Professional Documents

Culture Documents

5-Fatigue of Dental Ceramics in A Simulated Oral Environment

Uploaded by

michael.cretzuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5-Fatigue of Dental Ceramics in A Simulated Oral Environment

Uploaded by

michael.cretzuCopyright:

Available Formats

Journal of

Dental Research

http://jdr.sagepub.com/

Fatigue of Dental Ceramics in a Simulated Oral Environment

R. Morena, G.M. Beaudreau, P.E. Lockwood, A.L. Evans and C.W. Fairhurst

J DENT RES 1986 65: 993

DOI: 10.1177/00220345860650071901

The online version of this article can be found at:

http://jdr.sagepub.com/content/65/7/993

Published by:

http://www.sagepublications.com

On behalf of:

International and American Associations for Dental Research

Additional services and information for Journal of Dental Research can be found at:

Email Alerts: http://jdr.sagepub.com/cgi/alerts

Subscriptions: http://jdr.sagepub.com/subscriptions

Reprints: http://www.sagepub.com/journalsReprints.nav

Permissions: http://www.sagepub.com/journalsPermissions.nav

Citations: http://jdr.sagepub.com/content/65/7/993.refs.html

>> Version of Record - Jul 1, 1986

What is This?

Downloaded from jdr.sagepub.com at MCGILL UNIVERSITY LIBRARY on October 28, 2014 For personal use only. No other uses without permission.

Fatigue of Dental Ceramics in a Simulated Oral Environment

R. MORENA, G.M. BEAUDREAU, P.E. LOCKWOOD, A.L. EVANS, and C.W. FAIRHURST

Dental Materials Division, School of Dentistry, Medical College of Georgia, Augusta, Georgia 30912

Fatigue in ceramics refers to the subcritical growth of cracks, aided

by the combined influence of water and stress. The dynamic fatigue

(constant stressing rate) method was used to obtain subcritical crack

growth parameters for three dental ceramics: a feldspathic porcelain,

an aluminous porcelain, and a fine-grain, polycrystalline core material. The constant stressing rate experiments were carried out at

37"C for all three ceramics in distilled water, and, for the feldspathic

porcelain, in artificial saliva as well. Considerable differences were

found in the value of the crack growth exponent (n) among the three

ceramics. The feldspathic porcelain was lowest in n-value, while the

fine-grain ceramic had the highest n-value. No differences were found

for the feldspathic porcelain with respect to n measured in water and

in the artificial saliva. Lifetime prediction curves in 37C water, constructed from the n-values and inert strengths, showed that fatigue

failure within five years is a good possibility for feldspathic porcelain

specimens at stress levels which can reasonably be anticipated to

occur in the oral environment. Little likelihood of failure was perceived for the fine-grain ceramic. The aluminous porcelain was intermediate between these two materials with respect to failure

probability.

J Dent Res 65(7):993-997, July, 1986

Introduction.

It has long been known that the presence of water will degrade

the strength of silicate glasses and many other ceramic materials (Shand, 1958; Mould, 1959). Exposure to an aqueous

environment has also been found to affect the mechanical performance of dental ceramics. Sherrill and O'Brien (1974) demonstrated that the fracture stress of feldspathic and aluminous

dental porcelains decreased by nearly 30% when the samples

were broken in water. Southan and Jorgensen (1974) showed

that the ability of a dental porcelain to sustain a static load in

water decreased as the duration of load application increased.

The effect of aqueous exposure and other aspects of dental

porcelain mechanical behavior have been the subject of an

extensive review by Jones (1983), who also lists decreasing

strength with decreasing stress/strain rate as further evidence

for the detrimental role played by water.

The process of strength degradation of ceramics in aqueous

environments is termed fatigue and is believed to be caused

by a stress-corrosion process involving the stable growth of

small, pre-existing flaws (Hillig and Charles, 1965; Michalske

and Freiman, 1983). The effect of water is so pronounced that

stress-corrosion has been observed in silicate glasses at moisture levels as low as 0.017% relative humidity (Wiederhom,

1967). Failure, generally after long loading times and often at

stresses substantially less than the measured short-term fracture

stress, will ensue once these flaws attain a size equivalent to

that needed to initiate fast fracture.

The oral environment would appear to have all the factors

necessary for fatigue failure to occur in ceramic-based dental

prostheses. Water is, of course, the primary chemical species

Received for publication October 31, 1985

Accepted for publication April 10, 1986

This investigation was supported in part by USPHS Research Grant

DE07045 from the National Institute of Dental Research, National

Institutes of Health, Bethesda, MD 20892.

in saliva. A dental restoration would also be exposed to water

from a cementing agent as well as from the dentin tubules.

Stresses, both masticatory-related and also associated with

thermal expansion mismatches between the various components of the restoration, would be present to provide the driving

force for fatigue. Flaws in a dental ceramic may be introduced

by grinding during occlusal adjustment or may be intrinsic and

related to microstructural features (Jones and Wilson, 1975;

Corbitt et al., 1985). Finally, the range of temperatures that

would be encountered by a restoration during service in the

oral cavity is sufficiently elevated from ambient as to exacerbate any slow crack growth process (Ritter et al., 1985).

Failure of dental ceramic restorations caused by fatigue does

appear to be a possibility, as judged by several studies reported

by Lehman (1967) on long-term failures of feldspathic porcelain jacket crowns. McLean (1983) lists a failure rate of

15.2% within three years following placement in the mouth

for platinum-bonded, aluminous porcelain crowns in molar sites.

Similar studies documenting failures for porcelain-fused-to-metal

(PFM) crowns and bridges could not be found, although Warpeha and Goodkind (1976) list several types of persistent clinical failures observed with PFM crowns that were all associated

with the porcelain component. Delayed failures which occurred up to six weeks after firing have been observed by

Walton and O'Brien (1985) for model PFM crowns and were

attributed to a probable fatigue interaction. The large number

of commercial in vivo porcelain repair materials currently

available provides indirect testimony for the existence of longterm failures in PFM restorations (Ferrando et al., 1983).

Although the several studies cited have given evidence for

the fatigue susceptibility of various dental porcelains, no data

could be found in the literature relating to the fundamental

material parameters which determine the kinetics of slow crack

growth for dental ceramics. In the past 10 years, the discipline

of fracture mechanics has become firmly established for analyzing the fracture properties of ceramics and predicting their

fatigue behavior (Wiederhorn, 1974; Ritter, 1978). Slow crack

growth is described in terms of a fracture mechanics analysis

by a fundamental parameter the crack growth exponent, n

which is a material constant for a given environment. Assuming a power law expression for subcritical crack growth

(i.e., the rate of crack growth x K, where K, is the opening

mode stress intensity factor), the failure time of a ceramic

component experiencing slow crack growth-induced fatigue is

given (Pletka and Wiederhorn, 1982) by:

,

BSn -2t-an

(1)

failure time under a constant applied stress, Ua;

constant dependent on n, and also on crack geometry and the fracture toughness of the material;

and

S = inert or initial strength in the absence of subcritical crack growth.

Note that of two materials with comparable values of initial

strength that are candidates for a given application in which a

stress must be sustained without failure over a long time period, the material with the higher n value will be more likely

to survive.

where tf

B

Downloaded from jdr.sagepub.com at MCGILL UNIVERSITY LIBRARY on October 28, 2014 For personal use only. No other uses without permission.

993

994

J Dent Res July 1986

MORENA ET AL.

It was the objective of this study to determine the crack

growth exponent using standard fracture mechanics tests for a

number of restorative ceramics, including a polycrystalline core

material. Additionally, predicted lifetime curves, constructed

from the fatigue data using Eq. (1), will be presented so that

the survivability of various dental ceramics can be compared

under different levels of applied stress and fatigue conditions.

In general, lifetime prediction curves are constructed based on

values of n and B measured in controlled laboratory fatigue

tests, and with S, the inert strength of the component, obtained

on a geometry as representative as possible of the actual enduse.

Materials and methods.

The fatigue data were obtained by the dynamic or stressing

rate technique, in which fracture stress in the environment

under study is measured as a function of stressing rate. The

materials used in the study consisted of a feldspathic porcelain

(Ceramco Gingival, Ceramco, Inc., East Windsor, NJ), an

aluminous porcelain (Vitadur-N, Vident Corp., Baldwin Park,

CA), and a fine-grain polycrystalline "shrink-free" ceramic

(CerestoreT, Johnson & Johnson, East Windsor, NJ). These

latter two materials are intended for use as the core component

in all-ceramic replacement crowns. All materials were obtained

from regular commercial lots supplied by the vendor.

Specimens of both the feldspathic and aluminous porcelains

were vibration-condensed into thin disks by means of a split

brass mold. Unfired dimensions of these disks were typically

15 mm in diameter and 2.0 mm in thickness. Following removal from the mold, the specimens were permitted to air-dry

for at least two hours prior to being fired. Firing was carried

out in a commercial porcelain furnace (System 8, J.M. Ney

Co., Bloomfield, CT), following the firing schedule recommended by the respective porcelain manufacturer.

The fine-grain, polycrystalline core material was processed

into thin disks by a variant of the lost wax technique, with

commercial equipment supplied by the vendor. The time/temperature schedule recommended by the manufacturer was followed in firing the test specimens using the programed furnace

supplied as part of the processing unit.

Following firing, all specimens were ground and polished

on both surfaces using a sequence of steps culminating in 15pum diamond paste on a nylon cloth-backed bronze wheel. One

surface of each specimen received an additional polishing sequence through 1-pLm diamond paste. Final dimensions of the

polished disks for all three ceramics were typically 12.5 mm

in diameter and 1.0 mm in thickness. For all three materials

in this study, a sample size of 10-12 specimens was used for

each stressing rate and for the determination of inert strengths.

All specimens were tested such that the finest polished surface

was the tensile surface during fracture.

Prior to the strength-testing procedure, a single Vickers indentation was made in the center of the 1-pRm diamond polished surface of each specimen of the aluminous porcelain and

the fine-grain, polycrystalline core material. This was done to

ensure that a single dominant flaw would be present in the

material to minimize any variation in strength caused by the

presence of random handling damage. The load selected for

the indentation (4.9 N for the aluminous porcelain, 9.8 N for

the fine-grain ceramic) was the minimum necessary to produce

a significant decrease in strength (p < 0.05 by Student's t test)

relative to that of unindented specimens. No such indentation

was made for the feldspathic porcelain, since a previous study

(Corbitt et al., 1985) had indicated that the strength of this

material was controlled by large, intrinsic microcracks.

Evans (1974) has shown that the dependence of strength on

stressing rate, caused by subcritical crack growth, can be described by:

af

where

afo

(&/6 )1/n+ l

(2)

of = fracture stress determined at a given

stressing

rate,

(Ufo = a constant for a given environment,

& = stressing rate, and

&O = a normalizing constant (1 MPa/s).

The parameters n and coy were obtained from the stressing

rate experiments by fitting the dynamic fatigue data to a ln-ln

relationship, and carrying out a linear regression analysis. All

data points were used in these calculations. The value of n

obtained from Eq. (2) was corrected for the two materials

which had been indented by multiplying by a constant term,

1.31, to correct for residual stress effects associated with the

indentation (Lawn et al., 1981). The standard error of n was

determined from a statistical analysis of the linear regression,

using the approach derived by Pletka and Wiederhorn (1982).

The residual stress correction factor was included in this error

analysis.

The B term in Eq. (1) can be obtained (Ritter, 1978) from:

Un+lIi(3)

n +l()

where Si = inert or initial strength of laboratory specimens

in the absence of subcritical crack growth.

The strength values at each stressing rate were obtained with

a constant displacement rate mechanical testing machine (Model

TT-B, Instron Corp., Canton, MA). Test specimens were broken in bi-axial flexure by means of the piston-on-3-ball technique described by Wachtman et al. (1972). This technique

was selected since it eliminates spurious edge failures (which

occur in flexure tests) associated with stress concentrations at

contact points. This is because tensile stress in the bi-axial

flexure apparatus decays rapidly with increasing radial distance

from the center of the disk. The disks were concentrically

supported on three ball bearings (each 1.6 mm in diameter)

that were evenly spaced around a support circle having a radius

of 3.5 mm. The specimen-holder is shown in Fig. la. The

specimens were loaded to failure by a compressive load applied

by a right circular cylinder with a diameter of 1.6 mm. The

fracture stress was calculated (Wachtman et al., 1972) from

the load at failure by:

B

3P

of

l + 2 In

47r t2 (I+v)Lb

+

I+V

I+

v

lI

b2

S2a2

4a2l

2

(4)

where P = failure load

t = thickness of specimen

D = diameter of specimen

v = Poisson's ratio of specimen (assumed to be 0.25)

a = radius of support circle

b = radius of right circular cylinder

All stressing rate tests were carried out in a simulated oral

environment consisting of distilled water maintained at 370C

+ 0.50C by a thermostatically-controlled liquid circulator (Model

FE2, Haake Instruments Co., Saddle Brook, NJ). Specimens

were allowed to reach thermal equilibrium in the liquid meDownloaded from jdr.sagepub.com at MCGILL UNIVERSITY LIBRARY on October 28, 2014 For personal use only. No other uses without permission.

Vol. 65t No. 7

v~ ~

FATIGUE OF DEINTAL CERAMICS

995

that had received a relatively coarse final polish of 30 vm in

order to duplicate the actual surface condition of a ceramic

component in a dental restoration. All specimens for inert

strength determination were chosen from the same sample population from which test specimens for the stressing rate experiments were selected.

Results.

The dynamic fatigue curves are shown in Fig. 2 for the three

tested in water. Dynamic fatigue curves are compared

for the feldspathic porcelain evaluated in both water

and the artificial saliva environments. The error bars shown in

these Figs. for fracture stress correspond to the Mean + 1

S.D. No error bars are shown for stressing rate, since the

coefficient of variation (S.D./mean) was typically 5% or less.

Also shown in both Figs. is the coefficient of determination,

r2, for each test situation.

The results of the linear regression analyses on the dynamic

fatigue data are listed in Table 1. The value of the crack growth

exponent, measured in distilled water, varied from approximately 14.5 for the feldspathic porcelain to nearly 81 for the

fine-grain core material. The differences in n-value for the

three dental ceramics were found to be highly significant (p <

0.01) by the Tukey Multiple Range Test. No differences (p >

0.50 by Student's t test) were found in the crack growth exponent for the feldspathic porcelain when tested in the water

and artificial saliva environments. This agrees with stress-corrosion studies of other bioceramics where no differences were

recorded in the n-value between water and other biologic media, such as Krebs-Ringer solution and bovine serum (Rockar

and Pletka, 1978). The higher strength values measured at each

stressing rate for the feldspathic porcelain tested in water relative to the artificial saliva media are mirrored in the higher

ceramics

in Fig. 3

:X

.(

i..

B3i-axial flexure apparatus: A. Specimen-holder; B. EnvironFig. I

mental chamber.

Stressing Rate, MPals

dium for 10 min prior to breaking. The environmental chamber

with the specimen-holder in place is shown in Fig. lb. Data

were also obtained with an artificial saliva solution (Salivart,

Westport Pharm., Westport, CT), held at 370C + 0.50C for a

second set of feldspathic porcelain specimens to determine

whether differences in crack growth kinetics occur between the

two aqueous media. The stressing rates were determined directly from the chart recorder of the mechanical testing machine and spanned nearly four decades, from almost 0. 10 to

approximately 85 MPa/sec.

The inert strengths used to obtain the B term in Eq. (3) and

to predict lifetime behavior from Eq. (1) were obtained in biaxial flexure following the procedure outlined by Ritter et al.

(1985). Test specimens were broken in mineral oil at high

stressing rates ( 100 MPa/sec) with a thin layer of plastic

placed within the support cycle on the tensile surface to minimize further the possibility of exposure to water. Note that

two different measures of inert strength are used in Equations

(I) and (3). Si (Eq. 3) refers to the inert strength of laboratory

test specimens, which, for this study, were finely-polished disks

that, where specified, had received indentations on their tensile

surfaces. S (Eq. 1) relates to the inert strength of engineering

specimens which, ideally, should represent the actual size,

shape, manufacturing conditions, stress state, etc., of the component (Pletka and Wiederhorn, 1982). Since the stress distribution in a restoration such as a replacement crown is complex

even in relatively simple loading situations (Farah and Craig,

1975), lifetime curves for comparison of the three dental ceramics were constructed with S measured on unindented disks

0.20

1.0

.

48

100

10

120

Fine Grain Ceramic

0(

(r 068)

=

4.6

ffi 4A4

2

100

80

(r2=0 69)

0<n

IN 37 C H20

- 42

c;4.

60 u

4.01

Feldspathic Porcelain

3.8-

40

3.6

--

-1

0

+2.0

In (Stressing Rate, MPals)

Fig. 2in water.

Dynamic fatigue

curves at

+4 0

37C for the three dental ceramics

Downloaded from jdr.sagepub.com at MCGILL UNIVERSITY LIBRARY on October 28, 2014 For personal use only. No other uses without permission.

996

J Dent Res July 1986

MORENA ET AL.

Applied Stress(1 03psi)

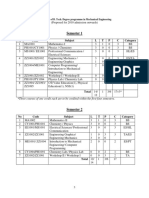

TABLE 1

DYNAMIC FATIGUE RESULTS

n-value

(mean + S.E.)

In Water

Feldspathic Porcelain

Aluminous Porcelain

Fine-grain Ceramic

In Artificial Saliva

Feldspathic Porcelain

1o01o Feldspathic

ufo (MPa)

44.0

78.7

105

1.8

II1

\~

Surface

Condition

72.7 + 8.2

Feldspathic Porcelain

147.9 + 18.2*

Aluminous Porcelain

Fine-grain Ceramic

131.6 8.2*

*Indented prior to being broken.

\\ \\

41.1

-1 yr.\

TABLE 2

INERT STRENGTH VALUES (Mean -+ S.D.)

20

Porcelain Aluminous Porcelain FFine Grain Ceramic

1 08

Si (MPa)

Polished through

1-pum diamond

10

I~~~~~

14.6 + 1.4

28.9 + 5.8

80.8

20.7

14.9

'I'

lI

II

II'

en

S(MPa)

Polished through

30-pum diamond

72.9 + 5.3

147.1 + 11.3

151.4 + 9.9

-1 mo.

106

h._v

(U

IIA

\~~~~~~~~~~~~~~~~~Il

day

--1

104_

Stressing Rate, MPals

\\

-1 hr.

1.0

U;

a

P

~~~~~~~~~~~~I

A

IL02

,I\ I,

II

'.

I1

102

zi

0

.2U

10

25

50

75

100

Applied Stress(MPa)

U.

Fig. 4

Lifetime curves for the three dental ceramics in 370C water.

value is comparable with that of silicate glasses (Wiederhorn

and Bolz, 1970), which are among the most fatigue-susceptible

of all ceramics. The close agreement with respect to n-value

between feldspathic porcelain and silicate glasses also pertains

Fig. 3

Dynamic fatigue curves at 37TC for feldspathic porcelain in

to other aspects of mechanical performance, such as strength

water and in artificial saliva.

and fracture toughness (Morena et al., 1984). These similarities indicate that the mechanical properties of a feldspathic

(tf0 value obtained for water. This effect is presumably due to

porcelain are controlled largely by the matrix glass and not by

a larger initial flaw size for the set of feldspathic porcelain

any crystalline phase(s).

specimens evaluated in the artificial saliva.

(b) The very high value measured for the fine-grain, "shrinkfree" ceramic core material agrees with data cited on fineThe various values of inert strength obtained on the test

materials are listed in Table 2. Lifetime curves, constructed

grain, ot-AI203 ceramics (Pletka and Wiederhorn, 1982). This

from the inert strengths and n-values using Equations (1) and

material should be relatively unaffected by the oral environment except in instances where a high tensile stress is main(4), are presented in Fig. 4. Also shown for each curve is the

90% confidence band, represented by dashed lines, and contained for a long time period.

structed according to a propagation of errors technique outlined

(c) The middle value recorded for the aluminous porcelain

by Pletka and Wiederhorn (1982).

places this material at a position intermediate between the feldspathic porcelain and the fine-grain core material with respect

to resistance to subcritical crack growth. The aluminous porDiscussion.

celain, despite a glassy content comparable with that of feldCrack growth exponents. - The widely different n-values

spathic porcelain (30-40 vol %), has a crack growth exponent

obtained in water for the three dental ceramics indicate that

significantly higher than that of a silicate glass. This indicates

these materials behave quite differently with respect to the

that direct interaction is occurring between cracks and the diseffect that an aqueous environment has on subcritical crack

persed phase (a-A1203), a behavior manifested in other fracgrowth and mechanical degradation:

ture properties as well (Morena et al., 1985).

(a) The low value obtained for the feldspathic porcelain inLifetime curves. - As noted, the lifetime curves apply strictly

dicates a material whose mechanical performance would be

to thin disks that are being subjected to a static applied stress.

appreciably adversely affected when exposed to water. This nThe slopes of these curves are governed by the n-value, which

Downloaded from jdr.sagepub.com at MCGILL UNIVERSITY LIBRARY on October 28, 2014 For personal use only. No other uses without permission.

-2.0

0

2.0

In (Stressing Rate, MPa/s)

4.0

997

FATIGUE OF DENTAL CERAMICS

Vol. 65 No. 7

is a material constant for a given environment. However, the

relative position of each curve is dependent on the inert strength,

S. Thus, if anything, the lifetime curves in Fig. 4 may well

underestimate actual fatigue degradation. This is because the

inert strength of a ceramic in a dental restoration would actually be less than that obtained on the laboratory specimens.

Design factors, such as stress concentrations at margins, and

interfacial stress - arising, for example, from differences in

thermal contraction between the components of a restoration

all would be present in a ceramic prosthesis to lower strength.

The usefulness of the lifetime curves can be illustrated by

employing them to predict the level of applied stress that would

cause failure within five years for the three dental ceramics.

Using the regression analyses for the lifetime curves, we find

that the five-year failure stress for these ceramics is:

feldspathic porcelain

aluminous porcelain

fine-grain ceramic

13.0 MPa (1900 psi)

42.1 MPa (6100 psi)

95.2 MPa (13,800 psi)

Stress of the magnitude needed to cause failure within five

years may well exist for PFM restorations in the oral environment. Finite element analyses of two-dimensional PFM model

central incisors indicate conservative estimates of masticatory

stress, ranging from 6.5 to 17.5 MPa on the upper incisor edge

(Farah and Craig, 1975; Anusavice et al., 1985). In addition,

residual mismatch stresses, arising from thermal contraction

differences between porcelain and metal in a PFM restoration,

can be substantial and attain a value as high as 50 MPa, as

shown by Anusavice et al. (1982) for model PFM crowns with

porcelain facial coverage.

The lifetime curves for the aluminous porcelain and finegrain ceramic core materials both suggest that long-term failure

should not be a problem for anterior applications. Although

no values of masticatory stress could be found in the literature

for posterior crowns, preliminary data (Anusavice, personal

communication) indicate a value of approximately 30 MPa.

Thus, should even moderate levels (15 MPa) of residual thermal mismatch stress exist for the aluminous porcelain, fatigue

failure could result. It is possible that the platinum backing

used in aluminous porcelain crowns could minimize moisture

contact, thus improving the fatigue resistance of aluminous

porcelain restorations. The fine-grain ceramic would appear to

be relatively immune to fatigue failure, even for posterior

placement. However, the steep slope of the lifetime curve could

pose a potential problem for restorations where a large tensile

value of residual mismatch stress exists (caused perhaps by a

gross compositional error for the overglaze), since rapid fatigue failure would occur once stresses much exceeded 95 MPa.

Future work. - Future investigations on fatigue will utilize

cyclic stressing to simulate mastication and will also determine

whether aging or crack tip blunting can occur at low stress

levels to mitigate, to some extent, the fatigue process.

Acknowledgments.

The authors wish to thank the Johnson & Johnson Company

for providing commercial lots of their dental ceramics. Thanks

are also expressed to Skelley Dental Arts, Inc., Aiken, SC,

for their assistance in fabricating the fine-grain ceramic core

specimens. Appreciation is also expressed to S.W. Twiggs for

assistance with statistical analyses.

REFERENCES

ANUSAVICE, K.J.; TWIGGS, S.W.; DEHOFF, P.H.; and FAIRHURST,

C.W. (1982): Correlation of Thermal Shock Resistance with Thermal Compatibility Data for Porcelain-Metal Systems, J Dent Res 61:419-422.

ANUSAVICE, K.J.; HOJJATIE, B.; and DEHOFF, P.H. (1985): Influence of

Metal Thickness in Stress Distribution on Metal Ceramic Crowns, J Dent

Res 64 (Spec Iss):246, Abst. No. 641.

CORBITT, G.V.; MORENA, R.; and FAIRHURST, C.W. (1985): Fracture

Stress of a Commercial Dental Porcelain and its Components, J Dent Res

64 (Spec Iss): 296, Abst. No. 1089.

EVANS, A.G. (1974): Slow Crack Growth in Brittle Materials Under Dynamic

Loading Conditions, Int J Frac 10:251-259.

FARAH, J.W. and CRAIG, R.G. (1975): Distribution of Stresses in PorcelainFused-to-Metal and Porcelain Jacket Crowns, J Dent Res 54:255-261.

FERRANDO, J.P.; GRASER, G.N.; TALLENTS, R.H.; and JARVIS, R.H.

(1983): Tensile Strength and Microleakage of Porcelain Repair Materials,

J Prosthet Dent 50:44-50.

HILLIG, W.B. and CHARLES, R.J. (1965): Surfaces, Stress-dependent Surface Reactions, and Strength. In: High Strength Materials, V.F. Zackay,

Ed., New York: Wiley, pp. 682-701.

JONES, D.W. (1983): The Strength and Strengthening Mechanisms of Dental

Ceramics: In: Dental Ceramics, Proceedings of the First International

Symposium on Ceramics, J.W. McLean, Ed., Chicago: Quintessence Publ.

Co., pp. 96-98 and 110-116.

JONES, D.W. and WILSON, H.J. (1975): Some Properties of Dental Ceramics, J Oral Rehab 2:379-396.

LAWN, B.R.; MARSHALL, D.B.; ANSTIS, G.R.; and DABBS, T.P. (1981):

Fatigue Analysis of Brittle Materials using Indentation Flaws, Part I: General Theory, J Mater Sci 16:2846-2854.

LEHMAN, M.L. (1967): Stability and Durability of Porcelain Jacket Crowns,

Br Dent J 123:419-426.

McLEAN, J.W. (1983): The Future for Dental Porcelain. In: Dental Ceramics,

Proceedings of the First International Symposium on Ceramics, J.W.

McLean, Ed., Chicago: Quintessence Publ. Co., pp. 26-27.

MICHALSKE, T.A. and FREIMAN, S.W. (1983): A Molecular Mechanism

for Stress Corrosion in Vitreous Silica, J Am Ceram Soc 66:284-288.

MORENA, R.; LOCKWOOD, P.E.; MACKERT, J.R., Jr.; and FAIRHURST,

C.W. (1984): Fracture Toughness and Crack-Microstructure Interaction of

a Dental Porcelain, J Dent Res 63 (Spec Iss): 234, Abst. No. 573.

MORENA, R.; LOCKWOOD, P.E.; and FAIRHURST, C.W. (1985): Fracture

Toughness of Commercial Dental Porcelains, Dent Mat (in press).

MOULD, R.E. (1959): The Strength and Static Fatigue of Glass, Glastech Ber

32K: 18-28.

PLETKA, B.J. and WIEDERHORN, S.M. (1982): A Comparison of Failure

Predictions by Strength and Fracture Mechanics Techniques, J Mater Sci

17:1247-1268.

RITTER, J.E., Jr. (1978): Engineering Design and Fatigue Failure of Ceramics.

In: Fracture Mechanics of Ceramics, Vol. 4, R.C. Bradt, D.P.H. Hasselman, and F.F. Lange, Eds., New York: Plenum Press, pp. 667-686.

RITTER, J.E.; VIGEDOMINE, M.; BREDER, K.; and JAKUS, K. (1985):

Dynamic Fatigue of Indented Soda-Lime Glass as a Function of Temperature, J Mater Sci 28:2868-2872.

ROCKAR, E.M. and PLETKA, B.J. (1978): Fracture Mechanics of Alumina

in a Simulated Biological Environment. In: Fracture Mechanics of Ceramics, Vol. 4, R.C. Bradt, D.P.H. Hasselman, and F.F. Lange, Eds.,

New York: Plenum Press, pp. 725-735.

SHAND, E.B. (1958): Glass Engineering Handbook, 2nd ed., New York:

McGraw-Hill, pp. 50-51.

SHERRILL, C.A. and O'BRIEN, W.J. (1974): Transverse Strength of Aluminous and Feldspathic Porcelain, J Dent Res 53:683-690.

SOUTHAN, D.E. and JORGENSEN, K.D. (1974): The Endurance Limit of

Dental Porcelain, Aust Dent J 19:7-11.

WACHTMAN, J.B., Jr.; CAPPS, W.; and MANDEL, J. (1972): Biaxial Flexure Tests of Ceramic Materials, J Mater 7:189-194.

WALTON, T.R. and O'BRIEN, W.J. (1985): Thermal Stress Failure of Porcelain Bonded to a Palladium-Silver Alloy, J Dent Res 64:476-480.

WARPEHA, W.S. and GOODKIND, R.J. (1976): Design and Technique Variables Affecting Fracture Resistance of Metal-Ceramic Restorations, J Prosthet

Dent 35:291-298.

WIEDERHORN, S.M. and BOLZ, L.H. (1970): Stress Corrosion and Static

Fatigue of Glass, J Am Ceram Soc 53:543-548.

WIEDERHORN, S.M. (1967): Influence of Water Vapor on Crack Propagation

in Soda-Lime Glass, J Am Ceram Soc 50:407-414.

WIEDERHORN, S.M. (1974): Mechanisms of Subcritical Crack Growth in

Glass. In: Fracture Mechanics of Ceramics, Vol. 4, R.C. Bradt, D.P.H.

Hasselman, and F.F. Lange, Eds., New York: Plenum Press, pp. 549-580.

Downloaded from jdr.sagepub.com at MCGILL UNIVERSITY LIBRARY on October 28, 2014 For personal use only. No other uses without permission.

You might also like

- 10-Numerical Simulations of Fast Crack Growth in Brittle Solids PDFDocument37 pages10-Numerical Simulations of Fast Crack Growth in Brittle Solids PDFmichael.cretzuNo ratings yet

- 9-Effect of Firing Temperature and Water Exposure On Crack Propagation in Unglazed PorcelainDocument8 pages9-Effect of Firing Temperature and Water Exposure On Crack Propagation in Unglazed Porcelainmichael.cretzuNo ratings yet

- 7-Effect of Thermal Tempering On Strength and Crack Propagation Behavior of Feldspathic PorcelainsDocument6 pages7-Effect of Thermal Tempering On Strength and Crack Propagation Behavior of Feldspathic Porcelainsmichael.cretzuNo ratings yet

- 4-Effects of Chemical Environments On Slow Crack Growth in Glasses and CeramicsDocument5 pages4-Effects of Chemical Environments On Slow Crack Growth in Glasses and Ceramicsmichael.cretzuNo ratings yet

- 15-Porcelain-Raw Materials, Processing, Phase Evolution, and Mechanical Behavior PDFDocument18 pages15-Porcelain-Raw Materials, Processing, Phase Evolution, and Mechanical Behavior PDFmichael.cretzuNo ratings yet

- 8-Effect of Aqueous SolutionsDocument5 pages8-Effect of Aqueous Solutionsmichael.cretzuNo ratings yet

- 6-Influence of Test Method On Failure Stress of Brittle Dental MaterialsDocument10 pages6-Influence of Test Method On Failure Stress of Brittle Dental Materialsmichael.cretzuNo ratings yet

- 14-The Role of Firing Temperature, Firing Time and Quartz Grain Size On PDFDocument8 pages14-The Role of Firing Temperature, Firing Time and Quartz Grain Size On PDFmichael.cretzuNo ratings yet

- 16-Evolution With Temperature of Crystalline and Amorphous Phases in Porcelain Stoneware PDFDocument6 pages16-Evolution With Temperature of Crystalline and Amorphous Phases in Porcelain Stoneware PDFmichael.cretzuNo ratings yet

- 1 PBDocument8 pages1 PBreyad03No ratings yet

- Vitrified TilesDocument13 pagesVitrified TilesChhotiSharmaNo ratings yet

- 11-Characterization of Surface Contact-Induced Fracture in Ceramics Using A Focused Ion Beam Miller PDFDocument6 pages11-Characterization of Surface Contact-Induced Fracture in Ceramics Using A Focused Ion Beam Miller PDFmichael.cretzuNo ratings yet

- Ultra MetabolismDocument166 pagesUltra MetabolismMark KovalNo ratings yet

- 10-Numerical Simulations of Fast Crack Growth in Brittle Solids PDFDocument37 pages10-Numerical Simulations of Fast Crack Growth in Brittle Solids PDFmichael.cretzuNo ratings yet

- Eat Your MedicineDocument18 pagesEat Your Medicinegungi1950No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Machine Design Fatigue Chapter 1 HistoryDocument80 pagesMachine Design Fatigue Chapter 1 HistoryMuzio GolaNo ratings yet

- Department of Structural Engineering: M B M Engineering CollegeDocument4 pagesDepartment of Structural Engineering: M B M Engineering CollegeAjayvidyanand SharmaNo ratings yet

- 1.5.3.1.10 Paper (2011) - SPE-0911-0086-JPT 3D Geomechanical Modeling Optimizes DrillingDocument3 pages1.5.3.1.10 Paper (2011) - SPE-0911-0086-JPT 3D Geomechanical Modeling Optimizes Drillingcapl930No ratings yet

- Aluminium Honeycomb Sandwich Collapse ModesDocument10 pagesAluminium Honeycomb Sandwich Collapse ModesSURESHNo ratings yet

- Design and Analysis Methods For Composite Bonded JDocument19 pagesDesign and Analysis Methods For Composite Bonded JAkash PorwalNo ratings yet

- Fiber-Reinforced Concrete: An Overview After 30 Years of DevelopmentDocument16 pagesFiber-Reinforced Concrete: An Overview After 30 Years of Developmenthemanth gandreddiNo ratings yet

- Effect of Degassing and Heat Treatment OnDocument9 pagesEffect of Degassing and Heat Treatment OnSinan YıldızNo ratings yet

- ASTM - E1820 - Measurement of Fracture ToughnessDocument53 pagesASTM - E1820 - Measurement of Fracture ToughnessFARUK ELALDINo ratings yet

- BS 7448-3 - 2005 (2007)Document62 pagesBS 7448-3 - 2005 (2007)Артем ТитовNo ratings yet

- STP1353 Eb.1415051 1 PDFDocument257 pagesSTP1353 Eb.1415051 1 PDFpaolaNo ratings yet

- Particle Size Reduction ResearchDocument15 pagesParticle Size Reduction ResearchEman SaidNo ratings yet

- Research ProposalDocument2 pagesResearch ProposalSoupramanien Kathirvelou100% (1)

- QP - Failure-Analysis-and-Design PDFDocument36 pagesQP - Failure-Analysis-and-Design PDFKarthick PrasadNo ratings yet

- Ebook Huesker.01Document19 pagesEbook Huesker.01Marcos MaNo ratings yet

- TWI Egypt Welding Inspection CoursesDocument59 pagesTWI Egypt Welding Inspection CoursesAli SASSINo ratings yet

- Damage Mechanisms and Local Approach To FractureDocument14 pagesDamage Mechanisms and Local Approach To Fractureamd mhmNo ratings yet

- Inspection and Remaining Life Evaluation of Process Plant EquipmentDocument27 pagesInspection and Remaining Life Evaluation of Process Plant Equipmentabisat02100% (2)

- Mechanical PDFDocument105 pagesMechanical PDFPrajwal PatilNo ratings yet

- Mayer Stark and Ambrose 2000 Fatigue Design Procedures PDFDocument7 pagesMayer Stark and Ambrose 2000 Fatigue Design Procedures PDFMas Arman TewoNo ratings yet

- Mechanics and Physics of Fracture: Multi-Scale Modeling of The Failure Behaviour of SolidsDocument3 pagesMechanics and Physics of Fracture: Multi-Scale Modeling of The Failure Behaviour of SolidsJoško FrančeskiNo ratings yet

- M. Tech. (Mechanical - Design Engineering)Document46 pagesM. Tech. (Mechanical - Design Engineering)sandipkulkarni27No ratings yet

- Making and Using U-Bend Stress-Corrosion Test Specimens: Standard Practice ForDocument7 pagesMaking and Using U-Bend Stress-Corrosion Test Specimens: Standard Practice ForHadi HowaidaNo ratings yet

- 9% Nickel Steel WeldingDocument11 pages9% Nickel Steel WeldingSridharan ChandranNo ratings yet

- Accepted Manuscript: 10.1016/j.polymertesting.2015.01.020Document32 pagesAccepted Manuscript: 10.1016/j.polymertesting.2015.01.020Dharun TNo ratings yet

- Comparison of The Stress Intensity Factor Influence Coefficients For Axial Id Surface Cracks in Cylinders of Rse-M and Api 579-1Document9 pagesComparison of The Stress Intensity Factor Influence Coefficients For Axial Id Surface Cracks in Cylinders of Rse-M and Api 579-1Андрей ЛозовойNo ratings yet

- 2001 Fatigue Fract Eng Mater StructDocument15 pages2001 Fatigue Fract Eng Mater Structjhon ortizNo ratings yet

- Engineering Failure Analysis-Crack GrowthDocument27 pagesEngineering Failure Analysis-Crack GrowthchandruNo ratings yet

- ME 210 Metallurgy and Materials EngineeringDocument5 pagesME 210 Metallurgy and Materials Engineeringnandan144No ratings yet

- IWSD - Module 2-2 - 5 Introduction To Fracture MechanicsDocument62 pagesIWSD - Module 2-2 - 5 Introduction To Fracture MechanicsPourya NouryNo ratings yet

- Elastomer SDocument209 pagesElastomer Sdanaluca2753100% (3)