Professional Documents

Culture Documents

DCV Spirax PDF

Uploaded by

Vaitheeswaran PalaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DCV Spirax PDF

Uploaded by

Vaitheeswaran PalaniCopyright:

Available Formats

TI-P134-04

ST Issue 8

Cert. No. LRQ 0963008

DCV4

Disc Check Valve

ISO 9001

Description

The DCV4 stainless steel disc check valve is of the wafer pattern

designed to be sandwiched between ANSI flanges. It is suitable for

use on a wide range of fluids for applications in process lines, hot

water systems, steam and condensate systems etc. Face-to-face

dimensions conform to EN 558 part 2, series 52.

As standard it will be supplied with a metal-to-metal seat

for use on steam applications. Where it will be used on oil, air,

gas and water applications, alternative seat material is available

- see 'Optional extras'.

Optional extras

High temperature springs for temperatures up to 400C.

Viton soft seats for oils, air and gas applications.

EPDM soft seats for water applications.

Standards

This product fully complies with the requirements of the

European Pressure Equipment Directive 97 / 23 / EC.

Certification

This product is available with certification to EN 10204 3.1.

Note: All certification / inspection requirements must be stated at

the time of order placement.

Sizes and pipe connections

DN15, DN20, DN25, DN40, DN50, DN80 and DN100

Suitable for installation between ANSI 150 or ANSI 300 flanges.

Materials

Material

Body

Austenitic stainless steel ASTM A351 CF3M

Disc

Austenitic stainless steel

Spring retainer

Austenitic stainless steel BS 1449 316 S11

Standard spring

Austenitic stainless steel BS 2056 316 S42

High temp. spring Nickel alloy

BS 1449 316 S11

Nimonic 90

Operation

Disc check valves are opened by the pressure of the fluid and

closed by the spring as soon as the flow ceases and before the

reverse flow occurs.

Open

Pressure / temperature limits

C

Steam

saturation

curve

Pressure bar g

No. Part

4 2 3

Temperature C

Standard shut-off

Standard valves conform to DIN 3230 part 3, BN2.

Valves conforming to DIN 3230 part 3, BO3 available on request.

Soft seated versions meet DIN 3230 part 3 BN1 and BO1 provided

a differential pressure exists.

Closed

The product must not be used in this region.

A- B -D High temperature spring and without spring.

E - C -D Standard spring.

Please note: The figures displayed are only relevant when a

metal-to-metal seat is used. If Viton or EPDM seats are used the

product is restricted to the limits of the seat material chosen.

Body design conditions for saturated steam service

ANSI 300

PMA Maximum allowable pressure

49 bar g @ 37C

TMA Maximum allowable temperature

400C @ 29 bar g

Minimum allowable temperature

-29C

Maximum

operating

pressure

49 bar g @ 37C

PMO for saturated steam service

Standard spring

300C @ 31.5 bar g

Maximum

High

TMO operating

temperature

300C @ 29 bar g

temperature

spring

Without spring

400C @ 29 bar g

Minimum operating temperature

-29C

Note: For lower operating temperatures consult Spirax Sarco

Viton seat

-15C to +250C

Temperature limits

EPDM seat

-29C to +150C

Designed for a maximum cold hydraulic test pressure of 76 bar g

Local regulations may restrict the use of this product to below the conditions quoted.

In the interests of development and improvement of the product, we reserve the right to change the specification without notice.

Copyright 2008

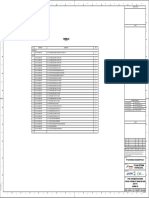

Dimensions / weights (approximate) in mm and kg

ANSI

300

A

54

67

73

95

111

149

181

Size

DN15

DN20

DN25

DN40

DN50

DN80

DN100

ANSI

150

B

47

57

67

86

105

136

174

C

38

46

54

76

95

130

160

D

25

31

35

45

56

71

80

E

22.35

27.35

33.15

49.15

59.15

90.15

111.15

Kv values

DN

15

20

25

40

Kv

4.4

7.5

12

26

For conversion:

Cv (UK) = Kv x 0.963

F Weight

15

0.24

20

0.41

25

0.54

40

1.15

50

1.84

80

3.69

100

5.70

50

80

100

39

84

150

Cv (US) = Kv x 1.156

B

Centering dimension for ANSI 150

Opening pressures in mbar

Differential pressures with zero flow for standard and high

temperature springs.

Flow direction

DN

15

25

22.5

20

20

25

22.5

20

25

25

22.5

20

40

28

24

20

50

29

24.5

20

80

31

25.5

20

A

Centering dimension for ANSI 300

100

33

26.5

20

Where lowest opening pressures are required, valves without

springs can be installed in vertical pipes with bottom-to-top flow.

Without spring

2.5

2.5

2.5

4.0

4.5

5.5

6.5

Pressure loss diagram

Pressure loss in bar

Water flowrate in Vw I /s

Water flowrate in Vw m3 /h

Pressure loss diagram with open valve at 20C. The values indicated

are applicable to spring loaded valves with horizontal flow. With

vertical flow, insignificant deviations occur only within the range of

partial opening.

The curves given in the chart are valid for water at 20C. To

determine the pressure for other fluids the equivalent water volume

flowrate must be calculated and used in the graph.

xV

1000

Vw = Equivalent water volume flow in l / s or m/h

= Density of fluid kg/m

V

= Volume of fluid l/s or m/h

Vw =

Where:

Pressure loss information for steam, compressed air and gases

is available from Spirax Sarco.

How to order

Example: 1 off Spirax Sarco DN40, DCV4 stainless steel disc

check valve for fitting between ANSI 300 flanges.

Safety information, installation and maintenance

For full details see the Installation and

Maintenance Instructions (IM-P134-08)

supplied with the product.

DCV4 disc check valves must be fitted

in accordance with the direction of

flow arrow indicating correct fluid flow

direction. When fitted with a spring

they can be installed in any plane.

When supplied without a spring they

must be fitted in a vertical flow line

with the flow from bottom-to-top.

* Note:

Flanges, bolts (or studs), nuts and joint gaskets are to be

provided by the installer. Disc check valves are non-maintainable

(no spares are available). Disc check valves are not suitable for

use where heavily pulsating flow exists, such as close to a

compressor.

Various options are denoted by a marking on the valve body:'N'

High temperature spring Standard metal disc

'W'

Without spring

Standard metal disc

'V'

Standard spring

Viton soft faced disc

'E'

Standard spring

EPDM soft faced disc

'WV' Without spring

Viton soft faced disc

'WE' Without spring

EPDM soft faced disc

'T'

Valves tested to DIN 3230 part 3, B03

No identification indicates a standard spring with a metal disc.

Disposal

If a product which contains a Viton component has been subjected

to a temperature approaching 315C or higher, then it may have

decomposed and formed hydrofluoric acid. Avoid skin contact and

inhalation of any fumes as the acid will cause deep skin burns and

damage to the respiratory system. Viton must be disposed of in a

recognised manner as stated in the Installation and Maintenance

Instructions (IM-P134-08). No other ecological hazard is anticipated

with the disposal of this product providing due care is taken.

DCV4 Disc Check Valve

TI-P134-04 ST Issue 8

You might also like

- API 6A Gate ValvesDocument12 pagesAPI 6A Gate ValvesLee Sweningson100% (1)

- Allweiler SN SeriesDocument12 pagesAllweiler SN SeriesAlexis Ernesto Cardenas BeltranNo ratings yet

- Secador SMC Idf 15C1-6Document36 pagesSecador SMC Idf 15C1-6marioNo ratings yet

- Turbine Fuel SystemDocument66 pagesTurbine Fuel SystemDamon Leong100% (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- LPG PracticeDocument91 pagesLPG PracticeКирилл Винокуров100% (14)

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- Direct Acting Excess Pressure ValvesDocument8 pagesDirect Acting Excess Pressure ValvescartarNo ratings yet

- BHEL SupercriticalDocument40 pagesBHEL SupercriticalSam100% (2)

- Centrifugal Pump BrochuresDocument16 pagesCentrifugal Pump BrochuresAbsar Mamun100% (3)

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- As 0201 Gauge Valves and Pressure Gauge Accessories enDocument36 pagesAs 0201 Gauge Valves and Pressure Gauge Accessories enTomas PinheiroNo ratings yet

- Thumb Rules For Chemical EngineerDocument44 pagesThumb Rules For Chemical EngineerNallathambiNo ratings yet

- LPG TanksDocument48 pagesLPG TanksdlebreromNo ratings yet

- FlowMon Catalogue 2Document12 pagesFlowMon Catalogue 2dhanu_aquaNo ratings yet

- Mozambique Offshore: Rovuma Offshore Gas Discoveries 2010 and 2011Document12 pagesMozambique Offshore: Rovuma Offshore Gas Discoveries 2010 and 2011tsar mitchelNo ratings yet

- Pbs Turbo LTD./ 595 01 - Velka Bites, Czech RepublikDocument23 pagesPbs Turbo LTD./ 595 01 - Velka Bites, Czech Republikslava50% (2)

- Hydro TestDocument28 pagesHydro TestNabankur Ray100% (1)

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- Hydro-Test Procedure For HDPE PipelineDocument14 pagesHydro-Test Procedure For HDPE PipelineAhmedNo ratings yet

- Desuperheater That Combines Proven Technologies For Better Operational EconomyDocument4 pagesDesuperheater That Combines Proven Technologies For Better Operational Economyhappale2002No ratings yet

- Hydraulic Tubes and PipesDocument18 pagesHydraulic Tubes and Pipeshp_vijaykNo ratings yet

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- V9271 Fivalco 2902eDocument6 pagesV9271 Fivalco 2902eharenas7No ratings yet

- Purga Fondo BBV 980 A PDFDocument2 pagesPurga Fondo BBV 980 A PDFaugusto7777No ratings yet

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991No ratings yet

- Double Reg Valves PDFDocument15 pagesDouble Reg Valves PDFNoushad P HamsaNo ratings yet

- Manual Ecoflux en - KrohneDocument14 pagesManual Ecoflux en - Krohnemmihai_popa2006No ratings yet

- Steam TrapDocument2 pagesSteam TrapAmpornchai PhupolNo ratings yet

- Fig. 1 Type 3351-1 Pneumatic On/off ValveDocument6 pagesFig. 1 Type 3351-1 Pneumatic On/off ValveZoran DanilovNo ratings yet

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDocument10 pagesHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111No ratings yet

- Valvula Bola Sarco m40Document3 pagesValvula Bola Sarco m40radacoNo ratings yet

- Series 240 Pneumatic Control Valve Type 3241-1 and Type 3241-7 Globe Valve Type 3241Document8 pagesSeries 240 Pneumatic Control Valve Type 3241-1 and Type 3241-7 Globe Valve Type 3241SantaAgataNo ratings yet

- Tyco Catalogue NetDocument34 pagesTyco Catalogue NetAhmad Nasser0% (1)

- ValvesDocument6 pagesValvesstevegazeleyNo ratings yet

- As 0201 en Gauge Valves and Pressure Gauge AccessoriesDocument36 pagesAs 0201 en Gauge Valves and Pressure Gauge AccessoriesTache MihaiNo ratings yet

- Asco S V7394R5Document16 pagesAsco S V7394R5Jorge Jarpa VNo ratings yet

- 3-Way Valve - ThreadedDocument4 pages3-Way Valve - ThreadedAhrian BenaNo ratings yet

- VAL Team Adca: Steam Distribution Manifold MASDocument4 pagesVAL Team Adca: Steam Distribution Manifold MASEdgar León100% (2)

- Pfeiffer Br26d EngDocument4 pagesPfeiffer Br26d EngAleksandr KrigerNo ratings yet

- Guth VSR Modulating ValvesDocument8 pagesGuth VSR Modulating ValvesRaul Guevara TorresNo ratings yet

- ValvulaDocument8 pagesValvulaJosé Gasset Del ValleNo ratings yet

- SONDA cONDUTIVÍMETRO PDFDocument8 pagesSONDA cONDUTIVÍMETRO PDFAngeloNo ratings yet

- Uniworld: Series Pneumatic ValvesDocument2 pagesUniworld: Series Pneumatic ValvesSyarif Mutsaqqif100% (1)

- Vann Air ValveDocument4 pagesVann Air ValveDedeLesmanaNo ratings yet

- Clorius Temperature Control Valves ManualDocument6 pagesClorius Temperature Control Valves ManualalvinNo ratings yet

- KSB Butterfly Valve Boax-B SeriesDocument20 pagesKSB Butterfly Valve Boax-B SeriesswcciqbalNo ratings yet

- AV13 Air Vent For Steam Systems: DescriptionDocument2 pagesAV13 Air Vent For Steam Systems: DescriptionUtku KepcenNo ratings yet

- Catalog Valve KSBDocument58 pagesCatalog Valve KSByoboo100% (1)

- SAMSON Control Valves Type 3213 Type 3214 t5868Document12 pagesSAMSON Control Valves Type 3213 Type 3214 t5868Sai SarihadduNo ratings yet

- Diaphragm-Seal Type Pressure Gauges: OutlineDocument40 pagesDiaphragm-Seal Type Pressure Gauges: OutlineFadlul Akbar HerfiantoNo ratings yet

- Wafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ADocument4 pagesWafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ARadu GanciuNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveCatalina NutaNo ratings yet

- Clorius Controls 3-Way Control Valves TYPE Soft Seated: Nodular Cast Iron, DN 80 - 300 MM InstructionsDocument29 pagesClorius Controls 3-Way Control Valves TYPE Soft Seated: Nodular Cast Iron, DN 80 - 300 MM InstructionsromanNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Tip 3241-7 PozicionatorDocument8 pagesTip 3241-7 PozicionatorEmir DelicNo ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- PressureDocument84 pagesPressureHangloque GabanoNo ratings yet

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDocument5 pagesSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroNo ratings yet

- Process ValveDocument38 pagesProcess ValvetabiiNo ratings yet

- Model BFV-N Butterfly Valve Grooved End Technical Data General DescriptionDocument4 pagesModel BFV-N Butterfly Valve Grooved End Technical Data General DescriptionPatricio SabettaNo ratings yet

- Neojv 0040 enDocument0 pagesNeojv 0040 enLuis GuevaraNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Price List - Audco - 2011 - 12Document3 pagesPrice List - Audco - 2011 - 12samvendan100% (1)

- ListDocument12 pagesListashishtaneja30No ratings yet

- Type Test ReportDocument17 pagesType Test ReportVaitheeswaran PalaniNo ratings yet

- Check ValveDocument2 pagesCheck ValveVaitheeswaran PalaniNo ratings yet

- ITQ Series: Economic Style Electric ActuatorDocument8 pagesITQ Series: Economic Style Electric ActuatorVaitheeswaran PalaniNo ratings yet

- Instalación Profesional Puertas Lambo (En Inglés)Document24 pagesInstalación Profesional Puertas Lambo (En Inglés)fuentesmsNo ratings yet

- ME 301-Midterm-2022-2-PrintDocument1 pageME 301-Midterm-2022-2-PrintGintoki SakataNo ratings yet

- The Vertical Limbs of A U Shaped Tube Are Filled With A Liquid of DensityDocument14 pagesThe Vertical Limbs of A U Shaped Tube Are Filled With A Liquid of DensityUdeshaWickramaraachchi100% (1)

- A New LNG Baseload ProcessDocument9 pagesA New LNG Baseload ProcessPatrascu MariusNo ratings yet

- Flow Simulation Report Square Nozzle 3-1 InchDocument18 pagesFlow Simulation Report Square Nozzle 3-1 InchVianAlwiNo ratings yet

- Fluid FrictionDocument10 pagesFluid FrictionUmesh PatilNo ratings yet

- Impulse Turbine Questions g3Document8 pagesImpulse Turbine Questions g3VipulKukkarNo ratings yet

- EN Pressure sdr17Document1 pageEN Pressure sdr17Alan FloresNo ratings yet

- 21071-D-1910-2560-7501 - 30 (Unit 1910 Overall) Rev 0Document30 pages21071-D-1910-2560-7501 - 30 (Unit 1910 Overall) Rev 0Hadi SuagungNo ratings yet

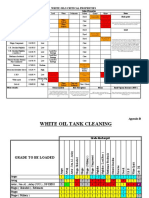

- Oil Tank CleaningDocument4 pagesOil Tank CleaningMituNo ratings yet

- Pesticide Application Equipment and Safety: Prepared by Aggrey Atuhaire, +256-779864929Document44 pagesPesticide Application Equipment and Safety: Prepared by Aggrey Atuhaire, +256-779864929aariksaNo ratings yet

- Wildem PumpDocument35 pagesWildem PumpDiogo CarpNo ratings yet

- Coil Tubing ESP APCDocument6 pagesCoil Tubing ESP APCJhon Doe100% (1)

- Standard Clamping Elements PDFDocument175 pagesStandard Clamping Elements PDFGiannis IoannouNo ratings yet

- 2017 Winter Question Paper PDFDocument4 pages2017 Winter Question Paper PDFJanardan JakhadNo ratings yet

- How Do You Make LiquidDocument2 pagesHow Do You Make LiquidjukortaNo ratings yet

- Thermodynamic Final Exam ReviewDocument15 pagesThermodynamic Final Exam ReviewvistahpNo ratings yet

- VTC ConsolidatedDocument23 pagesVTC ConsolidatedRamKS80No ratings yet

- Throttling Characteristics of Multi-Hole Orifice in Multi Stage AssemblyDocument13 pagesThrottling Characteristics of Multi-Hole Orifice in Multi Stage AssemblyGuglielmoNo ratings yet

- WellHead PDFDocument6 pagesWellHead PDFsolomonicbdmNo ratings yet

- 1 Pieza PSV-3X4Document4 pages1 Pieza PSV-3X4jose ocanaNo ratings yet