shear in Slabs and Foundations ExplainedDocument5 pagesPunching Shear in Slabs and Foundations ExplainedUsman ShahidNo ratings yet

- CavitationDocument1 pageCavitationmcsfuvNo ratings yet

- Explicit Friction Factor Accuracy and Computational Efficiency For Turbulent Flow in PipesDocument27 pagesExplicit Friction Factor Accuracy and Computational Efficiency For Turbulent Flow in PipesJoão Rubens MartinsNo ratings yet

- Consolidation of Soils: ABSTRACT: Primary Compression and Secondary Compression of Saturated Soils Are ConsistentDocument16 pagesConsolidation of Soils: ABSTRACT: Primary Compression and Secondary Compression of Saturated Soils Are ConsistentRivaiNo ratings yet

- Sewerage Manual Part 1 - With EurocodesDocument107 pagesSewerage Manual Part 1 - With Eurocodeselsayedamr100% (1)

- What Is New With DSA Potential Upcoming Additions To Specification Information For PM Field TripDocument56 pagesWhat Is New With DSA Potential Upcoming Additions To Specification Information For PM Field TripNrjNo ratings yet

- Fema 451 Part 2Document509 pagesFema 451 Part 2Sagar M JadhavNo ratings yet

- Week 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensityDocument27 pagesWeek 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensitySamantha NamzugNo ratings yet

- COMPARISON OF COMPOSITE BEAM DESIGNDocument8 pagesCOMPARISON OF COMPOSITE BEAM DESIGNMohamed Abo-ZaidNo ratings yet

- Department of Civil Engineering, SNP College, RamanagaraDocument26 pagesDepartment of Civil Engineering, SNP College, RamanagaraChaithra ShreeNo ratings yet

- Structural Solutions of India: of Pile Lateral Load TestDocument6 pagesStructural Solutions of India: of Pile Lateral Load TestSatyaprakash PrasadNo ratings yet

- Sikaplan WT 4220 Sheet Membrane Potable Water Reservoirs EngDocument20 pagesSikaplan WT 4220 Sheet Membrane Potable Water Reservoirs EngMartin UrbietaNo ratings yet

- ARCH 252 Lecture 2 - Introduction To Structure Systems - Masonry Structures Design - Spring 2021Document15 pagesARCH 252 Lecture 2 - Introduction To Structure Systems - Masonry Structures Design - Spring 2021teifNo ratings yet

- 03 07 - Sup SlabDocument124 pages03 07 - Sup Slabجميل عبد الله الحماطيNo ratings yet

- Buckling Restrained Braced FramesDocument25 pagesBuckling Restrained Braced Framesash100% (2)

- Design of Reinforced Concrete Beams For ShearDocument35 pagesDesign of Reinforced Concrete Beams For ShearinthirankuNo ratings yet

- Materials SelectionDocument14 pagesMaterials Selectionchen18111004 KFUEITNo ratings yet

- EFCO LITE Column and Hand E FormDocument7 pagesEFCO LITE Column and Hand E FormsonymeganNo ratings yet

- ShearWall SNI2847 2013Document6 pagesShearWall SNI2847 2013Tony WangNo ratings yet

- 1) Water Supply Project:: Main Functions of The DepartmentDocument36 pages1) Water Supply Project:: Main Functions of The DepartmentMehulNo ratings yet

- Machine Design Lesson on Buckling of Slender ColumnsDocument10 pagesMachine Design Lesson on Buckling of Slender ColumnsCarl JavierNo ratings yet

- Castellated Beams - New DevelopmentsDocument5 pagesCastellated Beams - New DevelopmentsScott NorrisNo ratings yet