Professional Documents

Culture Documents

C210 WML 605

Uploaded by

Efrén SantínOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C210 WML 605

Uploaded by

Efrén SantínCopyright:

Available Formats

0000-00

05-3

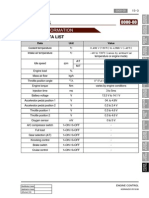

1. SPECIFICATION

Description

Operating type

Clutch cover

Clutch pedal

Clutch disc

Specification

Hydraulic type

Type

Diaphragm spring strap

Adjusting type

SATIC (Self Adjusting Technology with

Integrated Cassette) type

Type

Suspended type

Max. operating travel

135 3 mm

Pedal free play (Longitudinal)

7.1 3 mm

Pedal free play (Transverse)

3 mm

Type

Dry type single diaphragm (Rigid type)

Diameter of facing

Outer: 250 1 mm

Inner:160 0.8 mm

Thickness of disc

Free: 8.7 0.3 mm

When loaded: 8.0 0.2 (at 7,800 N)

Numbers of disc

Weight

1.18 kg

Flywheel type

DMF (Dual Mass Flywheel)

Setting load of clutch cover assembly

At least 7,800 N

Clutch master cylinder Operating travel

30 mm

Inner diameter

17.46 mm

Concentric slave

cylinder

Maximum operating travel

12.55 mm

Operating pressure

Maximum 50 bar

Clutch oil

Standard

DOT 3 or DOT 4

Capacity

As required

05-4

2. TIGHTENING TORQUE

Description

Tightening torque

Amount

Upper (17 mm)

85.0 to 100 Nm

Front (14 mm)

54.0 Nm + 20

Rear (14 mm)

51.3 to 56.7 Nm

Lower (14 mm)

56.0 to 62.0 Nm

Pressure plate assembly bolt (Hexagon 6 mm)

21.0 to 27.0 Nm

Concentric slave cylinder bolt (Hexagon 5 mm)

10 to 16 Nm

Concentric slave cylinder oil pipe nut

24.5 to 28.4 Nm

Remove the nut if it is

necessary. (Once

removed, apply the

Loctite on the thread

before installation.)

Master cylinder nut (12 mm)

7.8 to 17.6 Nm

Master cylinder oil pipe nut (10 mm)

14.7 to 17.6 Nm

Master cylinder push rod lock nut

8.8 to 13.7 Nm

Clutch oil chamber screw and bolt (10 mm)

3.9 to 7.8 Nm

Clutch housing bolt

Oil pipe nut (10 mm)

14.7 to 17.6 Nm

Clutch pedal mounting nut (12 mm)

7.8 to 17.6 Nm

Stopper bolt

16 to 22 Nm

0000-00

05-5

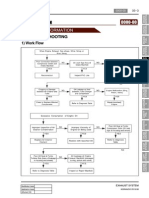

1. OVERVIEW

The hydraulic clutch transmits the force required to operate the clutch pedal to the concentric slave

cylinder fitted to the clutch housing as a hydraulic pressure.

(The hydraulic pressure is transmitted in the following order: Clutch pedal - Clutch master cylinder Clutch pipe - Clutch damper - Clutch pipe and hose - Concentric slave cylinder - Pressure plate Flywheel.)

If a driver depress the clutch pedal, the hydraulic pressure is generated in the master cylinder. It is

transmitted to the concentric slave cylinder through the pipe, resulting in the cylinder being forced out. At

this time, the clutch disc is forced against the cylinder by pushing the cover. This, in turn, remove the

flywheel from the pressure plate. As a consequence, the power from the engine will be cut off and the

gear change can be carried out.

05-6

2. SATIC (SELF ADJUSTING TECHNOLOGY WITH

INTEGRATED CASSETTE)

1) System Description

Function

On the conventional clutch, the pedal force tends

to increase in proportion to the degree of disc

run-out. However, the SATIC clutch has the

adjusting function which activates the cassette

system inserted to the clutch cover to maintain a

constant pedal force and clearance when the

disc runs out. (Unlike SAT type, SATIC type

does not need SST for clutch cover removal.)

Operation

Diaphragm spring rotates the adjusting

equipment as clutch disc is wearing and so,

pressure plate is pushed to clutch disc side at the

amount of wear.

Disc wear (Free play) Diaphragm spring

(1) Adjusting equipment (2, 3) Pressure

plate (4)

0000-00

05-7

2) Overview

Driving elements

The driving elements consist of two flat surfaces machined to a smooth finish.

One of these is the rear face of the engine flywheel and the other is the clutch pressure plate. The clutch

pressure plate is fitted into a clutch steel cover, which is bolted to the flywheel.

Driven elements

The driven element is the clutch disc with a splined hub which is free to slide lengthwise along the splines

of the input shaft.

The driving and driven elements are held in contact by spring pressure. This pressure is exerted by a

diaphragm spring in the clutch cover pressure plate assembly.

Operating Elements

The clutch "release" system consists of the clutch pedal and clutch release cylinder.

This system directly releases the clutch by using hydraulic pressure while the conventional clutch system

releases the clutch by using release lever and release fork. This system provides higher efficiency than

conventional clutch system, and its durability is superior.

- Clutch master cylinder (mounted on clutch pedal)

- Concentric slave cylinder pipe (mounted inside of transmission)

05-8

3) Layout

Clutch disc

Clutch cover assembly

Clutch setting jig

Dual mass flywheel (DMF)

Concentric slave cylinder

0000-00

05-9

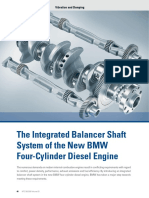

3. DUAL MASS FLYWHEEL (DMF)

The dual mass flywheel (DMF) is of having a mass divided into two halves.

While one mass is connected to the engine crankshaft, which is affected by the mass moment of inertia

of the engine, the other mass is affected by one of the transmission.

The divided dual masses are connected to the coil spring and damping system internally.

The DMF has the following benefits:

-

Reducing fuel consumption by lowering engine speed

Reducing rattling noise and vehicle vibration in all driving ranges

Reducing synchronization wear

Facilitating gear change

Protecting power train parts by preventing excessive load from being delivered

1. Primary flywheel

2. Secondary flywheel

3. Arc damper spring

4. Torque limiter

5. Ring gear

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Oferta Red LIneDocument10 pagesOferta Red LIneEfrén SantínNo ratings yet

- Major Dimension: Top ViewDocument16 pagesMajor Dimension: Top ViewEfrén SantínNo ratings yet

- C210 WML 203Document30 pagesC210 WML 203Efrén SantínNo ratings yet

- C210 WML 206Document20 pagesC210 WML 206Efrén SantínNo ratings yet

- C210 WML 104Document1 pageC210 WML 104Efrén SantínNo ratings yet

- C210 WML 208Document9 pagesC210 WML 208Efrén SantínNo ratings yet

- C210 WML 201Document13 pagesC210 WML 201Efrén SantínNo ratings yet

- C210 WML 102Document1 pageC210 WML 102Efrén SantínNo ratings yet

- C210 WML 103Document1 pageC210 WML 103Efrén SantínNo ratings yet

- C210 WML 202Document30 pagesC210 WML 202Efrén SantínNo ratings yet

- Troubleshooting: 1) Work FlowDocument4 pagesTroubleshooting: 1) Work FlowEfrén SantínNo ratings yet

- C210 WML 204Document10 pagesC210 WML 204Efrén SantínNo ratings yet

- C210 WML 209Document13 pagesC210 WML 209Efrén SantínNo ratings yet

- C210 WML 207Document7 pagesC210 WML 207Efrén SantínNo ratings yet

- C210 WML 212Document11 pagesC210 WML 212Efrén Santín0% (1)

- C210 WML 211Document11 pagesC210 WML 211Efrén SantínNo ratings yet

- C210 WML 213Document5 pagesC210 WML 213Efrén SantínNo ratings yet

- C210 WML 210Document12 pagesC210 WML 210Efrén SantínNo ratings yet

- C210 WML 214Document15 pagesC210 WML 214Efrén SantínNo ratings yet

- C210 WML 215Document48 pagesC210 WML 215Efrén SantínNo ratings yet

- Specifications: Smart Key Module Component Item SpecificationsDocument32 pagesSpecifications: Smart Key Module Component Item SpecificationsEfrén SantínNo ratings yet

- C210 WML 501Document14 pagesC210 WML 501Efrén SantínNo ratings yet

- Lamp Specifications: 1) Exterior LampsDocument41 pagesLamp Specifications: 1) Exterior LampsEfrén SantínNo ratings yet

- C210 WML 502Document6 pagesC210 WML 502Efrén SantínNo ratings yet

- C210 WML 505Document49 pagesC210 WML 505Efrén SantínNo ratings yet

- Unit Item SpecificationDocument22 pagesUnit Item SpecificationEfrén SantínNo ratings yet

- C210 WML 503Document120 pagesC210 WML 503Efrén SantínNo ratings yet

- C210 WML 506Document50 pagesC210 WML 506Efrén SantínNo ratings yet

- C210 WML 508Document24 pagesC210 WML 508Efrén SantínNo ratings yet

- Specification: Pin No. Specification Pin No. SpecificationDocument8 pagesSpecification: Pin No. Specification Pin No. SpecificationEfrén SantínNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BMWHEXDocument373 pagesBMWHEXcrazycuban29No ratings yet

- MT 75 Manual Transmission Overhaul GuideDocument31 pagesMT 75 Manual Transmission Overhaul GuidefrodarturNo ratings yet

- IVECO TRAKKER TRACTOR HEAD 4X2 and 6X4 (05-18-2016) PDFDocument2 pagesIVECO TRAKKER TRACTOR HEAD 4X2 and 6X4 (05-18-2016) PDFJohn YangNo ratings yet

- Iseki TM223 (H)Document132 pagesIseki TM223 (H)CangasGaileNo ratings yet

- Automotive Superlatives Attributes Largest, Smallest, FastDocument33 pagesAutomotive Superlatives Attributes Largest, Smallest, FastrohitNo ratings yet

- Parts Manual - 1629343 - (B222E) - (08-2007)Document738 pagesParts Manual - 1629343 - (B222E) - (08-2007)Nguyễn Văn Hùng100% (1)

- 2000 ATRA Seminar Manual ContentsDocument275 pages2000 ATRA Seminar Manual Contentschoco8450% (2)

- Mining Product CatalogueDocument19 pagesMining Product CataloguefrancanNo ratings yet

- Scissor Lift Suri CheclistDocument4 pagesScissor Lift Suri CheclistErnest Ngosa SawasawaNo ratings yet

- Work Boats Waflaf 2346 - 7760Document8 pagesWork Boats Waflaf 2346 - 7760Adhietama SumarsonoNo ratings yet

- Brochure Ew145b Prime t3 en 30 2000065 CDocument16 pagesBrochure Ew145b Prime t3 en 30 2000065 CM Asad UllahNo ratings yet

- Printing Machinery Maintenance 'L' Scheme SyllabusDocument75 pagesPrinting Machinery Maintenance 'L' Scheme SyllabusShione T MundawararaNo ratings yet

- CLUTCH Clutch System FIAT 500Document28 pagesCLUTCH Clutch System FIAT 500FSR1407100% (3)

- Backhoe Loader B877F Specs and FeaturesDocument8 pagesBackhoe Loader B877F Specs and FeaturesAL NOOR GROUPNo ratings yet

- Your Partner in Materials Handling.: Cat Lift TrucksDocument3 pagesYour Partner in Materials Handling.: Cat Lift Trucksjoao mariaNo ratings yet

- 16 S 2320tdDocument2 pages16 S 2320tdSanti BaiocchiNo ratings yet

- The Integrated Balancer Shaft System of The New BMW Four-Cylinder Diesel EngineDocument6 pagesThe Integrated Balancer Shaft System of The New BMW Four-Cylinder Diesel EngineZhihai DengNo ratings yet

- Cat Sos 793&793b TrucksDocument7 pagesCat Sos 793&793b TrucksmkNo ratings yet

- Characteristics of Chain DrivesDocument4 pagesCharacteristics of Chain DrivesOwa RoperezNo ratings yet

- Clean-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-AdjustDocument136 pagesClean-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-Adjust-Check-AdjustAlejo Pazmiño50% (2)

- Mtu Sales ProgramDocument36 pagesMtu Sales ProgrammajdirossrossNo ratings yet

- Steyr 4 & 6 Cylinder Engine Workshop ManualDocument326 pagesSteyr 4 & 6 Cylinder Engine Workshop ManualMarinko100% (8)

- PH3 KWID DetailsDocument5 pagesPH3 KWID DetailsRavi RaiNo ratings yet

- 55 MTS Turntable Ladder-DLK 55CSDocument17 pages55 MTS Turntable Ladder-DLK 55CSPillaChantasNo ratings yet

- CENT Condition Monitoring ServiceDocument2 pagesCENT Condition Monitoring ServicesupljinaNo ratings yet

- Vol 56 No 03 - Shaft and Hub Keyway and Key SizesDocument4 pagesVol 56 No 03 - Shaft and Hub Keyway and Key SizesramsesluNo ratings yet

- Cat 963 CDocument20 pagesCat 963 CA2 BUDNo ratings yet

- Carry Out Minor Vehicle Maintenance and ServicingDocument20 pagesCarry Out Minor Vehicle Maintenance and ServicingMikel Legaspi100% (3)

- Paper Shredder MachineDocument16 pagesPaper Shredder MachineEphraim MekonnenNo ratings yet

- Location of Components: SMCS - 4300 5050Document43 pagesLocation of Components: SMCS - 4300 5050Francisco ValienteNo ratings yet