Professional Documents

Culture Documents

Ti 2 315 Us Spirax Sarco

Uploaded by

GUZMANCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ti 2 315 Us Spirax Sarco

Uploaded by

GUZMANCopyright:

Available Formats

Float &

Thermostatic

Steam Traps

Cast Iron Float & Thermostatic Steam Traps

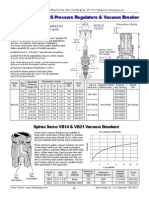

FTBSuper Capacity Series

Typical Applications

All process heat exchange equipment, particularly when controlled by modulating temperature

control valves; unit heaters and air heating coils.

The trap contains a

Model

FTB-20 FTB-30 FTB-50 FTB-125 FTB-175 FTB-200

float valve mechanism

PMO

20 psig 30 psig 50 psig 125 psig 175 psig 200 psig

which modulates to

discharge condensate

Sizes

2"

2"

1-1/2"

2-1/2"

2", 2-1/2"

1-1/2"

continuously at steam

temperature. NonConnections

NPT

condensible gases

Cast Iron Body

Construction

are released by a

Stainless Steel

separate internal

Internals

balanced pressure

Options

Gauge glass, Vacuum Breaker

thermostatic air vent.

2" FTB-20

4

9

1

19

8

18

Construction Materials

No.

1

2

1

3

4

5

6

7

8

9

Part

Material

Body

Cover Screws

Cast Iron

Carbon Steel

2 3

ASTMA126 CL B

ASTM A449 Type

Cover Gasket

Graphite

Cover

Cast Iron

ASTM A126 CL B

Valve Seat

Stainless Steel

Valve Seat Gasket

Stainless Steel (FTB-20)

Valve Assembly Gasket Graphite

Main Valve

Stainless Steel

Assembly Screws

ASTM A193 Grade B8

Ball Float

Stainless Steel

Air Vent Assembly

Air Vent Head

Air Vent Seat

Stainless Steel

Stainless Steel

Stainless Steel

516

17

4

1-1/2" FTB-50

1-1/2" FTB200

2" FTB-175

1

18

8

2 3

6

16

17 15 5

4

9

15

Main Valve Assy Housing Stainless Steel

16

Pivot Pin

Stainless Steel

17

Valve Head

Stainless Steel

(FTB-20, 175, 200)

Cast Stainless Steel

18

Float Arm

Stainless Steel

19

Seat Bracket

Stainless Steel (FTB-20)

Head Bracket, Stop, Link Stainless Steel (FTB-20)

2" FTB-30

2-1/2" FTB-125

2-1/2" FTB-175

(FTB-30, 125, 200)

18

8

For Capacities, see TI-2-317-US

3 6

16

7 15 17

Pressure Shell Design Conditions

Limiting Operating Conditions

Max. Operating Pressure (PMO)

FTB-20: 20 psig

FTB-30: 30 psig

FTB-50: 50 psig

FTB-125:125 psig

FTB-175:175 psig

FTB-200: 200 psig

Max. Operating Temperature

450F @ 200 psig

2:164

(1.4 barg)

(2.1 barg)

(3.4 barg)

(8.6 barg)

(12.1 barg)

(14.0 barg)

PMA FTB-125

175 psig/up to 450F

Max. allowable FTB-175

temp.

FTB-200

200 psig/up to 450F

FTB-20

FTB-30

125 psig/up to 450F

FTB-50

TMA FTB-125

450 F/0-175 psig

Max. allowable FTB-175

temp. FTB-20

FTB-30

450 F/0-125 psig

FTB-50

FTB-200

450F/0-200 psig

12.1 barg/up to 232C

14 barg/up to 232C

8.6 barg/up to 232C

232C/0-12.1 barg

232C/0-8.6 barg

Local regulation may restrict the use of this product below the conditions quoted. Limiting conditions refer to standard connections only.

In the interests of development and improvement of the product, we reserve the right to change the specification.

TI-2-315-US 2.14

Cast Iron Float & Thermostatic Steam Traps

FTBSuper Capacity Series

D

2" FTB-20

Dimensions

(nominal) in inches and millimeters

E

1-1/2"FTB-50

D

F

Type & Size A

B

C

D

FTB-20 12.2 5.9

4.5

0.5

2"

309 149 114 13

FTB-30 15.25 9.25 7.25 1.4

2"

387 235 184 35

FTB-50

1-1/2"

8.8

224

8.3 2.5 22 lb

211 64 10.0 kg

FTB-125

2-1/2"

15.6 9.25 7.25 1.4

15.6 3.75 90 lb

390 235 184 35 397

95 40.8 kg

4.25

108

3

76

0.68

17

Weight

10.7 3

43 lb

271

76 19.5 kg

15.6 3.75 89 lb

397

95 40.4 kg

Steam Traps

FTB-175 12.1 5.9

4.5

0.5

11.8 4

48 lb

2"

306 149 114 13 300

102

21.8 kg

FTB-200 10.8 5.8

3

1-1/2"

273 146 76

D

2"FTB-175

F

9.1 2.3 31 lb

232 64

D

E

0.6

14

Float &

Thermostatic

FTB-175 15.4 9.25 7.25 1.4

15.6 3.75 90 lb

2-1/2"

390 235 184 35 397

95 40.8 kg

F

F

C

C

A

B

1-1/2" FTB-200

2" FTB-30, 2-1/2" FTB-125 & 175

Installation

Sample Specification

A pipeline strainer should be installed ahead of any steam trap.

Full-port isolating valves should be placed to permit servicing.

The trap should be installed below the drainage point of the

equipment with a collecting leg before the trap, in a position

with the float arm in a horizontal plane so that the float rises and

falls vertically, and with the direction of flow as indicated on the

cover. Refer to IM-2-300-US for complete instructions.

Steam traps shall be of the mechanical float type having cast iron bodies,

NPT connections, and stainless steel valve heads and seats. Incorporated

into the trap body shall be a stainless steel balanced pressure thermostatic air vent capable of withstanding 450F and resisting waterhammer without sustaining damage. Internals of the trap shall be completely servicable

without disturbing the piping.

Maintenance

This product can be maintained

without disturbing the piping

connections. Complete isolation

from both supply and return line

is required before any servicing is

performed.

The trap should be

disassembled periodically for

inspection and cleaning of the

valve head and seat, and

operating mechanism.

Worn or damaged parts should be

replaced using a complete valve

mechanism assembly and/or air

vent assembly.

Complete installation and

maintenance instructions are

given in IM-2-300-US, which

accompanies the product.

Air V

N

ent A

J

ssem

M H

bly

L

2" FTB-20

Valve Mechanism

Assembly

D

E

A E

F D

Valv

eM

Asseechanism

mbly

Spirax Sarco, Inc., 1150 Northpoint Blvd, Blythewood, SC 29016

Spare Parts

Gasket Kit (3 of each)

B, F

Gastket Kit (3 of each) FTB-20 B, E

Air Vent Kit

H, J, L, M, N, V

Valve Mechanism

D, E, F

Kit (less float)

Float P

Spirax Sarco, Inc. 2014

TI-2-315-US 2.14

Telephone: (803) 714-2000 FAX (803) 714-2222

2:165

You might also like

- 2021 Physician Compensation Report - Updated 0821Document24 pages2021 Physician Compensation Report - Updated 0821Michael Knapp100% (3)

- Significant Supreme Court RulingsDocument5 pagesSignificant Supreme Court Rulingsapi-307941674No ratings yet

- PLL 2144Document80 pagesPLL 2144Amit TandelNo ratings yet

- Components of A Rainwater Harvesting SystemDocument38 pagesComponents of A Rainwater Harvesting SystembudiperNo ratings yet

- Charge PanelDocument5 pagesCharge PanelSanjeev Kumar T MNo ratings yet

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- 50hz - gcs16lrg - 0700 LennoxDocument16 pages50hz - gcs16lrg - 0700 Lennoxnvr735iNo ratings yet

- L&T Gate Globe Check Valves API 602Document12 pagesL&T Gate Globe Check Valves API 602Nilesh MistryNo ratings yet

- Forged Steel Valves PDFDocument12 pagesForged Steel Valves PDFDiwakar NigamNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Peco Gas Scrubber Fs 85 SL 01Document4 pagesPeco Gas Scrubber Fs 85 SL 01Rigoberto LozanoNo ratings yet

- Jean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Document209 pagesJean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Mi na100% (1)

- CraneDocument32 pagesCranesabes26100% (1)

- Cryogenic Service Ball ValveDocument2 pagesCryogenic Service Ball ValvesaminasritnNo ratings yet

- 1635 The Papal Stakes - Eric FlintDocument1,813 pages1635 The Papal Stakes - Eric Flintwon100% (2)

- Amot Thermostatic Valve Type B PDFDocument6 pagesAmot Thermostatic Valve Type B PDFMargaret DaughertyNo ratings yet

- Trampadevapor Flotador y TermostaticaDocument9 pagesTrampadevapor Flotador y TermostaticaLuis Gutiérrez AlvarezNo ratings yet

- Soot Blower (Sopladores de Hollin)Document6 pagesSoot Blower (Sopladores de Hollin)Eder Agustin Fernandez MedinaNo ratings yet

- Ti 2 313 Us SPIRAXDocument2 pagesTi 2 313 Us SPIRAXGUZMANNo ratings yet

- Model 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentDocument4 pagesModel 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentMohd HassanudinNo ratings yet

- 14 400E 6DC Final Valvula BermadDocument4 pages14 400E 6DC Final Valvula Bermadmax_powerNo ratings yet

- SS-AEPF Goodman Air ConditionerDocument8 pagesSS-AEPF Goodman Air ConditionerArmando EnriquezNo ratings yet

- Valve Spirax Sarco 25P Ti-3-015-UsDocument2 pagesValve Spirax Sarco 25P Ti-3-015-Ussugesus100% (2)

- Bimetallic Steam TrapsDocument2 pagesBimetallic Steam Trapsasad_naqviNo ratings yet

- 50B4KGDocument2 pages50B4KGonin007No ratings yet

- FP 400e-3dc PDFDocument4 pagesFP 400e-3dc PDFTessa CHNo ratings yet

- HR E577rDocument6 pagesHR E577rAnton RenaldoNo ratings yet

- Suction Heater - Asphalt & Fuel Oil Applications: SHO Series Starts atDocument2 pagesSuction Heater - Asphalt & Fuel Oil Applications: SHO Series Starts atJessica Tatiana Muñoz OrtizNo ratings yet

- Rowan University Design Guide 2013Document2 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- F LP - Gas - ValvesDocument2 pagesF LP - Gas - ValvesZMCONTROLNo ratings yet

- FHP Apseries WSHPDocument16 pagesFHP Apseries WSHPsajuhereNo ratings yet

- 43 430 UF Final PDFDocument4 pages43 430 UF Final PDFCarlos TarquinoNo ratings yet

- Especificaciones Equipos Paquetes PDFDocument8 pagesEspecificaciones Equipos Paquetes PDFDavid BallenNo ratings yet

- Parr 4560 ReactorDocument4 pagesParr 4560 Reactoradien_93No ratings yet

- Ga 250Document16 pagesGa 250g9g9No ratings yet

- Valvula de Control de 2 Vias dn15 100 en pv25 - 0Document6 pagesValvula de Control de 2 Vias dn15 100 en pv25 - 0Layton DfcNo ratings yet

- Burmad 400 Series-Globe Type Deluge ValveDocument8 pagesBurmad 400 Series-Globe Type Deluge Valvenastyn-1No ratings yet

- 11 042Document2 pages11 042toha82No ratings yet

- Catálogo Válvula DirecionalDocument20 pagesCatálogo Válvula DirecionalcristianoclemNo ratings yet

- L & M Series Ultra-Capacity Float & Thermostatic Steam Trap: Description How To OrderDocument2 pagesL & M Series Ultra-Capacity Float & Thermostatic Steam Trap: Description How To OrderJozsef MagyariNo ratings yet

- SSC Cat Spirax Sarco Vacuum BreakersDocument1 pageSSC Cat Spirax Sarco Vacuum BreakersEb RahimNo ratings yet

- Carrrier Manual 38ckc-c5pdDocument20 pagesCarrrier Manual 38ckc-c5pdAaron LeveyNo ratings yet

- Vortex TubeDocument3 pagesVortex TubeStreamtek Corp.No ratings yet

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiNo ratings yet

- Logos-Bac Ninh-Spec Sprinkler-HydrantDocument5 pagesLogos-Bac Ninh-Spec Sprinkler-HydrantAn TamNo ratings yet

- Basis of Design-Shop FloorDocument8 pagesBasis of Design-Shop FloorjnmanivannanNo ratings yet

- Enquiry - FFTG - Sprinkle - ValvesDocument8 pagesEnquiry - FFTG - Sprinkle - Valvesrkpatel40No ratings yet

- Bomba Neumatica PB 1/4Document16 pagesBomba Neumatica PB 1/4Marco MendozaNo ratings yet

- TVS 80-DC Series Automatic Differential Condensate ControllersDocument2 pagesTVS 80-DC Series Automatic Differential Condensate ControllersJozsef MagyariNo ratings yet

- SPW Immersion Fired - Specification Data Sheet (7000)Document9 pagesSPW Immersion Fired - Specification Data Sheet (7000)daemonohNo ratings yet

- Condensate Pumps and Energy Recovery PDFDocument17 pagesCondensate Pumps and Energy Recovery PDFPhani Raj MNo ratings yet

- Spirax Sarco 25 PDocument2 pagesSpirax Sarco 25 Pmairimsp2003No ratings yet

- FP 730-59 Data Sheet PDFDocument4 pagesFP 730-59 Data Sheet PDFCarlos TarquinoNo ratings yet

- 1190 TANK BLANQUETING REGULATOR Bulletin PDFDocument12 pages1190 TANK BLANQUETING REGULATOR Bulletin PDFM Betzabe MoraNo ratings yet

- Flutec High Pressure Ball ValveDocument2 pagesFlutec High Pressure Ball ValvefahazumeeNo ratings yet

- E00018 Cat en A4 v28 e FoodlineDocument28 pagesE00018 Cat en A4 v28 e FoodlinecerberusdodoNo ratings yet

- GoedhartVCI P 2012 en Version1 IDocument24 pagesGoedhartVCI P 2012 en Version1 IRodrigo GonçalvesNo ratings yet

- AH AV CatalogDocument16 pagesAH AV CatalognomurapreNo ratings yet

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- SITRANS AS 100 Acoustic Sensor: Lista de Precios y Configuración de ModelosDocument1 pageSITRANS AS 100 Acoustic Sensor: Lista de Precios y Configuración de ModelosGUZMANNo ratings yet

- Cross Reference: Thermodynamic Traps Steel Float & Thermostatic TrapsDocument1 pageCross Reference: Thermodynamic Traps Steel Float & Thermostatic TrapsGUZMANNo ratings yet

- Salsnes Filter SF EnglishDocument2 pagesSalsnes Filter SF EnglishGUZMANNo ratings yet

- Operating Manual VAMcDocument24 pagesOperating Manual VAMcGUZMANNo ratings yet

- Uni CellDocument2 pagesUni CellGUZMANNo ratings yet

- 9003 Sigma S1Ba Diaphragm Metering Pumps Performance DiagramDocument2 pages9003 Sigma S1Ba Diaphragm Metering Pumps Performance DiagramGUZMANNo ratings yet

- Mass Notification Solutions - E3 Series: SurvivabilityDocument2 pagesMass Notification Solutions - E3 Series: SurvivabilityGUZMANNo ratings yet

- 7100 Manual 9021-60554Document44 pages7100 Manual 9021-60554GUZMANNo ratings yet

- SITRANS CU 02 Control Unit: Lista de Precios y Configuración de ModelosDocument1 pageSITRANS CU 02 Control Unit: Lista de Precios y Configuración de ModelosGUZMANNo ratings yet

- Tabla Americana de Avances de Accesorios...Document9 pagesTabla Americana de Avances de Accesorios...GUZMANNo ratings yet

- Tabla Americana de Avances de Accesorios...Document9 pagesTabla Americana de Avances de Accesorios...GUZMANNo ratings yet

- CS-2401 600 Series IdentiFlex 602 Analog Addr PanelDocument3 pagesCS-2401 600 Series IdentiFlex 602 Analog Addr PanelGUZMANNo ratings yet

- SITRANS F US SONOFLO - Ultrasonic Flow Meters SONOKIT, 1-TrackDocument4 pagesSITRANS F US SONOFLO - Ultrasonic Flow Meters SONOKIT, 1-TrackGUZMANNo ratings yet

- Description: NGA Network Graphic AnnunciatorDocument1 pageDescription: NGA Network Graphic AnnunciatorGUZMANNo ratings yet

- CS-2023 600 Series Power SupliesDocument2 pagesCS-2023 600 Series Power SupliesGUZMANNo ratings yet

- SITRANS TF Transmitter For Temperature / Field Indicators: Lista de Precios y Configuración de ModelosDocument3 pagesSITRANS TF Transmitter For Temperature / Field Indicators: Lista de Precios y Configuración de ModelosGUZMANNo ratings yet

- Ter More Siste Nci AsDocument16 pagesTer More Siste Nci AsGUZMANNo ratings yet

- 9020-0622 ADPF Duct SensorDocument2 pages9020-0622 ADPF Duct SensorGUZMANNo ratings yet

- Mass Notification Solutions - E3 Series: SurvivabilityDocument2 pagesMass Notification Solutions - E3 Series: SurvivabilityGUZMANNo ratings yet

- GW Voice BrochureDocument8 pagesGW Voice BrochureGUZMANNo ratings yet

- CS-2025 600 Series Remote AnnunciatorsDocument2 pagesCS-2025 600 Series Remote AnnunciatorsGUZMANNo ratings yet

- CS-2027 600 Series Serial Annunciator DriversDocument2 pagesCS-2027 600 Series Serial Annunciator DriversGUZMANNo ratings yet

- CS-2073 600 Series Smart LinkDocument2 pagesCS-2073 600 Series Smart LinkGUZMANNo ratings yet

- Flex Series Brochure 9021 60287Document2 pagesFlex Series Brochure 9021 60287GUZMANNo ratings yet

- 9020-0623 ABD-2F Photo BeamDocument2 pages9020-0623 ABD-2F Photo BeamGUZMANNo ratings yet

- Cs 2501 GW UdactDocument3 pagesCs 2501 GW UdactGUZMANNo ratings yet

- 9020-0620 ATD-L2F Thermal SensorDocument2 pages9020-0620 ATD-L2F Thermal SensorGUZMANNo ratings yet

- 9020-0622 ADPF Duct SensorDocument2 pages9020-0622 ADPF Duct SensorGUZMANNo ratings yet

- P3 Chapter 2 End-Of-Chapter (Higher) Mark SchemeDocument3 pagesP3 Chapter 2 End-Of-Chapter (Higher) Mark SchemePaul LloydNo ratings yet

- Cen-Tech 63759Document8 pagesCen-Tech 63759GregNo ratings yet

- QM SyllabusDocument2 pagesQM SyllabusSanthosh Chandran RNo ratings yet

- The Modern Fire Attack - Phil Jose and Dennis LegearDocument7 pagesThe Modern Fire Attack - Phil Jose and Dennis LegearTomNo ratings yet

- Corporate Security Policy TemplateDocument4 pagesCorporate Security Policy TemplateCoronaNo ratings yet

- HooksDocument7 pagesHooksapi-233765416No ratings yet

- Geographical Perspective On Selected Issues and Problems #ToppersnotesDocument16 pagesGeographical Perspective On Selected Issues and Problems #ToppersnotesParidhi JainNo ratings yet

- P13Document21 pagesP13Saeful AzizNo ratings yet

- All About Ocean Life-Rachel BladonDocument6 pagesAll About Ocean Life-Rachel BladonRichard TekulaNo ratings yet

- The 3 Basic Listening Models and How To Effectively Use ThemDocument6 pagesThe 3 Basic Listening Models and How To Effectively Use ThemTzuyu TchaikovskyNo ratings yet

- ComFlor 80 Load Span Tables PDFDocument4 pagesComFlor 80 Load Span Tables PDFAkhil VNNo ratings yet

- Rubber Dam (Tooth Isolation)Document9 pagesRubber Dam (Tooth Isolation)NonoNo ratings yet

- iGCSE Biology Section 1 Lesson 1Document44 pagesiGCSE Biology Section 1 Lesson 1aastha dograNo ratings yet

- PS Ebook BagsPouches2 1116 HRDocument58 pagesPS Ebook BagsPouches2 1116 HRGovindarajulu RNo ratings yet

- Switching Power Supply Design: A Concise Practical Handbook: February 2022Document5 pagesSwitching Power Supply Design: A Concise Practical Handbook: February 2022Juan Gil RocaNo ratings yet

- Plain and Laminated Elastomeric Bridge Bearings: Standard Specification ForDocument4 pagesPlain and Laminated Elastomeric Bridge Bearings: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Polymer ProDocument25 pagesPolymer ProJeerisuda KingklangNo ratings yet

- Ship Captain's Medical Guide - 22nd EdDocument224 pagesShip Captain's Medical Guide - 22nd EdcelmailenesNo ratings yet

- OSCE Pediatric Dentistry Lecture-AnswersDocument40 pagesOSCE Pediatric Dentistry Lecture-AnswersR MNo ratings yet

- FT8 - Air System - Maintenance - P&W FT8 - Solar Turbines Technical BLOGDocument3 pagesFT8 - Air System - Maintenance - P&W FT8 - Solar Turbines Technical BLOGLibyanManNo ratings yet

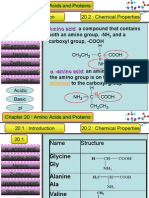

- Matriculation Chemistry Amino Acids-Part-1Document24 pagesMatriculation Chemistry Amino Acids-Part-1iki292No ratings yet

- Beta CaroteneDocument2 pagesBeta CaroteneValeria MarcuțăNo ratings yet

- Pre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka byDocument41 pagesPre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka by12mchc07No ratings yet

- How To Make Panna CottaDocument3 pagesHow To Make Panna CottaBintNo ratings yet

- PFA Vs PTFE in InstrumentationDocument5 pagesPFA Vs PTFE in InstrumentationArif HakimNo ratings yet