Professional Documents

Culture Documents

Welding Form

Uploaded by

Anand SomanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Form

Uploaded by

Anand SomanCopyright:

Available Formats

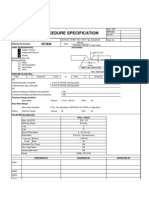

Supporting PQR No

Welding process(es)

: SMAW

Type

: Manual

Scope

: This welding procedure specification is applicable for repair welding of P No.1.

Materials without PWHT.

JOINTS: -(QW 402)

Joint Design

Root gap

Root land

Bevel Angle

Backing

Base material

Retainer

Base material

: Single V Groove Joint or as per approved drawing

: 1.5-3.0 mm or as per approved drawing

: 1.5-3.0 mm or as per approved drawing

: 65 5 C

: Nil

: NA

: Nil

: 10 mm

JOINT DESIGN (TYPICAL)

BASE METALS (QW 403)

P.No. / Group No.

: P.No. 1 Group No 2 to P.No.1 Group No 2

Specification Type & Grade

:-

Chemical Analysis

:-

Mechanical Properties

:-

Thickness Range Base Metal

Fillet

: 1.50 20 mm

: All

Weld pass thk < 13 mm

: Yes

FILLER METALS (QW 404)

Specification No. (SFA)

: A5.1

AWS No. Classification

: E7018

F.No.

:4

A.No.

:1

Size of Electrode/Filler metal

: 3.15 & 4.00 mm dia

Filler metal product from

: Electrode

Weld metal Thickness Range

: 20 mm Max.

Electrode Flux

: NA

Supplemental Filler Metal: NA

Fillet: NA

Consumable insert: NA

Change of alloy element

: NA

Brand Name / Trade Name

: NA

Power Feed rate: NA

POSITIONS (QW 405)

Position of Groove

Welding Progression

: All

: NA

Position of Fillet: All

PREHEAT (QW 406)

Preheat Temperature Min.

Inter pass Temperature Max.

: 30 C

: 300 C

Preheat Maintenance: NA

POST WELD HEAT TREATMENT (QW 407)

Type

: None

Temperature Range

: None

Rate of heating / cooling

: None

Time Range

: None

Loading / unloading (max)

: None

GAS (QW 408)

Flow Rate (lpm)

Gas

Shielding gas

: NA

Trailing

: NA

Backing

%Composition / Mixture

: NA

ELECTRICAL CHARACTERISTICS (QW 409)

Weld Pass

Process

Filler metal

Classification

Root Pass

Fill up &

Cap

SMAW

SMAW

E-7018

E-7018

Pulsing Current

Diameter

(mm)

3.15

3.15

4.00

Current

Type &

Polarity

Amps

(Range)

DC/EP

DC/EP

DC/EP

100-140

100-140

140-180

Volt

Travel Speed

Heat Input

(Range) Range (mm/min) K.I/mm (max)

24-28

24-28

24-28

150-200

150-200

200-250

: N.A

Heat Input (max)(KJ/mm)

: Refer table above

Tungsten Electrode Size & Type

: NA

Mode of metal transfer

: NA

Electrode wire feed speed range

: NA

TECHNIQUE (QW 410)

String or weave Bead

: Both (Weave not more than 3 times dia of electrode)

Office, Nozzle or Gas cup Size

: NA

Initial and Inter pass Cleaning

: Wire Brushing and Grinding

Method of back gouging

: Grinding if required

Oscillation

: N.A

Contact tube to work distance

: NA

Multiple or Single pass (per side)

: Multiple pass

Multiple or Single electrode

: Single

Electrode spacing

: N.A

Travel Speed (Range)

: Refer table above

Peening

: Not allowed

Use of thermal process

: Nil

Transfer mode

: NA

Torch orifice dia

Filler metal delivery

: NA

: NA

1.57

1.57

1.51

JOINTS: -(QW 402)

Joint Design

given

Root gap (A)

Root land (B)

Bevel angle

Backing

Base Material

Retainer

Base material thickness (t)

: Single V Groove Joint as per Sketch

Joint design (refer sketch encl)

: 1.5-2.0 mm

: 1.5-2.0 mm

: 65 5 C

: Nil

: NA

: NA

: 10 mm

BASE METALS (QW 403)

PREHEAT (QW 406)

Material Specification

: ASTM A216

Preheat Temperature

Type or Grade

: WCB

Inter pass Temperature : 300 C

P.No. Gr.No.

: P.No. 1 Gr.No.2

Thickness of Test Coupon

: 10 mm

Diameter of Test Coupon

: N.A

Size (mm) (l x w x t)

: 300 x 150 x 10 Thk

: 30 C

Others

: N.A

POST WELD HEAT TREATMENT (QW 407)

Temperature

Time Range

: None

: None

Cooling

: None

Rate of heating / cooling

: None

Loading / Unloading

FILLER METALS (QW 404)

Flow Rate (lpm)

: None

GAS (QW 408)

Gas

Shielding Gas

%Composition

SFA Specifications

: A5.1

: NA

AWS Classification

: E7018

Filler Metal F.No.

:4

Backing Gas

Weld Metal Analysis A.No.

:1

ELECTRICAL CHARECTERISTICS (QW 409)

Size of Filler Metal

: 3.15 mm dia

Current (A.C. or D.C.)

Filler Metal product from

(EP)

: Electrode

Polarity

Weld metal thickness (t)

: 10 mm

Amps

: 130 A

Trade name / brand name

: (ESAB 36H of M/s ESAB

Volts

: 27 V

Trailing Gas

India ltd Chennai, Ref TC Enclosed)

: NA

: NA

: D.C.

: Reverse (Electrode +ve)

Tungsten Electrode size

: NA

SIZE 3.15mm

Others: Heat Input

SIZE 4.00mm

Mode of metal transfer : NA

POSITION (QW 405)

( Refer Attached Welding Parameter Sheet)

Position of Groove

: 1G

Weld Progression

: N.A

: 1.40 KJ/mm

TECHNIQUE (QW 410)

Travel Speed

: 150 160 mm /min (for all pass / all layer)

String or weave Bead

: Both (Weave width not more than 3 times dia of electrode)

Oscillation

: N.A

Multi pass or Single pass (pre side)

: Multi pass

Single or Multiple electrodes

: Single

Method of back gauging

: None

Change of process

Orifice / nozzle size

: N.A

Peening

Gas cup size

: N.A

Transfer mode

Method of cleaning

: Wire brushing, Grinding

: N.A

: Nill

Torch orifice dia

: N.A

: N.A

Filler metal delivery

: NA

TENSILE TEST (QW 150): Report Ref:

Specimen

No

T1

T1

Width (mm)

Thickness (mm)Area (mm)

18.71

18.73

10.01

9.66

187.29

180.93

Ultimate Load (KN)

Ultimate Stress (Mpa)

Type of fracture &

location

99.15

97.90

529.39

541.09

Ductile & base

Ductile & base

GUIDED BEND TEST (QW 160):

Specimen size (mm) ( l x w x t ): 300 x 10 x 10

Specimen ID

FB1

FB2

FB1

FB2

Nature of Bend

Face Bend

Face Bend

Root Bend

Root Bend

Angle of Bend (Deg)

180

180

180

180

Dia of Roller (mm)(4t)

38.1

38.1

38.1

38.1

Free

Free

Free

Free

from

from

from

from

Result

defects. Satisfactory

defects. Satisfactory

defects. Satisfactory

defects. Satisfactory

TOUGHNESS TESTS (QW-170) : NA

FILLET-WELD TEST (QW-180)

Results

: N.A

Penetration into Parent metal: Yes/No

: N.A

Macro Results

: N.A

OTHER TESTS

SI. NO Type of ExaminationAcceptance standard/ Requirement

1 Visual Examination QW-302.4 of ASME Section IX

2 Liquid Penetrate Testing

As per ASME Sec. VIII Div. 1.A.8

3 Radiography

QW-191.2. of ASME Section IX

Acceptable Refer Lab Report

4 Hardness (HV10)

As per NACE MR 0175 / ISO 15156-2

Hardness survey as per sketch enclosed in report

:2003

Base

200 HV max

Base

: Average 158 HV

Weld

200 HV max

Weld

: Average 199 HV

HAZ

200 HV max

HAZ

: Average 191 HV

Acceptable Refer Lab Report

5 Macro examination Shall be free from defects

Free from crack, pin hole, porosity and other abnormalities.

Fusion Satisfactory.

Acceptable Refer Lab Report

We certify that statement in this record are correct and that the test welds were prepared, welded and tested in accordance

with the

You might also like

- The Iron Puddler My life in the rolling mills and what came of itFrom EverandThe Iron Puddler My life in the rolling mills and what came of itNo ratings yet

- Advanced WeldingDocument10 pagesAdvanced WeldingGanesanGovindarjNo ratings yet

- Welding Journal PDFDocument7 pagesWelding Journal PDFraisalfiansyahNo ratings yet

- Welding of Stainless Steel - Sndo KouDocument17 pagesWelding of Stainless Steel - Sndo KouGovind RajNo ratings yet

- Weld GaugesDocument15 pagesWeld GaugessojeckNo ratings yet

- GTAW and Power SourcesDocument18 pagesGTAW and Power SourcesRavi Kumar SinghNo ratings yet

- Gtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWDocument19 pagesGtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWNachiket MujumdarNo ratings yet

- GuideDocument2 pagesGuideSreekumar RajendrababuNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Submerged Arc WeldingDocument21 pagesSubmerged Arc WeldingSACHIN A. MORENo ratings yet

- Gmaw & Fcaw-MsmeDocument73 pagesGmaw & Fcaw-MsmemilindNo ratings yet

- Tips For The Practitioner.: Flame StraighteningDocument2 pagesTips For The Practitioner.: Flame StraighteningmikirscNo ratings yet

- Weld Joint Detail PDFDocument9 pagesWeld Joint Detail PDFKosit WongpinkaewNo ratings yet

- Welding and Fabrication NoteDocument54 pagesWelding and Fabrication NoteluminiousNo ratings yet

- 2 WeldingDocument30 pages2 WeldingAndronicoll Mayuga NovalNo ratings yet

- 6 GtawDocument30 pages6 Gtawmasmarkun4444No ratings yet

- Quantity Unit Tools Description RemarksDocument2 pagesQuantity Unit Tools Description RemarksnashNo ratings yet

- Panunumpa NG PropesyonalDocument71 pagesPanunumpa NG PropesyonalHenry SyNo ratings yet

- Welding Bevel Design 3.1 Bevels For Other Than GTAW Root PassDocument2 pagesWelding Bevel Design 3.1 Bevels For Other Than GTAW Root PassaezeadNo ratings yet

- Resistance WeldingDocument8 pagesResistance Welding0502raviNo ratings yet

- Gmaw Guide PDFDocument54 pagesGmaw Guide PDFJorge perezNo ratings yet

- PreheatDocument2 pagesPreheatScott TrainorNo ratings yet

- Arc Welding LabDocument28 pagesArc Welding LabFarman AliNo ratings yet

- Welding Process and ConsumableDocument64 pagesWelding Process and Consumablenizar_ikmps100% (1)

- Ddugky Welding Lab ManualDocument15 pagesDdugky Welding Lab ManualprakashNo ratings yet

- Weld RepairsDocument8 pagesWeld RepairsAhmedAleshiNo ratings yet

- Murex Tig Poster 2008 PDFDocument1 pageMurex Tig Poster 2008 PDFPCNo ratings yet

- Definition of Girth WeldDocument2 pagesDefinition of Girth WeldHung ChengNo ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- Surface Tension Transfer (STT) Pipe WeldingDocument3 pagesSurface Tension Transfer (STT) Pipe WeldingahmedNo ratings yet

- Fillet WeldsDocument17 pagesFillet Weldssoroush1111No ratings yet

- Cswip 3.1 QuizDocument70 pagesCswip 3.1 Quizalzaki100% (1)

- 13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202)Document5 pages13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202)IJAERS JOURNAL100% (1)

- Usability Designators FCAWDocument5 pagesUsability Designators FCAWAnonymous dh6DITNo ratings yet

- Is 7310 RequirementsDocument4 pagesIs 7310 RequirementsRavichandran Tirupattur SubramaniamNo ratings yet

- Welding Inspector Visual Acuity Record Form 455EDocument1 pageWelding Inspector Visual Acuity Record Form 455EJoshnewfoundNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- Ss Pipe WeldingDocument3 pagesSs Pipe WeldingshridharbshenoyNo ratings yet

- Weldability of MaterialsDocument5 pagesWeldability of MaterialsclnNo ratings yet

- Mini Projects For Mechanical 10Document12 pagesMini Projects For Mechanical 10ZEESHANA001No ratings yet

- Basic Welding TheoryDocument15 pagesBasic Welding TheoryCarina MostralesNo ratings yet

- WeldingDocument752 pagesWeldingAndres_Pastor1987100% (3)

- Lecture 1-Fundamentals of Welding MetallurgyDocument46 pagesLecture 1-Fundamentals of Welding MetallurgyHamiduNo ratings yet

- WeldingDocument68 pagesWeldingRajneesh Patel100% (1)

- GMAWDocument53 pagesGMAWJithuJohn100% (1)

- Flux-Cored Arc WeldingDocument30 pagesFlux-Cored Arc Weldinganon_795652448No ratings yet

- Welding Automation CatalogDocument112 pagesWelding Automation CatalogVirgil SorcaruNo ratings yet

- Welding DefectsDocument36 pagesWelding DefectsSunilNo ratings yet

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Welding Procedure Specification Structural-3GDocument3 pagesWelding Procedure Specification Structural-3Gdndudc78% (9)

- Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchDocument4 pagesWelding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchaNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- Welding Procedure Specification: Technip KT India LimitedDocument5 pagesWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- Welding Procedure Specification Pipe - 6GDocument3 pagesWelding Procedure Specification Pipe - 6Gdndudc97% (29)

- SPWM Vs SVMDocument11 pagesSPWM Vs SVMpmbalajibtechNo ratings yet

- Woldia University: A Non Ideal TransformerDocument24 pagesWoldia University: A Non Ideal TransformerKANDEGAMA H.R. (BET18077)No ratings yet

- All Siae Skus: SF Product Name SIAE Product Code Descrip:on Availability Product Family Unit LIST Price ($)Document7 pagesAll Siae Skus: SF Product Name SIAE Product Code Descrip:on Availability Product Family Unit LIST Price ($)Emerson Mayon SanchezNo ratings yet

- American J of Comm Psychol - 2023 - Palmer - Looted Artifacts and Museums Perpetuation of Imperialism and RacismDocument9 pagesAmerican J of Comm Psychol - 2023 - Palmer - Looted Artifacts and Museums Perpetuation of Imperialism and RacismeyeohneeduhNo ratings yet

- 27 Points of Difference Between Personnel Management & HRDDocument2 pages27 Points of Difference Between Personnel Management & HRDMurtaza Ejaz33% (3)

- End Points SubrogadosDocument3 pagesEnd Points SubrogadosAgustina AndradeNo ratings yet

- Age and Gender Detection Using Deep Learning: HYDERABAD - 501 510Document11 pagesAge and Gender Detection Using Deep Learning: HYDERABAD - 501 510ShyamkumarBannuNo ratings yet

- Registration Form - Synergies in Communication - 6th Edition - 2017-Drobot AnaDocument3 pagesRegistration Form - Synergies in Communication - 6th Edition - 2017-Drobot AnaAna IrinaNo ratings yet

- CM011l E01 Exp.3 DeJuanDocument3 pagesCM011l E01 Exp.3 DeJuanJarell De JuanNo ratings yet

- Main-A5-Booklet (Spreads) PDFDocument12 pagesMain-A5-Booklet (Spreads) PDFanniyahNo ratings yet

- EHVACDocument16 pagesEHVACsidharthchandak16No ratings yet

- IOM - Rampa Hidráulica - Blue GiantDocument32 pagesIOM - Rampa Hidráulica - Blue GiantPATRICIA HERNANDEZNo ratings yet

- Model Personal StatementDocument2 pagesModel Personal StatementSwayam Tripathy100% (1)

- Pin Joint en PDFDocument1 pagePin Joint en PDFCicNo ratings yet

- Mericon™ Quant GMO HandbookDocument44 pagesMericon™ Quant GMO HandbookAnisoara HolbanNo ratings yet

- Parts List 38 254 13 95: Helical-Bevel Gear Unit KA47, KH47, KV47, KT47, KA47B, KH47B, KV47BDocument4 pagesParts List 38 254 13 95: Helical-Bevel Gear Unit KA47, KH47, KV47, KT47, KA47B, KH47B, KV47BEdmundo JavierNo ratings yet

- Application of A HAZOP Study Method To Hazard Evaluation of Chemical Unit of The Power StationDocument8 pagesApplication of A HAZOP Study Method To Hazard Evaluation of Chemical Unit of The Power Stationshinta sariNo ratings yet

- TOK Assessed Student WorkDocument10 pagesTOK Assessed Student WorkPeter Jun Park100% (1)

- Advocating For Appropriate Educational ServicesDocument32 pagesAdvocating For Appropriate Educational ServicesTransverse Myelitis AssociationNo ratings yet

- Distribution of Continuous R.V.: Normal Distribution (CH 1.4) TopicsDocument7 pagesDistribution of Continuous R.V.: Normal Distribution (CH 1.4) TopicsPhạm Ngọc HòaNo ratings yet

- Konsep Negara Hukum Dalam Perspektif Hukum IslamDocument11 pagesKonsep Negara Hukum Dalam Perspektif Hukum IslamSiti MasitohNo ratings yet

- Role of Micro-Financing in Women Empowerment: An Empirical Study of Urban PunjabDocument16 pagesRole of Micro-Financing in Women Empowerment: An Empirical Study of Urban PunjabAnum ZubairNo ratings yet

- 01 GUL ZXRAN Basestation Hardware Structure-LDocument59 pages01 GUL ZXRAN Basestation Hardware Structure-Lmengistu yirga100% (1)

- Medha Servo Drives Written Exam Pattern Given by KV Sai KIshore (BVRIT-2005-09-ECE)Document2 pagesMedha Servo Drives Written Exam Pattern Given by KV Sai KIshore (BVRIT-2005-09-ECE)Varaprasad KanugulaNo ratings yet

- Synthesis Essay Final DraftDocument5 pagesSynthesis Essay Final Draftapi-283802944No ratings yet

- What Is Public RelationsDocument52 pagesWhat Is Public RelationsMarwa MoussaNo ratings yet

- ModelsimDocument47 pagesModelsimKishor KumarNo ratings yet

- Mortars in Norway From The Middle Ages To The 20th Century: Con-Servation StrategyDocument8 pagesMortars in Norway From The Middle Ages To The 20th Century: Con-Servation StrategyUriel PerezNo ratings yet

- General Introduction: 1.1 What Is Manufacturing (MFG) ?Document19 pagesGeneral Introduction: 1.1 What Is Manufacturing (MFG) ?Mohammed AbushammalaNo ratings yet

- The Making of A Scientist Class 10Document2 pagesThe Making of A Scientist Class 10abhigna.ravikumarNo ratings yet