Professional Documents

Culture Documents

9820 3582 05 User Guide MKIV Ethernet-IP 03

Uploaded by

binhleduc36Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9820 3582 05 User Guide MKIV Ethernet-IP 03

Uploaded by

binhleduc36Copyright:

Available Formats

User Guide for

Ethernet/IP Protocol on Elektronikon ComBox-E

Name

Mark IV : User Guide

Detail

User Guide Ethernet/IP Protocol on Elektronikon ComBox-E

Edition

Serc. Class

Modified from

1102 K/1

PC

Print date

Owner

AII

03

Family

Written by

CTE

Compare

Design checked.

Production checked.

Approved

Replaces

31/03/2006

Date

21/12/2006

Designation

9820 3582 05

Atlas Copco Airpower NV

Ethernet Protocol for ComBox-E

Document Information

Edition

0

01

02

03

Date

20/05/2005

19/09/2005

31/03/2006

21/12/2006

Description

Draft update

First release

Protocol update

ES 8 Commands deleted

Author

CTE-PDJ

CTE-PVL

CTE-MP

CTE-PDJ

Turbo commands deleted , Turbo External setpoint deleted , Turbo

Status Changed

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 1

Atlas Copco Airpower NV

Ethernet Protocol for ComBox-E

Table of Contents

User Guide for.....................................................................................................................................................................0

Ethernet/IP Protocol on Elektronikon ComBox-E ..............................................................................................................0

1 Preface.........................................................................................................................................................................4

2 The Physical set-up .....................................................................................................................................................4

2.1

Ethernet & the Network ......................................................................................................................................4

2.2

AB CompactLogix ..............................................................................................................................................6

3 Profile definition .........................................................................................................................................................7

3.1

Master Slave concept .......................................................................................................................................7

3.2

Buffer structure ...................................................................................................................................................7

3.3

Header .................................................................................................................................................................7

3.3.1

Master to Slave............................................................................................................................................7

3.3.2

Slave to Master............................................................................................................................................8

3.4

Data Record.........................................................................................................................................................9

3.4.1

Node Address ..............................................................................................................................................9

3.4.2

Ethernet Parameter ID for Data Reading...................................................................................................10

3.4.2.1 Compressor connection .........................................................................................................................10

3.4.2.2 Detailed General Compressor Condition...............................................................................................11

3.4.2.2.1 C.C.M. ............................................................................................................................................12

3.4.2.2.2 Status for Fixed Speed , AQ Fixed Speed , ES002.........................................................................13

3.4.2.2.3 Status for MCC...............................................................................................................................13

3.4.2.2.4 Status for VSD , AQ VSD , PET VSD Booster , ZB VSD............................................................14

3.4.2.2.5 Status for ZH Turbo........................................................................................................................14

3.4.2.2.6 Status for SF (Multi).......................................................................................................................14

3.4.2.2.7 Status for PET Fixed Speed............................................................................................................15

3.4.2.2.8 Status for BD Dryer (Stand alone)..................................................................................................16

3.4.2.2.9 Status for CD Dryer (Stand alone).................................................................................................17

3.4.2.2.10 Status for FD-Fixed Speed & FD-VSD Dryer (Stand alone)........................................................17

3.4.2.2.11 Status for MD-Fixed Speed Dryer (Stand alone)..........................................................................17

3.4.3

Inputs & Outputs .......................................................................................................................................18

3.4.3.1 Analogue Inputs Sensors & Calculated..............................................................................................18

3.4.3.2 ParameterID ..........................................................................................................................................18

3.4.3.2.1 Sensor Inputs ..................................................................................................................................18

3.4.3.2.2 Calculated (virtual) Inputs .............................................................................................................18

3.4.3.3 Status register Interpretation..............................................................................................................19

3.4.3.4 Value register Interpretation ..............................................................................................................19

3.4.3.4.1 Pressure Input .................................................................................................................................19

3.4.3.4.2 Temperature Input ..........................................................................................................................19

3.4.3.4.3 Vibration Input ...............................................................................................................................19

3.4.3.4.4 Level Input .....................................................................................................................................19

3.4.3.4.5 Conductivity Input..........................................................................................................................19

3.4.3.4.6 SPM Input.......................................................................................................................................19

3.4.3.4.7 Current Input ..................................................................................................................................20

3.4.3.4.8 Speed Input.....................................................................................................................................20

3.4.3.5 Digital (Voltage free contacts) Inputs ...................................................................................................21

3.4.3.6 Status register Interpretation..............................................................................................................21

3.4.3.7 Value register Interpretation ..............................................................................................................21

3.4.3.8 Analogue Outputs (Only for Turbo)......................................................................................................22

3.4.3.9 Registers................................................................................................................................................22

3.4.4

Counters ....................................................................................................................................................23

3.4.4.1 Compressor Counters ............................................................................................................................23

3.4.4.1.1 Counters for Fixed Speed ...............................................................................................................25

3.4.4.1.2 Counters for VSD ...........................................................................................................................26

3.4.4.1.3 Counters for ZB VSD .....................................................................................................................27

3.4.4.1.4 Counters AQ Fixed Speed .............................................................................................................28

3.4.4.1.5 Counters for AQ VSD ....................................................................................................................29

3.4.4.1.6 Counters for PET VSD ...................................................................................................................30

3.4.4.1.7 Counters for Turbo .........................................................................................................................31

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 2

Atlas Copco Airpower NV

Ethernet Protocol for ComBox-E

3.4.4.1.8 Counters PET Fixed Speed............................................................................................................32

3.4.4.1.9 Counters for SF (Multi) .................................................................................................................33

3.4.4.1.10 Counters for CD Dryer .................................................................................................................34

3.4.4.1.11 Counters for BD dryer (AII).........................................................................................................35

3.4.4.1.12 Counters for FD VSD dryer..........................................................................................................36

3.4.4.1.13 Counters MD dryer.......................................................................................................................37

3.4.4.1.14 Counters for ES002 .....................................................................................................................38

3.4.4.2 Multi Compressor Controller Counters .................................................................................................39

3.4.5

Special.......................................................................................................................................................40

3.4.5.1 VSD motor data.....................................................................................................................................40

3.5

Ethernet/IP parameters for change ....................................................................................................................40

3.5.1

Load/Unload Pressure Band change..........................................................................................................40

3.5.2

VSD Setpoint change ................................................................................................................................40

3.5.3

MCC Pressure Band change......................................................................................................................42

3.5.4

PET L/U Regulation Band Change ...........................................................................................................43

3.5.5

ZH Turbo Regulation Setpoint and Band Change.....................................................................................44

3.6

Ethernet/IP parameters for remote control ........................................................................................................45

3.6.1

Control Commands ...................................................................................................................................45

3.6.1.1 Compressor Control Mode Selection ....................................................................................................45

3.6.1.2 Compressor Commands ........................................................................................................................47

3.6.2

VSD external setpoint/speed control ......................................................................................................49

3.6.3

Reset Initial Settings (Analogue , Digital , Counter Inputs)......................................................................49

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 3

Atlas Copco Airpower NV

Ethernet Protocol for ComBox-E

1 Preface

This document describes Atlas Copcos Elektronikon MkIV Ethernet Profile that is used by the ComBox-E

communication processor.

This document gives an overview of the components that are required to setup and ComBox-E

In order to fully understand this document, the following information should be available:

Technical note : 9820 3585 00 How to setup a CAN network

Airmonitor Installation requirements

9820 4082 02 - 2

Ethernet IP_Setup Wizard UserGuide

9820 4082 10

The Physical set-up

2.1

Ethernet & the Network

In the Elektronikon MkIV system all compressors in an installation can be connected by a data and/or control network.

This is done according the Compressor Network Cabling Instruction (9820 3585 00). This instruction explains what

connectors and cables should be used to interconnect the different compressors/controllers in the network. Basically this

is a CAN-based local network.

In order to setup a Ethernet connection to one or several of the compressors in this network, a special module has to be

inserted in this network.

Elektronikon

Controller

..

CAN

ComBox-E

Ethernet/IP

PLC

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 4

Atlas Copco Airpower NV

Ethernet Protocol for ComBox-E

An example of our testcase

Ethernet/IP-Netwerk

CAN-Netwerk

Ethernet/IP-Netwerk

CAN-Netwerk

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 5

Atlas Copco Airpower NV

2.2

Ethernet Protocol for ComBox-E

AB CompactLogix

2.2.1 L35E CompactLogix Controller

For testing we used the L35E CompactLogic Controller.

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 6

Atlas Copco Airpower NV

Ethernet Protocol for ComBox-E

3 Profile definition

3.1

Master Slave concept

The profile is based upon the master-slave principle. This means all communication is initiated by the master and a

reply is generated by the slave (ComBox-E).

3.2

Buffer structure

The Profile can be used for buffers with different length. (Type of PLC)

The buffer is split into 2 parts :

header : 3 DINT

data section : n * data record (3 DINT)

Attention : not all functions allow more then 1 data record to be transferred. Basically read operations can be handled

for several data records in 1 cycle, while write operations are only valid for a single data record at a time.

3.3

Header

The header is a 3 DINT value. The interpretation is different for Master->slave and Slave->Master communication.

3.3.1

Sync

Master to Slave

Function

#-parameters

Synch. or Synchronisation bits can be used to synchronise master requests and slave answers. The slave will always

reflect the same bit sequence in its answer (see Slave to Master header). This way an old answer can be distinguished

from a new one.

Functions that are supported for master to slave

Value

0

1

3

Function (Master-> Slave

No task

Request Parameter Value (read)

Alter Parameter Value (write)

Note : only 1 parameter can be writing in 1 cycle, #

parameters must be 1

# parameters : number of data records in the message

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 7

Atlas Copco Airpower NV

3.3.2

Ethernet Protocol for ComBox-E

Slave to Master

The header is split into 3 areas.

Sync

Function

Error-code

The following functions are supported for slave to master:

Value

0

2

7

Function (Master-> Slave

No task, or no data yet

Transmit Parameter Value (s)

Task not possible

Synch. or Synchronisation bits will be set identical to the bits from the master-slave request.

Error Code :

Error Code

0

1

2

3

4

Explanation

No Error

Can Initializing

Function is not correct

Number of data records for reprogramming is not correct

(only one data record)

Too many parameters

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 8

Atlas Copco Airpower NV

3.4

Ethernet Protocol for ComBox-E

Data Record

Each data record 3 DINT long contains the following info:

Node ID

3.4.1

Parameter ID

Data Value

Node Address : 1 DINT, CAN address of slave to connect to

Parameter ID : 1 DINT, ID of the parameter to read/write , ( the Ethernet addresses in this manual are

decimal !!!!)

Data : 1DINT, containing actual data

Node Address

This is the Elektronikon MkIV CAN address : 1 to 30 (31 only used for default factory setting, should not be used in

network).

If there is no data error

byte1

byte2

byte3

byte4

byte3

byte4

Node ID

If there is a data error

byte1

byte2

Node ID

DataError :

DataError

1 error on the data

Parameter ID : shows the parameter thats being requested

Data value :

shows the data off the parameter when DataError is 0

Returns the nature of the error when DataError is 1

Value

1

2

3

4

5

Function

Node ID not found

Parameter not found

Command does not exist

Data is not valid

Can link is offline

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 9

Atlas Copco Airpower NV

3.4.2

3.4.2.1

Ethernet Protocol for ComBox-E

Ethernet Parameter ID for Data Reading

Compressor connection

Function to be used : Read 01

NodeAddress

DINT

7F

Parameter ID

DINT

0000

Parameter

Compressor Connection

Data 4 Bytes

DINT

Compressors Connection

Bit

0

1

.

29

Compressor with Node ID 1 is found

Compressor with Node ID 2 is found

Compressor with Node ID 30 is found

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 10

Atlas Copco Airpower NV

3.4.2.2

Ethernet Protocol for ComBox-E

Detailed General Compressor Condition

NodeAddress

DINT

Parameter ID

DINT

0400

0401

0402

Parameter

General status

AV4000 Status

CCM

(Compressor Controller Mode)

CMS

(Compressor Mechanical State)

Data 4 Bytes (DINT)

B1

B2

CS

CCM

CS_MCC

AV4000

STATUS

BOV actual

IGV actual

position [%]

position [%]

Bit

0

1

2

3

4

5

6

7

8

9

10

11

0

1

2

3

4

5

6

B3

B4

CMS

Not Used

GENERAL STATUS

Surge Nr (S) [ 9999 ]

Pre Warning

General Warning

General Shutdown-Warning

General Shutdown

General Service

General Start Failure

Emergency Stop

Manual/Automatic (COS1)

Local/Remote

Timer Not Active/Active

Pre-warning Service Running Hours

Pre-warning Service Accumulated M3

Shutdown to surge

Oil heater On

Oil Pump On

Manual valve control active

Opening IGV limited due to high motor current

Regulation Type (0 = constant pressure / 1 = auto-dual)

Idling Timer (0 = disabled / 1 = enabled)

CCM2a

CCM2b

CCM2e

CCM3a

CCM3b

CCM3e

CCM4a

CCM4b

CCM4c (Speed control )

CCM4d (MCC)

CCM4e

No Valid Data

Stopped

Unloaded

Loaded

00

10

40

01

11

41

02

12

22

32

42

00

01

02

04

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 11

Atlas Copco Airpower NV

3.4.2.2.1

Ethernet Protocol for ComBox-E

C.C.M.

2

Local Control (Keyboard)

This mode has 3 variants

2a

local pressure control

2b

External Load/Unload control (Pressure Switch)

2e

4-20 mA external speed control

Remote Control (Digital)

This mode has 3 variants

3a

local pressure control

3b

External Load/Unload control (Pressure Switch)

3e

4-20 mA external speed control

Remote Control (Communication remote)

This mode has 5 variants

4a

local pressure control

4b

remote setpoint control (Control over CAN)

4c

remote speed control (Control over CAN)

4d

MCC control

4e

4-20 mA external speed control

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 12

Atlas Copco Airpower NV

3.4.2.2.2

3.4.2.2.3

Ethernet Protocol for ComBox-E

Status for Fixed Speed , AQ Fixed Speed , ES002

STATE

name

STATE

Number

A

C

D

E

F

G

H

I

J

K

L

M

N

P

Q

R

S

T

V

1

3

4

5

6

7

8

9

10

11

12

13

14

16

17

18

19

20

22

Description

Compressor Off

Motor Stopped

Motor Stopped

Automatically Unloaded

Automatically Unloaded

Automatically Loaded

Manually Unloaded

Programmed Stop

Programmed Stop

Programmed Stop

Programmed Stop

Programmed Stop

Shutdown

Compressor is Starting

Compressor is Starting

Compressor is Starting

Manually Unloaded

Unload due to overpressure

Initializing

Status for MCC

STATE

name

STATE

Number

A

B

C

D

1

2

3

4

Description

Ready for Start

Central Control Regulating

Central Control Stopped

Start Impossible

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 13

Atlas Copco Airpower NV

3.4.2.2.4

3.4.2.2.5

3.4.2.2.6

Ethernet Protocol for ComBox-E

Status for VSD , AQ VSD , PET VSD Booster , ZB VSD

STATE

name

STATE

Number

A

C

D

E

F

G

I

J

K

L

N

P

Q

V

1

3

4

5

6

7

9

10

11

12

14

16

17

22

Description

Compressor Off

Motor Stopped

Motor Stopped

Motor Started

Automatically Unloaded

Automatically Speed Control

Programmed Stop

Programmed Stop

Programmed Stop

Motor Stopped

Shutdown

Compressor is Starting

Programmed Stop

Initializing

Status for ZH Turbo

STATE

name

STATE

Number

A

C

D

E

F

G

H

I

J

K

L

N

P

Q

R

S

U

V

X

Y

Z

1

3

4

5

6

7

8

9

10

11

12

14

16

17

18

19

21

22

24

25

26

Description

Compressor Off

Motor Stopped

Motor Stopped

Motor Started

Automatically Unloaded

Automatically Speed Control

Manually Unloaded

Programmed Stop

Programmed Stop

Programmed Stop

Programmed Stop

Shutdown

Compressor is Starting

Programmed Stop

Compressor is Starting

Manually Unloaded

Automatic Unload due to Surge

Initializing

Minimum Load

Full Load

Minimum Minimum Load

Status for SF (Multi)

STATE

name

STATE

Number

A

G

V

1

3

22

Description

Compressor Off

Compressor Running

Initializing

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 14

Atlas Copco Airpower NV

3.4.2.2.7

Ethernet Protocol for ComBox-E

Status for PET Fixed Speed

STATE

name

STATE

Number

A

C

D

E

F

G

H

I

J

K

L

M

N

P

Q

R

S

T

V

1

3

4

5

6

7

8

9

10

11

12

13

14

16

17

18

19

20

22

Description

Compressor Off

Motor Stopped

Motor Stopped

Automatically Unloaded

Automatically Unloaded

Automatically loaded 100%

Manually Unloaded

Programmed Stop

Programmed Stop

Programmed Stop

Programmed Stop

Programmed Stop

Shutdown

Compressor is Starting

Compressor is Starting

Compressor is Starting

Manually Unloaded

Unload due to overpressure

Initializing

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 15

Atlas Copco Airpower NV

3.4.2.2.8

Ethernet Protocol for ComBox-E

Status for BD Dryer (Stand alone)

STATE

name

STATE

Number

A

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

N

V2

V

X

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

-

Description

Stopped

Shifting

Pressure relief

Start blower

Heating Seq 1 (main on, regulating on)

Heating Seq 1 (main on, regulating off)

Heating Seq 1 (main off, regulating off)

Cooling 1: blower on

Cooling 2: blower off

Heating Seq 2 (main on, regulating on)

Heating Seq 2 (main on, regulating off)

Heating Seq 2 (main off, regulating off)

Cooling 3: cooling air valve open

Pressure equalisation

Split Flow Cool / Split Flow Ads

Waiting

Shifting

Pressure relief

Start blower

Heating Seq 1 (main on, regulating on)

Heating Seq 1 (main on, regulating off)

Heating Seq 1 (main off, regulating off)

Cooling 1: blower on

Cooling 2: blower off

Heating Seq 2 (main on, regulating on)

Heating Seq 2 (main on, regulating off)

Heating Seq 2 (main off, regulating off)

Cooling 3: cooling air valve open

Pressure equalisation

Split Flow Cool / Split Flow Ads

Waiting

Shutdown

Recovering from power failure

INIT

Can be one of the states: A1B15

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 16

Atlas Copco Airpower NV

3.4.2.2.9

3.4.2.2.10

3.4.2.2.11

Ethernet Protocol for ComBox-E

Status for CD Dryer (Stand alone)

STATE

name

STATE

Number

Description

A

A0

A1

A2

B0

B1

B2

W

V

1

2

3

4

5

6

7

8

9

Dryer off

Exhaust vessel A / Shifting

Regenerating vessel A

Pressurizing vessel A

Exhaust vessel B / Shifting

Regenerating vessel B

Pressurizing vessel B

Purge saving

Power on, checking auto restart conditions

(ARAVF)

Status for FD-Fixed Speed & FD-VSD Dryer (Stand alone)

STATE

name

STATE

Number

Description

A

C

E

G

N

P

1

3

5

7

14

16

22

Dryer off

Dryer stopped

Dryer starting

Dryer running

Dryer shutdown

Checking permissive start condition(s) (Dryer

Starting)

Power on, checking auto restart conditions

(ARAVF)

Status for MD-Fixed Speed Dryer (Stand alone)

STATE

name

STATE

Number

Description

A

N

V

1

14

22

Dryer off

Dryer shutdown

Power on, checking auto restart conditions

(ARAVF)

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 17

Atlas Copco Airpower NV

3.4.3

Ethernet Protocol for ComBox-E

Inputs & Outputs

3.4.3.1

Analogue Inputs Sensors & Calculated

The Elektronikon MkIV supports up to 55 analogue sensor inputs and 10 additional analogue calculated (virtual) inputs.

Each input has a value and a status register assigned.

The contents of these registers depend on the actual type of sensor that is connected. This can be different for every type

of compressor. E.g. standard compressors may have 1 to 4 pressure inputs, 1 to 10 temperature inputs, up to 7 SPM

inputs, Also, features and options may increment the number of sensors that are actually installed on your

compressor.

Before using the Ethernet/IP system it is therefore required to find out what sensors are really connected to your

compressors. This can e.g. be done with the FDP program. This program has a function that lists the sensors +

Ethernet/IP (use Profibus) registers for a selected compressor type (including features and options).

Once the list of sensors is known, the contents of the registers can be interpreted as described below.

3.4.3.2

ParameterID

3.4.3.2.1

Sensor Inputs

Function to be used : Read 01

NodeAddress

DINT

ParametersID

DINT

0000

0001

..

0053

0054

Data 4 Bytes (DINT)

B1

B2

W1

Analogue Input 1 Value

Analogue Input 2 Value

B4

W2

Analogue Input 1 Status

Analogue Input 2 Status

Analogue Input 54 Value

Analogue Input 55 Value

Analogue Input 54 Status

Analogue Input 55 Status

B3

3.4.3.2.2

Calculated (virtual) Inputs

Function to be used : Read 01

NodeAddress

DINT

ParametersID

DINT

0055

..

0064

Data 4 Bytes (DINT)

B1

B2

W1

Analogue Input 56 Value

B4

W2

Analogue Input 56 Status

Analogue Input 65 Value

Analogue Input 65 Status

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

B3

Page 18

Atlas Copco Airpower NV

3.4.3.3

Ethernet Protocol for ComBox-E

Status register Interpretation

Byte 3 (B3)

= 00

Byte 4 (B4)

= Input Status

The Input Status must be interpreted as Binary data (bit coded).

Each part ( bit ) of the data ( byte ) is indicating a specific item that applies on the Input function. In the following table,

an overview is given of all bits together with the corresponding meaning and interpretation.

Function

Description

Bit 7

Input

Set/Not Set

Bit 6

Sensor

Error

Bit 5

Permissive

Start

Bit 4

Service

Bit 3

Shutdown

Bit 2

Shutdown

Warning

Bit 1

Warning

Bit 0

PreWarning

Bit 1

Bit 0

Set

Not Set

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

3.4.3.4

Value register Interpretation

This depends on the type of inputs.

3.4.3.4.1

Pressure Input

The Pressure Input Value is a 2 byte integer, and contains the actual reading in mbar (0.001 bar)

For negative values, standard 2-complement notation is used.

Example:

Value = 7040 decimal or 0x1B80 hexadecimal = 7.040 bar.

Value = -1000 decimal (2-complement) or 0xFC18 = -1.000 bar

For sensor error the value the value 32767 or 7FFF (hex) is returned.

On some high pressure compressors (with working pressures above 30 bar) a special Pressure Input can be defined that

returns data in cBar (0.01 bar) in stead of mBar.

3.4.3.4.2

Temperature Input

The Temperature Input Value is a 2 byte integer, and contains the actual reading in 0.1C

For negative values, standard 2-complement notation is used.

Example:

Value = 855 decimal or 0x0357 hexadecimal = 85.5 C

Value = -250 decimal (2-complement) or 0xFF06 = -25.0 C

For sensor error the value the value 32767 or 7FFF (hex) is returned.

3.4.3.4.3

Vibration Input

The Vibration Input Value is a 2 byte integer, and contains the actual reading in 0.01m

For sensor error the value the value 32767 or 7FFF (hex) is returned.

3.4.3.4.4

Level Input

The Level Input Value is a 2 byte integer, and contains the actual reading in 0.1mm

For sensor error the value the value 32767 or 7FFF (hex) is returned.

3.4.3.4.5

Conductivity Input

The Conductivity Value is a 2 byte integer, and contains the actual reading in 1 S/cm

For sensor error the value the value 32767 or 7FFF (hex) is returned.

3.4.3.4.6

SPM Input

The SPM Input Value is a 2 byte register that must be seen as 2 x 1 byte.

Byte 1 : carpet value (in dB)

Byte 2 : peak value (in dB)

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 19

Atlas Copco Airpower NV

Example:

Ethernet Protocol for ComBox-E

Value = 0x1120 = > carpet value = 0x11, peak value = 0x20

For sensor error the value the value 0X7FFF (hex) is returned.

SPM values cannot be negative

3.4.3.4.7

Current Input

The Current Input Value is a 2 byte integer, and contains the actual reading in 0.1 A

For sensor error the value the value 32767 or 7FFF (hex) is returned.

3.4.3.4.8

Speed Input

The Speed Input Value is a 2 byte integer, and contains the actual reading in 1 rpm

For sensor error the value the value 32767 or 7FFF (hex) is returned.

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 20

Atlas Copco Airpower NV

Ethernet Protocol for ComBox-E

3.4.3.5

Digital (Voltage free contacts) Inputs

The Elektronikon MkIV supports up to 18 digital (voltage free) inputs. Each input has a value and a status register

assigned.

The contents of these registers is for digital inputs always the same, if the input is used. Before using the Ethernet/IP

system it is therefore required to find out what inputs are used on your compressors. This can e.g. be done with the FDP

program. This program has a function that lists the digital inputs + Profibus (Ethernet/IP has the same registers)

registers for a selected compressor type (including features and options).

Once the list of inputs is known, the contents of the registers can be interpreted as described below.

Function to be used : Read 01

NodeAddress

DINT

3.4.3.6

ParametersID

DINT

Data 4 Bytes

B1

0200

0201

..

0220

B2

W1

Digital Input 1 Value

Digital Input 2 Value

B4

W2

Digital Input 1 Status

Digital Input 2 Status

Digital Input 21 Value

Digital Input 21 Status

B3

Status register Interpretation

Byte 3 (B3)

Byte 4 (B4)

= 00

= Input Status

The Input Status must be interpreted as Binary data.

Each part ( bit ) of the data ( byte ) is indicating a specific item that applies on the Input function. In the following table,

an overview is given of all bits together with the corresponding meaning and interpretation.

Function

Description

Bit 7

Input

Set/Not Set

Bit 6

Sensor

Error

Bit 5

Permissive

Start

Bit 4

Service

Bit 3

Shutdown

Bit 2

Shutdown

Warning

Bit 1

Warning

Bit 0

PreWarning

Value 1

Value 0

Set

Not Set

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

Not used

Not used

Active

Not Active

Active

Not Active

3.4.3.7

Value register Interpretation

Value: 00

Digital input is Open

Value: 01

Digital input is Closed

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 21

Atlas Copco Airpower NV

3.4.3.8

Ethernet Protocol for ComBox-E

Analogue Outputs (Only for Turbo)

The Elektronikon MkIV supports up to 2 analogue outputs.

3.4.3.9

Registers

Function to be used : Read 01

NodeAddress

DINT

ParametersID

DINT

0700

0701

Data 4 Bytes (DINT)

B1

B2

W1

0

0

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

B3

B4

W2

Analogue Output 1 -Value

Analogue Output 2 -Value

Page 22

Atlas Copco Airpower NV

3.4.4

Ethernet Protocol for ComBox-E

Counters

3.4.4.1

Compressor Counters

The Elektronikon MkIV supports up to 33 counters (32-bit counters). Each input as 2 x 16bit value register assigned,

to allow a 32-bit value to be read.

Not all types of compressors use all types of counters. The list in this chapter provides an overview of the used counters

/ compressor type, and the units that are used

Function to be used : Read 01

Node Address

ParametersID

DINT

DINT

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

0314

..

0332

Data 4 Bytes (DINT)

B1

B2

B3

B4

W1

W2

Running Hours

Loaded Hours

Motor Starts

Module Hours

Accumulated Volume

Load cycle

VSD 1-20% RPM

VSD 20-40% RPM

VSD 40-60% RPM

VSD 60-80% RPM

VSD 80-100% RPM

Not yet used

50 % loaded hours

Load relay 2

Counter application Specific

..

Counter application Specific

yes, if VSD has unloading cycle (e.g. Z-VSD)

Interpretation of data in the registers

Example Running Hours

Running Hours B4 B5 B6 B7

00 2C 93 45 2921285 sec 811 hrs

An Example to calculate the VSD %Counters

Running Hours

65 s

1 - 20%

41 s

20 - 40 %

13 s

40 - 60 %

3 s

60 - 80 %

1 s

80 - 100 %

7 s

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 23

Atlas Copco Airpower NV

1 -20%

Ethernet Protocol for ComBox-E

41 s

20 - 40 %

13 s --> 13*100/65 = 20

--> 20% (round off downwards if the value is lower then xx,50 else round

40 - 60 %

3 s

--> 3*100/65 = 4,61

--> 5%

60 - 80 %

1s

-->

1*100/65 = 1,53

--> 2%

80 - 100 %

7s

-->

7*100/65 = 10,76

--> 11%

off upwards)

---------40 %

100 % - 40 % = 60%

1-20%

41 s

60%

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 24

Atlas Copco Airpower NV

3.4.4.1.1

Counters for Fixed Speed

ParameterID

F

I

X

E

D

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

Description

Running Hours

Loaded Hours

Motor Starts

Module Hours

Unit

s

s

Number

s

Load Relay

Number

0314

Description

Dryer Low Load Warnings

Unit

Number

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

Motor Rotations

Malfunctions Pres/Temp

Malfunctions Fail Pulse

Regreasing Actions

Number

Number

Number

Number

ParameterID

S

P

E

C

I

F

I

C

Ethernet Protocol for ComBox-E

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 25

Atlas Copco Airpower NV

3.4.4.1.2

Counters for VSD

ParameterID

F

I

X

E

D

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

S

P

E

C

I

F

I

C

Ethernet Protocol for ComBox-E

Description

Running Hours

Unit

s

Motor Starts

Module Hours

Accumulated Volume

Number

S

1000m3

VSD

VSD

VSD

VSD

VSD

1-20 % RPM

20-40 % RPM

40-60 % RPM

60-80 % RPM

80-100 % RPM

%

%

%

%

%

0314

Description

Dryer Low Load Warnings

Unit

Number

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

Motor Rotations

Malfunctions Pres/Temp

Malfunctions Fail Pulse

Regreasing Actions

Number

Number

Number

Number

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 26

Atlas Copco Airpower NV

3.4.4.1.3

Counters for ZB VSD

ParameterID

F

I

X

E

D

Ethernet Protocol for ComBox-E

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

Description

Running Hours

Unit

s

Motor Starts

Module Hours

Accumulated Volume

Number

S

1000m3

VSD 1-20 % RPM

VSD 20-40 % RPM

VSD 40-60 % RPM

VSD 60-80 % RPM

VSD 80-100 % RPM

Accumulated Volume Tout > 60C

Description

%

%

%

%

%

Unit

0314

S

P

E

C

I

F

I

C

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 27

Atlas Copco Airpower NV

3.4.4.1.4

Counters AQ Fixed Speed

ParameterID

F

I

X

E

D

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

0314

S

P

E

C

I

F

I

C

Ethernet Protocol for ComBox-E

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

Description

Running Hours

Loaded Hours

Motor Starts

Module Hours

Unit

s

s

Number

s

Load Relay

Number

Description

Drain Time

Fill Time

Unit

s

s

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 28

Atlas Copco Airpower NV

3.4.4.1.5

Counters for AQ VSD

ParameterID

F

I

X

E

D

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

0314

S

P

E

C

I

F

I

C

Ethernet Protocol for ComBox-E

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

Description

Running Hours

Unit

s

Motor Starts

Module Hours

Accumulated Volume

Number

S

1000m3

VSD

VSD

VSD

VSD

VSD

1-20 % RPM

20-40 % RPM

40-60 % RPM

60-80 % RPM

80-100 % RPM

%

%

%

%

%

Description

Drain Time

Fill Time

Unit

s

s

Motor Rotations

Malfunctions Pres/Temp

Malfunctions Fail Pulse

Regreasing Actions

Number

Number

Number

Number

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 29

Atlas Copco Airpower NV

3.4.4.1.6

Counters for PET VSD

ParameterID

F

I

X

E

D

Ethernet Protocol for ComBox-E

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

Description

Running Hours

Unit

s

Motor Starts

Module Hours

Accumulated Volume

Number

S

1000m3

VSD

VSD

VSD

VSD

VSD

1-20 % RPM

20-40 % RPM

40-60 % RPM

60-80 % RPM

80-100 % RPM

Description

%

%

%

%

%

Unit

0314

S

P

E

C

I

F

I

C

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 30

Atlas Copco Airpower NV

3.4.4.1.7

Counters for Turbo

ParameterID

F

I

X

E

D

Ethernet Protocol for ComBox-E

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

Description

Running Hours

Loaded Hours

Motor Starts

Module Hours

Unit

s

s

Number

s

Load Relay

Number

Description

Unit

0314

S

P

E

C

I

F

I

C

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 31

Atlas Copco Airpower NV

3.4.4.1.8

Counters PET Fixed Speed

ParameterID

F

I

X

E

D

Ethernet Protocol for ComBox-E

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

Description

Running Hours

Loaded Hours

Motor Starts

Module Hours

Unit

s

s

Number

s

Load Relay

Number

50 % loaded hours

Load relay 2

s

Number

Description

Unit

0314

S

P

E

C

I

F

I

C

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 32

Atlas Copco Airpower NV

3.4.4.1.9

Counters for SF (Multi)

ParameterID

F

I

X

E

D

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

0314

S

P

E

C

I

F

I

C

Ethernet Protocol for ComBox-E

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

Description

Running Hours

Module Hours

Description

Running Hours Element 1

Running Hours Element 2

Running Hours Element 3

Running Hours Element 4

Motor Starts Element 1

Motor Starts Element 2

Motor Starts Element 3

Motor Starts Element 4

Shutdowns Element 1

Shutdowns Element 2

Shutdowns Element 3

Shutdowns Element 4

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Units

s

Unit

S

S

S

S

Number

Number

Number

Number

Number

Number

Number

Number

Page 33

Atlas Copco Airpower NV

3.4.4.1.10

Counters for CD Dryer

ParameterID

F

I

X

E

D

Ethernet Protocol for ComBox-E

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

Description

Running Hours

Module Hours

Description

Units

s

Unit

0314

S

P

E

C

I

F

I

C

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 34

Atlas Copco Airpower NV

3.4.4.1.11

Counters for BD dryer (AII)

ParameterID

F

I

X

E

D

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

0314

S

P

E

C

I

F

I

C

Ethernet Protocol for ComBox-E

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

Description

Running Hours

Module Hours

Description

Actual State Time

Programmed State Time

Actual Half Cycle Time

Programmed Half Cycle Time

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Unit

s

Unit

s

s

s

s

Page 35

Atlas Copco Airpower NV

3.4.4.1.12

Counters for FD VSD dryer

ParameterID

F

I

X

E

D

Ethernet Protocol for ComBox-E

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

Description

Running Hours

Unit

s

Motor Starts

Module Hours

Number

s

Description

Unit

0314

S

P

E

C

I

F

I

C

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 36

Atlas Copco Airpower NV

3.4.4.1.13

Counters MD dryer

ParameterID

F

I

X

E

D

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

0314

S

P

E

C

I

F

I

C

Ethernet Protocol for ComBox-E

Description

Unit

Loaded Hours

Module Hours

Description

Dryer Low Load Warnings

Unit

Number

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 37

Atlas Copco Airpower NV

3.4.4.1.14

Counters for ES002

ParameterID

F

I

X

E

D

Ethernet Protocol for ComBox-E

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

0310

0311

0312

0313

ParameterID

Description

Running Hours

Loaded Hours

Motor Starts

Module Hours

Unit

s

s

Number

s

Load Relay

Number

Description

Unit

0314

S

P

E

C

I

F

I

C

0315

0316

0317

0318

0319

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

0330

0331

0332

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 38

Atlas Copco Airpower NV

Ethernet Protocol for ComBox-E

3.4.4.2

Multi Compressor Controller Counters

The Elektronikon MkIV contains 4 counters (32-bit counters) to perform the MCC load balancing between up to 4

compressors. Each such counter as 2 x 16bit value register assigned, to allow a 32-bit value to be read.

Only units where the MCC master function is active contain real data for this registers.

Function to be used : Read 01

NodeAddress

DINT

ParametersID

DINT

0500

0501

0502

0503

Data 4 Bytes (DINT)

B1

B2

B3

W1

Compressor 1 counter

Compressor 2 counter

Compressor 3 counter

Compressor 4 counter

B4

W2

Units

s

s

s

s

Data interpretation is the same as for the other counters

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 39

Atlas Copco Airpower NV

3.4.5

Ethernet Protocol for ComBox-E

Special

3.4.5.1

VSD motor data

The Elektronikon MkIV on VSD units contains some important data about the motor speed.This data can be read over

the modbus system.

Function to be used : Read 01

NodeAddress

DINT

ParametersID

DINT

800

801

802

803

Data 4 Bytes (DINT)

B1

B2

W1

0000 (Not Used)

0000 (Not Used)

0000 (Not Used)

0000 (Not Used)

B3

B4

W2

Required motor speed

Actual motor speed motor 1

Actual motor speed motor 2

Actual motor speed motor 3

Units

rpm

rpm

rpm

rpm

Each register contains a 16-bit value that is directly readable as the equivalent rpm.

3.5

3.5.1

Ethernet/IP parameters for change

Load/Unload Pressure Band change

It is possible to change the operating pressure band inside the Elektronikon MkIV, or to switch between the two

available pressure bands. These registers are only valid for Load/Unload compressors

Functions to be used :

For reading : Read 01

For writing :Command or reprogramming 03

NodeAddress

DINT

ParametersID

DINT

1060

1061

1062

1063

1064

Data 4 Bytes (DINT)

B1

B2

W1

0000 (Not Used)

0000 (Not Used)

0000 (Not Used)

0000 (Not Used)

0000 (Not Used)

B3

B4

W2

Pressure Band Selection

Loading pressure band 1

Unloading Pressure band 1

Loading pressure band 2

Unloading Pressure band 2

Pressure Band Selection : 1 = band 1, 2 = band 2

Attention : when writing values the following relations should be maintained :

Loading pressure < unloading pressure (per band)

Loading pressure should not be below the minimum setting that was factory defined.

Unloading pressure should not be above the maximum setting that was factory defined.

Values not fulfilling this will be refused.

3.5.2

VSD Setpoint change

It is possible to change the operating set point inside the Elektronikon MkIV, or to switch between the two available

pressure set points. These registers are only valid for VSD compressors

Functions to be used :

For reading : Read 01

For writing :Command or reprogramming 03

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 40

Atlas Copco Airpower NV

NodeAddress

DINT

ParametersID

DINT

1050

1051

1052

Data 4 Bytes (DINT)

B1

B2

W1

0000 (Not Used)

0000 (Not Used)

0000 (Not Used)

Ethernet Protocol for ComBox-E

B3

B4

W2

Setpoint Selection

Setpoint 1

Setpoint 2

Setpoint Selection : 1 = Setpoint 1, 2 = Setpoint 2

The set point must be within the limits that are factory defined for your machine type.

Values not fulfilling this will be refused by the MKIV.

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 41

Atlas Copco Airpower NV

3.5.3

Ethernet Protocol for ComBox-E

MCC Pressure Band change

In Elektronikons where the MCC master function is active it is possible to change the operating pressure band for this

master, or to switch between the two available pressure bands.

Functions to be used :

For reading : Read 01

For writing :Command or reprogramming 03

NodeAddress

DINT

ParametersID

DINT

1080

1081

1082

1083

1084

Data 4 Bytes (DINT)

B1

B2

W1

0000 (Not Used)

0000 (Not Used)

0000 (Not Used

0000 (Not Used

0000 (Not Used)

B3

B4

W2

MCC Pressure Band Selection

MCC Loading pressure band 1

MCC Unloading Pressure band 1

MCC Loading pressure band 2

MCC Unloading Pressure band 2

Pressure Band Selection : 0 = band 1, 1 = band 2

Attention : when writing values the following relations should be maintained :

Loading pressure < unloading pressure (per band)

Values not fulfilling this will be refused by the MKIV.

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 42

Atlas Copco Airpower NV

3.5.4

Ethernet Protocol for ComBox-E

PET L/U Regulation Band Change

Functions to be used :

For reading : Read 01

For writing :Command or reprogramming 03

NodeAddress

DINT

ParametersID

DINT

1090

1091

1092

1093

1094

1095

1096

1097

1098

1099

Data 4 Bytes (DINT)

B1

B2

W1

0000 (Not Used)

0000 (Not Used)

0000 (Not Used)

0000 (Not Used

0000 (Not Used

0000 (Not Used

0000 (Not Used

0000 (Not Used

0000 (Not Used

0000 (Not Used)

B3

B4

W2

Pressure Band Selection

Regulation Method

100 % Loading Pressure band1

50 % Loading Pressure band1

100 % Unloading Pressure band1

50 % Unloading Pressure band1

100 % Loading Pressure band2

50 % Loading Pressure band2

100 % Unloading Pressure band2

50 % Unloading Pressure band2

Pressure Band Selection : 1 = band 1, 2 = band 2

Regulation Method :

1

2

3

0 - 100 %

0 - 50 %

0 50 100 %

The values must be within the limits that are factory defined for your machine type.

Values not fulfilling this will be refused by the MKIV.

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 43

Atlas Copco Airpower NV

3.5.5

Ethernet Protocol for ComBox-E

ZH Turbo Regulation Setpoint and Band Change

Functions to be used :

For reading : Read 01

For writing :Command or reprogramming 03

NodeAddress

DINT

ParametersID

DINT

1110

1111

1112

1113

1114

1115

1116

Data 4 Bytes (DINT)

B1

B2

W1

0000 (Not Used)

0000 (Not Used)

0000 (Not Used)

0000 (Not Used

0000 (Not Used

0000 (Not Used

0000 (Not Used

B3

B4

W2

Setpoint selection

Setpoint 1

Load offset 1

Unload offset1

Setpoint 1

Load offset 1

Unload offset1

Setpoint Selection : 1 = Setpoint 1, 2 = Setpoint 2

The values must be within the limits that are factory defined for your machine type.

Values not fulfilling this will be refused by the MKIV.

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 44

Atlas Copco Airpower NV

3.6

3.6.1

Ethernet Protocol for ComBox-E

Ethernet/IP parameters for remote control

Control Commands

3.6.1.1

Compressor Control Mode Selection

The Elektronikon MkIV has a number of control modes that define the behaviour of a compressor in relation to external

inputs (pressure reading, start/stop commands,).

Each mode has a main type (= number 1 to 4), and a sub-type (a,b,c,..). The number of sub-types is different for each

main type.

When Ethernet/IP has to be used to control a compressor the main type ust be set to 4 (=remote control over

communication line). This has to be done through the display, select LAN Control. By default the compressor will

then enter the 4a mode.

Through Profibus it is now possible to activate the other sub-types.

Functions to be used :

For writing :Command or reprogramming 03

NodeAddress

DINT

ParametersID

2001

ParametersID

DINT

Value to write

1

2

3

Data 4 Bytes (DINT)

B1

B2

00

00

Description

Switch from 4a or 4c to 4b

Switch from 4b or 4c to 4a

Switch from 4a or 4b to 4c

B3

00

B4

Value

Accepted in mode

4a 4c

4b

4a 4b

Note

Mode 4a : remote control of start/stop but pressure control is done by the controller

Mode 4b : remote control of start/stop and pressure control is done from remote (Supervisory control) (also for VSD

setpoint control and Turbo)

Mode 4c : remote control of start/stop with external speed (only vsd) speed control)

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 45

Atlas Copco Airpower NV

Fixed Speed

VSD

VSD Throttle Valve

AQ Fixed Speed

AQ VSD

ZH Turbo

PET Fixed Speed

PET VSD

WCO Fixed Speed

WCO VSD

SF (Multi)

BD Dryer (AII)

FD VSD Dryer

MD Dryer

ES002

Fixed Speed

VSD

VSD Throttle Valve

AQ Fixed Speed

AQ VSD

ZH Turbo

PET Fixed Speed

PET VSD

WCO Fixed Speed

WCO VSD

SF (Multi)

BD Dryer (AII)

FD VSD Dryer

MD Dryer

ES002

Switch from 4a to 4b

X

X

X

X

X

X

X

X

X

X

Switch from 4b to 4a

X

X

X

X

X

X

X

X

X

X

Switch from 4a to 4c

Switch from 4c to 4a

X

X

X

X

Switch from 4b to 4c

Fixed Speed

VSD

VSD Throttle Valve

AQ Fixed Speed

AQ VSD

ZH Turbo

PET Fixed Speed

PET VSD

WCO Fixed Speed

WCO VSD

SF (Multi)

BD Dryer (AII)

FD VSD Dryer

MD Dryer

ES002

Ethernet Protocol for ComBox-E

Switch from 4c to 4b

X

X

X

X

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Page 46

Atlas Copco Airpower NV

Ethernet Protocol for ComBox-E

3.6.1.2

Compressor Commands

The commands that are described here are only available in the defined Compressor Control Modes.

Carefully consult the control concept of the compressors before using them.

Functions to be used :

For writing :Command or reprogramming 03

NodeAddress

DINT

ParameterID

2000

ParameterID

DINT

Value to write

1

2

3

4

5

6

7

8

9

10

11

2003

1

2

Data 4 Bytes (DINT)

B1

B2

00

00

B3

Command

Start

Stop

Load

Unload

MCC Start System

MCC Stop System

MCC Local

50 % Load (PET L/U Booster)

Not used

Start water-cooling pump (PET L/U or VSD

Booster + PETPACK functionality is active)

Stop water-cooling pump (PET L/U or VSD

Booster + PETPACK functionality is active)

Reset Shutdown

Reset Start Failures

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

B4

00

Value

Accepted in mode

4a / 4b

4a / 4b

4a / 4b

4b ( in 4a = Manual unload )

4a / 4d

4d

4d

4b

4b

4b

In all Modes

In all Modes

Page 47

Atlas Copco Airpower NV

Fixed Speed

VSD

VSD Throttle Valve

AQ Fixed Speed

AQ VSD

ZH Turbo

PET Fixed Speed

PET VSD

WCO Fixed Speed

WCO VSD

SF (Multi)

BD Dryer (AII)

FD VSD Dryer

MD Dryer

ES002

Start Command

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Ethernet Protocol for ComBox-E

Stop Command

X

X

X

X

X

X

X

X

X

X

X

X

X

X

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

Load Command

X

Unload Command

X

X

X

X

X

Page 48

Atlas Copco Airpower NV

3.6.2

Ethernet Protocol for ComBox-E

VSD external setpoint/speed control

On VSD units extended external control is possible whereby either the main motor speed of the pressure set point is

directly controlled from remote over Profibus.

This can be done with the following Profibus parameters.

Functions to be used :

For reading : Read 01

For writing :Command or reprogramming 03

NodeAddress

DINT

ParametersID

DINT

1070

1071

3.6.3

Data 4 Bytes (DINT)

B1

B2

W1

0000 (Not Used)

0000 (Not Used)

B3

B4

W2

External Setpoint

External Speed

Reset Initial Settings (Analogue , Digital , Counter Inputs)

Functions to be used :

For writing :Command or reprogramming 03

NodeAddress

DINT

Existing Node

ParametersI

D

DINT

2100

Data 4 Bytes (DINT)

B1

B2

W1

0000 (Not Used)

File: 9820 3582 05 User Guide MKIV Ethernet-IP 03.doc

B3

B4

W2

0000 (Not Used)

Page 49

You might also like

- M 37705 - MitsubishiDocument20 pagesM 37705 - MitsubishiStevenNo ratings yet

- La 6581cl - SanyoDocument5 pagesLa 6581cl - SanyoStevenNo ratings yet

- IRF840ADocument8 pagesIRF840AFRALIMNo ratings yet

- HGTG 30N60A4 - Fairchild PDFDocument8 pagesHGTG 30N60A4 - Fairchild PDFStevenNo ratings yet

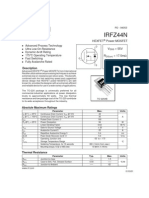

- Irfz 44 NDocument9 pagesIrfz 44 Nmadhuvariar100% (6)

- HEF4069UB Hex Inverter Gates Data SheetDocument7 pagesHEF4069UB Hex Inverter Gates Data SheetrharjaniNo ratings yet

- IRFB59N10D - International RectifierDocument11 pagesIRFB59N10D - International RectifierStevenNo ratings yet

- La 6581cl - SanyoDocument5 pagesLa 6581cl - SanyoStevenNo ratings yet

- Irfz44R: Hexfet Power MOSFET V 60V R 0.028 I 50 ADocument8 pagesIrfz44R: Hexfet Power MOSFET V 60V R 0.028 I 50 AAaron AndersNo ratings yet

- Infineon IRFS31N20D DataSheet v01 01 enDocument13 pagesInfineon IRFS31N20D DataSheet v01 01 enpetre blackNo ratings yet

- HGTG 30N60A4 - FairchildDocument20 pagesHGTG 30N60A4 - FairchildStevenNo ratings yet

- Ir 2113Document18 pagesIr 2113rohitsingh2909No ratings yet

- HA17458 - RenesasDocument9 pagesHA17458 - RenesasStevenNo ratings yet

- HGTG 30N60A4 - Fairchild PDFDocument8 pagesHGTG 30N60A4 - Fairchild PDFStevenNo ratings yet

- FFB 2907 - FairchildDocument8 pagesFFB 2907 - FairchildStevenNo ratings yet

- FFB 2907 - FairchildDocument13 pagesFFB 2907 - FairchildStevenNo ratings yet

- FMU 36R - Sanken PDFDocument5 pagesFMU 36R - Sanken PDFStevenNo ratings yet

- HA17458 HitachiDocument10 pagesHA17458 HitachiStevenNo ratings yet

- FFB 2907 - FairchildDocument5 pagesFFB 2907 - FairchildStevenNo ratings yet

- FFB 2907 - FairchildDocument8 pagesFFB 2907 - FairchildStevenNo ratings yet

- FFB 2907 - FairchildDocument5 pagesFFB 2907 - FairchildStevenNo ratings yet

- FMU 36R - Sanken PDFDocument5 pagesFMU 36R - Sanken PDFStevenNo ratings yet

- EASD 92-02R - Fuji ElectricDocument12 pagesEASD 92-02R - Fuji ElectricStevenNo ratings yet

- FFB 2907 - FairchildDocument5 pagesFFB 2907 - FairchildStevenNo ratings yet

- FAN 7311 - FairchildDocument13 pagesFAN 7311 - FairchildStevenNo ratings yet

- Epson S1D15712 SeriesDocument68 pagesEpson S1D15712 SeriesStevenNo ratings yet

- FFB 2907 - FairchildDocument5 pagesFFB 2907 - FairchildStevenNo ratings yet

- FAN 7310 - FairchildDocument12 pagesFAN 7310 - FairchildStevenNo ratings yet

- ESAD 92M-02R - Fuji ElectricDocument3 pagesESAD 92M-02R - Fuji ElectricStevenNo ratings yet

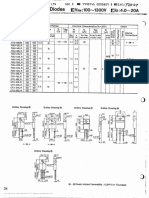

- ERA15-01 ERA15-10: Silicon Rectifier Diodes DO - 41Document2 pagesERA15-01 ERA15-10: Silicon Rectifier Diodes DO - 41StevenNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)