Professional Documents

Culture Documents

Industry Benchmark Survey: World Class Maintenance Benchmark Indicators

Uploaded by

CésarRenatoCopacondoriCuaylaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industry Benchmark Survey: World Class Maintenance Benchmark Indicators

Uploaded by

CésarRenatoCopacondoriCuaylaCopyright:

Available Formats

Industry Benchmark Survey

COMPANY NAME _______________________________ PLANT/FACILITY NAME _________________________________

LOCATION

_______________________________ LOCATION ___________________________________________

_______________________________

___________________________________________

_______________________________

___________________________________________

COMPANY REP.

_______________________________ TELEPHONE NO.___________________ FAX ________________

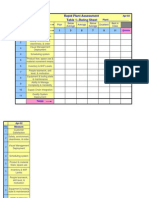

World Class Maintenance Benchmark Indicators

Indicator

1

2

3

4

5

6

7

8

9

10

Indicator

11

12

13

14

Indicator Description

What is the percent of annual total expense maintenance costs

to annual total plant sales? Total maintenance costs include

shutdown/turnaround annualized allocations.

What is the percent of annual total maintenance costs to plant

replacement asset value (RAV)? RAV is the cost of replacing

current assets.

What is the percent of maintenance stock value to RAV?

What is the RAV value per maintenance employee?

What is the cost per employee based on annual total expense

maintenance cost?

What is the number of maintenance craft personnel per first

line supervisor (company and contract)?

What is the number of maintenance craft personnel per

planner?

What is the number of first line supervisors per planner?

How many organizational levels between plant manager and

maintenance craft personnel?

What percent of critical performance measures have been

achieved?

Indicator Description

Training dollars represent what percent of the maintenance

budget?

What is the number of specific crafts used in routine

maintenance?

What percent of minor maintenance work is accomplished by

production?

What percent of equipment have Preventive Maintenance (PM)

Page 1 of 2

Response

Comments

World Class 1.5% TO 2.0%

World Class 0.5%

World Class > $5,000,000

World Class > $100,000

World Class - 15 to 20

World Class 30 to 60

World Class 2 to 3

World Class 2 to 3

World Class > 90%

Response

Comments

World Class 4% to 5%

World Class 2 to 3

World Class 30% to 40%

World Class 80%

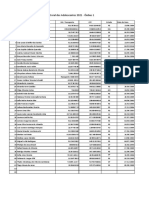

Industry Benchmark Survey

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

tasks been developed for and used?

In maintenance, how many hours is each craft person

scheduled?

What is the percent of completed work orders that have been

planned?

What is the percent of completed work orders that are PM?

What percent of systems have had a full Reliability Centered

Maintenance analysis?

How many weeks of backlog for the total maintenance crew?

What is the percent of completed work orders that are

emergency?

What is the percent of rework by maintenance?

What is the percent of overtime to total maintenance hours

worked?

What is the percent for availability for production systems?

(Use composite rate for multiple production systems).

What are the annual inventory turns for maintenance material

(annual issue dollars divided by average inventory dollars)?

What is the percent of emergency purchase orders?

What is the percent of on-time delivery for purchased goods?

What is the percent of vendor stock to on-hand maintenance

stores stock (by value)?

What is the percent of inventory accuracy of maintenance

spare parts?

What is the percent of maintenance parts stockouts?

What percent of warehouse line items show no issue in the

last three years?

Page 2 of 2

World Class 8 of 8 hrs or 100%

World Class > 95%

World Class 30 to 60

World Class > 20%

World Class 2 to 3 weeks

World Class < 5%

World Class < 5%

World Class - 5% to 8%

World Class 94%

World Class 3 to 4 turns

World Class < 10%

World Class > 90%

World Class > 30%

World Class > 98%

World Class < 5%

World Class < 10%

You might also like

- G. Spare Parts ManagementDocument12 pagesG. Spare Parts ManagementVipul TikekarNo ratings yet

- Complaint Form ABCDocument5 pagesComplaint Form ABCBernie WalshNo ratings yet

- G. Spare Parts ManagementDocument12 pagesG. Spare Parts Managementlmn_grssNo ratings yet

- Technical Aspect: Workshop 4Document5 pagesTechnical Aspect: Workshop 4Jeyms KarlosNo ratings yet

- JobSite Safety Inspection ChecklistDocument8 pagesJobSite Safety Inspection ChecklistBisaya ni BaiNo ratings yet

- System Installation Manual: Bendix/King ®Document126 pagesSystem Installation Manual: Bendix/King ®Aaron JuarezNo ratings yet

- Operation Management Answer-1Document13 pagesOperation Management Answer-1hemangi patelNo ratings yet

- Eohsms-02-C18 Loa WSH CoordinatorDocument2 pagesEohsms-02-C18 Loa WSH CoordinatorHassan AbdullahNo ratings yet

- LSCM Project Mp16009Document11 pagesLSCM Project Mp16009Ankit KumarNo ratings yet

- Job CardDocument1 pageJob CardZakaria ZebbicheNo ratings yet

- Job CardDocument1 pageJob CardTeferi AdugnaNo ratings yet

- University of The City of ManilaDocument1 pageUniversity of The City of ManilaTristan James SimNo ratings yet

- Industry & Competitive Situation AnalysisDocument19 pagesIndustry & Competitive Situation Analysistaghavi1347No ratings yet

- I C M P: Nventory Ontrol Odule RoceduresDocument37 pagesI C M P: Nventory Ontrol Odule Rocedurestamilbharathi94No ratings yet

- Nicholas Mohammed 2021Document4 pagesNicholas Mohammed 2021Nicholas MohammedNo ratings yet

- FactoryTalk View SE LabDocument164 pagesFactoryTalk View SE LabRoyal Ritesh SharmaNo ratings yet

- Spare Parts ManagementDocument18 pagesSpare Parts ManagementJoju Johny100% (1)

- SAP PM Interview QuestionsDocument6 pagesSAP PM Interview QuestionsSandeep Kumar PraharajNo ratings yet

- Reee 002Document15 pagesReee 002Imran Nawaz MehthalNo ratings yet

- U. S. Army Corps of Engineers Above-Ground Treatment System Performance ChecklistDocument8 pagesU. S. Army Corps of Engineers Above-Ground Treatment System Performance Checklistavisek_basuNo ratings yet

- Determining Spare Parts RequirementsDocument4 pagesDetermining Spare Parts RequirementsbijishvmNo ratings yet

- A Strategy For Performance ExcellenceDocument32 pagesA Strategy For Performance Excellencesubodh ranjanNo ratings yet

- 5S QualityDocument32 pages5S QualityOmkar BapatNo ratings yet

- Lesson 3 TechnicalDocument9 pagesLesson 3 TechnicalDailyn DulinayanNo ratings yet

- Cleaning, Washing and Rinsing of Turboshaft Engines: Comparison of Turbomeca ProceduresDocument69 pagesCleaning, Washing and Rinsing of Turboshaft Engines: Comparison of Turbomeca Procedures唐波No ratings yet

- Preventive Maintenance Expanded DefinitionDocument5 pagesPreventive Maintenance Expanded DefinitionCadcamdestek CukurocaNo ratings yet

- The 4Ms of Operations: Prepared By: Karla Jane F. BangaysisoDocument18 pagesThe 4Ms of Operations: Prepared By: Karla Jane F. BangaysisoKarla BangFerNo ratings yet

- This Study Resource Was: Activity #7-ReflectionDocument2 pagesThis Study Resource Was: Activity #7-ReflectionAnonymousNo ratings yet

- Smart Inventory Management System: OPUS Open Portal To University ScholarshipDocument23 pagesSmart Inventory Management System: OPUS Open Portal To University ScholarshipLalit Chikte100% (1)

- Life Span of MachineryDocument4 pagesLife Span of MachineryMintesnot BogaleNo ratings yet

- CAT MSR Philosophy 01-2003Document17 pagesCAT MSR Philosophy 01-2003MOHAMEDNo ratings yet

- SAP-PPDocument3 pagesSAP-PPAjay DayalNo ratings yet

- R&D MaintenanceDocument31 pagesR&D MaintenanceSajid ChaudharyNo ratings yet

- Industrial Manufacturing ERP: Request For Proposal TemplateDocument42 pagesIndustrial Manufacturing ERP: Request For Proposal TemplateSarras InfoNo ratings yet

- Process Validation ProtocolDocument10 pagesProcess Validation ProtocolDivya SekarNo ratings yet

- Form Audit EnergiDocument8 pagesForm Audit EnergiAfiedAndhyNo ratings yet

- TB1000 Unit 04-3 Items ExDocument4 pagesTB1000 Unit 04-3 Items ExAlou CortezNo ratings yet

- Deepak Pal Sad Report 2003Document29 pagesDeepak Pal Sad Report 2003Deepak PaulNo ratings yet

- GMP Audit Checklist For PharmaceuticalDocument32 pagesGMP Audit Checklist For PharmaceuticalSue neklawiNo ratings yet

- Production Scheduling at Different LevelsDocument11 pagesProduction Scheduling at Different LevelsgkrishnakumargNo ratings yet

- Yosef Haileeyesus PDFDocument123 pagesYosef Haileeyesus PDFEdwin Rodrigo Aguilar67% (3)

- Plant Maintenance QueriesDocument103 pagesPlant Maintenance QueriesNagendra PrabhuNo ratings yet

- Operating PlanDocument6 pagesOperating PlanAimee Lasaca100% (2)

- Material Requirement PlanningDocument5 pagesMaterial Requirement PlanningJommel GonzalesNo ratings yet

- Brammer Efficient MRO Procurement ManagementDocument6 pagesBrammer Efficient MRO Procurement ManagementFendi Mohamad Zaini100% (1)

- Part I: Executive Summary - Brief Description of The BusinessDocument9 pagesPart I: Executive Summary - Brief Description of The BusinessJani MarajanNo ratings yet

- Planning & Prog, Inventory, ReplenishingDocument18 pagesPlanning & Prog, Inventory, ReplenishingJoju JohnyNo ratings yet

- otlFKrfi Rfpmastertemplate 0Document11 pagesotlFKrfi Rfpmastertemplate 0pearlveeramNo ratings yet

- Client Evaluation Form: Strictly Private and ConfidentialDocument8 pagesClient Evaluation Form: Strictly Private and ConfidentialJuan Vicente Quiñones MarinNo ratings yet

- Baldwin Field Report FormDocument2 pagesBaldwin Field Report FormSMcNo ratings yet

- Six Sigma Green Belt Certification Workshop: LECTURE 8: Quality Function Deployment (QFD)Document4 pagesSix Sigma Green Belt Certification Workshop: LECTURE 8: Quality Function Deployment (QFD)Harshith Rao VadnalaNo ratings yet

- Rapid Plant Assessment Table 1 - Rating Sheet: Ratings Measure Score 1 3 5 7 9 11Document8 pagesRapid Plant Assessment Table 1 - Rating Sheet: Ratings Measure Score 1 3 5 7 9 11pratip064149No ratings yet

- Industry Benchmark Survey: World Class MaintenanceDocument2 pagesIndustry Benchmark Survey: World Class MaintenanceHenry Gonzalo López GarízaNo ratings yet

- Facility Engineering FinalDocument20 pagesFacility Engineering FinalJohnNo ratings yet

- Superdome Data Gathering RequestletterDocument2 pagesSuperdome Data Gathering RequestletterKaye Irish RosauroNo ratings yet

- Literature Review On Preventive MaintenanceDocument5 pagesLiterature Review On Preventive Maintenanceafmzndvyddcoio100% (1)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- SolidWorks SimulationDocument3 pagesSolidWorks SimulationCésarRenatoCopacondoriCuaylaNo ratings yet

- New American Inside Out: Below You Can Download Sample Units and Scope & Sequences For All Six LevelsDocument2 pagesNew American Inside Out: Below You Can Download Sample Units and Scope & Sequences For All Six LevelsCésarRenatoCopacondoriCuaylaNo ratings yet

- Plant Information PortalDocument2 pagesPlant Information PortalCésarRenatoCopacondoriCuaylaNo ratings yet

- The New Ansi Centrifufal PumpDocument7 pagesThe New Ansi Centrifufal PumpCésarRenatoCopacondoriCuaylaNo ratings yet

- Belt Conveyor Pulley Design-Why The FailureDocument38 pagesBelt Conveyor Pulley Design-Why The FailureCésarRenatoCopacondoriCuaylaNo ratings yet

- m3820, Manual Sqc2Document24 pagesm3820, Manual Sqc2CésarRenatoCopacondoriCuaylaNo ratings yet

- 2.1 RollersDocument2 pages2.1 RollersCésarRenatoCopacondoriCuaylaNo ratings yet

- 2 RollersDocument128 pages2 RollersCésarRenatoCopacondoriCuaylaNo ratings yet

- Unit 2.exercisesDocument8 pagesUnit 2.exercisesclaudiazdeandresNo ratings yet

- HIMYM Episode 4 Season 1Document29 pagesHIMYM Episode 4 Season 1ZayNo ratings yet

- Use Case NarrativeDocument2 pagesUse Case NarrativePrajwol Sangat100% (1)

- Business Finance: Quarter 2 - Module 6: Philosophy and Practices in Personal FinanceDocument2 pagesBusiness Finance: Quarter 2 - Module 6: Philosophy and Practices in Personal FinanceClemente AbinesNo ratings yet

- WFP Specialized Nutritious Foods Sheet: Treating Moderate Acute Malnutrition (MAM)Document2 pagesWFP Specialized Nutritious Foods Sheet: Treating Moderate Acute Malnutrition (MAM)elias semagnNo ratings yet

- Blockchain For The Cybersecurity of Smart CityDocument66 pagesBlockchain For The Cybersecurity of Smart CityGiovanni PintoNo ratings yet

- 23-12-22 National ConferenceDocument4 pages23-12-22 National ConferenceNIKITA CHAUHANNo ratings yet

- Pulsed-Field Gel Electrophoresis (PFGE) - PulseNet Methods - PulseNet - CDCDocument2 pagesPulsed-Field Gel Electrophoresis (PFGE) - PulseNet Methods - PulseNet - CDCChaitanya KNo ratings yet

- Coral Dos Adolescentes 2021 - Ônibus 1: Num Nome RG / Passaporte CPF Estado Data de NascDocument1 pageCoral Dos Adolescentes 2021 - Ônibus 1: Num Nome RG / Passaporte CPF Estado Data de NascGabriel Kuhs da RosaNo ratings yet

- Islam and PatriarchyDocument21 pagesIslam and PatriarchycarolinasclifosNo ratings yet

- JUNE 2018 QUESTION (1) (B)Document6 pagesJUNE 2018 QUESTION (1) (B)BryanNo ratings yet

- Sir Gawain and The Green Knight: A TranslationDocument39 pagesSir Gawain and The Green Knight: A TranslationJohn AshtonNo ratings yet

- Aims of The Big Three'Document10 pagesAims of The Big Three'SafaNo ratings yet

- CPFContributionRatesTable 1jan2022Document5 pagesCPFContributionRatesTable 1jan2022ysam90No ratings yet

- Master ClassesDocument2 pagesMaster ClassesAmandeep KumarNo ratings yet

- Shes Gotta Have It EssayDocument4 pagesShes Gotta Have It EssayTimothy LeeNo ratings yet

- Information Security NotesDocument15 pagesInformation Security NotesSulaimanNo ratings yet

- Campaign Period: Terms and Conditions "CIMB 4.7% FD/FRIA-i Bundle With CASA/-i"Document6 pagesCampaign Period: Terms and Conditions "CIMB 4.7% FD/FRIA-i Bundle With CASA/-i"Tan Ah LiannNo ratings yet

- John 5:31-47Document5 pagesJohn 5:31-47John ShearhartNo ratings yet

- Superstore PROJECT 1Document3 pagesSuperstore PROJECT 1Tosin GeorgeNo ratings yet

- 2b22799f-f7c1-4280-9274-8c59176f78b6Document190 pages2b22799f-f7c1-4280-9274-8c59176f78b6Andrew Martinez100% (1)

- Problem 7 Bonds Payable - Straight Line Method Journal Entries Date Account Title & ExplanationDocument15 pagesProblem 7 Bonds Payable - Straight Line Method Journal Entries Date Account Title & ExplanationLovely Anne Dela CruzNo ratings yet

- Worldpay Social Gaming and Gambling Whitepaper Chapter OneDocument11 pagesWorldpay Social Gaming and Gambling Whitepaper Chapter OneAnnivasNo ratings yet

- Implications - CSR Practices in Food and Beverage Companies During PandemicDocument9 pagesImplications - CSR Practices in Food and Beverage Companies During PandemicMy TranNo ratings yet

- Theological Seminary of Evengelical Kalimantan ChurchDocument15 pagesTheological Seminary of Evengelical Kalimantan ChurchPetra Aria Pendung Wu'iNo ratings yet

- P.S. Deodhar - Cinasthana Today - Viewing China From India-Tata McGraw Hill Education (2014)Document372 pagesP.S. Deodhar - Cinasthana Today - Viewing China From India-Tata McGraw Hill Education (2014)MANEESH JADHAVNo ratings yet

- 2010 Final Graduation ScriptDocument8 pages2010 Final Graduation ScriptUmmu Assihdi100% (1)

- Eo - Bhert 2023Document3 pagesEo - Bhert 2023Cyrus John Velarde100% (1)

- Assessment Task-2Document7 pagesAssessment Task-2Parash RijalNo ratings yet

- Case2-Forbidden CItyDocument10 pagesCase2-Forbidden CItyqzbtbq7y6dNo ratings yet