Professional Documents

Culture Documents

GWS 1-03 - EXAMPLE-Filler Material Control Ass

Uploaded by

PhoolPhoolOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GWS 1-03 - EXAMPLE-Filler Material Control Ass

Uploaded by

PhoolPhoolCopyright:

Available Formats

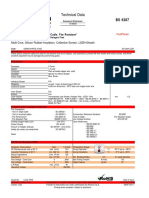

Purpose: To provide guidance and consistency in the evaluation of Welding Consumable Procurement and Control Stations.

Number of Pages:____6________

09/04/2008

Revision: 3

Reviewed By: __William R. Wingfield__

Effective Date:

Signature:___ (On File)_______

Z Number:____220365______

Date:__09/04/2008__

QA-IA Filler Material Procurement and Control Checklist

Checklist

Item

Number

Quality Assurance Requirement/Evaluation Criteria

Results

S/U/NA

Summary of Evaluation/Objective Evidence of Implementation

THIS IS AN UNCONTROLLED DOCUMENT - FOR REFERENCE ONLY

1

Procurement of Filler Materials

Do procurement documents (Form 838c) require the manufacturer or

vendor provide Certified Material Test Reports (CMTR) for the

materials? [A Cert. of Compliance may be substituted for a CMTR if

approved by the Welding Program Administrator (WPA)].

Program Reference: LANL Engineering Standards Manual ISD 341-2,

Chapter 13, Volume 1, General Welding Standards, Rev. 5, 7/21/08,

(GWS) 1-03 Welding and Brazing Material Procurement & Control,

Sec. 5.1, A.5 & A.6

Do CMTRs include the actual test results of chemical analysis,

mechanical tests, and examinations in accordance with GWS 1-03,

Attach 5, - Filler Material Procurement Required Tests and are

traceable by Lot, Batch, or Heat Number to the material delivered fo

use?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control, Sec. 5.1, A.1

Do low hydrogen SMAW electrodes (EXXX5, 6, and 8) meet diffusible

hydrogen of 4 mL/100 grams maximum and labeled with H4.

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.1, A.2

Do low hydrogen FCAW electrodes (EXXT-X) meet diffusible hydrogen

of 8 mL/100 grams maximum and labeled with H8.

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.1, A.3

Page - 1 -6

QA-IA Filler Material Procurement and Control Checklist

Checklist

Item

Number

Quality Assurance Requirement/Evaluation Criteria

Is weld filler material traceability maintained through point of use and

then filed in the project/program/facility files? [Note: Applies to ASME

Sec(s) I, III, VIII, and B31.3 Cat K & M, Safety Class, Safety

Significant, VSS, defense in depth, ML-1 & ML-2, and welding

procedure qualification tests.]

Results

S/U/NA

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.1, A, 4

Are special chemistry filler materials not included in ASME SFA or

AWS specifications purchased only after approval of LANL Welding

Program Administrator (WPA) or Engineering Standards Manager?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.1, B

2

1

Program Implementation

Is all weld filler material inspected for shipping damage by LANL QAPQ Receipt Inspection or Support Services Subcontractor (SSS) QC

Inspectors?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.2, A

Are CMTRs or Certificates of Analyses, checked against the original

purchase order requirements and verified against the chemical and

Mechanical requirements of ASME SFA, or AWS specifications?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.2, B

Is weld material stored so that its on pallets or bins so that its not in

contact with concrete floors?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.2, C

Are weld material storage areas clean, dry, enclosed, and controlled at

all times?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.2, C & 5.3 Local or Field Satellite Storage Areas.

Page - 2 -6

Summary of Evaluation/Objective Evidence of Implementation

QA-IA Filler Material Procurement and Control Checklist

Checklist

Item

Number

5

Quality Assurance Requirement/Evaluation Criteria

Results

S/U/NA

Is the weld material storage area temperature between 40F and

140F?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.2, C

Are bags of granular flux or spooled wire laying flat on pallets or

boards and in maintained in weather-proof packets or bags?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.2, D

Are electrodes, wires, etc. stacked separately and segregated from

each other? (i.e. E6010 not stored with E7018)?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.2, E

Is sufficient space and electrical power available to support electrode

storage ovens as well as portable ovens or heaters?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.3, A Local or Field Satellite Storage Areas

Are weld filler materials properly stored? (i.e. not in craft gang boxes,

lockers, vehicles, or left in work areas overnight or for the next shift.)

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.5 Weld Filler Material Issue and Control.

Storage Oven Requirements

Are all coated low-hydrogen electrodes, stored in welding electrode

storage ovens once the hermetically sealed container has been

opened? (i.e. E7018, E8018-B2L, E9018, E10018, etc)

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.4, A Storage Oven Requirements

Are electrode storage ovens tagged or labeled on the door, identifying

the electrodes stored in each section of the oven?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.4, A, 1 Storage Oven Requirements

Page - 3 -6

Summary of Evaluation/Objective Evidence of Implementation

QA-IA Filler Material Procurement and Control Checklist

Checklist

Item

Number

3

Quality Assurance Requirement/Evaluation Criteria

Results

S/U/NA

Are Electrode storage ovens capable of maintaining a temperature of

300 F 50? (Note: Per Attachment 1, Portable heaters producing

less than 250F are considered as ambient storage.)

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec 5.4, A, 2, & Attachment 1

Is a calibrated thermometer or other temperature measuring devise

maintained to perform daily temperature checks of rod storage ovens?

(Note: Documentation of this check is not required.)

Program Reference: GWS 1-03 Welding and Brazing Material

Procurement & Control Sec. 5.5, A, 1.

Are copies of CMTRs or C of Cs maintained for all filler materials?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.5, A, 1, Weld Filler Material Issue and Control

Is there a process to determine if a loss of power has occurred to the

rod storage ovens, or a reduction in minimum required temperature?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.5, I

Are portable rod ovens or heaters available where it is known the

Welding electrodes will exceed the ambient environment exposure

limits, listed in Sec. 5.7? Portable rod ovens for EXX18 & EXXX18

electrodes shall have the thermostat set between 250F & 350F.

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.5, J

Are low-hydrogen electrodes that are returned to the issue station in

portable ovens that have not been exposed to an ambient

environment, logged in and placed in a storage oven, and controlled to

prevent re-issue within 8 hours?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.8, C

Has an AWS-CWI or the WPA verified the Welding Checklist is correct

and complete and signed off, as the SME, on the Checklist?

Per 5.5, B, The tool room attendant or designated person shall verify

the Checklist against the material requisition form for filler material

and welder names and then issue material if appropriate. Control of

the filler material is required to be in place with excluded and exempted

welding. The original welding-related documents shall be kept in the

job or project document package until project completion. A copy of the

checklist and Weld Material Issue Cards shall be kept with the tool

Page - 4 -6

Summary of Evaluation/Objective Evidence of Implementation

QA-IA Filler Material Procurement and Control Checklist

Checklist

Item

Number

Quality Assurance Requirement/Evaluation Criteria

Results

S/U/NA

room attendant. After project completion the records shall be

forwarded to the facility or project/program record files for retention.

10

11

12

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.5, B

Are Weld Material Requisitions, available and being used to authorize

the specific AWS Designation, size, and quantity of filler material the

issue station attendants can issue to welders?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.5, A.2

Are low-hydrogen electrodes that have been exposed to ambient

environment conditions discarded?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.8, Return and Reissue Requirements for Welding Filler

Materials, paragraph B.

Are returned bare wire, flux-cored wire and other filler materials placed

in their storage location until reissue?

13

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.8, Return and Reissue Requirements for Welding Filler

Materials, paragraph E.

Is weld rod being returned at the end of the shift?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.8, Return and Reissue Requirements for Welding Filler

Materials, paragraph A.

Consumable Usage Requirements

Are waste ends, stubs and low-hydrogen electrodes exceeding the

exposure limits of Section 5.7, properly discarded in a scrap or trash

bin?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.6, E

Are weld rod exposure limits posted so welders and attendants are

aware of exposure limits? (Note this is not a hard requirement.)

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.6, D

Page - 5 -6

Summary of Evaluation/Objective Evidence of Implementation

QA-IA Filler Material Procurement and Control Checklist

Checklist

Item

Number

3

5

1

Quality Assurance Requirement/Evaluation Criteria

Results

S/U/NA

Summary of Evaluation/Objective Evidence of Implementation

Are welding consumables left lying around where inadvertent or

intentional use is possible?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.6, G

If spooled wire is left on wire feeds, is a weld wire usage log

maintained for the applicable machine?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.8, D.1

At all times through point of consumption, does bare wire in straight

lengths retain the manufacturers flag tag or identification; and spooled

wire retain the spool identification?

Reference: GWS 1-03 Welding and Brazing Material

Procurement and Control Sec. 5.6, H

Training

Does each authorized issue station have an attendant and back-up

identified?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.5, A,1

Has each attendant and back-up completed Training Plan 9781

(Course # 43390) Filler Material Control Rod Issue Attendant?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.5, A,1

Has each welder completed Training Plan 9780 (Course # 43389)

Filler Material Control Welder?

Reference: GWS 1-03 Welding and Brazing Material Procurement &

Control Sec. 5.6 Control of Welding Filler Material during Welding, B.

Comments:_______________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

Lead Auditor ____________________

Signature___________________

Note: remarks may be continued on reverse or an attached page as needed.

Page - 6 -6

Date___________________

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Symbols For Pipe FittingsDocument5 pagesSymbols For Pipe FittingsPhoolPhool100% (2)

- Analysis of Ink by TLCDocument7 pagesAnalysis of Ink by TLCkeshavNo ratings yet

- Theoretical and Actual CombustionDocument14 pagesTheoretical and Actual CombustionErma Sulistyo R100% (1)

- Strategy's Plan For MarketingDocument1 pageStrategy's Plan For MarketingPhoolPhoolNo ratings yet

- Sis 05 59 00Document1 pageSis 05 59 00PhoolPhoolNo ratings yet

- Acceptable ASTM EditionsDocument10 pagesAcceptable ASTM EditionsPhoolPhoolNo ratings yet

- 2016good and ImportantDocument4 pages2016good and ImportantMahdi koolivandNo ratings yet

- Method Statement For Insulation of Ducting SystemDocument11 pagesMethod Statement For Insulation of Ducting SystemSaijon chandyNo ratings yet

- Hardtop XP Alu: Technical Data SheetDocument5 pagesHardtop XP Alu: Technical Data SheetAfrizal Albar RamadhanNo ratings yet

- CI Injection P&ID (Printable)Document2 pagesCI Injection P&ID (Printable)Mehtab Alam ShaikhNo ratings yet

- C-23 Life Cycle of Process Plants PDFDocument9 pagesC-23 Life Cycle of Process Plants PDFnike_y2k100% (1)

- Turboflow XL 32Document10 pagesTurboflow XL 32Chris StroudNo ratings yet

- Edwards Vacuum Pump EDP Dry Pump Instruction ManualDocument84 pagesEdwards Vacuum Pump EDP Dry Pump Instruction ManualSuprapto ToNo ratings yet

- Murata High Voltage CeramicDocument38 pagesMurata High Voltage CeramictycristinaNo ratings yet

- Acetone ApplicationDocument3 pagesAcetone Applicationchem_ta100% (1)

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNo ratings yet

- Continuous Distillation Diagram ProcessDocument1 pageContinuous Distillation Diagram ProcessSebastianNo ratings yet

- Mechanical Designer Resume TemplateDocument1 pageMechanical Designer Resume TemplateHubertNo ratings yet

- N2XH FE 180/E: Controls, IncDocument2 pagesN2XH FE 180/E: Controls, IncShoaib-Ur -RehmanNo ratings yet

- Advanced Planning and SchedulingDocument7 pagesAdvanced Planning and Schedulingsheebakbs5144100% (1)

- A Presentation On PumpsDocument34 pagesA Presentation On PumpsSajjad Rasool ChaudhryNo ratings yet

- Cryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDocument2 pagesCryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDr. Awanish MishraNo ratings yet

- Types of Steam FlowmeterDocument20 pagesTypes of Steam FlowmeterLidijaSpaseskaNo ratings yet

- ISO 1459 Hots Dip GalvanizingDocument4 pagesISO 1459 Hots Dip GalvanizingLe Van TamNo ratings yet

- SMAC LCR16 Linear Rotary Actuator BrochureDocument2 pagesSMAC LCR16 Linear Rotary Actuator BrochureElectromateNo ratings yet

- Raichu R 2000Document7 pagesRaichu R 2000Shawn StevensNo ratings yet

- Weld Repair For Pressure Vessels Made From Cr-Mo SteelsDocument8 pagesWeld Repair For Pressure Vessels Made From Cr-Mo SteelsVedad ColakNo ratings yet

- Experiment 4 CombustionDocument8 pagesExperiment 4 CombustionJof RomanNo ratings yet

- Act 6+14Document4 pagesAct 6+14min95No ratings yet

- Astm F 1980-2Document6 pagesAstm F 1980-2Gabriel BiancoNo ratings yet

- Brass - WikipediaDocument18 pagesBrass - WikipediaTahafanMaggedonNo ratings yet

- TriNano Ultra Precision CMM (White Paper)Document6 pagesTriNano Ultra Precision CMM (White Paper)TriNanoNo ratings yet

- Pharm. LinimentsDocument38 pagesPharm. LinimentsDr-Md Abul BarkatNo ratings yet

- MICODocument4 pagesMICOmaniamsonNo ratings yet