Professional Documents

Culture Documents

QSP-1 Document and Data Control

Uploaded by

Jelena Kovač0 ratings0% found this document useful (0 votes)

104 views4 pagesQMS Procedure

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentQMS Procedure

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

104 views4 pagesQSP-1 Document and Data Control

Uploaded by

Jelena KovačQMS Procedure

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 4

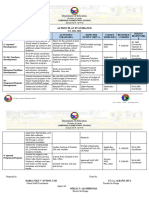

(Company Name)

Document And Data Control

QSP-1

DOCUMENT AND DATA CONTROL

PURPOSE

The purpose of this procedure is to define the process and responsibilities to

ensure that internal Quality Management System (QMS) documents, external

and customer supplied documents (standards, specifications, procedures, prints,

etc.), and data within (Company Name) are controlled.

OWNER

The Quality Manager is responsible to ensure that this procedure is fully

implemented, maintained, and continually improved.

DEFINITIONS

Data - Information used to control a process, normally in electronic form.

Examples are: programs used to control machinery such as CNC machines,

automated inspection programs that include pass/fail values, a database which

specifies calibration frequencies, MRP / ERP system data, etc.

Document - Written material that provides information relating to the

requirements of the Quality Management System (QMS) and is used as training

or reference material. Documents may be in the form of procedures, policies,

instructions, forms, prints, standards, drawings, pictures, videos, etc., and may

be hardcopy or electronic. Documents tell you how to do something. In the

case of blank forms, which are considered documents, they tell you what

information to record. NOTE: A completed form is a record and is controlled by

records management policies.

Controlled Copy The intent of document control is to ensure that people are

always using the latest revision of all documents. A controlled copy of any

QMS documentation means that there is a clearly identified distribution of each

copy. If the document is revised the QMS ensures that each distributed copy will

be replaced with an updated copy. Uncontrolled copies are those made

without updating the distribution requirements for the document. Methods for

ensuring such control of additional copies are defined within this document.

APPLICABILITY

This Procedure applies throughout (Company Name) to the following

documents, data, or other information sources that comprise the QMS:

Quality Manual & QMS Procedures & Forms Documents that describe the

QMS and specific QMS processes applicable across all departments / areas.

Local work instructions, forms, or other process specific documentation

Documents that are only applicable to a specific department / area process. The

following types of process specific documentation are used in our QMS: (e.g.

work instructions, process control plans, process FMEAs, process flow charts,

etc.)

Rev: 4/4/05

Page 1 of 4

(Company Name)

Document And Data Control

QSP-1

Part specific documentation - Documents that are only applicable to a part or

family of parts. The following types of part specific documentation are used in

our QMS: (e.g. part routings, BOMs, part control plans, part FMEAs, process

sheets, prints, set-up sheets, formulation sheets, etc.)

PROCEDURE

Control of Internal Quality Management System (QMS) Documents

Authorization and Revision Control All QMS documents are controlled

electronically whenever possible. The master electronic files are stored and

maintained on the computer located in the administrative office. The Quality

Manager is responsible to implement adequate controls to ensure that no

unauthorized changes are made to these files (e.g. read only file protection,

password protection, drive access restrictions, etc.). Since the QMS

documentation is hyperlinked wherever possible, file names or folder locations

should not be changed unless absolutely necessary. The person(s) who have

authority to authorize or change all QMS documents should be clearly identified

within each document as Process Owner, Document Owner or any other

appropriate statement that clearly identifies who has authority to approve any

changes to the document.

Identification of Changes Changes to QMS documents should be clearly

identified within the document whenever possible. This is to ensure that

employees clearly understand what has changed from the last revision and to

expedite training activities. Any practical means is allowed for this purpose.

Examples are using colored text to identify changes or placing a bar in the right

margin of changed text or including a revision history within the document.

Master Versions All networked computers in the company have a desktop

icon / shortcut which provides access to the master electronic copies of the QMS

documents. Only documents accessed in this manner are considered current

and may be used by company personnel. Employees should not copy any of

these files to their computers or other media unless permission is granted by the

Quality Manager. Where any QMS document is not controlled electronically via

the network then a printed master copy or master document list is maintained

by the process / document owner in a location accessible to all employees that

might use the document (so that they can verify that they are using the current

revision).

Controlled Copies Any documents that are consistently needed at the

process / machine / work area may be printed and distributed / posted with the

following controls. The number of controlled copies and location of each copy

must be clearly defined within the document. When changes are made to the

document it is the responsibility of the process / document owner to ensure that

all such copies are replaced with the updated version.

Rev: 4/4/05

Page 2 of 4

(Company Name)

Document And Data Control

QSP-1

Uncontrolled Copies Additional copies of QMS documents, especially

Forms and Process / Part specific documentation, may be printed out or copied

as needed (e.g. for training or production activities). However, it is the

responsibility of all personnel to verify that they are using the latest revision of

any printed document against the master electronic version. It is highly

recommended that these copies are destroyed after use to minimize the risk of

using obsolete documents.

Obsolete Copies Any obsolete copies of QMS documentation that need to be

retained should be filed in a way that prevents accidental use. For electronic

documents, an archive subdirectory should be created and any old file

revisions and access to the subdirectory should be limited for most employees.

Computer Backups and Virus Protection - Regular backups (minimum weekly)

of all critical information, including the companys QMS documentation and

electronic quality records, are made by the Quality Manager and at least one

copy is kept off-site for disaster recovery. A data recovery simulation should be

conducted at least annually to ensure that all data can be properly restored if it

ever becomes necessary. Virus protection is enabled for all computers with

Internet access. Virus data files should be updated at least weekly. Preferably,

virus protection software will be set for automatic updating and file / email

scanning features.

Document Reviews QMS documents are reviewed for accuracy and

completeness during each training event where they are used. Each trainer is

responsible to identify any necessary updates or improvements in a marked up

printed copy and initiate a document change through the process or document

owner.

CNC Programs CNC programs are controlled electronically on machine

memory and the computer network. All set-up personnel are authorized to make

changes to these programs. Notes are included in the programs to identify any

major changes and to communicate other relevant information.

Control of External Documents

General - Any documents of external origin that are used as part of the Quality

Management System must be verified as current and when necessary their

distribution controlled. During contract review and quality planning activities any

external documents (quality system standards, industry standards, customer

specifications, customer prints, codes, etc.) that are referenced and are needed

to meet customer or regulatory requirements are identified and obtained. It is

the responsibility of Top Management and each Process Owner to review,

implement, and maintain these documents and verify that they remain current at

appropriate frequencies.

Distribution If there are additional hard copies needed then a distribution list

should be included with the master copy. Whenever possible, external

documents should be scanned and an electronic process, customer, and/or part

Rev: 4/4/05

Page 3 of 4

(Company Name)

Document And Data Control

QSP-1

folder should be maintained on the network as part of the QMS documentation to

enable quick access to this information and the ability to verify current revision

status of any printed copies.

Customer Supplied Documentation - A master customer and/or part folder is

created and maintained in the administrative office for all customer supplied

documentation. This folder is the master file location for current revision

information pertaining to customer part drawings, process standards, and any

other relevant information supplied by the customer. A copy of any customer

supplied print will be issued with each job as necessary and should be discarded

after the job is complete. Top Management and each Process Owner are

responsible to review, distribute, and implement all customer engineering

standards / specifications, and any changes communicated by the customer, in a

timely manner. Part of this process is to update any affected part files, process

documentation, and/or QMS procedures and forms.

Training

General All QMS documentation is primarily in place for training company

personnel how to effectively do their job and better satisfy our customers.

Whenever a document is changed, an evaluation must occur by the process /

document owner as to whether training is necessary to implement this change.

The process / document owner is responsible to ensure that any training needs

are fulfilled. No records are required for this activity. Periodically the Quality

Manager will evaluate training effectiveness on recent document changes by

discussing the changes with affected personnel. This evaluation technique

should also be included as part of the internal audit program, see QSP-3.

Rev: 4/4/05

Page 4 of 4

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Teaching With TEACHFLIXDocument16 pagesTeaching With TEACHFLIXummu aimanNo ratings yet

- The Brain Fitness Book Activities and Puzzles To Keep Your Mind Active and Healthy (Rita Carter) (Z-Library)Document192 pagesThe Brain Fitness Book Activities and Puzzles To Keep Your Mind Active and Healthy (Rita Carter) (Z-Library)Richard Wokard100% (1)

- Holt Algebra 1 - Chapter 11 - Standardized TestDocument8 pagesHolt Algebra 1 - Chapter 11 - Standardized TestStanleyNo ratings yet

- Gibbs' Reflective Cycle ModelDocument2 pagesGibbs' Reflective Cycle ModelFrancis Obmerga92% (12)

- Black White Simple Professional Marketing Manager ResumeDocument1 pageBlack White Simple Professional Marketing Manager Resumeapi-707716627No ratings yet

- The Lion Sleeps TonightDocument1 pageThe Lion Sleeps Tonightncguerreiro100% (1)

- Q1 LP AP WEEK 4 DAY 1-5Document5 pagesQ1 LP AP WEEK 4 DAY 1-5jessibel.alejandroNo ratings yet

- Harshal Agrawal - PM ResumeDocument1 pageHarshal Agrawal - PM Resumeapi-354870783No ratings yet

- Emirates Future International Academy Grade-5 WorksheetDocument2 pagesEmirates Future International Academy Grade-5 WorksheetSajir ThiyamNo ratings yet

- Effectiveness of Modular Learning in Grade 12 HummsDocument28 pagesEffectiveness of Modular Learning in Grade 12 HummsSalvieMaria Adel DelosSantos100% (1)

- Improving Criminology Board PerformanceDocument14 pagesImproving Criminology Board PerformanceSharry CastilloNo ratings yet

- Sme Chapther Unsa: Plan Anual 2018Document6 pagesSme Chapther Unsa: Plan Anual 2018JuniorMendoza97No ratings yet

- Resume of Arindam PalDocument8 pagesResume of Arindam PalKrishna Moorthy GanesanNo ratings yet

- Using Historical Thinking to Teach GovernmentsDocument2 pagesUsing Historical Thinking to Teach GovernmentsSneha MishraNo ratings yet

- HSBC Praise Team Self-Evaluations - Vocal/Instrumental/TechDocument3 pagesHSBC Praise Team Self-Evaluations - Vocal/Instrumental/TechEric Powell100% (2)

- ThesisDocument108 pagesThesisDebasis PandaNo ratings yet

- STM32 Lec1Document15 pagesSTM32 Lec1enugraha01100% (1)

- Individual Project Report On Role of Robotic Process Automation (RPA) in Digital TransformationDocument13 pagesIndividual Project Report On Role of Robotic Process Automation (RPA) in Digital TransformationTest accNo ratings yet

- SCNN Scalogram-Based Convolutional Neural Network To Detect ObstructiveDocument12 pagesSCNN Scalogram-Based Convolutional Neural Network To Detect ObstructiveDayana VieiraNo ratings yet

- Italian PHD 2024 Version 01 Scholarship NetworkDocument5 pagesItalian PHD 2024 Version 01 Scholarship NetworkAthar SmartNo ratings yet

- Finan ResumeDocument3 pagesFinan ResumeNhat HoangNo ratings yet

- JATBMSBBAFIABAHonsBusinessEconomics ResDocument863 pagesJATBMSBBAFIABAHonsBusinessEconomics RespuneetNo ratings yet

- Gibb's Reflective CycleDocument11 pagesGibb's Reflective CycleLeornard MukuruNo ratings yet

- Weather Lesson PlanDocument13 pagesWeather Lesson Planapi-194520027No ratings yet

- ĐỀ SỐ 2Document3 pagesĐỀ SỐ 2Nguyễn Kiều OanhNo ratings yet

- Zimbabwe School Examinations Council Physics 9188/4: T-1Ufakose HighDocument6 pagesZimbabwe School Examinations Council Physics 9188/4: T-1Ufakose HighLaura MkandlaNo ratings yet

- 14JE000423-Rajat Kumar Jain - B.Tech (Computer Science and Engineering)Document2 pages14JE000423-Rajat Kumar Jain - B.Tech (Computer Science and Engineering)AshNo ratings yet

- ACTION PLAN IN GUIDANCE S.Y. 2021-2022Document2 pagesACTION PLAN IN GUIDANCE S.Y. 2021-2022Maria Noly Villotes EntinoNo ratings yet

- M.Tech 2023 CutoffDocument6 pagesM.Tech 2023 Cutoffmshail30No ratings yet

- Genalyn Puno Cordez Resume for IT Administration PositionDocument4 pagesGenalyn Puno Cordez Resume for IT Administration PositionJay Mark Albis SantosNo ratings yet