Professional Documents

Culture Documents

Industrial Hall Curs Constr

Uploaded by

Atasiei Monica GabrielaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Hall Curs Constr

Uploaded by

Atasiei Monica GabrielaCopyright:

Available Formats

Technical University Ghe.

Asachi , Iasi

Faculty of Civil Engineering

Industrial Hall

(Project)

Advisors:

S.l. dr. ing. G Oprisan

As. Ing. V. Munteanu

Student:

ATASIEI RAUL

Group:

3505

Industrial Hall Project

Theme of the project

Design an industrial building made of precast and prestressed concrete members.

This building is multi bayed with two spans, being a ground floor structure. The

reinforced concrete precast column has its end fixed in the foundation. The upper ends of

the columns are used as sub quarts for the prestressed transversal beams. The beams are

hinged on columns.

The roof is provided with longitudinal skylights made of steel frames and glass

window panels. Industrial hall is equipped with a traveling crane which is supported on

crane girders.

Given personal numerical data

L=12m (the span)

T=6m (the bay)

Crane type: Pc 20

Functional group: III

Height to the corbel level: 6.20m

Location of the industrial hall: Braila

Data taken from the STAS 800/82

A 5000mm

B 6250mm

hi 2160 mm

l1 325mm

c1 760mm

b 60mm

Qc 3070kg

G p 165000 kg

The following drawings are required:

1. Horizontal sections

2. Transversal sections

3. Longitudinal sections

Note: the transversal and longitudinal sections are combined with the facades

Determination of the height of the industrial building

Atasiei Raul, group 3505

I take the parapet height 1.45 m and the base beam 0.45 m

H cs H c H RG 0.164cm b 6.724m

1

H ws

H c H p H BB 4.00m

2

H ws

H cs h1 8.884m

In this case it results the bottom window being 2.10 m and the upper window 3.00 m.

Loads

Roof elements (E.P.)

d EP 1.50m

l EP 6.00m

G EP 1300daN

Roof elements (E.P.L.)

d EPL 1.50m

l EPL 6.00m

G EPL 1450daN

Roof elements (Skylight)

Industrial Hall Project

l L 6.00m

d L 3.00m

hL 1.58m

g L 52 daN m 2

Thermo-hydro insulation layer

g THI 48 daN m 2

Snow load

S k 1 C e C t s o , k 1.12 1.2 1 2.5 3.36 KN / m

Checking of the E.P.L. member

KN

dL

g L 1.00 g THI 1.5 S k 6.345

m

2

KN

6.35

m

pcalc 1.35

pcap

Transversal girder checking

G 1.35 4 G 2 G

G 35.202 tf

p

EP

calc

EPL

S L g L S GA S L g THI 1.5 S k 211.212 KN

From the catalogue I choose a transversal girder type G15-6T with 10T having

p cap 3.65

tf

m

Reinforced Concrete column checking

Windows

4

Atasiei Raul, group 3505

G w 30

daN

m2

n 2 1 .2

Wall claddings

G BCA 6 0.6 0.2 BCA

BCA 600

daN

m3

Loads evaluation

pm

pm,1

pp,2

N 1pp 2 G BCA 8.64 KN

2

N pp

S w G w 3 G BCA 18.36 KN

N pm

G T 1 105.606 KN

T

2

KN

c 24 2

m

GGR 51.02 KN

Industrial Hall Project

g ar 1.5 KN

GGT 33.25KN

n1 1.1

G ss hs hsm b c 12.995 KN

N pc GGR g ar 66.922 KN

G si hi him b c 25.488 KN

Gcs hs hsc b c 16.243KN

Gci hi hic b c 33.984 KN

Influence lines

TA

0.167

6

2 1

AT B

0.792

6

T B

4

0.042

6

P1 115 KN

P2 30 KN

P3 150 KN

P4 50 KN

n s 0.95

Rmax P1 1 3 P3 2 4 253.958 KN

c

Rmax

Rmax n s n 2 298.512 KN

Rmin P2 1 3 P4 2 4 76.667 KN

c

Rmin

Rmin n s n2 87.4 KN

Forces on the girder

Atasiei Raul, group 3505

N

1m

N

N

3m

4m

2m

1c

3c

4c

2c

1

123.984 KN

2

c

G ss N pc Rmax

396.429 KN

N m1 N pm (GTG n1 )

2

N m2 N 1pp N pp

N m3 0.35 0.4 0.3 24 1.008 KN

N m4 G si 25.488 KN

2 GTG n1

247.787 KN

2

c

c

Rmin

Rmax

Gcs 527 KN

N c1 2 N pm

N c2 2 N pc

N c3 2 0.35 0.4 0.3 c 2.016 KN

N c4 Gci 33.984 KN

Checking

hsm

him

N m2

0.364m

b n Rc

1

m

1

m

1

c

hsc

hic

N m2 N m3 N m4

0.383m

b n Rc

N c2

0.452m

b n Rc

1

c

N c2 N c3 N c4

0.473m

b n Rc

After the checking I have choose the initial columns for the both end and middle field.

7

Industrial Hall Project

Determination of the traveling crane length

hsm

0.525m

2

h

1

s

Am2 bRG

S s sm 0.575m

2

2

3

Am 0.40m

Am1 l1

Am max Am1 ; Am2 ; Am3 0.575

Am

b(RG)i

b(RG)s

Ss

Ac

Lp - lenght of the crane

L(+e)

Lr

hsc

0.575m

2

h

1

s

Ac2 bRG

S s sc 0.625m

2

2

3

Ac 0.40m

Ac1 l1

Ac max Ac1 ; Ac2 ; Ac3 0.625m

L p L Am Ac 13.8m

Corbel design

Atasiei Raul, group 3505

i

bRG

h

S s Am im 0.61m c 0.65m

2

2

hsm him

C c

0.625m

2

2

c

N pc Rmax

hc

0.401m hc 0.45m

b Rs

1

hc 0.15m

3

2

hci hc 0.30m

3

hcv

Superior corbel design

L LTG

1

10cm

2

Lr 15cm

Lcorbel Lr r 0.05m Lcorbel 0.10m

hsm

0.10m

2

sup

sup

hcorbel

2.5 Lcorbel 0.125m hcorbel

25cm

2 sup

i

hcorbel

hcorbel

0.167 m

3

1 sup

s

hcoebel

hcorbel

0.083m

3

r

Eccentricities

1. Eccentricity at the top level of the columns

e1

e1

Lr

0.175m

2

2. Eccentricity at the level of cross sectional changing

Industrial Hall Project

e2

e2

him hsm

0.025m

2

2

3. Eccentricity provided by the positioning of the runway girder

e3

hsm him

0.55m

2

2

Ac 0.625m

e3 m Am

e3 c

4. Eccentricity from wall cladding positioning

10

Atasiei Raul, group 3505

e4

e4

d p 20cm

1 15mm

dp

h

e4

1 sm 0.314m

2

2

dp

h

e5

1 im 0.340m

2

2

Wind loads

w z q ref c e z c p 0.528

KN

m

Loads from temperature variation

t n t n t 0 25 o C

t n t n t 0 25 o C

t c t n n nt 15 o C

L L t 2.16mm

n

F

I2

I1

L t

133.183KN

h

h 3 hs3

3 EI 1 3 n EI 1

3

s

Loads from traveling crane

11

Industrial Hall Project

Gc Q

2 944.85KN

4

G Q

1

Pt n c

2 f 47.243KN

4

nr

Fc

T fn Pt n j Pt n 1 2 3 4 90.548 KN

j 1

T T n3 117 .713KN

c

f

n

f

Seismic loads

S r k s r G 161.351KN

G P N s n d 2 Rmax Rmin n s n d 2151KN

Where G results from:

1. Thermo-hydro insulation

GTHI g THI S THI 69.12 KN

2. Sky-light weight

G s g s S s 36 KN

3. Roof elements

G EP 104 KN

G EPL 61.6 KN

GTG 66.5 KN

4. Self weight of upper part of R.C. column

G ss hs hsm bsm b 12.995KN

G pp S w G w S pp BCA n s 221.4 KN

5. Runway assemble

Gar 4 G RG 4 g ar T 240.80 KN

6. Snow

m

c

G snow 2 N snow

N snow

604.8 KN

12

Atasiei Raul, group 3505

7. Traveling crane

GTC 2 Rmax Rmin n s 716.134 KN

Diagrams on different loads patterns and combinations

1. Permanent loads at roof level

2. Permanent loads at corbel level

13

Industrial Hall Project

3. Claddings loads

14

Atasiei Raul, group 3505

4. Snow loads

5. Wind loads

6. Temperature variation

15

Industrial Hall Project

7. Crane loads

8. Special loads

16

Atasiei Raul, group 3505

Isolated foundation under precast R.C. column

p ef ,max 1.2 p conv

p conv 300 KPa

N tot M tot

N

M tot

tot

A

W

L B B L2

6

L 1.1 B 2.20m

N tot

M tot

1.2 p conv

B 2.00m

2

2

1.1 B

B 1.1 B

6

M tot

Hp

H p 0.9m

3 l s bs Rt

p max

H f H p 0.5 0.4m

H t H f 0.1 0.5m

17

You might also like

- Alumineum Rainscreen CladdingDocument10 pagesAlumineum Rainscreen CladdingAnonymous AJYdboNo ratings yet

- Celotex BBA - Cavity WallsDocument12 pagesCelotex BBA - Cavity Wallsfaber1972No ratings yet

- Millau Viaduct Case Study: World's Tallest BridgeDocument14 pagesMillau Viaduct Case Study: World's Tallest BridgeDevendra Kumar KumarNo ratings yet

- 5 Things You Need To Know Before Buying A Marine Air Conditioning SystemDocument16 pages5 Things You Need To Know Before Buying A Marine Air Conditioning SystemiBusinessLogicNo ratings yet

- Analysis of Self Supported Steel ChimneyDocument4 pagesAnalysis of Self Supported Steel ChimneyAtul Kumar EngineerNo ratings yet

- ArcelorMittal - High-Rise Buildings - WebDocument80 pagesArcelorMittal - High-Rise Buildings - WebAndrei MurariuNo ratings yet

- Analysis of The Static Tests of Boring Piles Through FDP (Full Displacement Pile) TechnologyDocument4 pagesAnalysis of The Static Tests of Boring Piles Through FDP (Full Displacement Pile) TechnologyJohn STCNo ratings yet

- HSIA: Bangladesh's Busiest AirportDocument24 pagesHSIA: Bangladesh's Busiest AirportMd. Pabel AhmedNo ratings yet

- Holcim AnnualReport06 eDocument172 pagesHolcim AnnualReport06 eihandrianNo ratings yet

- VSL CCT Pot BearingsDocument8 pagesVSL CCT Pot BearingsalsvsuryaNo ratings yet

- CANRM HeliportsDocument85 pagesCANRM HeliportsJayant LakhlaniNo ratings yet

- Product Catalog v015 Web PDFDocument47 pagesProduct Catalog v015 Web PDFfadi lamoNo ratings yet

- VEKA Group - A Guide To Sustainable Curtain Walling FinalDocument54 pagesVEKA Group - A Guide To Sustainable Curtain Walling Finalipman99No ratings yet

- Maffeis Engineering: Leaders in Tension Membrane and ETFE DesignDocument95 pagesMaffeis Engineering: Leaders in Tension Membrane and ETFE DesignAqil GhaffarNo ratings yet

- A1 20 WindowsDocument26 pagesA1 20 WindowsJacky TiongNo ratings yet

- Introduction To Aeronautical Engineering: Amir TeimourianDocument32 pagesIntroduction To Aeronautical Engineering: Amir TeimourianamirNo ratings yet

- QCVN-01-2019-BXD National Technical Regulation On Construction Planning (Eng)Document49 pagesQCVN-01-2019-BXD National Technical Regulation On Construction Planning (Eng)lwin_oo2435No ratings yet

- Ead 020002 00 0404 Balcony and Terrace Glazing System Without Vertical Frames 2016Document9 pagesEad 020002 00 0404 Balcony and Terrace Glazing System Without Vertical Frames 2016bmnNo ratings yet

- Concrete Steel Ratio For Bulk CheckDocument1 pageConcrete Steel Ratio For Bulk CheckTap RamosNo ratings yet

- Manual Kangaroo2 BR enDocument24 pagesManual Kangaroo2 BR enLeandro AthanasioNo ratings yet

- Victoria Falls Control Tower ReportDocument6 pagesVictoria Falls Control Tower ReportBright MuzaNo ratings yet

- Garry Kasparov Vs Anatoly Karpov 02 PDFDocument1 pageGarry Kasparov Vs Anatoly Karpov 02 PDFBrady AlférezNo ratings yet

- Diagram Skematik Instalasi CCTV Kawasan: LegendDocument2 pagesDiagram Skematik Instalasi CCTV Kawasan: Legendrizky nurhadyNo ratings yet

- Schüco Fassade FW 50+ - FW 60+Document112 pagesSchüco Fassade FW 50+ - FW 60+BrcakNo ratings yet

- PCs Corbel EN-4-2009 1228 0Document32 pagesPCs Corbel EN-4-2009 1228 0zeme6No ratings yet

- Macau Wind CodeDocument53 pagesMacau Wind CodeJack WenNo ratings yet

- Drywall Manual Fire ProtectionDocument33 pagesDrywall Manual Fire ProtectionPavaloaie Marian ConstantinNo ratings yet

- CPWD U Value Brickbat Coba Insulation IGDBookletDocument45 pagesCPWD U Value Brickbat Coba Insulation IGDBookletRamaiah KumarNo ratings yet

- 2018 Building Code Changes PDFDocument74 pages2018 Building Code Changes PDFvsdfsd258No ratings yet

- The art of power and perfection in actuator designDocument20 pagesThe art of power and perfection in actuator designAgustina De WinneNo ratings yet

- Designing of Offshore DNV Container: First A. Mihir Prakash Vaidya, Second B. Prof. P.M.KhanwalkarDocument4 pagesDesigning of Offshore DNV Container: First A. Mihir Prakash Vaidya, Second B. Prof. P.M.KhanwalkarRaul GutierrezNo ratings yet

- General Presentation 2Document33 pagesGeneral Presentation 2María Paula DávilaNo ratings yet

- Betopan Betopanplus Eng KKDocument48 pagesBetopan Betopanplus Eng KKkashmir_sefNo ratings yet

- Guidelines For The Establishment of Natural Gas Plant Facility in NigeriaDocument13 pagesGuidelines For The Establishment of Natural Gas Plant Facility in Nigeriaofforma NwaforNo ratings yet

- The Strength of Filler Joist Floors.Document4 pagesThe Strength of Filler Joist Floors.stan80100% (1)

- Design of Intze Tank in Perspective of Revision of IS: 3370Document5 pagesDesign of Intze Tank in Perspective of Revision of IS: 3370Innovative Research PublicationsNo ratings yet

- Chapter 1 Introduction - Manual For The Design of Timber BuildingDocument5 pagesChapter 1 Introduction - Manual For The Design of Timber Buildingrenuvenkat007No ratings yet

- Helpful ISO Container InformationDocument4 pagesHelpful ISO Container InformationDon LariviereNo ratings yet

- Hackney Tall Building Strategy Phase 1Document70 pagesHackney Tall Building Strategy Phase 1harishNo ratings yet

- Roof Structure Guide - Basics For The Design and Construction of Leightweight Sloped Roof Structures (SKAT, 1993, 144 PDocument77 pagesRoof Structure Guide - Basics For The Design and Construction of Leightweight Sloped Roof Structures (SKAT, 1993, 144 PDauji SahaNo ratings yet

- ARCH UPDA Questions - PREPARATIONDocument77 pagesARCH UPDA Questions - PREPARATIONMohammed YacobNo ratings yet

- Astm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)Document13 pagesAstm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)prasad_kcpNo ratings yet

- The Hong Kong Institute of Surveyors Quantity Surveying Division Assessment of Technical Competence Final Assessment - May 2011 Written TestDocument11 pagesThe Hong Kong Institute of Surveyors Quantity Surveying Division Assessment of Technical Competence Final Assessment - May 2011 Written TestalbertngNo ratings yet

- BB - Summer 2010Document13 pagesBB - Summer 2010AnneBricklayerNo ratings yet

- Manual To The Building Regulations: A Code of Practice For Use in EnglandDocument62 pagesManual To The Building Regulations: A Code of Practice For Use in EnglandSherif SeifEldin AbdelMoneimNo ratings yet

- SimFlex Navigator - List of Ship Model +++Document9 pagesSimFlex Navigator - List of Ship Model +++Lala RadinaNo ratings yet

- RM e Steel Design AashtoDocument46 pagesRM e Steel Design AashtoAlexi MilanNo ratings yet

- Securope On Hot Deck and Zinc Roof: Installer ManualDocument22 pagesSecurope On Hot Deck and Zinc Roof: Installer ManualDpto Ingenieria PROINTENo ratings yet

- SiP005 - Mooring Incorporating Bollards Guidance - March 2019 PublicationDocument31 pagesSiP005 - Mooring Incorporating Bollards Guidance - March 2019 PublicationLaurentiuMarianNo ratings yet

- (CQHP) Inspector Guideline For Civil WorkDocument55 pages(CQHP) Inspector Guideline For Civil WorkPyae Phyoe100% (1)

- BS en 13290-1-1999Document26 pagesBS en 13290-1-1999Santosh IngaleNo ratings yet

- Case Study: Pearl River Tower, Guangzhou, ChinaDocument12 pagesCase Study: Pearl River Tower, Guangzhou, ChinaDiệp NguyễnNo ratings yet

- QCS 2010 Section 22 Part 5Document15 pagesQCS 2010 Section 22 Part 5Abdelazim Mohamed0% (1)

- Riodin XEDocument2 pagesRiodin XEAntónio NôroNo ratings yet

- CCTV SystemDocument3 pagesCCTV SystemMohamed MaherNo ratings yet

- Tank DesignDocument108 pagesTank DesignFRBM2No ratings yet

- Rev.02-Fresh Water-Calculation-ReportDocument59 pagesRev.02-Fresh Water-Calculation-ReportprojectNo ratings yet

- BodrumDocument8 pagesBodrumAlper YildirimNo ratings yet

- M4 Deck DrawingsDocument544 pagesM4 Deck DrawingsVinay Kumar Neelam100% (1)

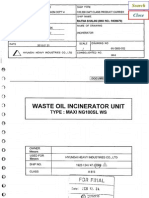

- HHI-INC-1923-RO WASTE OIL INCINERATOR UNITDocument166 pagesHHI-INC-1923-RO WASTE OIL INCINERATOR UNITAnurag Singh60% (5)

- Excel Tasks 01Document1 pageExcel Tasks 01ponimin83No ratings yet

- Nat TreasuresDocument40 pagesNat TreasuresAtasiei Monica GabrielaNo ratings yet

- Automated Structural RestorationDocument46 pagesAutomated Structural RestorationAtasiei Monica GabrielaNo ratings yet

- Computer Aided Design - SAAP 2000Document43 pagesComputer Aided Design - SAAP 2000Atasiei Monica GabrielaNo ratings yet

- Large Earthquakes of The WorldDocument9 pagesLarge Earthquakes of The WorldAtasiei Monica GabrielaNo ratings yet

- Calculate The Stiffness Matrix For A Regular Plan FrameDocument6 pagesCalculate The Stiffness Matrix For A Regular Plan FrameAtasiei Monica GabrielaNo ratings yet

- The Wall of IserlohnDocument9 pagesThe Wall of IserlohnAtasiei Monica GabrielaNo ratings yet

- Geo Detaliu UnprotectedDocument25 pagesGeo Detaliu UnprotectedAtasiei Monica GabrielaNo ratings yet

- Rooftop TraneDocument108 pagesRooftop TraneJuan Andres ArenasNo ratings yet

- Implant Training: by Abdul Basith.P 16103112Document24 pagesImplant Training: by Abdul Basith.P 16103112Samil MusthafaNo ratings yet

- Catalog: Blower Coil Air Handler Models BCHD and BCVDDocument104 pagesCatalog: Blower Coil Air Handler Models BCHD and BCVDjopaypagasNo ratings yet

- RCC M-25 concrete using 20mm aggregateDocument1 pageRCC M-25 concrete using 20mm aggregateAGEI UNo ratings yet

- Building Your Shipping Container HomeDocument7 pagesBuilding Your Shipping Container HomeMukhtar Oyewo100% (1)

- TG-BEC - 2012 (Rev. 1) PDFDocument147 pagesTG-BEC - 2012 (Rev. 1) PDFEllderNo ratings yet

- Factors That Caused Glass Curtain Wall Visual DistortionDocument4 pagesFactors That Caused Glass Curtain Wall Visual DistortionHAN HAN100% (1)

- SOS Children's Village Aqaba, JordanDocument24 pagesSOS Children's Village Aqaba, JordanSadia SamiNo ratings yet

- Passive Solar Handbook PDFDocument298 pagesPassive Solar Handbook PDFFernando RodriguezNo ratings yet

- W1 CEMENT STRENGTHENER FOR TILE BONDING AND WATERPROOFINGDocument3 pagesW1 CEMENT STRENGTHENER FOR TILE BONDING AND WATERPROOFINGLee LeeNo ratings yet

- Construction of Stone Masonry Footing PDFDocument6 pagesConstruction of Stone Masonry Footing PDFvenkateswara rao PothinaNo ratings yet

- PWD Comfort Rooms Floor PlanDocument8 pagesPWD Comfort Rooms Floor Planakositeodoro100% (1)

- Construction of Drain, Tuff Tile, P.C.C, Noorzai Colony PashtoonabadDocument5 pagesConstruction of Drain, Tuff Tile, P.C.C, Noorzai Colony PashtoonabadMunir HussainNo ratings yet

- RC Module 10 Short ColumnsDocument16 pagesRC Module 10 Short ColumnsEddie BoongalingNo ratings yet

- Coventry UniversityDocument104 pagesCoventry Universitymz-documentsNo ratings yet

- 5.2.3 Piling WorksDocument12 pages5.2.3 Piling WorksPaul KwongNo ratings yet

- Seismic Design Guide For Low-Rise Confined Masonry BuildingsDocument90 pagesSeismic Design Guide For Low-Rise Confined Masonry Buildingsmbiancar100% (1)

- User'S Information Manual: Single Package Air Conditioner Gas/ElectricDocument4 pagesUser'S Information Manual: Single Package Air Conditioner Gas/ElectricIlikeb@chNo ratings yet

- Inelastic Material Behavior ExplainedDocument17 pagesInelastic Material Behavior ExplainedJONATHAN RAJ A/L SEMANNo ratings yet

- 1 - Legends & SymbolsDocument1 page1 - Legends & SymbolsJing JingNo ratings yet

- Composite Beam PossibilitiesDocument4 pagesComposite Beam PossibilitiesAlberto García MárquezNo ratings yet

- GYPROC LEEDv4 GenericBrochureDocument40 pagesGYPROC LEEDv4 GenericBrochureKoala Tube88No ratings yet

- Flame SpreadDocument4 pagesFlame Spreadjack peterson mileNo ratings yet

- California Plumbing Code - Matrix Adoption Table Chapter 3 - General RegulationsDocument10 pagesCalifornia Plumbing Code - Matrix Adoption Table Chapter 3 - General RegulationsAnonymous PCsoNCt0mFNo ratings yet

- A Guide To Part F of The Northern Ireland BuildingDocument20 pagesA Guide To Part F of The Northern Ireland BuildingSamuel FuentesNo ratings yet

- Portland Cement Plaster - SpecDocument7 pagesPortland Cement Plaster - Speclinga2014No ratings yet

- Duct Insulation Sealing PDFDocument8 pagesDuct Insulation Sealing PDFGuillermo MartínezNo ratings yet

- Am220kxvjnh Id PDFDocument1 pageAm220kxvjnh Id PDFMarwene HlaouiNo ratings yet

- Adp Fsa Heater InstallDocument20 pagesAdp Fsa Heater Installgroomerz6612No ratings yet

- Reinforced Concrete Design: By: Prof. Dr. Haleem K. HussainDocument63 pagesReinforced Concrete Design: By: Prof. Dr. Haleem K. HussainMutaalekNo ratings yet