Professional Documents

Culture Documents

Nozzle Lab Experiment

Uploaded by

ThaboJaftaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nozzle Lab Experiment

Uploaded by

ThaboJaftaCopyright:

Available Formats

Steam Nozzle Experiment

Department of Mechanical and Industrial Engineering Technology

Laboratory Report

Steam Nozzle Experiment

By

AT JAFTA

(Student No -201427383)

A laboratory report submitted

in partial fulfilment of the requirements for the module

THERMODYNAMICS IV (IMT 441)

FOR THE DEGREE OF BACHELOR OF

MECHANICAL ENGINEERING TECHNOLOGY

Submitted to

Module Lecturer Mr Bakaya Kyahurwa

DEPARTMENT OF MECHANICAL AND INDUSTRIAL ENGINEERING

TECHNOLOGY

FACULTY OF ENGINEERING AND THE BUILT ENVIRONEMNT

UNIVERSITY OF JOHANNESBURG

Submitted: Wednesday 11th March, 2015

Page | 0

Steam Nozzle Experiment

DECLARATION

I .. hereby declare that this laboratory report is wholly

my own work and has not been submitted anywhere else for academic credit, either by myself

or another person.

I understand what plagiarism implies and declare that this report embodies my own ideas,

words, phrases, arguments, graphics, figures, results and organization except where reference

is explicitly made to another work.

I understand further that any unethical academic behaviour, which includes plagiarism, is

seen in a serious light by the University of Johannesburg and is punishable by disciplinary

action as stipulated by the university rules and regulations.

Finally, I understand that fulfilment of this laboratory task complies with the objective of the

ECSA ELO 4 and it must therefore be passed. I declare that this is not the product of a group

work but is my own individual work.

Name: ..

Student No: . .

Signature: ..................................................

Date: ..............................................

]

Page | 1

Steam Nozzle Experiment

TABLE OF CONTENTS

DECLARATION

INTRODUCTION

1.1.

Aim..............................................................................................................................4

1.2.

Theory behind the experiment.....................................................................................4

1.3.

Apparatus.....................................................................................................................5

SECTION TWO

Table 1: Recorded Pressures and Absolute Pressures............................................................7

Recorded Temperature and Atmospheric Pressure.................................................................8

2.1 Results

2.1.1 Sample of Calculations..................................................................................................8

2.1.2 Theoretical Calculations..........................................................................................8

2.1.3 Experimental Calculations........................................................................................9

REFERENCES

Page | 2

13

Steam Nozzle Experiment

LIST OF FIGURES

figure 1: Steam Nozzle Experiment Apparatus.........................................................................5

figure 2 : Schematic Diagram of Nozzle and Dimensions.........................................................5

figure 3: Converging-Diverging Nozzle configuration..............................................................6

figure 4: Ms Excel Spreadsheet sample used to draw the m/a vs absolute pressure graph......11

figure 5: M/A vs Absolute Pressure graph................................................................................11

Page | 3

Steam Nozzle Experiment

SECTION ONE

INTRODUCTION

1.1.

Aim

The aim/objective of the laboratory task is to determine the following:

The mass flow rate of steam

Critical Velocity

Critical Pressure

After the values for the mass of flow rate of steam, critical velocity and pressure are obtained,

the experimental values are then compared to the experimental values then conclusions

whether then values correlate or not can be made.

1.2.

Theory behind the experiment

According to Eastop & McConkey, a nozzle is a duct with a varying cross-sectional area in

which a steadily flowing fluid can be made to accelerate by a pressure drop along a duct.

It can be assumed that the flow through a duct is subsonic since M<1 through a converging

duct followed by a diverging duct after the throat which is supersonic. It can hypothetically

be deduced that in a nozzle, as the cross-sectional area decreases, the pressure drops whilst

the velocity increases on the contrary.

Equations that will be used for calculations include

where Pc= critical pressure, n=1,135 for dry saturated

Cc =

Page | 4

where Cc= Critical Velocity of steam

Steam Nozzle Experiment

1.3.

Apparatus

figure 1: Steam Nozzle Experiment Apparatus

figure 2 : Schematic Diagram of Nozzle and Dimensions

figure 3: Converging-Diverging Nozzle configuration

in addition to the apparatus listed above, a barometer is used to determine the ambient

temperature.

Page | 5

Steam Nozzle Experiment

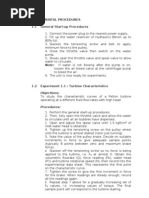

1.4 Procedure

Page | 6

Measure the atmospheric pressure and temperature from the barometer.

Insert the open end of the probe into the converging end of nozzle and take the

gauge pressure reading.

Open the valve to let compressed steam flow through the nozzle. Observe the

gauge pressure readings as you move the probe further into the nozzle along

the nozzle centre line. Record the gauge pressure every 2.5cm marked off on

the profile of the nozzle on the outside of chamber.

Calculate the critical pressure at throat.

Plot a graph of M/A Vs Absolute pressure along the profile of the nozzle.

From the graph determine the pressure at the throat (critical pressure)

Steam Nozzle Experiment

SECTION TWO

RESULTS AND CALCULATIONS

Table 1: Recorded Pressures and Absolute Pressures

Mark Point

Pgauge (KPa)

Pabsolute (KPa)

Pabsolute (KPa)

220

308

310

220

308

310

220

308

310

220

308

310

220

308

310

220

308

310

220

308

310

220

308

310

220

308

310

10

220

308

310

11

200

288

290

12

180

268

270

13

160

248

250

14

150

238

240

15

140

228

230

16

135

223

220

17

120

208

210

18

120

208

210

19

110

198

200

20

105

193

190

21

100

188

190

22

100

188

190

23

100

188

190

24

95

183

180

25

90

178

180

Page | 7

Steam Nozzle Experiment

Recorded Temperature and Atmospheric Pressure

= 95C

Patmos = 660 mm Hg

2.1 Results

2.1.1 Sample of Calculations

1 mm Hg = 133.322 Pa

Therefore, Patmos

= 87.99 KPa 88KPa

P1 = Pg1 + Patmos

= 220 + 87.99

= 308 KPa

2.1.2

Theoretical Calculations

Pa

Page | 8

Steam Nozzle Experiment

s1 = 6.980 = sc= sf@180+ xc sfg@180

xc =

= 0.968

vc=xcvg@180

= 0.968 x 0.9772

= 0.94593 m3/kg

hc = hf@180 + xc x hfg@180

= 491 + 0.968 (2211)

= 2631.25 kJ/kg

Cc =

=

= 439.04 m/s

Ac =

=

= 1.8096 x 10-5 m2

mc x vc= Ac x Cc

mc

8.3297 x 10-3kg/s

2.1.3 Experimental Calculations

Sample between mark point 1 11

s1 = sg@310 = s11 = 6.980 KJ/kg.K

Page | 9

Steam Nozzle Experiment

s11 = sf@280 + x10 x sfg@280

x11 =

=

=

0.996

h11 = hf@290 + x11 x hfg@290

= 557 + 0.996 (2167)

= 2715 KJ/kg

V11 = x11 vg@280

= 0.996(0.6251)

= 0.6226 m3/kg

C11 =

=

= 148.3 m/s

Page | 10

238.195 kg/m2.s

Steam Nozzle Experiment

figure 4: Ms Excel Spreadsheet sample used to draw the m/a vs absolute pressure graph

figure 5: M/A vs Absolute Pressure graph

2.2 Observations from the graph

Critical Point lies at the uppermost point of the graph

Pc = 185 kPa

Page | 11

Steam Nozzle Experiment

= 455 kg/m2.s

Ac =

=

= 1.8096 x 10-5 m2

Therefore,

mc = Ac x 455

= 1.8096 x 10-5 x 455

= 8.23368 x 10-3kg/s

Experimental Values

Theoretical Values

Pcritical= 185 KPa

Pcritical= 180 KPa

mc=8.23368 x 10-3kg/s

mc= 8.3297 x 10-3kg/s

Table 2: Comparison of Experimental and Theoretical Values

2.3 Conclusions

The aim of comparing the experiments and theoretical methods has been achieved. The

experimental values to a large degree correlate with the theoretical values with a minute

percentage error of 1.1% for mc and 2.8% for the pressure at the critical region P c, the minute

difference in the theoretical and practical could be caused by parallax error when taking

readings.

Page | 12

Steam Nozzle Experiment

REFERENCES

[1]

Eastop, McConkey, Applied Thermodynamics for Engineering Technologists,

Pearson., England , 1993, p. 287-301.

[2]

Cengel, Boles., An Engineering Approach to Thermodynamics, McGraw Hill Science,

USA, 2010, p. 258-267.

[3]

Elements of Heat Engines Vol II

http://www.thermodynamicsheatengines.com/HeatEnginesVol%202%20Chapter

%208%20RS.pdf, Accessed 08 March 2015.

[4]

Dr R.K Bansal., Mechanical Engineering, Laxmi Publications, India, 1993, p. 199201.

Page | 13

Steam Nozzle Experiment

Page | 14

You might also like

- Steam Nozzle Experiment (Power Planet Lab)Document21 pagesSteam Nozzle Experiment (Power Planet Lab)Ali Madrid0% (1)

- CH 3Document5 pagesCH 3Amaterasu Susanoo Tsukuyomi100% (3)

- 11.a.ii - ME03031 QA 1Document22 pages11.a.ii - ME03031 QA 1Bakkiya Raj100% (1)

- Lecture 16 Problems in Steam TurbineDocument17 pagesLecture 16 Problems in Steam TurbineKaran Gangwar100% (1)

- Determination of Nozzle Efficiency Experiment ResultsDocument6 pagesDetermination of Nozzle Efficiency Experiment ResultsMuhammad Firdaws0% (2)

- PP Lab Reports - Steam Power PlantDocument5 pagesPP Lab Reports - Steam Power PlantMuhammad Waleed TariqNo ratings yet

- Machinery Example Problems Ch12 - GearTeamDocument51 pagesMachinery Example Problems Ch12 - GearTeamGonKilNo ratings yet

- Compressible Flow in Convergence NozzleDocument8 pagesCompressible Flow in Convergence Nozzleutub3abr0No ratings yet

- Air Compressor Performance TestDocument7 pagesAir Compressor Performance TestRajneeshKrNo ratings yet

- Pelton Turbine CharacteristicsDocument10 pagesPelton Turbine CharacteristicsViknesh MjNo ratings yet

- CENTRIFUGAL PUMP EQUATIONSDocument38 pagesCENTRIFUGAL PUMP EQUATIONSRichard Manongsong100% (1)

- Exp3-Direct Weighing MethodDocument19 pagesExp3-Direct Weighing MethodSaurabh TripathiNo ratings yet

- Two Stage Air CompressorDocument5 pagesTwo Stage Air Compressorkhalijahjamal0% (1)

- Compressor NumericalDocument18 pagesCompressor NumericalSweekar Khadka100% (1)

- Balancing CONCLUSIONDocument2 pagesBalancing CONCLUSIONSyahdi Rosli100% (1)

- Experimental Determination of Nozzle Efficiency VariationDocument8 pagesExperimental Determination of Nozzle Efficiency VariationSunil Choudhary50% (2)

- Applied Thermodynamics: Unit-IiiDocument50 pagesApplied Thermodynamics: Unit-IiiRupesh Shanmughom SNo ratings yet

- Universal Governor AppartusDocument21 pagesUniversal Governor Appartusramniwas123No ratings yet

- Nozzle Problems For PracticeDocument3 pagesNozzle Problems For Practicestmurugan100% (1)

- Steam Turbine 1Document73 pagesSteam Turbine 1Balaji Kalai0% (1)

- Emm3812 - Static and Dynamic BalancingDocument7 pagesEmm3812 - Static and Dynamic Balancingsyamil100% (2)

- Everything You Need to Know About Air CompressorsDocument16 pagesEverything You Need to Know About Air CompressorsIzzul Hazim33% (6)

- Turning Moment Diagrams PDFDocument20 pagesTurning Moment Diagrams PDFMohammad Rahat Rahman100% (1)

- ME 58 FinalDocument27 pagesME 58 FinalMarvin Cuizon VallarNo ratings yet

- Lab Report AircondDocument4 pagesLab Report AircondSuraya JasmaniNo ratings yet

- Experiment 3 Air Compressor PDFDocument9 pagesExperiment 3 Air Compressor PDFah qian100% (1)

- Chapter 4-Power Turbines 5Document20 pagesChapter 4-Power Turbines 5Abdullatif AlOmair100% (1)

- eXPERIMENT NO 06 FMDocument9 pageseXPERIMENT NO 06 FMAsim Bajwa100% (1)

- Forced Convection Lab Report AnalysisDocument10 pagesForced Convection Lab Report AnalysisEugene100% (1)

- Thick Cylinder Laboratory ExerciseDocument7 pagesThick Cylinder Laboratory Exercisemohammed33% (6)

- Mechanics of Machines - 1 PDFDocument8 pagesMechanics of Machines - 1 PDFtetirichie100% (1)

- Trifilar Suspension 1Document4 pagesTrifilar Suspension 1Ninad BhanuNo ratings yet

- C-D Nozzle PDFDocument38 pagesC-D Nozzle PDFAnonymous VKv75qe98No ratings yet

- RESULT, DISCUSSION, Calculation, ConclusionDocument11 pagesRESULT, DISCUSSION, Calculation, ConclusionHafizszul Feyzul80% (5)

- 4 Rough Draft2 Impact of A Water JetDocument14 pages4 Rough Draft2 Impact of A Water JetBrennan GenusaNo ratings yet

- Trial On Reciprocating CompressorDocument3 pagesTrial On Reciprocating CompressorHardik S. Borse100% (1)

- Experiment 4 (Combined Convectionn Radiation) PDFDocument8 pagesExperiment 4 (Combined Convectionn Radiation) PDFAnonymous 9C0AfJoq100% (2)

- Centrifugal Pump Report CompletedDocument24 pagesCentrifugal Pump Report CompletedMohamad Fareez Roslan100% (1)

- Pelton Wheel TurbineDocument8 pagesPelton Wheel TurbineSiew LynNo ratings yet

- GT Powerplants Additional ExamplesDocument8 pagesGT Powerplants Additional ExamplesKarina Nur Rakhmawaty25% (4)

- WL377e - Natural Convection and Radiation - V0.1Document49 pagesWL377e - Natural Convection and Radiation - V0.1Petrônio PauloNo ratings yet

- Strain and Deflection of A Circular Plate - Lab ReportDocument4 pagesStrain and Deflection of A Circular Plate - Lab ReportRoshane NanayakkaraNo ratings yet

- Centrifugal Pump Problems Part 1Document16 pagesCentrifugal Pump Problems Part 1Bandaiah GNNo ratings yet

- Lab 2 ThermalDocument18 pagesLab 2 ThermalMuhamad Arif100% (1)

- Pressure Distribution Over A Circular Cylinder PDFDocument11 pagesPressure Distribution Over A Circular Cylinder PDFShiv MauryaNo ratings yet

- How Jet Angles Affect Fluid ForcesDocument11 pagesHow Jet Angles Affect Fluid Forcesjoshx12No ratings yet

- To Perform Torsion Test On Mild Steel and Cast Iron PDFDocument10 pagesTo Perform Torsion Test On Mild Steel and Cast Iron PDFHAQSHAY100% (3)

- Faculty of Engineering & Built Environment Subject: Ege 3411 Laboratory Investigations 2 Experiment 1: Gear TrainDocument7 pagesFaculty of Engineering & Built Environment Subject: Ege 3411 Laboratory Investigations 2 Experiment 1: Gear TrainJameel MalikNo ratings yet

- Lab 4Document13 pagesLab 4Edward XavierNo ratings yet

- Convergent & Convergent-Divergent Nozzle Performance Lab ReportDocument25 pagesConvergent & Convergent-Divergent Nozzle Performance Lab ReportAkmal Aiman100% (1)

- Pressure Nozzle Distribution UnitDocument16 pagesPressure Nozzle Distribution UnitAlmeghalawyNo ratings yet

- Thermodynamics Lab Report - Application of The Perfect Gas Laws in The Determination of Adiabatic Index of AirDocument9 pagesThermodynamics Lab Report - Application of The Perfect Gas Laws in The Determination of Adiabatic Index of Airqiaunus69% (13)

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument16 pagesUniversity of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456No ratings yet

- 2023 - MTF12A - Lab GuideDocument30 pages2023 - MTF12A - Lab GuideSiyabonga MasukuNo ratings yet

- Mka 03 (A) Pelton TurbineDocument7 pagesMka 03 (A) Pelton TurbinevinoNo ratings yet

- Mechanical Measurements Lab ManualDocument26 pagesMechanical Measurements Lab ManualseminarprojectNo ratings yet

- Engineering ExperimentDocument58 pagesEngineering ExperimentAbu YusufNo ratings yet

- Pulsating Heat Pipe ReportDocument65 pagesPulsating Heat Pipe ReportIdul Azharul HoqueNo ratings yet

- BR Article 12156 en 1 PDFDocument23 pagesBR Article 12156 en 1 PDFThaboJaftaNo ratings yet

- A Validated Numerical Investigation of T PDFDocument11 pagesA Validated Numerical Investigation of T PDFThaboJaftaNo ratings yet

- High and Maximum Containment LaboratoriesDocument23 pagesHigh and Maximum Containment LaboratoriesThaboJaftaNo ratings yet

- Complete EDM Handbook - 8Document14 pagesComplete EDM Handbook - 8ThaboJaftaNo ratings yet

- Complete EDM Handbook - 2 PDFDocument19 pagesComplete EDM Handbook - 2 PDFSaeed MohammedNo ratings yet

- Health Risk CommunicationsDocument36 pagesHealth Risk CommunicationsThaboJaftaNo ratings yet

- Determination of Wall Thickness and Height When Cutting Various MDocument114 pagesDetermination of Wall Thickness and Height When Cutting Various MThaboJaftaNo ratings yet

- Engineering Proposal: Waste Remedial SystemDocument7 pagesEngineering Proposal: Waste Remedial SystemThaboJaftaNo ratings yet

- Complete EDM Handbook - 1 IntroDocument9 pagesComplete EDM Handbook - 1 IntroThaboJaftaNo ratings yet

- Mechanics of Machines 4 ProjectDocument21 pagesMechanics of Machines 4 ProjectThaboJaftaNo ratings yet

- Refractory Materials Design (Autosaved) SDocument13 pagesRefractory Materials Design (Autosaved) SThaboJaftaNo ratings yet

- Refractory Materials Design (Autosaved) SDocument13 pagesRefractory Materials Design (Autosaved) SThaboJaftaNo ratings yet

- Gas Turbine Theory and Construction ExplainedDocument29 pagesGas Turbine Theory and Construction ExplainedDee ⎝⏠⏝⏠ DeeNo ratings yet

- STC PDFDocument34 pagesSTC PDFМиша ШаулаNo ratings yet

- Minicap FTC260, FTC262: Technical InformationDocument20 pagesMinicap FTC260, FTC262: Technical InformationAmanda PorterNo ratings yet

- CQ B TECHNIQUESDocument37 pagesCQ B TECHNIQUESeddie6355100% (3)

- CBSE Class 11 English Sample Paper Set 5Document8 pagesCBSE Class 11 English Sample Paper Set 5Shantam BasuNo ratings yet

- Chapter 4: Input/Output Programming of 8051 CPUDocument7 pagesChapter 4: Input/Output Programming of 8051 CPUIsmailNo ratings yet

- Heidegger On Destruction - Chung ChinDocument16 pagesHeidegger On Destruction - Chung ChinAprilo DielovaNo ratings yet

- Modul Cemerlang Matematik JPN Kedah 2016 PDFDocument102 pagesModul Cemerlang Matematik JPN Kedah 2016 PDFAnna ZubirNo ratings yet

- 2 Linking Operations To Finance and ProductivityDocument14 pages2 Linking Operations To Finance and ProductivityAidan HonnoldNo ratings yet

- TATA Gluco PDFDocument5 pagesTATA Gluco PDFsidharth dasNo ratings yet

- DD Cen TR 10347-2006Document14 pagesDD Cen TR 10347-2006prabagaran88% (8)

- AIA Design Development Deliverable ListDocument8 pagesAIA Design Development Deliverable Listpeterhwilliams100% (1)

- TTBR 10 January 2024 LDocument22 pagesTTBR 10 January 2024 Lfossil.tractor0sNo ratings yet

- RUDDER PLATING DIAGRAMDocument1 pageRUDDER PLATING DIAGRAMMuhammad Ilham AlfiansyahNo ratings yet

- Complete The Table With The Missing WordsDocument2 pagesComplete The Table With The Missing WordssoniaNo ratings yet

- ImmortalDocument4 pagesImmortalMaNithyaVishalanandaNo ratings yet

- Caterpillar FAPT Presentation PDFDocument18 pagesCaterpillar FAPT Presentation PDFJuniOrs RiVeraNo ratings yet

- Operator Identities 2Document3 pagesOperator Identities 2jasmonNo ratings yet

- The Earls Sinful Quest - Lisa CampellDocument148 pagesThe Earls Sinful Quest - Lisa CampellEirini DiamantopoulouNo ratings yet

- TOEFL Module 1 - ReadingDocument65 pagesTOEFL Module 1 - ReadingImam NurviyantoNo ratings yet

- PHD Call - TCD - Micha Ruhl - PHD Project Short DescriptionDocument2 pagesPHD Call - TCD - Micha Ruhl - PHD Project Short DescriptionabuzarNo ratings yet

- Serospin Operating Manual 20100407Document19 pagesSerospin Operating Manual 20100407Verdana50% (2)

- End UserDocument205 pagesEnd Userghica05No ratings yet

- User Manual ConsoleDocument45 pagesUser Manual Consoledhana0809No ratings yet

- Greek MathemaDocument6 pagesGreek MathemaSebastian GhermanNo ratings yet

- RFIADocument11 pagesRFIAMary Joy TorresNo ratings yet

- Creative NonfictionDocument11 pagesCreative NonfictionRubelyn CagapeNo ratings yet

- WozairDocument4 pagesWozairRajakumar Bajji SubburamanNo ratings yet

- Satellite Communication Uplink Transmitter Downlink Receiver and TransponderDocument2 pagesSatellite Communication Uplink Transmitter Downlink Receiver and TransponderTHONTARADYA CHANNELNo ratings yet

- Mahamrityunjaya MantraDocument8 pagesMahamrityunjaya MantraBalakrishnan KannanNo ratings yet

- DVRP Newsletter Resilience Vol. 2, Issue 2Document6 pagesDVRP Newsletter Resilience Vol. 2, Issue 2Lucius Doxerie Sr.No ratings yet