Professional Documents

Culture Documents

Applied Thermodynamics and Fluids

Uploaded by

Krishna SwamyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applied Thermodynamics and Fluids

Uploaded by

Krishna SwamyCopyright:

Available Formats

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

UNIT I

LAWS OF THERMODYNAMICS AND BASIC IC ENGINE CYCLES

Part A

1. What is meant by thermodynamic system? How do you classify it?

Thermodynamic system is defined as the any space or matter or group of matter where the energy transfer or

energy conversions are studied.

It may be classified into three types.

(a) Open system

(b) Closed system

(c) Isolated system

2. What is meant by closed system? Give an example.

When a system has only heat and work transfer, but there is no mass transfer, it is called as closed system.

Example: Piston and cylinder arrangement.

3. Define a open system, Give an example.

When a system has both mass and energy transfer it is called as open system.

Example: Air Compressor.

4. Differentiate closed and open system.

Closed System

Open System

1. There is no mass transfer. Only heat and

1. Mass transfer will take place, in addition to

work will transfer.

the heat and work transfer.

2. System boundary is fixed one

2. System boundary may or may not change.

3. Ex: Piston & cylinder arrangement, Thermal 3. Air compressor, boiler

power plant

5. Define an isolated system

Isolated system is not affected by surroundings. There is no heat, work and mass transfer take place. In this

system total energy remains constant.

Example: Entire Universe

6. What is meant by thermodynamic property?

Thermodynamic property is any characteristic of a substance which is used to identify the state of the system

and can be measured, when the system remains in an equilibrium state.

7. How do you classify the property?

Thermodynamic property can be classified into two types.

1. Intensive or Intrinsic and

2. Extensive and Extrinsic property.

8. Define Intensive and Extensive properties.

The properties which are independent on the mass of the system is called intensive properties.

e.g., Pressure, Temperature, Specific Volume etc.,

The properties which are dependent on the mass of the system is called extensive properties.

e.g., Total energy, Total volume, weight etc.

9. Differentiate Intensive and Extensive properties.

Intensive Properties

Extensive Properties

1. Independent on the mass of the system

Dependent on the mass of the system.

2. If we consider part of the system these

If we consider part of the system it will have a

properties remain same.

lesser value.

e.g. pressure, Temperature specific volume

e.g., Total energy, Total volume, weight etc.,

etc.,

3. Extensive property/mass is known as

-intensive property

10. What do you understand by equilibrium of a system?

When a system remains in equilibrium state, it should not undergo any charges to its own accord.

11. What is meant by thermodynamic equilibrium?

When a system is in thermodynamic equilibrium, it should satisfy the following three conditions.

(a) Mechanical Equilibrium :- Pressure remains constant

(b) Thermal equilibrium :- Temperature remains constant

(c) Chemical equilibrium : There is no chemical reaction.

12. State the First law of thermodynamics (MU Apr95)

First of thermodynamics states that when system undergoes a cyclic process the net heat transfer is equal to

work transfer.

13. What is meant by open and closed cycle.

In a closed cycle, the same working substance will re circulate again and again.

In a open cycle, the same working substance will be exhausted to the surroundings after expansion.

St.Josephs College of Engineering

1

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

14. What is meant by reversible and irreversible process.

A process is said to be reversible, it should trace the same path in the reverse direction when the process is

reversed. It is possible only when the system passes through a continuous series of equilibrium state.

If a system does not pass through continuous equilibrium state, then the process is said to be irreversible.

15. What is Quasi Static process?

The process is said to be quasi static, it should proceed infinitesimally slow and follows continuous series of

equilibrium states. Therefore, the quasi static, it should proceed infinitesimally slow and follows continuous

series of equilibrium states. Therefore, the quasi static process may be an reversible process.

16. Explain Zeroth Law of thermodynamics?

Zeroth law of thermodynamics states that when two systems are separately in thermal equilibrium with a third

system, then they themselves are in thermal equilibrium with each other.

17. Define the term enthalpy?

The Combination of internal energy and flow energy is known as enthalpy of the system. It may also be

defined as the total heat of the substance.

Mathematically, enthalpy (H) = U + pv KJ)

Where, U internal energy

p pressure

v volume

In terms of Cp & T H = mCp (T2-T1)KJ

18. Define the term internal energy

Internal energy of a gas is the energy stored in a gas due to its molecular interactions. It is also defined as the

energy possessed by a gas at a given temperature.

19. What is meant by thermodynamic work?

It is the work done by the system when the energy transferred across the boundary of the system. It is mainly

due to intensive property difference between the system and surroundings.

20. Define an isentropic process.

Isentropic process is also called as reversible adiabatic process. It is a process which follows the law of pV y = C

is known as isentropic process. During this process entropy remains constant and no heat enters or leaves the

gas.

21. What is the difference between steady flow and non flow process?

During the steady flow process the rate of flow of mass and energy across the boundary remains constant. In

case of non flow across the system and boundary.

22. State the Kelvin Plank statement of second law of thermodynamics

Kelvin Plank states that it is impossible to construct a heat engine working on cyclic process, whose only

purpose is to convert all the heat energy given to it into an equal amount of work.

23. State Clausius statement of second law of thermodynamics.

It states that heat can flow from hot body to cold without any external aid but heat cannot flow from cold body

to hot body without any external aid.

24. State Carnots theorem.

No heat engine operating in a cyclic process between two fixed temperature, can be more efficient than a

reversible engine operating between the same temperature limits.

25. Write the expression for efficiency of the otto cycle?

1

Efficiency n =1 - --------(r)r-1

26. What is meant by cutoff ratio?

Cutoff ratio is defined as the ratio of volume after the heat addition to before the heat addition. It is denoted by

the letter p

27. What are the assumptions made for air standard cycle.

1. Air is the working substance.

2. Throughout the cycle, air behaves as a perfect gas and obeys all the gas laws.

3. No chemical reaction takes place in the cylinder

4. Both expansion and compression are strictly isentropic

5. The values of specific heats of the air remain constant throughout the cycle

28. What is meant by air standard efficiency of the cycle?

It is defined as the ratio of work done by the cycle to the heat supplied to the cycle.

Work done

Efficiency n = -------------Heat supplied

St.Josephs College of Engineering

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

29. Define Mean effective pressure of an I.C. engine.

Mean effective pressure is defined as the constant pressure acting on the piston during the working stroke. It is

also defined as the ratio of work done to the stroke volume or piston displacement volume.

30. The Brayton cycle is mainly used in _______

Gas turbine power plant.

31. Give the expression for efficiency of the Brayton cycle.

1

Efficiency n = 1 - ---------- where Rp pressure ratio.

(Rp)y-1

32. What is a Gas turbine? How do you classify.

Gas turbine is an axial flow rotary turbine in which working medium is gas.

Classification of gas turbine.

1. According to the cycle of operation

a) open cycle b) closed cycle and c) semi closed cycle.

2. According to the process

a) constant volume and b) constant pressure process.

33. What is meant by closed cycle gas turbine?

In closed cycle gas turbine, the same working fluid is recirculated again and again.

34. What is meant by open cycle gas turbine?

In open cycle gas turbine, the exhaust gas form turbine is exhausted to the atmosphere and fresh air is taken in

compressor for every cycle

35. What is the function of intercooler in gas turbines? Where it is placed?

The intercooler is placed between L.P. and H.P. compressors. It is used to cool the gas coming form L.P.

compressor to its original temperature..

36. What is the function of regenerator in gas turbine?

The main function of heat regenerator is to exchange the heat from exhaust gas to the compressed air for

preheating before combustion chamber. It increases fuel economy and increase thermal efficiency.

37. What is meant by single acting compressor?

In single acting compressor, the suction, compression and delivery of air take place on one side of the

piston.

38. What is meant by double acting compressor?

In double acting reciprocating compressor, the suction compressin and delivery of air take place on both

side of the piston.

39. What is meant by single stage compressor?

In single stage compressor, the compression of air from the initial pressure to the final pressure is carried

out in one cylinder only.

40. Define clearance ratio

Clearance ratio is defined as the ratio of clearance volume to swept volume (or) stroke volume.

Vc

Vc clearance volume

C = -------Vs swept volume

Vs

41. What is compression ratio?

Compression ratio is defined as the ratio between total volume and clearance volume.

Total volume

Compression ratio = ------------------Clearance Volume

42. What are the factors that effect the volumetric efficiency of a reciprocating compressor?

1) Clearance volume 2) Compression ratio

43. What is meant by Point and Path function?

The quantities which is independent on the process or path followed by the system is known as point functions.

Example: Pressure, volume, temperature, etc.,

The quantities which are dependent on the process or path followed by the system is known as path functions.

Example: Heat transfer, work transfer.

PART B

1.

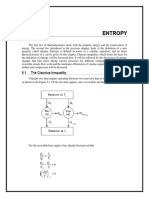

When a system is taken from state l to state m, in Fig., along path lqm, 168 kJ of heat flows into the

system, and the system does 64 kJ of work :

(i) How much will be the heat that flows into the system along path lnm if the work done is 21 kJ?

St.Josephs College of Engineering

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

(ii) When the system is returned from m to l along the curved path, the work done on the system is 42 kJ.

Does the system absorb or liberate heat, and how much of the heat is absorbed or liberated?

(iii) If Ul = 0 and Un = 84 kJ, find the heat absorbed in the processes ln and nm.

Qlqm = 168 kJ

Wlqm = 64 kJ

We have, Qlqm = (Um Ul) + Wlqm

168 = (Um Ul) + 64

Um Ul= 104 kJ. (Ans.)

(i) Qlnm = (Um Ul) + Wlnm

= 104 + 21

= 125 kJ. (Ans.)

(ii)

Qml = (Ul Um) + Wml

= 104 + ( 42)

= 146 kJ. (Ans.)

The system liberates 146 kJ.

(iii) Wlnm = Wln + Wnm

= Wlm = 21 kJ

[Wnm = 0, since volume does not change.]

Qln = (Un Ul) + Wln = (84 0) + 21

= 105 kJ. (Ans.)

Now Qlmn= 125 kJ = Qln + Qnm

Qnm = 125 Qln = 125 105

2.

= 20 kJ. (Ans.)

A fluid system, contained in a piston and cylinder machine, passes through a complete cycle of four

processes. The sum of all heat transferred during a cycle is 340 kJ. The systems completes 200

cycles per min. Complete the following table showing the method for each item, and compute the

net rate of work output in kW.

Process

Q (kJ/min)

W (kJ/min)

E (kJ/min)

12

4340

23

42000

St.Josephs College of Engineering

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

4200

73200

41

Sum of all heat transferred during the cycle = 340 kJ.

Number of cycles completed by the system = 200 cycles/min.

Process 12 :

Q=E+W

0 = E + 4340

E = 4340 kJ/min.

Process 23 :

Q=E+W

42000 = E + 0

E = 42000 kJ/min.

Process 34 :

Q=E+W

4200 = 73200 + W

W = 69000 kJ/min.

Process 41 :

Qcycle= 340 kJ

The system completes 200 cycles/min

Q12 = Q23 + Q34 + Q41

= 340 200

= 68000 kJ/min

0 + 42000 + ( 4200) + Q41 = 68000

Q41 = 105800 kJ/min.

Now, dE= 0, since cyclic integral of any property is zero.

E12 + E23 + E34 + E41 = 0

4340 + 42000 + ( 73200) + E41 = 0

E41 = 35540 kJ/min.

W41 = Q41 E41

= 105800 35540

= 141340 kJ/min

Process

Q (kJ/min)

W (kJ/min)

12

0

4340

23

42000

0

34

4200

69000

41

105800

141340

Since Qcycle= Wcycle

Rate of work output = 68000 kJ/min

3.

2014-2015

34

E (kJ/min)

4340

42000

73200

35540

= 1133.33 kW. (Ans.)

A fluid system undergoes a non-flow frictionless process following the pressure-volume relation as

where p is in bar and V is in m3. During the process the volume changes from 0.15 m3

to 0.05 m3 and the system rejects 45 kJ of heat. Determine :

(i) Change in internal energy ;

(ii) Change in enthalpy.

Initial volume, V1 = 0.15 m3

Final volume, V2 = 0.05 m3

Heat rejected by the system, Q = 45 kJ

Work done is given by,

St.Josephs College of Engineering

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

= 5.64 105 N-m = 5.64 105 J

2014-2015

[1 Nm = 1 J]

= 564 kJ

(i) Applying the first law energy equation,

Q=U+W

45 = U + ( 564)

U = 519 kJ. (Ans.)

This shows that the internal energy is increased.

(ii) Change in enthalpy,

H = U + (pV)

= 519 103 + (p2V2 p1V1)

= 34.83 105 N/m2

= 101.5 bar = 101.5 105 N/m2

H = 519 103 + (101.5 105 0.05 34.83 105 0.15)

= 519 103 + 103(507.5 522.45)

= 103(519 + 507.5 522.45) = 504 kJ

4.

Change in enthalpy = 504 kJ. (Ans.)

The following equation gives the internal energy of a certain substance u = 3.64 pv + 90 where u is

kJ/kg, p is in kPa and v is in m3/kg.A system composed of 3.5 kg of this substance expands from an

initial pressure of 500 kPa and a volume of 0.25 m3 to a final pressure 100 kPa in a process in which

pressure and volume are related by pv1.25 = constant. (i) If the expansion is quasi-static, find Q, U

and W for the process. (ii) In another process, the same system expands according to the same

pressure-volume relationship as in part (i), and from the same initial state to the same final state as

in part (i), but the heat transfer in this case is 32 kJ. Find the work transfer for this process.

(iii) Explain the difference in work transfer in parts (i) and (ii).

St.Josephs College of Engineering

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

Internal energy equation : u = 3.64 pv+ 90

Initial volume, V1 = 0.25 m3

Initial pressure, p1 = 500 kPa

Final pressure, p2 = 100 kPa

Process: pv1.25 = constant.

(i) Now, u = 3.64 pv+ 90

u = u2 u1 = 3.64 (p2v2 p1v1) ...per kg

U = 3.64 (p2V2 p1V1) ...for 3.5 kg

Now, p1V11.25 = p2V21.25

= 0.906 m3

U= 3.64 (100 103 0.906 500 103 0.25) J

[1 Pa = 1 N/m2]

= 3.64 105 (0.906 5 0.25) J

= 3.64 105 0.344 J = 125.2 kJ

i.e., U = 125.2 kJ. (Ans.)

For a quasi-static process

= 137.6 kJ

Q = U+ W

= 125.2 + 137.6

= 12.4 kJ

i.e., Q = 12.4 kJ. (Ans.)

(ii)

Here Q = 32 kJ

Since the end states are the same, U would remain the same as in (i)

W = Q U= 32 ( 125.2) = 157.2 kJ. (Ans.)

(iii)

5.

The work in (ii) is not equal to p dV since the process is not quasi-static.

0.2 m3 of air at 4 bar and 130C is contained in a system. A reversible adiabatic expansion takes

place till the pressure falls to 1.02 bar. The gas is then heated at constant pressure till enthalpy

increases by 72.5 kJ. Calculate :

(i) The work done ;

St.Josephs College of Engineering

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

(ii) The index of expansion, if the above processes are replaced by a single reversible polytropic

process giving the same work between the same initial and final states.

Take cp = 1 kJ/kg K, cv = 0.714 kJ/kg K.

Initial volume, V1 = 0.2 m3

Initial pressure, p1 = 4 bar = 4 105 N/m2

Initial temperature, T1 = 130 + 273 = 403 K

Final pressure after adiabatic expansion,

p2 = 1.02 bar = 1.02 105 N/m2

Increase in enthalpy during constant pressure process = 72.5 kJ.

(i) Work done :

Process 1-2 : Reversible adiabatic process :

Also

= 0.53 m3

= 272.7 K

Mass of the gas,

where, R = (cp cv) = (1 0.714) kJ/kg K

= 0.286 kJ/kg K

= 286 J/kg K or 286 Nm/kg K

St.Josephs College of Engineering

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

Process 2-3. Constant pressure :

Q23 = m cp (T3 T2)

72.5 = 0.694 1 (T 3 272.7)

T3 = 377 K

Also,

V3= 0.732 m3

Work done by the path 1-2-3 is given by

W123 = W12 + W23

Hence, total work done = 85454 Nm or J.

(ii) Index of expansion, n :

If the work done by the polytropic process is the same,

n = 1.062

Hence,

6.

value of index = 1.062. (Ans.)

A cylinder contains 0.45 m3 of a gas at 1 105 N/m2 and 80C. The gas is compressed to a volume of

0.13 m3, the final pressure being 5 105 N/m2. Determine :

(i) The mass of gas ;

(ii) The value of index n for compression ;

(iii) The increase in internal energy of the gas ;

(iv) The heat received or rejected by the gas during compression.

Take = 1.4, R = 294.2 J/kgC.

Initial volume of gas, V1 = 0.45 m3

Initial pressure of gas, p1 = 1 105 N/m2

Initial temperature, T1 = 80 + 273 = 353 K

Final volume after compression, V2 = 0.13 m3

The final pressure, p2 = 5 105 N/m2.

(i) To find mass m using the relation

(ii) To find index n using the relation

St.Josephs College of Engineering

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

(3.46)n = 5

Taking log on both sides, we get

n loge 3.46 = loge 5

n = loge 5/loge 3.46 = 1.296. (Ans.)

(iii) In a polytropic process,

T2 = 353 1.444 = 509.7 K

Now, increase in internal energy,

U = mcv (T2 T1)

= 49.9 kJ. (Ans.)

(iv) Q = U + W

= 67438 N-m or 67438 J = 67.44 kJ

Q = 49.9 + ( 67.44) = 17.54 kJ

7. 0.1 m3 of an ideal gas at 300 K and 1 bar is compressed adiabatically to 8 bar. It is then cooled at

constant volume and further expanded isothermally so as to reach the condition from where it

started. Calculate :

(i) Pressure at the end of constant volume cooling.

(ii) Change in internal energy during constant volume process.

(iii) Net work done and heat transferred during the cycle. Assume

cp = 14.3 kJ/kg K and cv = 10.2 kJ/kg K.

Given: V1 = 0.1 m3 ; T1 = 300 K ; p1 = 1 bar ; cp = 14.3 kJ/kg K ; cv = 10.2 kJ/kg K.

(i) Pressure at the end of constant volume cooling, p3:

Characteristic gas constant,

St.Josephs College of Engineering

10

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

R = cp cv = 14.3 10.2 = 4.1 kJ/kg K

Considering process 1-2, we have :

= 544.5 K

Considering process 31, we have

p3V3 = p1V1

(ii) Change in internal energy during constant volume process, (U3 U2) :

Mass of gas,

Change in internal energy during constant volume process 23,

U3 U2 = mcv(T3 T2)

= 0.00813 10.2 (300 544.5)

(Since T 3 = T1)

= 20.27 kJ (Ans.)( ve sign means decrease in internal energy)

During constant volume cooling process, temperature and hence internal energy is reduced. This

decrease in internal energy equals to heat flow to surroundings since work done is zero.

(iii) Net work done and heat transferred during the cycle :

W23 = 0 ... since volume remains constant

St.Josephs College of Engineering

11

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

= 14816 Nm (or J) or 14.82 kJ

Net work done = W12 + W23 + W31

= ( 20.27) + 0 + 14.82

= 5.45 kJ

ve sign indicates that work has been done on the system. (Ans.)

For a cyclic process :

Heat transferred during the complete cycle = 5.45 kJ

ve sign means heat has been rejected i.e., lost from the system. (Ans.)

Flow of fluid = 10 kg/min

Properties of fluid at the inlet :

Pressure, p1 = 1.5 bar = 1.5 105 N/m2

Density, 1 = 26 kg/m3

Velocity, C1 = 110 m/s

Internal energy, u1 = 910 kJ/kg

Properties of the fluid at the exit :

Pressure, p2 = 5.5 bar = 5.5 105 N/m2

Density, 2 = 5.5 kg/m3

Velocity, C2 = 190 m/s

Internal energy, u2 = 710 kJ/kg

Heat rejected by the fluid,

Q = 55 kJ/s

Rise is elevation of fluid = 55 m.

(i) The change in enthalpy,

h = u + (pv)

St.Josephs College of Engineering

12

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

= 1 105 0.0577 105

= 105 0.9423 Nm or J

= 94.23 kJ

u = u2 u1

= (710 910)

= 200 kJ/kg

Substituting the value in eqn. (i), we get

h = 200 + 94.23

= 105.77 kJ/kg. (Ans.)

(ii) The steady flow equation for unit mass flow can be written as

Q = KE + PE + h + W

where Q is the heat transfer per kg of fluid

= 55 6 = 330 kJ/kg

= 12000 J or 12 kJ/kg

PE = (Z2 Z1) g = (55 0) 9.81 Nm or J

= 539.5 J or 0.54 kJ/kg

Substituting the value in steady flow equation,

330 = 12 + 0.54 105.77 + W or W

= 236.77 kJ/kg.

= 39.46 kJ/s

9.

= 39.46 kW. (Ans.)

At the inlet to a certain nozzle the enthalpy of fluid passing is 2800 kJ/kg, and the velocity is 50 m/s.

At the discharge end the enthalpy is 2600 kJ/kg. The nozzle is horizontal and there is negligible

heat loss from it.(i) Find the velocity at exit of the nozzle.(ii) If the inlet area is 900 cm2 and the

specific volume at inlet is 0.187 m3/kg, find the mass flow rate.(iii) If the specific volume at the

nozzle exit is 0.498 m3/kg, find the exit area of nozzle.

St.Josephs College of Engineering

13

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

Conditions of fluid at inlet (1) :

Enthalpy, h1 = 2800 kJ/kg

Velocity, C1 = 50 m/s

Area, A1 = 900 cm2 = 900 104 m2

Specific volume, v1 = 0.187 m3/kg

Conditions of fluid at exit (2) :

Enthalpy, h2 = 2600 kJ/kg

Specific volume, v2 = 0.498 m3/kJ

Area, A2 =?

Mass flow rate,

=?

(i) Velocity at exit of the nozzle, C2 :

Applying energy equation at 1 and 2, we get

were Q = 0, W = 0, Z1 = Z2

= 201250 N-m

C22 = 402500

C2 = 634.4 m/s. (Ans.)

(ii) Mass flow rate

By continuity equation,

Mass flow rate = 24.06 kg/s. (Ans.)

iii) Area at the exit, A2 :

St.Josephs College of Engineering

14

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

A2 = 0.018887 m2 = 188.87 cm2

Hence, area at the exit = 188.87 cm2. (Ans.)

10. Air at a temperature of 20C passes through a heat exchanger at a velocity of 40 m/s where its

temperature is raised to 820C. It then enters a turbine with same velocity of 40 m/s and expands

till the temperature falls to 620C. On leaving the turbine, the air is taken at a velocity of 55 m/s to

a nozzle where it expands until the temperature has fallen to 510C. If the air flow rate is 2.5 kg/s,

calculate :

(i) Rate of heat transfer to the air in the heat exchanger ;

(ii) The power output from the turbine assuming no heat loss ;

(iii) The velocity at exit from the nozzle, assuming no heat loss.

Take the enthalpy of air as h = cpt, where cp is the specific heat equal to 1.005 kJ/kgC and t the

temperature.

Temperature of air, t1 = 20C

Velocity of air, C1 = 40 m/s.

Temperature of air after passing the heat exchanger, t2 = 820C

Velocity of air at entry to the turbine, C 2 = 40 m/s

Temperature of air after leaving the turbine, t 3 = 620C

Velocity of air at entry to nozzle, C3 = 55 m/s

Temperature of air after expansion through the nozzle, t 4 = 510C

Air flow rate,

= 2.5 kg/s.

(i) Heat exchanger :

Rate of heat transfer :

Energy equation is given as,

Here, Z1 = Z2, C1, C2 = 0, W12 = 0

mh1 + Q12 = mh2

or Q12 = m(h2 h1)

= mcp (t2 t1)

= 2.5 1.005 (820 20) = 2010 kJ/s.

St.Josephs College of Engineering

15

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

Hence, rate of heat transfer = 2010 kJ/s. (Ans.)

(ii) Turbine :

Power output of turbine :

Energy equation for turbine gives

[Since Q23 = 0, Z1 = Z2]

= 2.5 [201 + 0.7125] = 504.3 kJ/s or 504.3 kW

Hence, power output of turbine = 504.3 kW. (Ans.)

(iii) Nozzle:

Velocity at exit from the nozzle :

Energy equation for nozzle gives,

[Since W34 = 0, Q3 4 = 0, Z1 = Z2]

C4 = 473.4 m/s.

Hence, velocity at exit from the nozzle = 473.4 m/s. (Ans.)

12. A single stage single acting reciprocating air compressor has air entering at 1 bar, 20C and

compression occurs following polytrophic process with index 1.2 upto the delivery pressure of 12

bar. The compressor runs at the speed of 240 rpm and has L/D ratio of 1.8. The compressor has

mechanical efficiency of 0.88. Determine the isothermal efficiency and cylinder dimensions. Also

3

find out the rating of drive required to run the compressor which admits 1 m of air per minute.

St.Josephs College of Engineering

16

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

13. An engine working on Otto cycle has a volume of 0.45 m3, pressure 1bar and temperature 30C

at the beginning of compression stroke. At the end of compression stroke, the pressure is 11 bar. 210

kJ of heat is added at constant volume. Determine : (i) Pressures, temperatures and volumes at

salient points in the cycle, (ii) Percentage clearance, (iii) Efficiency, (iv) Net work per cycle, (v)

Mean effective pressure and (vi) Ideal power developed by the engine if the number of working

cycles per minute is 210. Assume the cycle is reversible.

V2 = 0.081 m3

Temperature and pressure at point 3 can be determined using above equations.

Similarly, calculate temperature and pressure at point.

St.Josephs College of Engineering

17

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics

Department of Mechanical Engineering

2014-2015

14 .An engine with 200 mm cylinder diameter and 300 mm stroke works on theoretical Diesel cycle. The

initial pressure and temperature of air used are 1 bar and 27C. The cut-off is 8% of the stroke. Determine:

(i) Pressures and temperatures at all salient points, (ii) Theoretical air standard efficiency, (iii) Mean

effective pressure and (iv) Power of the engine if the working cycles per minute are 380. Assume that

compression ratio is 15 and working fluid is air. Consider all conditions to be ideal.

1. Determine stroke volume

2. Use gas equation to find mass of air in the cylinder

3. Process 1-2 (Adiabatic) and Process 3-4 (Isentropic) Use relations between pressure, volume and

temperature

St.Josephs College of Engineering

18

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

UNIT II

THERMODYNAMICS OF REFRIGERATORS AND PUMPS

PART- A

1. Define Quality of steam. What is the various quality of steam?

The Quality of steam is the ratio of mass of dry steam actually present to the mass of wet steam which

contains it. Various qualities of steam are (i) Wet steam (ii) Dry steam (iii) Superheated steam.

2. Define dryness fraction.

It is a measure of quality of steam. It is the ratio of mass of vapour to the total mass of the steam. It is

denoted by X.

3. Define heat engine, heat pump, and refrigerator.

Heat engine: A system which by operating in a cyclic manner produces net work from a supply of

heat. (Or) A heat engine is any continuously operating thermodynamic system across the boundaries of

which flow only heat and work.

Heat Pump: A device that transfers heat from a low temperature medium to a high temperature

medium is called a heat pump.

Refrigerators: A device that transfers heat from low temperatures to high temperature region is known

as refrigerator.

4. What is the difference between boiler mountings and accessories?

Boiler Mountings

The necessary devices installed or

mounted for the safety of boiler and its

control are called boiler mountings.

Boiler Accessories

The devices which are installed in the boiler

for their efficient operation and smooth

working are called boiler accessories.

1. 1. Water level indicator.

2. Safety valves.

3. Fusible plug.

4.Pressure gauge

1.

2.

3.

4.

Water heating devices.

Water feeding devices.

Super heater

Economizer

5. What is the function of pressure relief valve?

The pressure is relieved by allowing the pressurised fluid to flow from an auxiliary passage out of the

system. The relief valve is designed or set to open at a predetermined set pressure to protect pressure

vessels and other equipment from being subjected to pressures that exceed their design limits.

6. What is the function of safety valve?

It is a mechanical device used to safe guard the boiler, in case the pressure inside the boiler rises above

its normal working pressure.

7. Define C.O.P of refrigeration. What is the unit of refrigeration?

It is defined as the ratio of net refrigeration effect to the work required to produce the effect.

Capacity of refrigeration unit is generally defined in ton of refrigeration. A ton of refrigeration is

defined as the quantity of heat to be removed in order to form one ton (1000 kg) of ice at 00C in 24 hrs,

from liquid water at 00 C. This is equivalent to 3.5 kJ/s (3.5 kW) or 210 kJ/min.

8. Define refrigeration effect.

The amount of heat extracted in a given time is known as refrigeration effect.

9. Differentiate vapour compression system and vapour absorption system.

S. No. Vapour Compression System

Vapour Absorption System

Due to compressor and fan more wear and Only moving part is liquid pump, less wear

1

tear.

and tear.

Electrical power is essential to operate the Electrical power is not essential to operate

2

system

the system (heat energy is used).

Compressor is used to compress the Compressor is used to compress the

3

Refrigerant.

Refrigerant.

10. What are the various modes of heat transfer?

Modes of Heat Transfer (i) Conduction (ii) Convection (iii) Radiation

11. Define Conduction

Energy transfers across a system boundary due to a temperature difference by the mechanism of inter

molecular interactions. Conduction needs mater and does not require any bulk motion of matter.

12. Define Convection.

An energy transfer across a system boundary due to a temperature difference by the combined

mechanism of intermolecular interactions and bulk transport. Convection needs fluid mater.

13. Define black body.

A black body is one which absorbs heat radiation of all wave length falling on it.

St.Josephs College of Engineering

19

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

14. Define grey body.

If a body absorbs definite percentage of incident radiations irrespective of their wavelength, then the

body is known as grey body.

15. What is the difference between forced and free convection?

If the fluid motion is produced due to change in density resulting from temperature gradients, the mode

of heat transfer is said to be free or natural convection.

If the fluid is artificially created by means of an external force like a blower or fan, that type of heat

transfer is known as forced convection.

16. Define Emissivity.

Emissivity is defined as the ratio between energy radiated by the surfaces at temperature and the energy

radiated by black surface at same temperature.

17. What is meant by radiation shape factor?

The shape factor is defined as the fraction of the radiative energy that is diffused from one surface

element and strikes the other surface directly with no intervening reflections.

18. Write the difference between water tube and fire tube boiler.

S.No Fire tube boiler

Water tube Boiler

1.

Hot Gases flows through the tubes.

Water flows through the tube

2.

Compact and easy design.

Complicated design

3.

Benson boiler

Babcock and Wilcox boiler

19. How the boiler efficiency is calculated?

For a steam generating unit, efficiency is defined as the ratio of heat absorbed by the boiler fluid to the

fuel fired.

Boiler = Heat absorbed by boiler fluid X100

Fuel fired (or) fuel supplied

20. What are fins? Why fins are used?

A fin is a surface that extends from an object to increase the rate of heat transfer to or from the

environment by increasing convection. Examples of fins: 1.Thin rods on the condenser in back of

refrigerator.

2. Honeycomb surface of a car radiator.3. Corrugated surface of a motor cycle engine. 4. Coolers of PC

boards.

21. Sketch the vapour compression refrigeration cycle process.

22. What are the processes that constitute a Rankine cycle?

Process 12: Isentropic expansion of the working fluid through the turbine from saturated vapour at

state 1 to the condenser pressure.

Process 23: Heat transfer from the working fluid as it flows at constant pressure through the

condenser with saturated liquid at state 3.

Process 34: Isentropic compression in the pump to state 4 in the compressed liquid region.

Process 41: Heat transfer to the working fluid as it flows at constant pressure through the boiler to

complete the cycle.

23. How do you determine the state of steam?

If V > vg then super-heated steam, V= vg then dry steam and V < vg then wet steam.

24. Define enthalpy of steam.

It is the sum of heat added to water from freezing point to saturation temperature and the heat absorbed

during evaporation.

St.Josephs College of Engineering

20

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

25. Explain the term critical point, critical temperature and critical pressure.

In the T-S diagram the region left of the waterline, the water exists as liquid. In right of the dry steam

line, the water exists as a super heated steam. In between water and dry steam line the water exists as a

wet steam. At a particular point, the water is directly converted into dry steam without formation of wet

steam. The point is called critical point. The critical temperature is the temperature above which a

substance cannot exist as a liquid; the critical temperature of water is 374.15 oC. The corresponding

pressure is called critical pressure.

26. Find the mass of 0.7 m3of wet steam at 1500C and 90% dry.

The specific volume of dry steam at 1500C, vg = 0.3928 m3/kg;

The mass of 0.7 m3of wet steam at 1500C and 90% dry is: 0.7 / (0.39280.9) = 1.98 kg.

27. Determine the enthalpy and sp. volume of steam at a pressure of 6 bar having a quality of 0.85.

h = hf + x hfg = 1213.35+.85 X 1571.0 = 2548.7 kJ/kg ; v = xvg = 0.85 X 0.03244=0.027574 m3/kg

28. What are the major components in a steam power plant?

29. Show Rankine cycle on T-s diagram.

30. What are the ways by which Rankine cycle efficiency may be improved?

(i) Operating the boiler at high pressure with reheat and (ii) regeneration

31. Write down the expression for efficiency of Rankine cycle without considering pump work.

32. What is reversed carnot heat engine? What are the limitations of carnot cycle?

1. No friction is considered for moving parts of the engine.

2. There should not be any heat loss

33. What is the difference between a heat pump and a refrigerator?

Heat pump is a device which operating in cyclic process, maintains the temperature of a hot body at a

temperature higher than the temperature of surroundings.

A refrigerator is a device which operating in a cyclic process, maintains the temperature of a cold body

at a temperature lower than the temperature of the surroundings.

34. Why a heat engine cannot have 100% efficiency?

For all the heat engines there will be a heat loss between system and surroundings. Therefore we cant

convert all the heat input into useful work.

35. What are the processes involved in Carnot cycle.

Carnot cycle consist of

i) Reversible isothermal compression

ii) Isentropic compression

iii) Reversible isothermal expansion

iv) Isentropic expansion

St.Josephs College of Engineering

21

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

35. Write the expression for COP of a heat pump and a refrigerator?

COP of heat pump

Heat Supplied

T2

COP HP =

------------------- =

-------Work input

T2-T1

COP of Refrigerator

Heat extracted

T1

COP Ref = --------------=

-------Work input

T2-T1

36. Why Carnot cycle cannot be realized in practical?

(i) In a Carnot cycle all the four processes are reversible but in actual practice there is no process is

reversible.

(ii) There are two processes to be carried out during compression and expansion. For isothermal

process the piston moves very slowly and for adiabatic process the piston moves as fast as possible.

This speed variation during the same stroke of the piston is not possible.

(iii) It is not possible to avoid friction moving parts completely.

Unit II Part B

1. A reversible heat engine operates between two reservoirs at temperatures 700C and

50C. The engine drives a reversible refrigerator which operates between reservoirs at

temperatures of 50C and 25C. The heat transfer to the engine is 2500 kJ and the net

work output of the combined engine refrigerator plant is 400 kJ. (i) Determine the heat

transfer to the refrigerant and the net heat transfer to the reservoir at 50C. (ii) Reconsider

given that the efficiency of the heat engine and the C.O.P. of the refrigerator are each 45

per cent of their maximum possible values.

Ans)

Temperature, T1 = 700 + 273 = 973 K

Temperature, T2 = 50 + 273 = 323 K

Temperature, T3 = 25 + 273 = 248 K

The heat transfer to the heat engine, Q1 = 2500 kJ

The network output of the combined engine refrigerator plant,

W = W1 W2 = 400 kJ.

(i) Maximum efficiency of the heat engine cycle is given by

W1 = 0.668 2500 = 1670 kJ

St.Josephs College of Engineering

22

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

Since, W1 W2 = W = 400 kJ

W2 = W1 W

= 1670 400

= 1270 kJ

Q4 = 3.306 1270

= 4198.6 kJ

Q3 = Q4 + W2

= 4198.6 + 1270

= 5468.6 kJ

Q2 = Q1 W1

= 2500 1670

= 830 kJ.

Heat rejection to the 50C reservoir

= Q2 + Q3

= 830 + 5468.6

= 6298.6 kJ. (Ans.)

(ii) Efficiency of actual heat engine cycle,

= 0.45 max

= 0.45 0.668

= 0.3

W1 = Q1

= 0.3 2500

= 750 kJ

W2 = 750 400

= 350 kJ

C.O.P. of the actual refrigerator cycle,

= 0.45 3.306 = 1.48

Q4 = 350 1.48

= 518 kJ. (Ans.)

Q3 = 518 + 350

= 868 kJ

Q2 = 2500 750

= 1750 kJ

Heat rejected to 50C reservoir

= Q2 + Q3

= 1750 + 868

= 2618 kJ. (Ans.)

2. (i) A reversible heat pump is used to maintain a temperature of 0C in a refrigerator

when it rejects the heat to the surroundings at 25C. If the heat removal rate from the

refrigerator is 1440 kJ/min, determine the C.O.P. of the machine and work input

required. (ii) If the required input to run the pump is developed by a reversible engine

which receives heat at 380C and rejects heat to atmosphere, then determine the overall

C.O.P. of the system.

St.Josephs College of Engineering

23

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

Ans)

2014-2015

(i) Temperature, T 1 = 25 + 273 = 298 K

Temperature, T2 = 0 + 273 = 273 K

Heat removal rate from the refrigerator,

Q1 = 1440 kJ/min = 24 kJ/s

Now, co-efficient of performance, for reversible heat pump,

W = 2.2 kW

i.e., Work input required = 2.2 kW. (Ans.)

Q2 = Q1 + W = 24 + 2.2 = 26.2 kJ/s

(ii) Refer Fig.

The overall C.O.P. is given by,

For the reversible engine, we can write

St.Josephs College of Engineering

24

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

298(Q4 + 2.2) = 653 Q4

Q4(653 298) = 298 2.2

Q3 = Q4 + W

= 1.847 + 2.2

= 4.047 kJ/s

Substituting this value in eqn. (i), we get

If the purpose of the system is to supply the heat to the sink at 25C, then

3. A Rankine cycle operates between pressures of 80 bar and 0.1 bar. The maximum cycle

temperature is 600C. If the steam turbine and condensate pump efficiencies are 0.9

and 0.8 respectively, calculate the specific work and thermal efficiency. Relevant steam

table extract is given below.

St.Josephs College of Engineering

25

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

Ans)

At 80 bar, 600C :

h1 = 3642 kJ / kg ;

s1 = 7.0206 kJ / kg K.

Since s1 = s2,

7.0206 = sf2 + x2 sfg2

= 0.6488 + x2 7.5006

= 0.85

Now, h2 = hf2 + x2 hfg2

= 191.9 + 0.85 2392.3

= 2225.36 kJ/kg

Actual turbine work

= turbine (h1 h2 )

= 0.9 (3642 2225.36)= 1275 kJ/kg

Pump work = vf ( p2 )( p1 p2 )

= 10.09 kJ/kg

Specific work (Wnet ) = 1275 10.09

= 1264.91 kJ / kg. (Ans.)

where, Q1 = h1 hf4

But hf4 = hf3 + pump work

= 191.9 + 10.09

St.Josephs College of Engineering

26

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

= 202 kJ/kg

Thermal efficiency, th =

= 0.368 or 36.8 %. (Ans.)

4. (i) Find the enthalpy and internal energy of unit mass of steam at temperature of 200C

when (a) Dry saturated (b) Steam delivered at 0.7MPa and (c) quality is 0.85.

(ii) Steam enters a steam turbine at a pressure of 10 bar and 300C with a velocity of 50m/s.

The steam leaves the turbine at 1.5 bar and with a velocity of 200m/s. Determine the work

done per kg of steam flow through the turbine. Assume that the process to be reversible and

neglect the change in potential energy.

5. Explain with neat sketch about steam power plant.

Ans) Steam is an important medium of producing mechanical energy. Steam has the advantage that, it can

be raised from water which is available in abundance it does not react much with the materials of the

equipment of power plant and is stable at the temperature required in the plant. Steam is used to drive

steam engines, steam turbines etc. Steam power station is most suitable where coal is available in

St.Josephs College of Engineering

27

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

abundance.

Thermal electrical power generation is one of the major methods. Out of total power developed in India

2

about 60% is thermal. For a thermal power plant the range of pressure may vary from 10 kg/cm to super

critical pressures and the range of temperature may be from 250C to 650C.

Essentials of Steam Power Plant Equipment

A steam power plant must have following equipment:

(a) A furnace to burn the fuel.

(b) Steam generator or boiler containing water. Heat generated in the furnace is utilized to

convert water into steam.

(c) Main power unit such as an engine or turbine to use the heat energy of steam and perform

work.

(d) Piping system to convey steam and water.

In addition to the above equipment the plant requires various auxiliaries and accessories depending upon

the availability of water, fuel and the service for which the plant is intended.

The flow sheet of a thermal power plant consists of the following four main circuits:

4.

Feed water and steam flow circuit.

5.

Coal and ash circuit.

6.

Air and gas circuit.

7.

Cooling water circuit.

Steam Power Plant Layout

Air taken from the atmosphere is first passed through the air pre-heater, where it is heated by flue

gases. The hot air then passes through the furnace. The flue gases after passing over boiler and super

heater tubes, flow through the dust collector and then through economizer, air pre-heater and finally they

are exhausted to the atmosphere through the chimney.

6. What is meant by fire tube boiler? Explain with neat sketch.

Ans) A fire-tube boiler is a type of boiler in which hot gases from a fire pass through one or more tubes

running through a sealed container of water. The heat of the gases is transferred through the walls of the

tubes by thermal conduction, heating the water and ultimately creating steam.

Types of fire-tube boiler

Cornish boiler

Lancashire boiler

Scotch marine boiler

Locomotive boiler

Vertical fire-tube boiler

St.Josephs College of Engineering

28

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

Advantages of fire tube boilers

Low cost

Fluctuations of steam demand can be met easily

It is compact in size.

Cochran Boiler Salient features

The dome shape of the furnace causes the hot gases to deflect back and pass through the flue. The

unburnt fuel if any will also be deflected back.

Spherical shape of the top of the shell and the fire box gives higher area by volume ratio.

It occupies comparatively less floor area and is very compact.

It is well suited for small capacity requirements.

Very compact and requires minimum floor area

Any type of fuel can be used with this boiler

Well suited for small capacity requirements gives about 70% thermal efficiency with coal firing and

about 75% with oil firing.

7. What are the various boiler mountings? Explain any two with neat sketch.

1. Various boiler mountings

Mainly seven (7) mountings are required and essential to a Boiler.

1. Water level indicator.

2. Main Steam stop valve.

3. Pressure gauge.

4. Feed check valve.

5. Fusible plug.

6. Blow down valve.

7. Safety valve.

Water level indicator

To know the water level in the boiler the handles of the steam cock and water cock are kept in

vertical

positions.

Water rushes through the bottom casting and steam rushes through the upper casting to the gauge

glass

tube.

The level of water corresponds to the water level in the boiler

St.Josephs College of Engineering

29

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

Fusible plug

Under normal working conditions, the fusible plug is completely covered with water.

Hence the temperature of the plug is not increased appreciably during combustion process.

When the water level falls below the safe limit the fusible plug is uncovered from water and

exposed to steam.

The furnace heat over heats the plug and it melts the fusible metal and copper plug falls

down.

Due to this water steam mixture rushes into the furnace and the fire is extinguished

8. What are the various boiler accessories? Explain any two with neat sketch.

Ans) Various boiler accessories

Economiser Air Preheater Super Heater Steam Separator Steam Trap Feed Pump

i) Economiser

The feed water is pumped to the bottom header and this water is carried to the top header number of

vertical tubes.

Hot flue gases are allowed to pass over the external surface of the tubes.

The feed water which flows upward in the tubes is heated by the flue gases.

This preheated water is supplied to the water.

Scrappers are moved slowly moved up and down to clean the surface of the tubes.

Economiser

St.Josephs College of Engineering

30

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

(ii) Air Preheater

Hot flue gases pass through the tubes of air preheater after leaving the boiler or economiser.

Air and flue gases flow in opposite directions.

Baffles are provided in the air preheater and the air passes number of times over the tubes.

Heat is absorbed by the air from the flue gases.

This preheated is supplied to the furnace to aid combustion.

Air Preheater

St.Josephs College of Engineering

31

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

9. Steam at 480oC, 90 bar is supplied to a Rankine cycle. It is reheated to 12 bar and 480 oC.

The minimum pressure is 0.07 bar. Find the work output and cycle efficiency using steam

tables with and without considering pump work.

St.Josephs College of Engineering

32

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

St.Josephs College of Engineering

33

2014-2015

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

10. What are the various types of boilers? Explain any one type of high pressure boiler

with neat sketch.

Ans) A boiler is basically a closed vessel in to which water is heated until water is converted in top

steam at required pressure.

1. Classification of Boilers.

A. According to relative position of water and hot gases.

B. According to geometric orientation of boiler.

C. According to location of furnace.

D. According to method of water circulation.

E. According to working pressure.

F. According to mobility of boiler.

Benson Boiler

(a)

Natural circulation boilers require expansion joints but these are not required for Benson as

the pipes are welded. The erection of Benson boiler is easier and quicker as all the parts are

welded at site and workshop job of tube expansion is altogether avoided.

(b)

The transport of Benson boiler parts is easy as no drums are required and majority of the

parts are carried to the site without pre-assembly.

(c)

The Benson boiler can be erected in a comparatively smaller floor area. The space problem

does not control the size of Benson boiler used.

(d)

The furnace walls of the boiler can be more efficiently protected by using small diameter

and close pitched tubes.

(e)

The super heater in the Benson boiler is an integral part of forced circulation system,

therefore no special starting arrangement for super heater is required.

(f)

The Benson boiler can be started very quickly because of welded joints.

(g)

The Benson boiler can be operated most economically by varying the temperature and

pressure at partial loads and overloads. The desired temperature can also be

maintained constant at any pressure.

(h)

Sudden fall of demand creates circulation problems due to bubble formation in the natural

circulation boiler which never occurs in Benson boiler. This feature of insensitiveness to load

fluctuations makes it more suitable for grid power station as it has better adaptive capacity to

meet sudden load fluctuations.

(i)

The blow-down losses of Benson boiler are hardly 4% of natural circulation boilers of same

capacity.

(j)

Explosion hazards are not at all severe as it consists of only tubes of small diameter and has

very little storage capacity compared to drum type boiler.

St.Josephs College of Engineering

34

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

11. A simple Rankine cycle works between pressures 28 bar and 0.06 bar, the initial

condition of steam being dry saturated. Calculate the cycle efficiency, work ratio and

specific steam consumption.

From steam tables,

At 28 bar :

h1 = 2802 kJ/kg,

s1 = 6.2104 kJ/kg K

At 0.06 bar : hf2 = hf3 = 151.5 kJ/kg,

hfg2 = 2415.9 kJ/kg,

sf2 = 0.521 kJ/kg K,

sfg2 = 7.809 kJ/kg K

vf = 0.001 m3/kg

Considering turbine process 1-2, we have :

s1 = s 2

6.2104 = sf2 + x2 sfg2

= 0.521 + x2 7.809

x2 = 0.728

h2 = hf2 + x2 hfg2

= 151.5 + 0.728 2415.9

= 1910.27 kJ/kg

Turbine work, Wturbine = h1 h2

= 2802 1910.27

= 891.73 kJ/kg

Pump work, Wpump = hf4 hf3

= vf (p1 p2)

St.Josephs College of Engineering

35

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

= 2.79 kJ/kg

[Since, hf4 = hf3 + 2.79 = 151.5 + 2.79 = 154.29 kJ/kg]

Net work, Wnet = Wturbine Wpump

= 891.73 2.79

= 888.94 kJ/kg

Cycle efficiency

= 0.3357 or 33.57%. (Ans.)

= 0.997. (Ans.)

Specific steam consumption =

= 4.049 kg/kWh.

12. What is meant by water tube boiler? Explain with neat sketch.

Ans) The boilers can be classified according to the following criteria. According to of water and hot gases:

(a)

Water tube

(b)

Fire tube.

In water tube boilers, water circulates through the tubes and hot products of combustion flow over

these tubes. In fire tube boiler the hot products of combustion pass through the tubes, which are

surrounded, by water. Fire tube boilers have low initial cost, and are more compacts. But they are more

likely to explosion, water volume is large and due to poor circulation they cannot meet quickly the change

St.Josephs College of Engineering

36

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

in steam demand. For the same output the outer shell of fire tube boilers is much larger than the shell of

water-tube boiler. Water tube boilers require less weight of metal for a given size, are less liable to

explosion, produce higher pressure, are accessible and can respond quickly to change in steam demand.

Tubes and drums of water-tube boilers are smaller than that of fire-tube boilers and due to smaller size of

drum higher pressure can be used easily. Water-tube boilers require lesser floor space. The efficiency of

water-tube boilers is more.

UNIT III BASIC CONCEPTS OF FLUID MECHANICS AND FLOW OF FLUIDS

Part A

1. Define fluids.

Fluid may be defined as a substance which is capable of flowing. It has no definite shape of its own, but

confirms to the shape of the containing vessel.

2. What are the properties of ideal fluid?

Ideal fluids have following properties

It is incompressible; It has zero viscosity; Shear force is zero

3. What are the properties of real fluid?

Real fluids have following properties

i)It is compressible; ii) They are viscous in nature; iii) Shear force exists always in such fluids.

4. Define density and specific weight.

Density is defined as mass per unit volume (kg/m3)

Specific weight is defined as weight possessed per unit volume (N/m3)

5. Define Specific volume and Specific Gravity.

Specific volume is defined as volume of fluid occupied by unit mass (m3/kg)

Specific gravity is defined as the ratio of specific weight of fluid to the specific weight of standard fluid.

6. Define Surface tension and Capillarity.

Surface tension is due to the force of cohesion between the liquid particles at the free surface.

Capillary is a phenomenon of rise or fall of liquid surface relative to the adjacent general level of liquid.

7. Define Viscosity.

It is defined as the property of a liquid due to which it offers resistance to the movement of one layer of

liquid over another adjacent layer.

8. Define kinematic viscosity.

It is defined as the ratio of dynamic viscosity to mass density. (m/sec)

9. Define Relative or Specific viscosity.

It is the ratio of dynamic viscosity of fluid to dynamic viscosity of water at 20C.

10. Define Compressibility.

It is the property by virtue of which fluids undergoes a change in volume under the action of external

pressure.

11. Define Newtons law of Viscosity.

According to Newtons law of viscosity the shear force F acting between two layers of fluid is

St.Josephs College of Engineering

37

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

proportional to the difference in their velocities du and area A of the plate and inversely proportional to

the distance between them.

12. What is cohesion and adhesion in fluids?

Cohesion is due to the force of attraction between the molecules of the same liquid.

Adhesion is due to the force of attraction between the molecules of two different liquids or between the

molecules of the liquid and molecules of the solid boundary surface.

13. State momentum of momentum equation?

It states that the resulting torque acting on a rotating fluid is equal to the rate of change of moment of

momentum

14. What is momentum equation?

It is based on the law of conservation of momentum or on the momentum principle It states that, the net

force acting on a fluid mass is equal to the change in momentum of flow per unit time in that direction.

15. Why is it necessary in winter to use lighter oil for automobiles than in summer? To what

property does the term lighter refer?

The term lighter refers to the property called viscosity. In winter, if heavy oil is used for automobiles, the

oil becomes more viscous, and doesnt serve lubrication purpose. So lighter oil is used.

16. If the pressure on the fluid is increased from 75 bar to 140 bar, the volume of liquid decreases by

0.15%. Find the bulk modulus of elasticity of the liquid.

dp

4.33 x 109 N/m2

dV

17. At a certain point in flowing caster oil, the shear stress is 2 N/m2 and velocity gradient is 0.25/sec.

The mass density of the oil is 800kg/m3. Find the kinematic viscosity of oil in stokes.

du

dy

2

8Ns / m2

0.25

m2 / s 18. State Pascals

100

law.

This

law

indicates that the pressure intensity at any point in a static liquid is equal in all directions.

19. Does viscosity vary with pressure and temperature?

The value of of liquid or gas is practically independent of pressure for the range generally countered

in practice but it varies widely with temperature. The temperature has predominant effect on the viscosity

of the liquids. With the increase in temperature, the viscosity decreases rapidly.

20. Discuss about Newtonian and Non Newtonian Fluids

Newtonian fluids. These fluids follow Newtons viscosity equation. For such fluids does not change

with rate of deformation.

Non Newtonian fluids: There fluids which do not follow the linear relationship between the shear stress and the rate of

deformation

21. State Bernoullis Theorem as applicable to fluid flow..

Bernoullis Theorem states that an ideal incompressible fluid when flow is steady and continuous, the sum of pressure

energy, kinetic energy and potential energy is constant along the stream line.

22. What are the three major assumptions made in the Bernoullis Theorem.

The liquid is ideal and incompressible

The flow is steady and continuous

All the frictional losses are negligible

23. Mention the applications of Bernoullis Equation

Venturimeter

Orifice meter

Pitot Tube

24. What is Venturimeter?

Venturimeter is a device used to measure the rate of flow through pipes.

25. Write the expression for discharge through a venturimeter.

Q= C d

a1a2

a12 a22

* 2 gh

PART B

1. The velocity distribution over a plate is given by u = (3/4) * y - y2, where u is velocity in m/s and at a

depth y in m above the plate. Fin

d the shear stress at a distance of 0.3 m from the top of

plate. Take dynamic viscosity of the fluid is taken as 0.95 Ns/m2.

(du/dy)=(3/4)-2y

=0.1425 N/mm2

2. Inside a 60 mm diameter cylinder a piston of 59 mm diameter rotates concentrically. Both the

cylinder and piston are 80 mm long. If the space between the cylinder and piston is filled with oil of

St.Josephs College of Engineering

38

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

viscosity of 0.3 N.s/m2 and a torque of 1.5 Nm is applied, find: the r.p.m. of the piston, and the power

required.

U=(DN/60) A=dl

=/(du/dy)

Shear force F = x A,

T=Fxd/2

Power required = 2 NT/60

3. A cylinder 100mm diameter rotates in an annular sleeve 102mm internal diameter at 100 rpm. The

cylinder is 300mm long. If the dynamic viscosity of the lubricant between the two cylinders is

0.1poise, (assuming velocity profile linear between the cylinders) find the torque needed to drive the

cylinder against visco resistance.

U=(DN/60)

=/(du/dy)

Shear force F = x A,

T=Fxd/2

4. A shaft of diameter 30cm rotates concentrically inside a sleeve having diameter 31cm and length

30cm. Find the viscosity of the fluid that fills the gap between the cylinders, if a torque of 9.81Nm is

required to maintain the speed at 60 rpm.

U=(DN/60) A=dl

=/(du/dy)

Shear force F = x A,

T=Fxd/2

5.

St.Josephs College of Engineering

39

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

6. A plate 0.0254 mm distant from a fixed plate, moving at 61 cm/s requires a force of 0.2 kg(f)/m 2 to

maintain this speed. Find the dynamic viscosity of fluid between the plates.

du=u-0

=/(du/dy)

7. A shaft 300 mm in diameter revolves in a guide bearing 600 mm long at 500 rpm. If the oil film

between the shaft and the bearing is 0.13mm and viscosity of oil is 0.32373 poise, what is the power

absorbed?

The dynamic viscosity of oil is 0.03 Pas. (Pas = (N/m2) s).

Shear stress on the shaft surface = = (du/dy) = (u/y)

u = DN/60 = 0.3 400/60 = 6.28 m/s

= 0.03 {(6.28 0)/ 0.001} = 188.4 N/m2

Surface area of the two bearings, A = 2 DL

Force on shaft surface = A = 188.4 (2 0.3 0.3) = 106.6 N

Torque = 106.6 0.15 = 15.995 Nm

Power required = 2 NT/60 = 2 400 15.995/60 = 670 W.

8. A flat plate 0.75 m2 in area moves through the oil between large fixed parallel plates 150 mm apart is

filled with oil of kinematic viscosity of 0.8x10-4 m2/s , specific gravity 0.75 and the plate moving with

the velocity of 1m/s, calculate the drag force when (i) The plate is from one of the planes and (ii) The

plate is midway between the planes.

oil

water

Kinematic Viscosity

Specfic gravity S=

Total Shear Stress= 1 2

ie...

St.Josephs College of Engineering

u

u

t1

t2

40

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

u

u

A

t2

t1

Now F=

Find F1 & F2

9. A cubical block of 20cm edge weighing 20 kg(f) is allowed to slide down a plane inclined at 20 to

the horizontal on which there is a thin film of viscosity 0.22 x 10-3 kg(f) s/m2. What terminal velocity the

block will obtain, if the film thickness is 0.025 mm?

F=wcos ,

F y

, U=(DN/60),

A u

Kinematic Viscosity

10. Calculate the capillary effect in millimeters in a glass tube of 4 mm diameter, when immersed in (1)

water and (2) mercury the temperature of the liquid is 20C and the values of surface tension of water and

mercury at 20C in contact with air are 0.0735 N/m and 0.51 N/m respectively. The contact angle for

water = 0 and for mercury = 130. Take specific weight of water at 20C as equal to 9790 N/m3 and

specific gravity of mercury is 13.6.

, (i) h= 7.51 mm, (ii) h=-2.46 mm.

, d= 100 mm,

11.

12. Derive the continuity equation of differential form. Discuss whether the equation is valid for a steady

or unsteady flow, viscous or inviscid flow, compressible or incompressible flow.

St.Josephs College of Engineering

41

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

For 3D incompressible fluid,

2014-2015

13. A pipe line carrying oil of specific gravity 0.87 changes in diameter from 200 mm diameter at position

1 to 500 mm diameter at position 2 which is 4 meters at a higher level. If the pressures at 1 and 2 are

100 kN/m2 and 60 kN/m2 respectively and the discharge is 0.2 m3/s, determine: (a) Loss of head, (b)

Direction of flow.

At point A

v12 p1

z1

Total Energy E1

2g w

At point B

v22 p2

z2

Total Energy E2

2g w

Loss of head h f E1 E 2

If E1 E 2 direction A to B,

If E1 E 2 direction B to A,

14. A horizontal venturimeter with inlet and throat diameter 300 mm and 100 mm respectively is used to

measure the flow of water. The pressure intensity at inlet is 130 kN/m2 while the vacuum pressure head at

throat is 350 mm of mercury. Assuming that 3% head lost between the inlet and throat. Find the value of

coefficient of discharge for the venturimeter and also determine the rate of flow.

Differential head,

; Q=

15. An orifice meter with orifice diameter 15 cm is inserted in a pipe of 30 cm diameter. The pressure

difference measured by a mercury oil differential manometer on the two sides of the orifice meter gives a

reading of 50 cm of mercury. Find the rate of flow of oil of sp.gr 0.9 and C d = 0.6.

= 137414.25 cm3/s

UNIT IV

DIMENSIONAL AND MODEL ANALYSIS

Part A

1-What are the uses of dimensional homogeneity?

To determine the dimension of a physical variable To convert units from one system to another.

2. Name the different forces present in fluid flow

Inertia force, viscous force, Surface tension force, Gravity force

3. When in a fluid considered steady?

In steady flow, various characteristics of following fluids such as velocity, pressure, density,

temperature etc at a point do not change with time. So it is called steady flow.

4. What is kinematic similarity?

It is the similarity of motion corresponds to the points in the model and the prototype

5. Mention the types of models.

1. Undistorted models

2. Distorted models

6. Define Mach number.

It is the square root of Inertia force to the elastic force

St.Josephs College of Engineering

42

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

L V

2

2014-2015

kL2

7. Define Reynolds Number.

It is the ratio of Inertia force to the viscous force

Re

VL

8. State the methods of dimensional analysis.

1. Rayleighs method; 2. Buckinghams theorem

9. State Buckinghams theorem

It states that if there are n variables in a dimensionally homogeneous equation and if these variables

contain m fundamental dimensions (M, L, T), then they are grouped into (n-m), dimensionless

independent -terms.

10. State the limitations of dimensional analysis.

1. Dimensional analysis does not give any due regarding the selection of variables.

2. The complete information is not provided by dimensional analysis.

3. The values of coefficient and the nature of function can be obtained only by experiments or from

mathematical analysis.

11. Define Similitude

Similitude is defined as the complete similarity between the model and prototype.

12. State Froudes model law

Only Gravitational force is more predominant force. The law states The Froudes number is same for

both model and prototype.

13. Define Weber Number.

It is the ratio of inertia force to the surface tension force

We

LV 2

14. What are the factors to the determined when viscous fluid flows through the circular pipe ?

Velocity distribution across the section; Ratio of maximum velocity to the average velocity; Shear

stress distribution; Drop of pressure for a given length .

Using Buckinghams theorem, show that the drag FD of a supersonic aircraft is given by:

FD L2 V 2 (Re, M) . Where,

Re VL = Reynolds number, M V c = Mach number,

= fluid density,

K , V = velocity of aircraft, K = bulk modulus of fluid,

c = sonic velocity =

2

L = chord length, L = wing area = chord x span, = a functional notation.

15. What is meant by undistorted models?

The model which is geometrically similar to its prototype is known as undistorted models. In such

models, the conditions of similitude are fully satisfied.

16. Describe briefly the selection of repeating variables in Buckingham theorem.

There is no separate rule for selecting repeating variables. But the number of repeating variables is

equal to the fundamental dimensions of the problem. Generally , V, , or , V, D are chosen as repeating

variables. In addition to this, the following points should be kept in mind while selecting repeating

variables. (i) No more variable should be dimensionless (ii) The selected two repeating variables should

not have the same dimensions. (iii) The selected repeating variables should be independent as far as

possible.

17. Define the term dimensional homogeneity.

Dimensional homogeneity means, the dimensions of the terms on left hand side should be same as the

dimensions of the terms on right hand side.

18. Define Euler number

It is defined as the square root of the ratio of inertia force to the pressure of a flowing fluid.

Eu

L2V 2

pL2

16. What is kinematic similarity?

It is the similarity of forces. The flows in the model and prototype are of dynamic similar.

20. Define the term scale effect.

St.Josephs College of Engineering

43

ISO 9001 - 2008

EI-6403/Applied Thermodynamics and Fluid Dynamics Department of Mechanical Engineering

2014-2015

It is impossible to predict the exact behavior of the prototype by model testing alone. The two models

of same prototype behavior will be different. Scale ratios will not be same. So discrepancy between model

and prototype will always occur. It is known as scale effect.

21. Distinguish between Rayleighs method and Buckinghams theorem

S.No Rayleighs method

Buckinghams theorem

1

The expression is determined for a variable It is easy for the number of independent

depending upon maximum three or four

variables being more than three or four

variables only.

2

This method is difficult for more than or

In this method, n variables can be used

four variables.

without any difficulties.

22. What are the points to be remembered while deriving expressions using dimensional analysis?

(i) First, the variables controlling the phenomenon should be identified and expressed in terms of

primary dimensions (ii) Any mathematical equation should be dimensionally homogeneous.(iii) In

typical cases a suitable mathematical model is constructed to simplify the problem with suitable

assumptions

23. What are the similarities between model and prototype?

(i) Geometric Similarity (ii) Kinematic Similarity (iii) Dynamic Similarity

24. State the Fourier law of dimensional homogeneity.

The law of Fourier principle of dimensional homogeneity states an equation which expresses a

physical phenomenon of fluid flow should be algebraically correct and dimensionally homogeneous.

25. State the Euler model law and give its significance.

Only pressure is more predominant force in addition to the inertia force. According to this law, the

Euler number is same for both prototype and model. The Euler number itself is significant criterion in

the following phenomena: (i) Where the gravity and surface tension forces are fully absent and the

turbulence is fully developed with negligible viscous force. (ii) It is applied in cavitations

phenomena.

PART B

1. The pressure difference P in a pipe of diameter D and length l due to turbulent flow depends on the

velocity V, viscosity , density and roughness K. By using dimensional analysis, obtain an expression

for the pressure difference P .

Solution: