Professional Documents

Culture Documents

Lvac-Sat Procedure For Equipment Test-Ss1

Uploaded by

Balamurugan SelvarajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lvac-Sat Procedure For Equipment Test-Ss1

Uploaded by

Balamurugan SelvarajCopyright:

Available Formats

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

Contract No:

GC 081117B0

Rev.

Date

Page 1 of 10

0

13-02-11

RASLAFFAN CITY

33/11KV SS1 SUBSTATION

SAT FOR LVAC ELECTRICAL EQUIPMENT TEST

Title of Document

Name of project

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Contract No

GC 081117B0

Name of client

Qatar Petroleum (QP)

Name of main contractor

LARSEN & TOUBRO LTD ECC DIVISION

Electrical

Discipline

Document No.

Rev.

No.

Date

2908-BG35-4033

Prepared by

Reviewed by

Reviewed by

Approved by

PM

Approved by

Customer Rep.

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

Contract No:

GC 081117B0

Page 2 of 10

CONTENTS

SL.NO

DESCRIPTION

Title & Approval sheet

Contents

Purpose

Introduction

Abbreviation used

Guidelines to organize the SAT for LVAC

Documentation required

List of LVAC Electrical Equipment test and Procedure

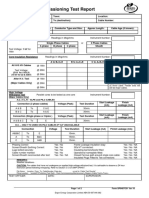

Test Report

Rev.

Date

0

13-02-11

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

3. PURPOSE:

Contract No:

GC 081117B0

Page 3 of 10

Rev

Date

0

13-02-11

This test document specifies the scope, the item to be tested and the test procedures for the

verification of LVAC switchboard. This test document provides systematic procedures in line with Contract

requirements and specifications to conduct the SAT Successfully

WHO SHOULD USE THIS DOCUMENT This document is for Site Acceptance Test and Testing engineer, Quality

Assurance personnel, L&T / QP representatives to test and evaluate the system.

4.

Introduction

The purpose of this document is to define the Site Acceptance Test procedure of 33/11kv SS1 LVAC

switchboard equipment for L&T contract with QP project GC 081117B0 Epic For Electrical And Telecom

Utilities For Support Services Area Phase I & II And West End Extension Of Raslaffan City.

The tests are performed by approved Testing engineers and witnessed by L&T / QP nominated representatives.

Each test, which will be signed off upon completion by Testing engineers and L&T / QP representatives.

This complete SAT document is in two parts. This part specify the Site Acceptance Procedure and the next part

specify the SAT Test Sheets of the equipment and functionalities

Comments are noted in separate Incident and Correction Reports (snag list) attached to the SAT Procedure.

The Site Acceptance Certificate will be signed off upon satisfactory completion of the test by both Testing

engineers and L&T / QP representatives.

5. Abbreviation Used

SAT -Site Acceptance Test

GA -General Arrangement

SLD -Single Line Diagram

QP -Qatar Petroleum

L&T -Larsen & Toubro

LVAC-Low Voltage Alternating Current

6.

GUIDELINES TO ORGANIZE SAT FOR LVAC ELECTRICAL EQUIPMENT.

Testing coordinator Responsibility:

Obtain Consolidated Permit to Work (CPW).

The Test panel is ready for pre-commissioning tests.

Availability of Qualified approved testing engineer.

Availability of tools and Test Kits and equipments with valid calibration certificate.

Stable Power Supply for testing.

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

Contract No:

GC 081117B0

Page 4 of 10

Rev

Date

0

13-02-11

QA/QC Engineer:

Ensure all AFC drawings are available and work procedures are as per QP standards.

Preparing request for inspections and getting clearances.

Complying, Inspecting as per the checklist and maintaining all quality records, standards.

Check all Testing instruments used are calibrated.

7. DOCUMENTATION REQUIREMENT:

Approved Drawing, Two sets of Drawings one for the witness engineer and one for the Testing engineer.

Catalogues, O&M Manuals, all relevant specifications and protection requirements.

Approved site test procedures and format.

Weekly Pre Commissioning & Testing Schedule.

Clearance from QA/QC to proceed with Testing

8.

LIST OF LVAC ELECTRICAL EQUIPMENT TEST

I.

Current Transformer test

II.

Voltage Transformer test

III.

MCCB test

IV.

Breaker with Micro logic Relay test

V.

Meter calibration

VI.

Auxiliary relay test

VII.

Busbar contact resistance test

VIII.

High voltage test

A.

Current Transformer test:

Purpose: The following Tests shall be performed and Witnessed by the Clients to ensure the Current

Transformer operations and its Specific Functions following the Approved SLD.

Procedure: All tests shall be in accordance with IEC standards IEC 60044 1

a.)The Visual Inspection shall include

Check nameplate information for correctness

Check tightness of all CT secondary Terminal

Check that all grounding cables are securely connected

Check color codes(or)sleeves for secondary wiring and size of wires against specs

Check proper lugs has been used in termination

Check CTs location physically and secondary terminal labeling printed

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

Contract No:

GC 081117B0

Page 5 of 10

Rev

Date

0

13-02-11

b.)The Electrical Test shall include

Insulation Resistance Measurement

Polarity Tests

CT Winding Resistance

Knee Point Voltage Measurement

Ratio Test

c.)Insulation Resistance Measurement:

Purpose: To ensure that the CT is without any insulation failure.

Procedure: As per the standard IEC 60076, the calibrated Instrument was used to apply the +ve DC voltage to

Test point and the ve DC terminal for reference point (i.e. Earth) for various condition as per the attached format

the test to be perform, and note down the value

Method: Based on the leakage current measurement from test point to reference point the insulation resistance

value was calculated by the instrument automatically

d.)Polarity Tests:

Purpose: The test is to ensure that CT connected is optimized to the circuits and to ensure the direction of

connections.

Procedure: During the ratio test the angle displacement for primary and secondary are measured by the testing

kit automatically and confirmed the polarity.

Method: OK = phase Isec phase Iprim = -45< 0 < +45

NOT OK = all other cases

e.)CT Winding resistance Measurement:

Purpose: The Test to ensure that winding has got the acceptable resistance as per the FAT reports.

Procedure: Inject the test D.C Current and D.C voltage as per the recommendations into the winding at the

temperature and the similar resistance shall be converted for 75 Deg C.

Measure the Resistance from the kit and recorded in the Test reports.

Method: Based on voltage drop between the winding, the resistance was calculated

Note: Care should be taken for the Discharging the winding after the test.

f.)Knee Point Voltage:

Purpose: The test is to determine the saturation level of C.T. and to verify as per the Design requirement.

Procedure: The calibrated instrument was used to apply the AC voltage Gradually at CT secondary up to the level

of mention VK in name plate.

Method: According to IEC 60044-1, the knee point is defined as the point on the curve where a voltage increment

of 10%Increases the current by 50%.

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

Contract No:

GC 081117B0

Page 6 of 10

Rev

Date

0

13-02-11

Note: Demagnetize the core after the test.

g.)Ratio Test:

Purpose: The test is to ensure that the Current transformer shall be selected for the opt ratio with the rated

primary and the secondary current.

Procedure: The calibrated instrument was used to inject the recommended current to primary of the current

transformer and measure the CT secondary.

Method: The magnitude of the measured secondary current and injected primary current the ratio and error was

calculated by the instrument automatically.

Ratio: Measured pri (A) /Measured sec (A)

Error: (Kn x Isec - Iprim) / Iprim) x 100 Here: Kn-act pri/act sec

Test Documents:

Refer SAT for Current Transformer Test Sheet attached.

Note: Copy of the same test sheets will be used other Feeders CTs.

B. Voltage Transformer test:

Purpose: The following Tests shall be performed and Witnessed by the Clients to ensure the Voltage

Transformer operations and its Specific Functions are following the Approved SLD.

Procedure: All tests shall be in accordance with IEC standards IEC 60044-2

a.)The Visual Inspection shall include

Check nameplate information for correctness

Check tightness of all terminals

Check that all grounding cables are securely connected

Check color coded or sleeves for secondary wiring and size of wires against specs

Check proper lugs has been used in termination

Check VTs location physically and secondary terminal labeling printed

b.)The Electrical Test shall include

Insulation Resistance Measurement

Polarity Tests

VT Winding Resistance

Ratio Test

c.)Insulation Resistance Measurement

Purpose: To ensure that the VT is without any insulation failure.

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

Contract No:

GC 081117B0

Page 7 of 10

Rev

Date

0

13-02-11

Procedure: As per the standard IEC 60076, the calibrated Instrument was used to apply the +ve DC voltage to

Test point and the ve DC terminal for reference point (i.e. Earth) for various condition as per the attached format

the test to be perform, and note down the value

Method: Based on the leakage current measurement from test point to reference point the insulation resistance

value was calculated by the instrument automatically

d.)Polarity Tests:

Purpose: The test is to ensure that VT connected is optimized to the circuits and to ensure the direction of

connections.

Procedure: During the ratio test the angle displacement for primary and secondary are measured by the testing

kit automatically and confirmed the polarity.

Method: OK = phase Vsec phase Vprim = -45< 0 < +45

NOT OK = all other cases

e.)VT Winding resistance Measurement:

Purpose: The Test to ensure that winding has got the acceptable resistance as per the FAT reports.

Procedure: Inject the test D.C Current and D.C voltage as per the recommendations into the winding at the

temperature and the similar resistance shall be converted for 75 Deg C.

Measure the Resistance from the kit and recorded in the Test reports.

Method: Based on voltage drop between the winding, the resistance was calculated

Note: Care should be taken for the Discharging the winding after the test

f.)Ratio Test:

Purpose: The test is to ensure that the Voltage transformer shall be selected for the opt ratio with the rated

primary and the secondary voltage.

Procedure: The calibrated instrument was used to inject the recommended Voltage to primary of the Voltage

transformer and measure the VT secondary.

Method: The magnitude of the measured secondary voltage and applied primary voltage the ratio and error was

calculated by the instrument automatically.

Ratio: Measured pri (V) /Measured sec (V)

Error: (Kn x Vsec - Vprim) / Vprim) x 100 Here: Kn-act pri/act sec

Test Documents:

Refer SAT for voltage Transformer Test Sheet attached.

Note: Copy of the same test sheets will be used other Bays VTs.

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

Contract No:

GC 081117B0

Page 8 of 10

Rev

Date

0

13-02-11

C. MCCB test:

Purpose:

This test verifies the MCCB Tripping characteristics and rating are following the given name plate as per the

approved SLD data. In brief, the test verifies the MCCB trip test for each phase

Procedure:

1. Record the name and reference number of the panel to be tested in the test sheet

i.

Trip test: The calibrated instrument used to inject the 2 times of set current of MCCB in each pole to

pole, then the trip time was noted from the instrument and ensure that the time following the trip

characteristic as per the name plate.

2. Record if any comments in the Indication and Correction Report

Test Document:

Refer SAT Test Sheet

SAT for MCCB: Copy of the same test sheets will be used for the other MCCB.

D.Breaker with Micro logic Relay test:

Purpose:

This test verifies the Micro logic relay Tripping characteristics and rating are following the given name plate as

per the approved SLD data. In brief, the test verifies the Micro logic relay with Breaker trip test for each phase

Procedure:

1. Record the name and reference number of the panel to be tested in the test sheet

i.

Trip test: The calibrated instrument used to inject the recommended current in Breaker pole to pole of

each phase, then the trip time was noted from the instrument and ensure that the time following the

trip characteristic as per the name plate.

2. Record if any comments in the Indication and Correction Report

Test Document:

Refer SAT Test Sheet

SAT for Micro logic relay: Copy of the same test sheets will be used for other Breaker Micro logic relay

E. Ammeters/voltmeter calibration:

Purpose:

This test verifies the Meters operation and rating are following the name plate as per the approved schematic.

In brief, the test verifies the Meter error and operation of the particular meter.

Procedure:

1. Record the name and reference number of the panel to be tested in the test sheet

i.

Secondary injection test: The calibrated instrument used to inject from 0-1A of current in Meters

secondary terminal, Based on the secondary value the meter will display primary values ,the displayed

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

Contract No:

GC 081117B0

Page 9 of 10

Rev

Date

0

13-02-11

primary value are noted and error are calculated manually using the below mention formula.

Error = (Actual value - observed value)/ Actual value

2. Record if any comments in the Indication and Correction Report

Test Document:

Refer SAT Test Sheet

SAT for Ammeter/voltmeter: Copy of the same test sheets will be used for other Meters.

F. Auxiliary relay test:

i.

Trip circuit supervision relay-XR350

Purpose:

This test verifies the functionality and properties of Trip Circuit Supervision Relay under test

Procedure:

1. Select a Trip Circuit Supervision Relay from any one of the incomers

2. Record the Panel Reference in the test sheet

3. Perform the following routine tests which is applicable for this relay

Name Plate Rating Details

General Inspection

Resistance Check

Secondary Injection Test

Measurement of trip Circuit Current

Relay Operation Check

4. Record if any comments in the Indication and Correction Report attached.

Test Document:

Refer SAT Test Sheet

SAT for XR-350 relay: Copy of the same test sheets will be used for other XR-350.

G. Busbar contact test:

Purpose:

This test verifies the contact resistance of LVAC switchboard Busbar under test

Procedure:

1. Record the panel Reference in the test sheet

Contact resistance test: Test follows the standards IEC 62271-200,the calibrated testing instrument was used

to inject recommended current in LVAC Busbar of each verticals, Based on the voltage drop of one end to other

end of busbar the resistance was calculated by the instrument automatically. Ensure the value is following the

FAT value

The resistance is calculated R Contact = Applied-mV / I test

LARSEN & TOUBRO LIMITED- ECCD

ELECTRICAL AND TELECOM UTILITIES FOR SUPPORT SERVICE AREA

PHASE I & II AND WEST END EXTENSION, RAS LAFFAN

Doc No:

2908-BG35-4033

Contract No:

GC 081117B0

Page 10 of 10

Rev

Date

0

13-02-11

2. Record if any comments in the Indication and Correction Report attached.

Test Document:

Refer SAT Test Sheet

SAT for Busbar contact resistance

H. High voltage test:

Purpose:

This test verifies the Insulation level of LVAC switchboard Busbar under test

Procedure:

1. Record the panel Reference in the test sheet

High voltage test: The calibrated testing instrument was used to apply recommended2000v AC (80% of FAT

test voltage) in LVAC Busbar for each phase separately as per the format.Based on the leakage current

measurement of busbar the Insulation level was ensured. Ensure the value is following the FAT value

2. Record if any comments in the Indication and Correction Report attached.

Test Document:

Refer SAT Test Sheet

SAT for LVAC High voltage test

9. Test Reports

All Site Test Report Formats is attached for the Individual tests.

ATTACHED TEST FORMATS

1. SAT FOR LVAC CT TEST

a) INCOMER CT TEST

b) OUTGOING CT TEST

2. SAT FOR LVAC VT TEST

3. SAT FOR LVAC MCCB TEST

4. SAT FOR LVAC BREAKER WITH MICROLOGIC RELAY TEST

5. SAT FOR LVAC AMMETER CALIBRATION

6. SAT FOR LVAC VOLTMETER CALIBRATION

7. SAT FOR LVAC TRIP CKT SUPR-RELAY TEST

8. SAT FOR LVAC BUSBAR RESISTANCE TEST

9. SAT FOR LVAC HIGH VOLTAGE TEST

1. SAT FOR LVAC CT TEST

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR CURRENT TRANSFORMER

33/11KV SS-1

Drawing No

2908-2-54-0206

LVAC

Equipment

CURRENT TRANSFORMER

Site location

Bay No

1.1 METERING CT: INCOMER-01 & 02

Make

Sl. No

SACI

R-

Y-

B-

1.2. Name Plate Details

CT

Desgn.

Core No.

Class

Ratio

Rct

KVP

Burden

Purpose

CT1

1200/1

10VA

KW-Metering

CT2

1200/1

10VA

KW-Metering

CT3

1200/1

10VA

KW-Metering

1.3. Insulation Resistance Measurement:

R-PHASE

Y-PHASE

B-PHASE

PRI TO EARTH

PRI TO SEC

SEC TO EARTH

Note: Primary Earth done with 1KV and rest with 500 V Megger for 1 Min

1.4. Polarity Test

CT

Designation

CORE NO

TERMINAL

CT1-3

S1-S2

R-PH

Y-PH

B-PH

1.5. CT Winding Resistance

MEASURED RESISTANCE (IN m )

CT Desgn.

CORE NO

TERMINAL

R-PH

CT1-3

Y-PH

B-PH

S1-S2

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 1 of 2

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR CURRENT TRANSFORMER

33/11KV SS-1

Drawing No

2908-2-54-0206

LVAC

Equipment

CURRENT TRANSFORMER

Site location

Bay No

1.6. Knee Point Voltage measurement:

CT Desgn.

CORE NO

TERMINAL

CT1-3

CORE1

S1-S2

R PHASE

Vk

(in

Imag

Volts)

(in mA)

Y PHASE

Vk

(in

Imag

Volts)

(in mA)

B PHASE

Vk

(in

Imag

Volts)

(in mA)

1.7. Ratio Test

CT

Designation

Core

Terminal

Injected Primary

Current (Amps)

Expected

Sec.Current

(Amps)

CT1

R-Phase

S1-S2

600

0.500

CT2

Y-Phase

S1-S2

600

0.500

CT3

B-Phase

S1-S2

600

0.500

Measured

Sec.Current

(Amps)

% Error

1.8. Check List for Print out

1. CT ratio and polarity test ( for all cores and taps)

2. Knee point test ( for all cores and taps)

3. Winding resistance test (for all core & taps)

:

:

:

1.9. General Checks

1. Shorting of all unused cores

2. Check for tightness of all CT terminals

:

:

1.10 REMARK:

Sl.no

Equipment / Instrument

Make

Equipment Sl No.

1

2

3

4

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 2 of 2

Calibration Due

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR CURRENT TRANSFORMER

33/11KV SS-1

Drawing No

2908-2-54-0206

LVAC

Equipment

CURRENT TRANSFORMER

Site location

Bay No

1. OUTGOING FEEDER CTS: Q2, Q5, Q23 & Q28

Make

SACI

Sl. No

R-

Y-

B-

2. Name Plate Details

CT

Desgn.

Core No.

Class

Ratio

Rct

KVP

Burden

Purpose

CT1

250/1A

5VA

Metering

CT2

250/1A

5VA

Metering

CT3

250/1A

5VA

Metering

3. Insulation Resistance Measurement:

Ref

R-PHASE

Y-PHASE

B-PHASE

PRI TO EARTH

PRI TO SEC

SEC TO EARTH

Note: Primary Earth done with 1KV and rest with 500 V Megger for 1 Min

4. Polarity Test:

CT

Designation

CORE NO

TERMINAL

CT1-3

S1-S2

R-PH

Y-PH

B-PH

5. CT Winding Resistance

CT Desgn.

CORE NO

TERMINAL

CT1-3

S1-S2

MEASURED RESISTANCE (IN m )

R-PH

Y-PH

B-PH

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 1 of 2

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR CURRENT TRANSFORMER

33/11KV SS-1

Drawing No

2908-2-54-0206

LVAC

Equipment

CURRENT TRANSFORMER

Site location

Bay No

6. Knee Point Voltage measurement

CT Desgn.

CORE NO

TERMINAL

CT1-3

CORE1

S1-S2

R PHASE

Vk

(in

Imag

Volts)

(in mA)

Y PHASE

Vk

(in

Imag

Volts)

(in mA)

B PHASE

Vk

(in

Imag

Volts)

(in mA)

7. Ratio Test

CT

Designation

PHASE

Terminal

Injected Primary

Current (Amps)

Expected

Sec.Current

(Amps)

CT1

R-Phase

S1-S2

125

0.5

CT2

CT3

Y-Phase

B-Phase

S1-S2

S1-S2

125

125

0.5

0.5

Measured

Sec.Current

(Amps)

% Error

8. Check List for Print out

1. CT ratio and polarity test ( for all cores and taps)

2. Knee point test ( for all cores and taps)

3. Winding resistance test (for all core & taps)

:

:

:

9. General Checks

1. Shorting of all unused cores

2. Check for tightness of all CT terminals

3. Neutral Earthing / Single point Earthing

:

:

:

10. Remarks

Sl.no

Equipment / Instrument

Make

Equipment Sl No.

1

2

3

4

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 2 of 2

Calibration Due

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR CURRENT TRANSFORMER

33/11KV SS-1

Drawing No

2908-2-54-0206

LVAC

Equipment

CURRENT TRANSFORMER

Site location

Bay No

1. OUTGOING FEEDER CTS: Q3, Q6, Q9 & Q20

Make

SACI

Sl. No

R-

Y-

B-

2. Name Plate Details

CT

Desgn.

Core No.

Class

Ratio

Rct

KVP

Burden

Purpose

CT1

200/1A

5VA

Metering

CT2

200/1A

5VA

Metering

CT3

200/1A

5VA

Metering

3. Insulation Resistance Measurement:

Ref

R-PHASE

Y-PHASE

B-PHASE

PRI TO EARTH

PRI TO SEC

SEC TO EARTH

Note: Primary Earth done with 1KV and rest with 500 V Megger for 1 Min

4. Polarity Test:

CT

Designation

CORE NO

TERMINAL

CT1-3

S1-S2

R-PH

Y-PH

B-PH

5. CT Winding Resistance

CT Desgn.

CORE NO

TERMINAL

CT1-3

S1-S2

MEASURED RESISTANCE (IN m )

R-PH

Y-PH

B-PH

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 1 of 2

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR CURRENT TRANSFORMER

33/11KV SS-1

Drawing No

2908-2-54-0206

LVAC

Equipment

CURRENT TRANSFORMER

Site location

Bay No

6. Knee Point Voltage measurement

CT Desgn.

CORE NO

TERMINAL

CT1-3

CORE1

S1-S2

R PHASE

Vk

(in

Imag

Volts)

(in mA)

Y PHASE

Vk

(in

Imag

Volts)

(in mA)

B PHASE

Vk

(in

Imag

Volts)

(in mA)

7. Ratio Test

CT

Designation

PHASE

Terminal

Injected Primary

Current (Amps)

Expected

Sec.Current

(Amps)

CT1

R-Phase

S1-S2

100

0.5

CT2

CT3

Y-Phase

B-Phase

S1-S2

S1-S2

100

100

0.5

0.5

Measured

Sec.Current

(Amps)

% Error

8. Check List for Print out

1. CT ratio and polarity test ( for all cores and taps)

2. Knee point test ( for all cores and taps)

3. Winding resistance test (for all core & taps)

:

:

:

9. General Checks

1. Shorting of all unused cores

2. Check for tightness of all CT terminals

3. Neutral Earthing / Single point Earthing

:

:

:

10. Remarks

Sl.no

Equipment / Instrument

Make

Equipment Sl No.

1

2

3

4

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 2 of 2

Calibration Due

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR CURRENT TRANSFORMER

33/11KV SS-1

Drawing No

2908-2-54-0206

LVAC

Equipment

CURRENT TRANSFORMER

Site location

Bay No

1. OUTGOING FEEDER CTS: Q1 & Q19

Make

SACI

Sl. No

R-

Y-

B-

2. Name Plate Details

CT

Desgn.

Core No.

Class

Ratio

Rct

KVP

Burden

Purpose

CT1

400/1A

5VA

Metering

CT2

400/1A

5VA

Metering

CT3

400/1A

5VA

Metering

3. Insulation Resistance Measurement:

Ref

R-PHASE

Y-PHASE

B-PHASE

PRI TO EARTH

PRI TO SEC

SEC TO EARTH

Note: Primary Earth done with 1KV and rest with 500 V Megger for 1 Min

4. Polarity Test:

CT

Designation

CORE NO

TERMINAL

CT1-3

S1-S2

R-PH

Y-PH

B-PH

5. CT Winding Resistance

CT Desgn.

CORE NO

TERMINAL

CT1-3

S1-S2

MEASURED RESISTANCE (IN m )

R-PH

Y-PH

B-PH

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 1 of 2

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR CURRENT TRANSFORMER

33/11KV SS-1

Drawing No

2908-2-54-0206

LVAC

Equipment

CURRENT TRANSFORMER

Site location

Bay No

6. Knee Point Voltage measurement

CT Desgn.

CORE NO

TERMINAL

CT1-3

CORE1

S1-S2

R PHASE

Vk

(in

Imag

Volts)

(in mA)

Y PHASE

Vk

(in

Imag

Volts)

(in mA)

B PHASE

Vk

(in

Imag

Volts)

(in mA)

7. Ratio Test

CT

Designation

PHASE

Terminal

Injected Primary

Current (Amps)

Expected

Sec.Current

(Amps)

CT1

R-Phase

S1-S2

200

0.5

CT2

CT3

Y-Phase

B-Phase

S1-S2

S1-S2

200

200

0.5

0.5

Measured

Sec.Current

(Amps)

% Error

8. Check List for Print out

1. CT ratio and polarity test ( for all cores and taps)

2. Knee point test ( for all cores and taps)

3. Winding resistance test (for all core & taps)

:

:

:

9. General Checks

1. Shorting of all unused cores

2. Check for tightness of all CT terminals

3. Neutral Earthing / Single point Earthing

:

:

:

10. Remarks

Sl.no

Equipment / Instrument

Make

Equipment Sl No.

1

2

3

4

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 2 of 2

Calibration Due

2. SAT FOR LVAC VT TEST

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR VOLTAGE TRANSFORMER

33/11 KV S/S-1

Drawing No

2908-2-54-0206

LVAC

Equipment

VOLTAGE TRANSFORMER

Site location

Bay No

For 1CPT1, 2CPT1, 3CPT1, 4CPT1

1. Name Plate Details

:

Make

R-

Y-

Sl. No

Ratio

: 415V/3 / 110V/3

Burden

: 50VA

Purpose

: Protection/Metering

B-

2. Insulation Resistance Measurement:

Minimum Value: 1M /KV

Temperature

Applied Voltage

(VDC)

500 V

Description

Primary Earth

Primary- Secondary

500 V

Secondary -Earth

500 V

3. Polarity Test

R-PH(G)

Y-PH(G)

C

B-PH(G)

VT Designation

CORE NO

TERMINAL

XCPT1

CORE 1

1r - 1n

R-PH

Y-PH

B-PH

4. VT Winding Resistance:

Temperature:

VT Designation

CORE NO

TERMINAL

XCPT1

CORE 1

1r - 1n

MEASURED RESISTANCE ( IN OHMS)

R-PH

Y-PH

B-PH

At ambT

At ambT

At ambT

At 75 C

At 75 C

At 75 C

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 1 of 2

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

Site location

Bay No

SITE ACCEPTANCE TEST FOR VOLTAGE TRANSFORMER

33/11 KV S/S-1

Drawing No

2908-2-54-0206

LVAC

Equipment

VOLTAGE TRANSFORMER

5. Primary Injection Test / Ratio Test:

VT

Designation

PHASE

TERMINAL

XCPT1

XCPT1

XCPT1

R-PH

Y-PH

B-PH

1r - 1n

APPLIED PRIMARY

VOLTS

CALC

SEC.VOLTS

MEASURED

SEC.VOLTS

% ERROR

6. Check List for Print out

VT ratio and polarity test ( for all cores and taps)

VT secondary winding resistance ( for all cores and taps)

:

:

7. General Checks

General visual inspection

Name plate details

HV Terminal Marking

LV Terminal Marking

Check for tightness of all VT terminals

:

:

:

:

:

8. General Checks

:

MCB rating

Equipment Grounding System

:

:

9. Remarks

Sl.no

Equipment / Instrument

Make

Equipment Sl No.

1

2

3

4

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 2 of 2

Calibration Due

3. SAT FOR LVAC MCCB TEST

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END

EXTENSION OF RAS LAFFAN CITY GC081117B0

Site location

Bay No

SITE ACCEPTANCE TEST FOR MCCB

Drawing No

2908-2-54-0206

Equipment

MCCB

33/11KV S/S-1

LVAC

MOULDED CASE CB

1. Name Plate Details:

Make

: MERLIN GERIN

Feeder

Type

Frequency

: 50 Hz

Aux. Volts

Nominal Current

Range

Feeder Ratings

2. TRIP TEST

LONG INVERSE OVER CURRENT:

Operating time measured at 2Is (sec)

Set

(Is) Amp

Phase

R Phase

Y-Phase

B-Phase

MCCB Found Healthy

3. REMARK

Sl.no

YES / NO

:

Equipment / Instrument

Make

Equipment Sl No.

1

2

LARSEN & TOUBRO

QATAT PETROLEUM

Signature

Signature

Name

Name

Date

Date

Doc.No.

Rev

Calibration Due

4. SAT FOR LVAC MICROLOGIC

RELAY TEST

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

Site location

Bay No

33/11KV S/S-1

LVAC

SITE ACCEPTANCE TEST FOR MOULDED CASE C.B

Drawing No

2908-2-54-0206

Equipment

MCCB WITH MICROLOGIC

MOULDED CASE WITH MICROLOGIC TEST FOR QM1, QM2 & QB

1. NAME PLATE DETAILS:

MAKE

MERLIN GERLIN

TYPE

NW12H1

FREQUENCY

50HZ

NOMINAL CURRENT

1250 A

AUX VOLTS

110 V DC

SERIAL NO

SETTINGS :

SHORT CIRCUIT

INSTANETANEOUS

EARTH FAULT

2. BREAKER TESTS

2.1 SHORT CIRCUIT:

PHASE

SETTING OF CURRENT

INJECTED CURRENT

OPERATED TIME

SETTING OF CURRENT

INJECTED CURRENT

OPERATED TIME

SETTING OF CURRENT

INJECTED CURRENT

OPERATED TIME

R - PH

Y - PH

B - PH

2.2 INSTANETANEOUS

PHASE

R - PH

Y - PH

B - PH

2.3 EARTH FAULT

PHASE

NEUTRAL

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 1 of 2

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

Site location

Bay No

33/11KV S/S-1

LVAC

SITE ACCEPTANCE TEST FOR MOULDED CASE C.B

Drawing No

2908-2-54-0206

Equipment

MCCB WITH MICROLOGIC

3. Tripping of CB By simulating of Relay Operation

1. Relay found Healthy

: Yes / No

2. Ammeter and Selector switch Found Healthy

: Yes / No

3. Aux contacts

: ok / with comments

4. REMARK:

Sl.no

Equipment / Instrument

Make

Equipment Sl No.

1

2

3

4

LARSEN & TOUBRO

QATAR PETROLEUM

Signature

Signature

Name

Date

Doc. No.

Name

Date

Page 2 of 2

Calibration Due

5. SAT FOR LVAC AMMETER

CALIBRATION

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END

EXTENSION OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR AMMETER CALIBRATION

33/11KV S/S-01

Drawing No

2908-2-54-0206

LVAC

Equipment

AMMETER

Site location

Bay No

AMMETER CALIBRATION

1.

Name Plate Details:

Make

Feeder Ref

Type

Range

S.NO

2. MEASUREMENT TEST :

Secondary Injected Current in

Amps

3. Ammeter Found Healthy:

Expected Current in

(A)

Ammeter Reading in (A)

% Error

YES / NO

Instruments Used:

SL.NO

DESCRIPTION

MAKE

EQUIPMENT

CALIBRATION

CALIBRATION

SL.NO

ON DATE

DUE DATE

1

2

3.

LARSEN & TOUBRO

QATAT PETROLEUM

Signature

Signature

Name

Name

Date

Date

Doc.No.

Rev

6. SAT FOR LVAC VOLTMETER

CALIBRATION

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END

EXTENSION OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR VOLTMETER CALIBRATION

33/11KV S/S-01

Drawing No

2908-2-54-0206

LVAC

Equipment

VOLTMETER

Site location

Bay No

VOLTMETER CALIBRATION

1.

Name Plate Details:

Make

Feeder Ref

Type

Range

S.NO

2. MEASUREMENT TEST:

Injected Voltage in Volts

Expected Voltage in

(kv)

Voltmeter Reading in (kv)

% Error

3. Voltmeter Found Healthy: YES / NO

Instruments Used:

SL.NO

Description

MAKE

EQUIPMENT

SL.NO

CALIBRATION

ON DATE

CALIBRATION

DUE DATE

1

2

LARSEN & TOUBRO

QATAT PETROLEUM

Signature

Signature

Name

Name

Date

Date

Doc.No.

Rev

7. SAT FOR TRIP CKT SUPR

RELAY

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR TRIP CKT SUPRV RELAY

33/11KV S/S-01

Drawing No

2908-BG35-4004

LVAC

Equipment

XR-350

Site location

Bay No

1. Name Plate Rating Details of the Equipment

Relay Make

REYROLLE

Relay Model

XR350

MLFB Number

7PG1753-3CC10-4BE0

Serial Number

Rated Voltage

125 VDC

Rated Frequency

DC

Contacts Details

2NO; 2NC

2. General Inspection of Relay

S.No

Description

Installation and Correct Wiring as per drawing

Terminal Tightness

Relay Earth Connected to Local Earth Bar

Pass

3. Resistance Check

Measure the resistance of each coil and its external resistor; record the values in the following table

Element

Coil Resistance

External Resistance

A

B

C

4. Secondary Injection

Inject the relay including the external resistor, and record the values of pick-up voltage and current in

the following table.

Element

Pick-Up Volts

Pick-Up Current

A

B

C

LARSEN & TOUBRO

QATAT PETROLEUM

Signature

Signature

Name

Name

Date

Date

Doc.No.

Rev

Fail

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END EXTENSION

OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR TRIP CKT SUPRV RELAY

33/11KV S/S-01

Drawing No

2908-BG35-4004

LVAC

Equipment

XR-350

Site location

Bay No

5. Referring to the circuit diagram, replace the trip link with an ammeter and, with the trip circuit

operational, measure the trip circuit current with the breaker in the open and closed state.

Breaker Open

mA

Breaker Closed

mA

6. With CB closed short in turn coil A and check for no trip

7. Check for relay Operation by breaking the trip circuit continuity

Instruments Used:

Sl.no

Description

Make

Equipment

Calibration

Calibration

Sl.no

On date

Due date

1

2

LARSEN & TOUBRO

QATAT PETROLEUM

Signature

Signature

Name

Name

Date

Date

Doc.No.

Rev

8. SAT FOR MAIN CIRCUIT

RESISTANCE TEST

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END

EXTENSION OF RAS LAFFAN CITY GC081117B0

Site location

Bay No

SITE ACCEPTANCE TEST FOR LVAC MAIN CIRCIUT RESISTANCE

33/11KV S/S-01

Drawing No

2908-2-54-0206

LVAC

Equipment

BUSBAR

Make

: BIN GHALIB

Type

: 3PH 4 BUS

Serial No.

Rated current

: 1600A

Rated frequency

: 50HZ

Rated Voltage

: 415V

Short time rating

: 50KA/SEC

Control voltage

: 110V DC

Sl.No.

Contact Resistance Between

Cubicles

COL:1- COL:02

COL:1- COL:03

COL:1- COL:04

COL:1- COL:05

COL:1- COL:06

COL:1- COL:08

COL:1- COL:09

COL:1- COL:10

COL:1- COL:11

10

COL:1- COL:12

11

COL:1- COL:13

12

---

13

---

Bus bars Found Healthy :

R-phase in

micro-ohms

Y-phase in

micro-ohms

B-phase in

micro-ohms

NEUTRAL in

micro-ohms

YES / NO

REMARK:

Sl.no

Equipment / Instrument

Make

Equipment Sl No.

Calibration Due

1

2

LARSEN & TOUBRO LTD

QATAR PETROLEUM

Signature

Signature

Name

Name

Date

Doc. No.

Date

Page 1 of 1

9. SAT FOR BUSBAR HIGH

VOLTAGE TEST

CONTRACT: EPIC FOR ELECTRICAL AND TELECOM UTILITIES FOR

SUPPORT SERVICES AREA PHASE I & II AND WEST END

EXTENSION OF RAS LAFFAN CITY GC081117B0

SITE ACCEPTANCE TEST FOR LVAC HV TEST

33/11KV S/S-01

Drawing No

2908-2-54-0206

LVAC

Equipment

LVAC BUSBAR

Site location

Bay No

HIGH VOLTAGE TEST FOR 415V LVAC BOARD

Make

: BIN GHALIB

Type

: 3PH 4 BUS

Serial No.

Rated current

: 1600A

Rated frequency

: 50HZ

Rated Voltage

: 415V

Short time rating

: 50KA/SEC

1. INSULATION RESISTANCE TEST:

(1KV FOR 1 MINUTE)

MEGGER VALUE BEFORE

HV TEST

MAIN CIRCUIT

MEGGER VALUE AFTER

HV TEST

R (Y+B+N+PE)

Y (B+R+N+PE)

B (N+R+Y+PE)

N (PE+R+Y+B)

2. HV VOLTAGE : 2000V AC FOR 60SEC

REF

Leakage Current in mA

R (Y+B+N+PE)

Y (B+R+N+PE)

B (N+R+Y+PE)

N (PE+R+Y+B)

BUS BAR FOUND HEALTHY:

OK / NOT

3. REMARK:

Sl.no

Equipment / Instrument

Make

Equipment Sl No.

1

2

LARSEN & TOUBRO

QATAT PETROLEUM

Signature

Signature

Name

Name

Date

Date

Doc.No.

Rev

Calibration Due

You might also like

- 1 - Hi Pot Test Procedure For SwitchyardDocument6 pages1 - Hi Pot Test Procedure For Switchyardbayu dewanto100% (1)

- Ac Panel Test ProsedureDocument6 pagesAc Panel Test ProsedureUtku Can KılıçNo ratings yet

- Test On 110kV Power Cable After Installation 1Document7 pagesTest On 110kV Power Cable After Installation 1Hicham BelmaatiNo ratings yet

- Gms Ele Itp 001 HV & LV SwitchgearDocument12 pagesGms Ele Itp 001 HV & LV Switchgearnidnitrkl051296100% (1)

- Test Procedure TXDocument4 pagesTest Procedure TXVasu100% (1)

- MV Cable Hi-Pot Test ShetDocument1 pageMV Cable Hi-Pot Test ShetAhmad Dagamseh100% (1)

- Voltage Transformer CommissioningDocument12 pagesVoltage Transformer CommissioningjamilNo ratings yet

- Testing of Circuit Breaker Classification of The Test: (H) Short Line Fault Tests (N) Reactor Current Switching TestsDocument14 pagesTesting of Circuit Breaker Classification of The Test: (H) Short Line Fault Tests (N) Reactor Current Switching TestsRANGASWAMY SNo ratings yet

- MV&LV Switchgear Test ReportDocument4 pagesMV&LV Switchgear Test ReportUtku Can Kılıç100% (1)

- Electrical TestDocument3 pagesElectrical TestAce SpionNo ratings yet

- Elect 03 Method Statement For Testing of MV Cables For CSE at SS1Document8 pagesElect 03 Method Statement For Testing of MV Cables For CSE at SS1Qwe7 Al-Al50% (2)

- E14-B LV Switchboard and MCCDocument3 pagesE14-B LV Switchboard and MCCAmyNo ratings yet

- Cpr-3 - Catalouge Rele RubberDocument2 pagesCpr-3 - Catalouge Rele Rubbermanuel100% (1)

- Secondary Injection KitDocument9 pagesSecondary Injection KitSamundar KhanNo ratings yet

- Notes On Tripping RelaysDocument7 pagesNotes On Tripping RelaysSenthil KumarNo ratings yet

- Testing Procedure For Potential Transormer: Prepared byDocument1 pageTesting Procedure For Potential Transormer: Prepared byGuru MishraNo ratings yet

- 007 LV & Control Cable Pre-CommissioningDocument6 pages007 LV & Control Cable Pre-CommissioningMohamed KasemNo ratings yet

- SwitchgearDocument25 pagesSwitchgearalstom100% (1)

- LV Dielectric TestingDocument2 pagesLV Dielectric TestingwaseemsamsodienNo ratings yet

- Site Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)Document3 pagesSite Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)m khNo ratings yet

- Testing and Commissioning of MetalClad SwitchgearDocument3 pagesTesting and Commissioning of MetalClad SwitchgearPradeep Kumar MaraptlaNo ratings yet

- 57-Power Transformer Installation ChecklistDocument4 pages57-Power Transformer Installation Checklistprithiviraj50% (2)

- Batteries For UPS PDFDocument4 pagesBatteries For UPS PDFrajpre1213No ratings yet

- Testing Procedures: CT Test FormatDocument2 pagesTesting Procedures: CT Test FormatEngr Zainulabidin KaimkhaniNo ratings yet

- Oil Filled Transformers Standard Testing ProcedureDocument17 pagesOil Filled Transformers Standard Testing ProcedureNajeeb AbbasiNo ratings yet

- Quality Procedure - Testing ManualDocument43 pagesQuality Procedure - Testing Manualsheik hussain100% (1)

- Testing and Commissioning of Substation DC SystemDocument4 pagesTesting and Commissioning of Substation DC Systemjob_pNo ratings yet

- Job Procedure 02 For TRANSFORMERDocument7 pagesJob Procedure 02 For TRANSFORMERSoumik KarNo ratings yet

- Check List For UPSDocument1 pageCheck List For UPSsiruslara6491No ratings yet

- Bus BArDocument822 pagesBus BArCHANDER SINGH WARKADE100% (1)

- Voltage Withstand TestDocument4 pagesVoltage Withstand Testmshahidshaukat100% (1)

- Testing and Commissioning Procedure: 2007 EDITION (Incorporating Corrigendum No. Gsee01)Document98 pagesTesting and Commissioning Procedure: 2007 EDITION (Incorporating Corrigendum No. Gsee01)Khairil ZainudinNo ratings yet

- Generator Dynamic Testing Procedure 09.06.14Document19 pagesGenerator Dynamic Testing Procedure 09.06.14thegemishere0% (1)

- Testing and Commissioning ProceduresDocument8 pagesTesting and Commissioning Proceduresbhukya lachiramNo ratings yet

- Method Statemnet For 11kV Cable SATDocument47 pagesMethod Statemnet For 11kV Cable SATZaheer Ahamed92% (12)

- Department of Electrical & InstrumentationDocument18 pagesDepartment of Electrical & InstrumentationIzul Hakim100% (1)

- 11kv SwitchgearDocument12 pages11kv Switchgearmuhammad nazir0% (1)

- CL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00Document9 pagesCL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00MohamedElmahdyNo ratings yet

- Gis Testing RequirementsDocument7 pagesGis Testing Requirementswaqas_a_shaikh4348No ratings yet

- 01 - 4 Test Report For Power Transformer 1Document7 pages01 - 4 Test Report For Power Transformer 1PUSHPARAJ MAURYANo ratings yet

- ACB Protective RelayDocument6 pagesACB Protective RelayUrsula JohnsonNo ratings yet

- What Is VLFDocument9 pagesWhat Is VLFnysa6987No ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeederDocument8 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeedererstendrainNo ratings yet

- SP0407C01 HV Cable Commissioning Test ReportDocument2 pagesSP0407C01 HV Cable Commissioning Test Reportkajale.shrikantNo ratings yet

- Secondary Injection TestingDocument5 pagesSecondary Injection Testing322399mk7086100% (3)

- Difference Between PSC & PFCDocument3 pagesDifference Between PSC & PFCBatangKidlat100% (1)

- Power Transformer Testing & Commissioning Procedure - Rev R0Document16 pagesPower Transformer Testing & Commissioning Procedure - Rev R0nanaNo ratings yet

- Protection Relay Test ReportDocument6 pagesProtection Relay Test ReportahmedelgharibNo ratings yet

- Switchgear and Circuit Breaker - TestingDocument18 pagesSwitchgear and Circuit Breaker - TestingSyam KushainiNo ratings yet

- Testing and Commissioning of MetalClad SwitchgearDocument4 pagesTesting and Commissioning of MetalClad Switchgearvijaydev75100% (1)

- Commissioning Report 24V: Instruction PageDocument8 pagesCommissioning Report 24V: Instruction PageTrịnh Đức HạnhNo ratings yet

- Project Specification For Field Testing of Electrical SystemsDocument22 pagesProject Specification For Field Testing of Electrical SystemsJayce PinedaNo ratings yet

- Low Voltage Electrical Switchboard Testing ProceduresDocument1 pageLow Voltage Electrical Switchboard Testing Proceduresrozi54No ratings yet

- Motor Electric Test RecordDocument1 pageMotor Electric Test RecordArka HatiNo ratings yet

- Sat Procedure For MV SWGR Panels PDFDocument4 pagesSat Procedure For MV SWGR Panels PDFAmr ElkadyNo ratings yet

- MN000301R171Document24 pagesMN000301R171juancgr77No ratings yet

- CCM 2.5MVATX QASCO CommissioningTest Report.Document13 pagesCCM 2.5MVATX QASCO CommissioningTest Report.Ginger TurnerNo ratings yet

- Maint - Check List - Oil Filled TransforsDocument2 pagesMaint - Check List - Oil Filled TransforsramNo ratings yet

- Method Statement For DC PANELDocument6 pagesMethod Statement For DC PANELUtku Can KılıçNo ratings yet

- Method Statement For Battery ChargerDocument6 pagesMethod Statement For Battery ChargerUtku Can Kılıç100% (1)

- Site Acceptance Test For 132Kv Gis: Make Name / Type of Equipment Serial Number Rating Power Voltage CurrentDocument2 pagesSite Acceptance Test For 132Kv Gis: Make Name / Type of Equipment Serial Number Rating Power Voltage CurrentBalamurugan SelvarajNo ratings yet

- Site Acceptance Test For 33Kv Gis: Make Name / Type of Equipment Serial Number Rating Power Voltage CurrentDocument1 pageSite Acceptance Test For 33Kv Gis: Make Name / Type of Equipment Serial Number Rating Power Voltage CurrentBalamurugan SelvarajNo ratings yet

- Site Acceptance Test For 132Kv Gis: Make Name / Type of Equipment Serial Number Rating Power Voltage CurrentDocument2 pagesSite Acceptance Test For 132Kv Gis: Make Name / Type of Equipment Serial Number Rating Power Voltage CurrentBalamurugan SelvarajNo ratings yet

- Recurring Deposits Maturity Value Calculator: RD CalculationDocument4 pagesRecurring Deposits Maturity Value Calculator: RD CalculationBalamurugan SelvarajNo ratings yet

- Commissioning Test Procedure Subtransmission CablesDocument8 pagesCommissioning Test Procedure Subtransmission Cablesjkhgvdj mnhsnjkhgNo ratings yet

- Pre-Com. Procedure For Tertiray - 415V SWGRDocument13 pagesPre-Com. Procedure For Tertiray - 415V SWGRBalamurugan SelvarajNo ratings yet

- Transformer Protections: Prepared By, S.BalamuruganDocument32 pagesTransformer Protections: Prepared By, S.BalamuruganBalamurugan SelvarajNo ratings yet

- ANR96 IM125-U-A v4.1Document58 pagesANR96 IM125-U-A v4.1Melissa OspinaNo ratings yet

- TSSR 2g Grahafamily3 PKMDocument43 pagesTSSR 2g Grahafamily3 PKMHaryo WNo ratings yet

- NS500 Installation Manual PDFDocument300 pagesNS500 Installation Manual PDFAce Daniel100% (1)

- QuestionsDocument7 pagesQuestionssayarlayNo ratings yet

- Pre Installationfor Opgw 48 FDocument5 pagesPre Installationfor Opgw 48 FMayank PorwalNo ratings yet

- O&M MANUAL - Grease Lubrication System PDFDocument81 pagesO&M MANUAL - Grease Lubrication System PDFsundyaNo ratings yet

- Acceptance Test FormDocument4 pagesAcceptance Test Formareza983691No ratings yet

- Mil STD 461eDocument111 pagesMil STD 461eparam_scribdNo ratings yet

- Optical Connectivity CatalogDocument49 pagesOptical Connectivity CatalogJosephus RavaneraNo ratings yet

- General Packet Radio System & MMSDocument47 pagesGeneral Packet Radio System & MMSAzeemuddin KhajaNo ratings yet

- Saes P 116Document25 pagesSaes P 116giblu111100% (2)

- Nortel Voip 1120E/1140E Quick Reference Guide: Northwestern University Information TechnologyDocument2 pagesNortel Voip 1120E/1140E Quick Reference Guide: Northwestern University Information TechnologyAriel Añino DiazNo ratings yet

- GE Cordless Phone Manual 27851FE1 - IBDocument2 pagesGE Cordless Phone Manual 27851FE1 - IBSurvivalist1No ratings yet

- Advanced Cable Fault Locating - Oct 11-06Document302 pagesAdvanced Cable Fault Locating - Oct 11-06wroy_373837302100% (1)

- Nokia PC Suite 7.1: User'S Guide ForDocument29 pagesNokia PC Suite 7.1: User'S Guide ForVaibhav ZawarNo ratings yet

- BT Wholesale Broadband Connect (WBC) Fibre To The Premise (FTTP)Document5 pagesBT Wholesale Broadband Connect (WBC) Fibre To The Premise (FTTP)sirtaj123No ratings yet

- Radio Receivers ProblemsDocument9 pagesRadio Receivers ProblemsJineshBagadia0% (1)

- Parts Manual - Carro de Limpeza TennantDocument184 pagesParts Manual - Carro de Limpeza TennantMarcelo LopesNo ratings yet

- NEC ResidentialChanges2008Document2 pagesNEC ResidentialChanges2008ap00No ratings yet

- Quadband CombinerDocument2 pagesQuadband CombinerAnuradha ThilakarathnaNo ratings yet

- How To Fix Battery Drain Problem On iOS - EditedDocument2 pagesHow To Fix Battery Drain Problem On iOS - EditedalexNo ratings yet

- Manual Harris Ts250Document113 pagesManual Harris Ts250Efrain NavaNo ratings yet

- Vodafone K4201 Quick Start GuideDocument20 pagesVodafone K4201 Quick Start GuideBojezz CelebsNo ratings yet

- gx5500s MoDocument100 pagesgx5500s MoHenry AlvaxNo ratings yet

- Introducing The Powerful and Sleek Lenovo Ideatab S2110.: Dimensions: Operating System: Connectivity/RadiosDocument2 pagesIntroducing The Powerful and Sleek Lenovo Ideatab S2110.: Dimensions: Operating System: Connectivity/RadiossoporteproNo ratings yet

- Data Analysis Cases With Real Data Case 3.1Document5 pagesData Analysis Cases With Real Data Case 3.1nikhiltiwari12389No ratings yet

- Tutorials rj45 PDFDocument2 pagesTutorials rj45 PDFmihaidumitruNo ratings yet

- TH 3jrs ManualDocument11 pagesTH 3jrs ManualOscar NavaNo ratings yet

- Valere HSeriesRectifierFlyer 110105Document2 pagesValere HSeriesRectifierFlyer 110105Mariano Andres TorresNo ratings yet

- eBILL Oct2016 1.48527906Document8 pageseBILL Oct2016 1.48527906norezanharudinNo ratings yet