Professional Documents

Culture Documents

Mechanics 24

Uploaded by

olwe90Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanics 24

Uploaded by

olwe90Copyright:

Available Formats

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

Design of Valves Used in Reciprocating Compressors

MIRCEA HORIA TIEREAN, LIANA SANDA BALTES

Material Engineering and Welding Department

Transilvania University of Brasov

29 Eroilor Blvd., 500036 Brasov

ROMANIA

mtierean@unitbv.ro; baltes@unitbv.ro http://www.unitbv.ro/sim

Abstract: - This paper presents the critical points in designing of valves used in reciprocating compressors. The design

is focused in valve type, dimensioning of the main elements and materials choice. There are presented the results

obtained in CFD of valves and the method of computing the centreline diameter of the valve rings and seats to

compensate the thermal expansion during operation in compressors.

Key-Words: - valve, reciprocating compressor, fluid dynamics, FEA

1 Introduction

2 Valve types

Designing and implementing valves to improve

efficiency and reliability of reciprocating compressors

can be complex due to the many paramaters that can

affect performance. A designer must understand the flow

of gas through the valves, the way the valves operate in

the compressor and how reliability can be affected under

a wide range of different gases compositions and

operating conditions.

A reciprocating compressor or piston compressor is a

compressor that uses pistons driven by a crankshaft to

deliver gases at high pressure. Reciprocating

compressors are typically used where high compression

ratios (ratio of discharge to suction pressures) are

required per stage without high flow rates, and the

process fluid is relatively dry. The reciprocating

compressors (fig. 1) are standardized in API 618:

Reciprocating Compressors for Petroleum, Chemical,

and Gas Industry Services. Arrangements may be of

single-or dual-acting design.

Valves are crucial components of reciprocated

compressors. There are three kinds of valves that are

used in reciprocating compressors: poppet valves (fig.

2), plate valves (fig. 3) and ring valves (fig. 4).

Fig.2 Poppet valve

Fig.3 Plate valve

Fig.4 Ring valve

The choice of valve type is according the work

conditions [2]. Poppet valves are recommended up to 15

MPa differential/30 MPa discharge pressure and 600

rpm. Plate valves are recommended up to 20 MPa

differential/40 MPa discharge pressure and 1800 rpm.

Ring valves are recommended up to 30 MPa

differential/60 MPa discharge pressure and 600 rpm.

Fig.1 Reciprocating compressor section view [1]

ISSN: 1790-2769

138

ISBN: 978-960-474-140-3

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

Ring valves have balanced flow through the seat, lift and

exit areas, creating a lower pressure drop across the

valve, which limits valve losses and increases the

efficiency of the valve. Conventional flat-plate designs

force the gas to make two 90 turns before passing

through the valve. More importantly, any impurities in

gas (liquids, dirt, mechanical debris etc.) must also

follow this path. At only 300 rpm, these materials have

less than 100 milliseconds to pass through these turns.

As a result, these inclusions often strike squarely on the

valve plate at full speed, developing premature failure.

These same materials pass through the ring valve with

minimal impact on the rounded disc (fig. 3).

seats increase the discharge valve clearance, which in

turn increases the cylinder clearance, and reduces the

amount of gas the cylinder will compress. Stronger

materials will allow for thinner seats and eliminate this

problem.

The seat is primarily liable to wear from the moving

elements contacting the sealing surface. The guard is

susceptible to wear from the springs cycling in the

spring pockets. The material elected must be hard

enough to combat this wear.

Many seats and guards are castings, usually nodular

iron, which allow complex geometries to reduce losses.

Others are fully machined from bar stock. This allows

the use of a wide range of materials that confers

flexibility to designer for different kind of applications.

It also eliminates the possibility of finding porosity

while machining the part.

The most common materials for non-corrosive

environments are nodular iron and low carbon steel. For

small quantities of hydrogen sulphide, nodular iron is

preferred to steel, because there is less chance of

corrosion cracking. For highly corrosive environments,

4541 or 4021 stainless steels are used.

The spring is the most highly stressed component of the

compressor valve, and is typically the major cause of

valve failures. The spring material should have a high

stress limit, resist to taking a set at normal compressor

operating temperatures, and should be able to withstand

corrosion in the gas [4].

Chrome silicon and chrome vanadium have very good

mechanical properties, are available in spring quality

wire, and will not take a set at normal compressor

operating temperatures. While these materials have poor

corrosion resistance, they are known to provide

acceptable service in small concentrations of corrosives

in lubricated cylinders. Hastelloy and Inconel are

commonly used in corrosive applications. They have

good corrosion resistance when designed at stress levels

acceptable for the material, but are relatively weak in

dynamic applications. These materials have low

mechanical properties and good quality wire is not

generally available. High cobalt materials such as

Elgiloy are also used in corrosive environments. These

materials have good corrosion resistant properties and

better mechanical properties than Hastelloy or Inconel,

but are also more expensive.

The moving elements are subject to corrosives and high

stress levels, but are also subject to high impacts against

the guard when they open, and against the seat when

they close. Therefore, material selection is very

important to the success of the valve. This is where the

most significant improvements affecting valve reliability

have been made over the last decade.

Former valve designs used metallic plates, which are

inexpensive, can withstand high differential pressures,

Fig.5 The gas flow in valves

The main factors that affect the performance of

compressor valves [2]:

the valves do not open and close instantly, that

induces the horsepower losses;

there must be a sufficient number of valves installed

in a compressor cylinder to effectively allow gas

flow into and out of the cylinder efficiently;

valve materials must be properly selected to be

compatible with the constituents in the gas stream.

This is especially important when corrosives are

present;

valves in lubricated cylinders are subject to sticktion,

an adhesion of the valve elements to the seat and

guard, which might delay the opening or closing of

the element which can be detrimental to performance

and valve reliability;

dirt and debris can prevent the valve from properly

functioning;

pulsations in the inlet and discharge gas piping can

alter the timing of the valve motion and decrease

efficiency and reliability.

3 Valve materials

Seats and guards are generally made of the same

material. The selection of this material is important

because the seats and outer rim of the suction valve

guard are subjected to stresses. These stresses vary with

the cylinder pressure throughout the compression cycle.

Weaker materials require the seat to be thicker. Thicker

ISSN: 1790-2769

139

ISBN: 978-960-474-140-3

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

swelling or distorting. To reduce the effects of moisture

absorption, uneven fibre orientation, thermal expansion,

and moulded-in stress, close control of manufacturing

processes is required. Proper drying, machining, heattreating, and moulding practices are critical in reducing

distortion. Designing a valve with clearances that allow

for thermal expansion is also recommended.

PEEK offers several advantages over nylon [2]:

PEEK has temperature limits that ensure retention

and stability of load-bearing properties and

dimensions at high temperatures. This provides more

reliable performance;

tensile, flexural, and compressive strengths are

maintained at high temperatures;

it resists to flex fatigue;

it has lower water absorption rates to ensure

dimensional integrity;

it resists to deformation at high temperatures.

PEEK is very difficult to mould. The moulding

temperature is 335 C, and controlling this temperature

throughout the process is critical. A lower temperature

will lead to a higher viscosity and the mould will not be

filled properly. A higher temperature will cause the resin

to oxidize and form particles referred to as char, which

reduces the strength of the material.

PEEK is a more expensive material; so many

manufacturers will use regrind or a lower viscosity resin.

Regrind is waste material that is ground back into a

powder and blended with virgin PEEK material, which

will decrease the dynamic strength of the material.

According to material technology and supplier, the

mechanical and thermal properties vary within a small

range. Some mechanical and thermal properties for three

kinds of PEEK are presented in Table 1.

and are not affected, by high temperatures. However,

these desirable properties are outweighed by the

disadvantages of metallic elements. They are prone to

impact fatigue, susceptible to corrosion damage and are

very unforgiving of dirt and debris.

In the 1960s, plastic elements emerged and began to

replace metallic elements. Plastic materials offer several

advantages over metallic elements:

are able to withstand higher impact velocities than

metal plates;

allow them to be applied at higher lifts and speeds;

make them more tolerant of liquids that are often

present in the gas;

are resistant to most corrosive elements commonly

found in process gas streams;

will follow the frame of the seat and provide a better

seal;

are easily applied in non-lubricate machines, because

they can operate against metallic parts without

causing excessive wear;

reduce wear on the seat, so that seats do not have to

be reconditioned or replaced as frequently;

small pieces of dirt or metal can embed in a plastic

element without causing a failure;

are less likely to do damage to other components

such as the cylinder liner, piston rings, and rider

bands when breaks and falls into the cylinder.

In the 1970s, Nylon was the material of choice for valve

elements. By the mid 1980s, PEEK (Poly Ether Ether

Ketone) has been introduced and is currently the most

commonly used material for valve elements.

Pure nylon is too weak to withstand the discharge

temperatures of most compressors. There are many

different glasses and sizes of fibres used for

reinforcement, but are usually supplied with 30% of

chopped glass fibres. It is essential that the fibres adhere

to the nylon, so coupling agents are generally used to

ensure this process.

Nylon plates tend to change their shape in service by

4 Thermal behavior of parts

During operation in compressor the thermal regime of

valves is according to the destination. The suction valves

work the range (2035) C but the discharge valves

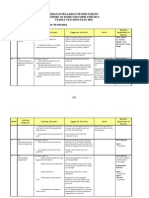

Table 1. Properties of 30% glass filled PEEK [7]

Supplier

Thermal

Mechanical

Property

Specific gravity

Ultimate tensile strength [MPa]

Tensile Young modulus [MPa]

Tensile elongation at break [%]

Flexural strength [MPa]

Coefficient of linear thermal expansion [/ C]

Heat deflection temperature [C]

Melting point [C]

Continuous service temperature [C]

ISSN: 1790-2769

Ketron

Compression moulded

1.45

117

5171

3

193

2.5E-05

316

340

249

140

Extruded

1.54

124

6895

3

193

2.2E-05

316

340

249

Victrex

Injection moulded

1.50

156

9701

2

233

2.2E-05

316

340

249

ISBN: 978-960-474-140-3

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

work the range (20145) C [6]. Because the

coefficient of linear thermal expansion of PEEK is

approximately two times greater than the coefficient of

linear thermal expansion of stainless steel, if the same

initial centreline is used for rings and seats, after thermal

expansions the valve will not work. For this reason, it is

necessary to realize different initial dimensions for

centreline diameters, for both rings and seats.

The temperature variation function of time and space

inside the body is given by Fouriers differential

equation:

76.4

20

76.3

R1 , i

S1 , i

76.2

76.1

20

40

60

80

100

120

140

R0 , i , S0 , i

150

Fig.6 The thermal expansion of 2nd ring (---) and seat

( ) centreline diameter stage 1, discharge valve

(1)

where: T is the temperature; t is the time; c is the

specific heat; is the specific mass; i is the thermal

conductivity of the mass, in i direction; Q is the flow

of the internal sources of heat.

The finite element method is the way to solve the

problem of thermal conduction, so, the differential

equation (1) is equivalent to the minimum of the

functional:

___

114.55

114.5

20

145

R1 , i

S1 , i

114.4

114.3

2

2

2

T

T

1 T

+

+

2QT dV +

x

y

z

2 V x

y

z

2

1

+ qT dS2 + h(T T ) dS3

2

S2

S3

76.1

15

(cT ) = x T + y T + z T + Q

t

x x y y z z

,

145

114.25

20

15

40

60

80

100

R0, i , S0, i

120

140

150

Fig.7 The thermal expansion of 3rd ring (---) and seat

(___) centreline diameter stage 1, discharge valve

(2)

where: h is the convection efficiency coefficient, from

the S3 surface to the environment; T is the temperature

of the environment.

The finite element equation in stationary heat transfer is

[3]:

[k ]{T } = { F },

(3)

and the thermal characteristics matrix is:

[ k ] = [ B] [ ] [ B] dV + h [ N ] [ N ] dS3.

T

(4)

S3

Fig.8 Bending of the ring (thickness 10mm) seated on the

outer diameter, max=22.35 MPa

The formula of the applied thermal flow is:

{F} = [ N ] {Q} dV [ N ] {q} dS2 + h [ N ] {T} dS3 , (5)

T

S2

S3

[N] being the form functions matrix.

Due to this model, it is possible to calculate the

temperature at each point and the thermal expansion as

well.

After machining, each ring was heat treated one hour at

230 C to eliminate internal stresses. The seats are

machined using the computed values of the centerline

diameters. During operation in compressor, the

centerline diameters will vary as shown in figures 5 and

6 [6]. In figures 8 and 9 there are presented von Mises

stresses on the ring and guard of the discharge valve.

ISSN: 1790-2769

Fig.9 Von Mises stresses on the guard, max=176.2 MPa

141

ISBN: 978-960-474-140-3

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

5 Fluid flow through valves

The main problem in fluid flow study is to ensure a gas

velocity lower than 80 m/s.

More often than note, the fluid processed by the

compressor is a complex mixture of chemical

nonreacting compounds, usually hydrocarbons. A

detailed analysis of the fluid flow through the

compressor valves requires accurate knowledge of the

transport properties of the mixture. Among these, the

most important are the dynamic viscosity and thermal

conductivity [8].

The mixture laminar viscosity is calculated using the

Wilkes' mixing model [9]. First, the viscosity coefficient

is computed for each individual species using

Sutherland's law, as follows:

Fig.10 The fluid velocity in suction valve (3D view)

n T 2 T0 + S

=

0 T0 T + S ;

(6)

where T is the local static temperature, 0, T0, and S are

constants for each component.

For N total species, the individual viscosity coefficients

are combined using

xi i

;

(7)

(x )

i i i, j

mixt

Fig.11 The fluid velocity vector in suction valve (3D

view, detail)

where i,j is mixing coefficient computed as

2

1

1

i 2 M j 4

1 + M

j i

M

81 + i

Mj

i , j

(8)

In the previous relation i is dynamic viscosity and Mi is

molar mass of each component of the flowing gas.

The same model was used to obtain the thermal

conductivity of the flowing gas:

xi i

;

(9)

=

mixt

( x cond )

i, j

Fig.12 The fluid pressure in suction valve (3D view)

condi , j

i

j 4

1 + M

j i

M

81 + i

Mj

.

1

2 M

(10)

where i is thermal conductivity of each component of

the flowing gas and =1.

We done studies refers to the valves of the first stage of

the 285 mm diameter reciprocating compressor, with the

pressures Psuction = 1.2 MPa, Pdischarge = 2.8 MPa and

temperatures Tsuction = 38C, Tdischarge = 118 C [5].

Figure 10 shows the 3D model of the fluid velocity in

the suction valve. The maximum speed is 51.6 m/s.

ISSN: 1790-2769

Fig.13 The fluid velocity vector in discharge valve (3D

view, detail)

142

ISBN: 978-960-474-140-3

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

[3] Kardenstuncer, H., Norrie, D.H., Finite element

handbook, McGraw-Hill, New York, 1987.

[4] Metcalf, J.R., Effects of compressor valves on

reciprocating compressor performance, Cook

Manley, Stafford, 2000.

[5] Tierean, M., Eftimie, L., Baltes, L., C.F.D. in

Reciprocating Compressors Valves, Annals of

DAAAM for 2007 & Proceedings of the 18th

International DAAAM Symposium, Published by

DAAAM International, Vienna, Austria 2007, pp.

757-758.

[6] Tierean, M., Baltes, L., Thermal behavior of valve

rings during operation in compressors, Bulletin of the

Transilvania University of Brasov, Vol. 12(47) series A, 2005, pp. 297-302.

[7] Tierean, M., Baltes, L.S, Design of Valve Rings

Obtained from Composite Materials, Proceedings of

the 6th International Conference Challenges in

Higher Education and Research in the 21st

Century, Sozopol, Bulgaria, 2008, pp. 268-271.

[8] White, F.M., Fluid Mechanics, McGraw-Hill ISBN,

9780072831801, New York, 2001.

[9] Wilke, C.R., A Viscous Equation for Gas Mixtures,

In: Journal of Chemical Physics, vol. 18, 1950, pp.

517-519.

In figure 11, the fluid velocity vector is presented and

figure 12 shows the pressure map in the same valve. The

fluid velocity vector in discharge valve is presented in

figure 13.

The F.E.A. was done using CFX 5.7.1 and Ansys

Workbench 9.0

6 Conclusion

The design of valves ensures the compression process

parameters and the reliability.

Using the FEA the designer can calculate the centerline

diameters of the rings and seats for machining. In

operation, with thermal expansion, good response of the

valve is obtained and adequate tightness is achieved.

Having the values of the velocities and pressure, the

designer can establish the adequate dimensions of the

suction and discharge channels and holes, the value of

the closing element lift and the contact areas.

An important parameter determined from the CFD

analysis is the pressure drop across the valve. The

designer may choose to minimize it in order to allow for

lower input work requirement and thus better

compressor efficiency while considering the geometrical

restrictions imposed by the compressor.

References:

[1] Bloch, H.P., Compressors and Modern Process

Applications, John Wiley & Sons, Inc., Hoboken,

New Jersey, 2006.

[2] Foremann, S., Compressor valves and unloaders for

reciprocating compressors, Dresser-Rand, Painted

Post, New York, 1999.

ISSN: 1790-2769

143

ISBN: 978-960-474-140-3

You might also like

- Capability LifecycleDocument1 pageCapability Lifecycleolwe90No ratings yet

- Character Record SheetsDocument14 pagesCharacter Record SheetsChristian Lee ChildsNo ratings yet

- POD 5960SeriesDualColumnTabletop Rev6 0113Document2 pagesPOD 5960SeriesDualColumnTabletop Rev6 0113olwe90No ratings yet

- Sae Technical Paper Series: Terry D. Day and Sydney G. RobertsDocument21 pagesSae Technical Paper Series: Terry D. Day and Sydney G. Robertsolwe90No ratings yet

- SAE Paper 2000-01-0418 Advanced Material TechnologiesDocument7 pagesSAE Paper 2000-01-0418 Advanced Material Technologiesolwe90No ratings yet

- FTADocument1 pageFTAolwe90No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Physics Year 10 Assessment TestDocument16 pagesPhysics Year 10 Assessment TestJoyceNo ratings yet

- Ultrasonic Vortex Flowmeter "Ultra Yewflo-Uyf200": KAWANO Takashi MATSUNAGA Yoshinori ANDOH Tetsuo Yasumatsu AkioDocument4 pagesUltrasonic Vortex Flowmeter "Ultra Yewflo-Uyf200": KAWANO Takashi MATSUNAGA Yoshinori ANDOH Tetsuo Yasumatsu AkiohendrabudimanNo ratings yet

- Pipingchevronoffshore 2Document56 pagesPipingchevronoffshore 2Velpandian ManiNo ratings yet

- Interference of Light: Presnted By: Jignasha PatelDocument16 pagesInterference of Light: Presnted By: Jignasha PatelBhargavNo ratings yet

- Stainless WDocument8 pagesStainless WsunsirNo ratings yet

- Alberti PhdthesisDocument234 pagesAlberti PhdthesisUsman AliNo ratings yet

- 5054 s16 QP 21Document20 pages5054 s16 QP 21pixelhoboNo ratings yet

- Annular Pressure Seals and Hydrostatic Bearings: Luis San AndrésDocument36 pagesAnnular Pressure Seals and Hydrostatic Bearings: Luis San AndrésisidropeNo ratings yet

- Investigatory Project File 2Document12 pagesInvestigatory Project File 2hepele8650No ratings yet

- CHME 789 Soft Matter Exam No. 1Document8 pagesCHME 789 Soft Matter Exam No. 1Laura GTNo ratings yet

- Calculate Mass of Air, Pressure at Pool Bottom, Breathing UnderwaterDocument2 pagesCalculate Mass of Air, Pressure at Pool Bottom, Breathing UnderwaterHaffiz AtingNo ratings yet

- 8P2A.3 & 4 Newton's Laws of Motion PPT 2017Document52 pages8P2A.3 & 4 Newton's Laws of Motion PPT 2017Jerome Nicolas Jr. MoraNo ratings yet

- Machinery fault diagnosis guide to vibration analysisDocument42 pagesMachinery fault diagnosis guide to vibration analysisAbdurrhman AlzhraniNo ratings yet

- Physics Form 4 Yearly Lesson Plan 2010Document26 pagesPhysics Form 4 Yearly Lesson Plan 2010Mohd Khairul AnuarNo ratings yet

- 5054 w16 QP 11 PDFDocument20 pages5054 w16 QP 11 PDFMuhammad SaifNo ratings yet

- Model and Analyze Hydraulic SystemsDocument16 pagesModel and Analyze Hydraulic Systemsعلي كامل الاسديNo ratings yet

- Studying Pendulum MotionDocument13 pagesStudying Pendulum MotionMubashir AijazNo ratings yet

- Fluorescence SpectrosDocument10 pagesFluorescence SpectrosChamith HerathNo ratings yet

- SpectrOil 100 Series DatasheetDocument2 pagesSpectrOil 100 Series DatasheetClydeA.SardoncilloNo ratings yet

- IMI CCI Product VSGIC DesuperheaterDocument4 pagesIMI CCI Product VSGIC DesuperheaterangeloNo ratings yet

- Vibration and Shock Isolation-Advanced Antivibration ComponentsDocument55 pagesVibration and Shock Isolation-Advanced Antivibration Componentshiginio.moro6182No ratings yet

- MNDocument2 pagesMNBenzeneNo ratings yet

- 2021 - February 19Document11 pages2021 - February 19jeffNo ratings yet

- Adnan Majeed Binary Solid Solution Inorganic Chemistry IIIDocument14 pagesAdnan Majeed Binary Solid Solution Inorganic Chemistry IIIFarhanaNo ratings yet

- Effect of Crystallinity On Electrical Properties of ElectronDocument4 pagesEffect of Crystallinity On Electrical Properties of Electronapi-3837841No ratings yet

- HM 289 Experiments With A Pelton Turbine Gunt 848 PDF 1 en GBDocument3 pagesHM 289 Experiments With A Pelton Turbine Gunt 848 PDF 1 en GBbeshirNo ratings yet

- Major Earthquake and Volcano HotspotsDocument41 pagesMajor Earthquake and Volcano HotspotsClark Justine LigaoNo ratings yet

- Ultrasound - Clinical Science Questions and AnswersDocument2 pagesUltrasound - Clinical Science Questions and AnswersSaqibKhan100% (8)

- BSC Physics 2019Document189 pagesBSC Physics 2019kab28No ratings yet

- Analyse de La Déformation Et Évaluation de La Sécurité Des Tunnels de Métro ExistantsDocument11 pagesAnalyse de La Déformation Et Évaluation de La Sécurité Des Tunnels de Métro ExistantsMed El Hadi AbidiNo ratings yet