Professional Documents

Culture Documents

Product Data 232 Ceilcote Flakeline

Uploaded by

Mohd MustafhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Data 232 Ceilcote Flakeline

Uploaded by

Mohd MustafhaCopyright:

Available Formats

DEFG

CEILCOTE 232 Flakeline

Flake Filled Novolac Vinyl Ester Coating

Description

CEILCOTE 232 FLAKELINE coating is a flake filled,

catalyzed novolac vinyl ester system, which exhibits excellent

resistance to both aliphatic and aromatic organic solvents and

concentrated organic and inorganic acids.

Priming

Prime surfaces with 2.0 to 5.0 wet mils of Ceilcote 380 Primer.

Use CEILCOTE 380 Primer with the addition of CEILCOTE

C#1 Powder (5.2 lbs per 5 gal unit) when spark testing (high

voltage holiday testing) will be conducted on concrete.

Typical Uses

Tanks & steel structures.

Trenches & pits.

Vaults & dikes.

Secondary containment.

Floors.

Advantages

Outstanding chemical resistance.

Quick turn around for service.

Flake filled, providing high resistance to permeation

Can be applied by spray, brush or roller

Color

Gray. Consult Ceilcote for special colors.

Chemical Resistance

Information on the chemical resistance properties will be

furnished on request.

Substrate

Refer to Ceilcote steel specification CPT-2 or Ceilcote

concrete specification CPT-1.

Surface Preparation

Metal - For immersion or intermittent splash and spillage

conditions, abrasive blast to White Metal in accordance with

Steel Structures Painting Council Specifications SP-5 or

NACE Specification #1. For fumes and dry environments,

abrasive blast to Near White in accordance with SP-10 or

NACE #2. A minimum surface profile of 3.0 mils is required.

Concrete Abrasive blasting or scarification to remove

laitance and surface contaminants is recommended. Concrete

must be thoroughly cured, free of oils, curing solutions and

mold release agents, dust and must be dry at time of

application. Use ASTM D 4263 (plastic sheet test method) to

ensure concrete is moisture free. If moisture is detected, retest until dry.

Application

Mixing Ratio

CEILCOTE 380 Primer

380 Primer Resin

#2 Hardener

CEILCOTE 232 Flakeline

232 Flakeline Resin

#2 Hardener

Page 1 of 3

The coating system consists of a primer, spray applied base

coat and topcoat, with a nominal dry film thickness of 30 to 40

mils. It can be applied on concrete and metal surfaces with

proper surface preparation.

By Volume

1 gal

2.5 oz

1 gal

2.5 oz

Mechanically premix CEILCOTE 232 resin for 2 minutes prior

to adding hardener. After initial mixing, add 2-1/2 oz of #2C

Hardener per gallon of CEILCOTE 232 resin and mix three

additional minutes.

Apply CEILCOTE 232 resin and hardener at 20 to 32 mils

WFT to yield 15 to 25 mils DFT, target of 18 mils DFT. Allow to

harden. Repeat for second coat application.

Thinning

None required. DO NOT THIN.

Application Equipment

May be applied by spray, brush or roller.

procedure for equipment recommendations.

See installation

Brush or Roller

When applied by brush or roller, three coats may be required

to achieve recommended film thickness.

Handling Properties

Working Time

50F (10C)

70F (21C)

90F (32C)

Recoat

50F (10C)

70F (21C)

90F (32C)

380 Primer

60 min.

45 min.

20 min.

380 Primer

5 hrs

2 hrs

1 hrs

232 Flakeline

1-1/2 hr.

1 hr.

45 min

232 Flakeline

12-24 hrs

4-8 hrs.

3-4 hrs.

CEILCOTE 232 Flakeline coating must be recoated within 7

days when shaded from sunlight. If the coating is applied in

sunlight (even on cloudy days) it must be recoated within 4

hours to obtain proper intercoat adhesion.

Time to Place in Service

50F (10C)

70F (21C)

90F (32C)

48 hrs.

24 hrs.

16 hrs.

CEILCOTE 232 Flakeline

Flake Filled Novolac Vinyl Ester Coating

Coverage

CEILCOTE 380 Primer

Concrete

160 - 200 ft2/gal (3.9-4.9 m2/liter)

2

(with C-1 Powder) approx. 140 - 160 ft /gal

2

2

Steel

250 - 300 ft /gal (6-7.2m /liter)

CEILCOTE 232 Flakeline

25 to 35 ft2/gal (.6 to .85 m2/liter)

Packaging

The following standard packages are available:

CEILCOTE 380 Primer

1, 5, 30 gal units

CEILCOTE 232 Flakeline

, 4, 25 gal units

Observe safe storage practices by separating resins from

hardeners, by keeping solvents in a cool area, free of sources

of ignitions.

Product Material Safety Data Sheets are available and should

be consulted when handling products. These products are for

industrial and professional use only; application directions

must be followed.

Maintenance

Periodically inspect the applied material and repair localized

areas as needed. Consult your CEILCOTE representative for

additional information.

Storage

Store in a cool, dry and covered location away from fire

hazards and direct sunlight. Minimum shelf life* at 70F (21C)

for products indicated below:

CEILCOTE 380 Primer

6 months

CEILCOTE 232 Flakeline

3 months

Higher temperatures will shorten the shelf life of these

products. The packing drums are to be kept tightly sealed and

are to be resealed each time materials have been removed.

All liquid products are to be stored in a frost-free place.

Safety

Store in cool, dry area [50- 90 F (10 - 32 C)] away from

direct sunlight, flame or other hazards.

CEILCOTE 232 Flakeline contains vinyl ester resins and

cumene peroxide catalyst. The products components have

been formulated to optimize physical characteristics such as

filling capacity, abrasion, moisture and chemical resistance

while minimizing hazardous physical and health factors

encountered during application. A concerted effort is made to

be aware of the latest chemical toxicological information and

to apply this knowledge in a responsible manner to insure

product safety.

During application of CEILCOTE 232 Flakeline materials,

always wear gloves and appropriate work clothing to minimize

contact. Ventilation is required with special consideration for

enclosed or confined areas. Air movement must be designed

to insure turnover at all locations in work area and adjacent

areas to avoid buildup of heavy vapors. Use caution when

handling flammable liquids, eliminate sources of ignition from

work area and containers with residues.

Page 2 of 3

4/5/06

CEILCOTE 232 Flakeline

Flake Filled Novolac Vinyl Ester Coating

Technical and Physical Data

Generic Type

Viscosity - mixed

Tensile Bond Strength

Tensile Strength

Density (wt. per gal)

Moisture Permeability

Service Temperature Limits

Tabor Abrasion

Shelf Life*

Volatile Organic

Compounds

Flash Point

Test Standard

Unit

Value

Vinyl ester

ASTM D 2393

ASTM D 4541

ASTM D-638

ASTM D 1475

ASTM E96 Proc. E

Immersion/Condensing Fumes

Occasional Splash & Spill

Continuous Dry

CS 17 wheel, 1,000 gm, 1,000

revolution

cps

Psi (MPa)

Psi (MPa)

lbs/gal (kg/liter)

perm inch

F (C)

mg

3,000 @ 77 F

1,200-1,500 (8-10)

2,500-3,000 (17-20)

9.9 + 0.2 (1.15 + 0.02)

0.0016

140 (60)

200 (93)

350 (177)

78

EPA Method 24

Months

lbs/gal (g/l)

3 @ 70 F (21 C )

1.55 (186)

Pensky Martens Closed Cup

F (C)

89F (32C)

* 30 days or less at greater than 80F (26.7C).

Important Note

The information in this data sheet is not intended to be exhaustive; any person using the product for any purpose other than that specifically recommended in this data sheet without first

obtaining written confirmation from us as to the suitability of the product for the intended purpose does so at their own risk. All advice given or statements made about the product (whether in

this data sheet or otherwise) is correct to the best of our knowledge but we have no control over the quality or the condition of the substrate or the many factors affecting the use and application

of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any liability at all for the performance of the product or for (subject to law) any loss or damage

arising out of the use of the product. WE HEREBY DISCLAIM ANY WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED, BY OPERATION OF LAW OR OTHERWISE,

INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. All products supplied and technical advice given

are subject to our Conditions of Sale. You should request a copy of this document and review it carefully. The information contained in this data sheet is liable to modification from time to time

in the light of experience and our policy of continuous development. It is the user's responsibility to check with their local International Paint representative that this data sheet is current prior to

using the product.

Issue date: 18/06/07

DE International and all product names mentioned in this publication are trademarks of, or licensed to, Akzo Nobel.

,

Akzo Nobel

www.ceilcotecc.com

www.international-pc.com

Page 3 of 3

4/5/06

You might also like

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Ceilcote 242mr FlakelineDocument3 pagesCeilcote 242mr FlakelineBoris CardenasNo ratings yet

- Phenoline 353 PDSDocument2 pagesPhenoline 353 PDSGerson SuarezNo ratings yet

- Sellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SLDocument2 pagesSellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SLEleazar MendezNo ratings yet

- HYSOL® FP4323 (ES4323) : Technical Data SheetDocument2 pagesHYSOL® FP4323 (ES4323) : Technical Data SheetAsad NaeemNo ratings yet

- Intergard 251 Tech Data SheetDocument0 pagesIntergard 251 Tech Data SheetL Mahender ReddyNo ratings yet

- Sikacrete 114 AEDocument4 pagesSikacrete 114 AEMicheal B HaizenNo ratings yet

- Conbextra EP75Document4 pagesConbextra EP75Venkata Raju KalidindiNo ratings yet

- Henk Loctite Gasket Seal 2 TdsDocument1 pageHenk Loctite Gasket Seal 2 TdsGabo TellezNo ratings yet

- Ceilcote 2000 - Technical Data SheetDocument4 pagesCeilcote 2000 - Technical Data SheetAlpAccess Alpinism UtilitarNo ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- Conbextra Ep75Document4 pagesConbextra Ep75Sathiya SeelanNo ratings yet

- Carbocoat 8215 PDS 6-10Document2 pagesCarbocoat 8215 PDS 6-10Mayur PatelNo ratings yet

- Polyclad 975 H PDSDocument2 pagesPolyclad 975 H PDSLinnie McleodNo ratings yet

- Technical Data Sheet: EPIKURE™ Curing Agent 3274Document4 pagesTechnical Data Sheet: EPIKURE™ Curing Agent 3274Kelvin Allan Soler LopezNo ratings yet

- Baltoflake - English (Uk) - Issued.25.03.2010Document4 pagesBaltoflake - English (Uk) - Issued.25.03.2010Mohamed FaragNo ratings yet

- Interseal 547 PaintDocument4 pagesInterseal 547 PaintSUBHOMOYNo ratings yet

- Carboguard 885 PDSDocument2 pagesCarboguard 885 PDSsyazwanjohnmazlanNo ratings yet

- HysolDocument2 pagesHysoljorgequijanoNo ratings yet

- Intergard 475HS: Primed SurfacesDocument3 pagesIntergard 475HS: Primed SurfaceskareemNo ratings yet

- Enviroline 2405 Application Guidelines: Protective Coatings Technical SupportDocument12 pagesEnviroline 2405 Application Guidelines: Protective Coatings Technical SupportskNo ratings yet

- Interprime 198 PDFDocument4 pagesInterprime 198 PDFandreaju2013No ratings yet

- Protective Coating-3Document0 pagesProtective Coating-3Sivaratnam NavatharanNo ratings yet

- CEILCOTE 505 Coroline.Document2 pagesCEILCOTE 505 Coroline.stuart3962No ratings yet

- Flexane 80 CompoundDocument3 pagesFlexane 80 Compoundabh_omegaNo ratings yet

- Internationa Paint MSDSDocument4 pagesInternationa Paint MSDStsoheil100% (1)

- Carboguard 888 PDSDocument3 pagesCarboguard 888 PDSsalamrefighNo ratings yet

- Tectyl 502CDocument2 pagesTectyl 502Cmoinu85No ratings yet

- Interline985 - Matcote DatasheetDocument4 pagesInterline985 - Matcote DatasheetLee PachecoNo ratings yet

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocument2 pagesRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNo ratings yet

- RTV Is800 SeriesDocument4 pagesRTV Is800 SeriesFaraan KhanNo ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSfazeel mohammedNo ratings yet

- Phenoline 187 Primer PDSDocument2 pagesPhenoline 187 Primer PDSVajid MadathilNo ratings yet

- SikaTop Seal 107 PDS (CE)Document5 pagesSikaTop Seal 107 PDS (CE)Vladimir StojanovicNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Sikacrete 114Document2 pagesSikacrete 114the pilotNo ratings yet

- Interthane 990: Product DescriptionDocument4 pagesInterthane 990: Product Descriptionsorion61No ratings yet

- Hardtop Flexi Technical Data SheetDocument3 pagesHardtop Flexi Technical Data SheetMohamed FaragNo ratings yet

- Interthane 990 en O-FDocument4 pagesInterthane 990 en O-Fapde06No ratings yet

- Epirez 733 Ultra High Build Epoxy CoatingDocument3 pagesEpirez 733 Ultra High Build Epoxy CoatingRai Hasnain Ahmad DahaNo ratings yet

- Sikaflex 2c NS EZ Mix UsDocument3 pagesSikaflex 2c NS EZ Mix Usتوان امتياس سامسدينNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- Conbextra EP10Document4 pagesConbextra EP10Venkata Raju KalidindiNo ratings yet

- Enviroline 124 PDFDocument4 pagesEnviroline 124 PDFNageswara Rao BavisettyNo ratings yet

- Polyflex UltrachemDocument2 pagesPolyflex UltrachemBraulio Candela NoriegaNo ratings yet

- Nitocote HT120Document4 pagesNitocote HT120Venkata Raju KalidindiNo ratings yet

- Ipd Pds Sikaflex221 Us 1Document4 pagesIpd Pds Sikaflex221 Us 1Dennis UbillusNo ratings yet

- Loctite 2701: Technical Data SheetDocument3 pagesLoctite 2701: Technical Data SheethendrabudimanNo ratings yet

- Sylgard 160Document3 pagesSylgard 160diogocNo ratings yet

- Conbextra EP10TGDocument2 pagesConbextra EP10TGBambang SasikiranaNo ratings yet

- Nitocote NT550Document4 pagesNitocote NT550Venkata Raju KalidindiNo ratings yet

- Stand OxDocument2 pagesStand OxSimon DanishNo ratings yet

- Nitoseal 220 PDFDocument4 pagesNitoseal 220 PDFmilanbrasinaNo ratings yet

- 2 Sikacrete-114 PDS GCC (06-2018) 1 1Document3 pages2 Sikacrete-114 PDS GCC (06-2018) 1 1Sri KanthNo ratings yet

- Interthane 990 HS DatasheetDocument4 pagesInterthane 990 HS DatasheetBalasubramanian AnanthNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsFrom EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Guideline On Reproductive Health Policy and Programme at The WorkplaceDocument54 pagesGuideline On Reproductive Health Policy and Programme at The WorkplaceMohd MustafhaNo ratings yet

- Arc WeldingDocument12 pagesArc Weldingsalekojic5332100% (1)

- Guidelines on Medical Surveillance for Chemical ExposureDocument140 pagesGuidelines on Medical Surveillance for Chemical ExposureMohd MustafhaNo ratings yet

- GUideline On Preventing and Responding To Drug and Alcohol 2004Document36 pagesGUideline On Preventing and Responding To Drug and Alcohol 2004Mohd MustafhaNo ratings yet

- Eu-1-2 TG-S50 - GB - 1 SDSDocument8 pagesEu-1-2 TG-S50 - GB - 1 SDSMohd MustafhaNo ratings yet

- Controlling Hazardous Fumes and Gases During WeldingDocument2 pagesControlling Hazardous Fumes and Gases During WeldingMohd MustafhaNo ratings yet

- ActA1268 - AKTA KILANG DAN JENTERA (PINDAAN) 2006Document28 pagesActA1268 - AKTA KILANG DAN JENTERA (PINDAAN) 2006ariffabusemanNo ratings yet

- Workplace first-aid guidelinesDocument22 pagesWorkplace first-aid guidelinesdrstein197450% (2)

- COP On Indoor Air QualityDocument24 pagesCOP On Indoor Air QualityMohd Mustafha100% (1)

- Mortars UsDocument1 pageMortars UsMohd MustafhaNo ratings yet

- Sika Grout 212 215 212hp - MsdsDocument5 pagesSika Grout 212 215 212hp - MsdsMohd MustafhaNo ratings yet

- Wpa Sho 2015Document10 pagesWpa Sho 2015Mohd MustafhaNo ratings yet

- Akta 514 Akta Keselamatan Dan Kesihatan Pekerjaan 1994Document48 pagesAkta 514 Akta Keselamatan Dan Kesihatan Pekerjaan 1994nazrics100% (9)

- Wpa Sho 2015Document10 pagesWpa Sho 2015Mohd MustafhaNo ratings yet

- Thesis On Laser CuttingDocument8 pagesThesis On Laser Cuttingtonyacartererie100% (2)

- The Milling Machine: Learning ObjectivesDocument16 pagesThe Milling Machine: Learning ObjectivesAlex Ander100% (1)

- QuestionsDocument22 pagesQuestionsTriciaMichi HoNo ratings yet

- Blast Furnace Presentation Ver1Document39 pagesBlast Furnace Presentation Ver1abhijit kumarNo ratings yet

- Everything About Metallizing CoatingsDocument3 pagesEverything About Metallizing CoatingsSantiago PeñaNo ratings yet

- Exxonmobil FCC TechnologyDocument4 pagesExxonmobil FCC TechnologySubhasish Mitra100% (2)

- Nippo CemDocument3 pagesNippo CemSAMNo ratings yet

- Scrap TicketDocument11 pagesScrap TicketVikas KashyapNo ratings yet

- Lecture 3Document17 pagesLecture 3Elmokadem EinsteinNo ratings yet

- Bondhus CatalogDocument52 pagesBondhus CatalogCarbide Processors IncNo ratings yet

- A. Stucki Company: Retroxt LP Bolt On Side Bearing 07563Document1 pageA. Stucki Company: Retroxt LP Bolt On Side Bearing 07563oliveira1305No ratings yet

- Mix Your Own Oil Stains + Quick Oil Stains From Japan ColorsDocument3 pagesMix Your Own Oil Stains + Quick Oil Stains From Japan ColorsRueth AnnafeyeNo ratings yet

- Versilon HP Pfa 400 High Purity TubingDocument2 pagesVersilon HP Pfa 400 High Purity TubingDHAVALNo ratings yet

- Melwa (Western Provice) 2018-03-22Document89 pagesMelwa (Western Provice) 2018-03-22Lakshan FonsekaNo ratings yet

- Mil PRF 83483Document1 pageMil PRF 83483JOSENo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher NikhilNo ratings yet

- Astm A351-A351mDocument5 pagesAstm A351-A351mLuRobert100% (3)

- Victorian (Sterling)Document13 pagesVictorian (Sterling)NickiedeposieNo ratings yet

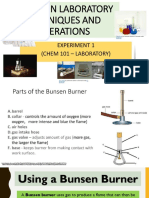

- Common Laboratory TechniquesDocument16 pagesCommon Laboratory TechniquesNiki KevinNo ratings yet

- Design and Fabrication of Die for Metal Powder CompactionDocument69 pagesDesign and Fabrication of Die for Metal Powder CompactionMohit Assudani100% (2)

- Duratomic TP Brochure GT15-214 PDFDocument24 pagesDuratomic TP Brochure GT15-214 PDFDeysi CardenasNo ratings yet

- Binder MCM 001Document13 pagesBinder MCM 001hsemargNo ratings yet

- Degradation of MaterialsDocument29 pagesDegradation of MaterialsjamesNo ratings yet

- Bar and DrawingDocument54 pagesBar and DrawingJe Siti NazuraNo ratings yet

- Profile of The Company: Francis Klein & Co. Private LimitedDocument7 pagesProfile of The Company: Francis Klein & Co. Private LimitedAmit KumarNo ratings yet

- Hempafloor Self-Level 200Document2 pagesHempafloor Self-Level 200Fadi MagdyNo ratings yet

- Kia k3 Body Shop ManualDocument10 pagesKia k3 Body Shop Manualjonathan100% (25)

- Lab Report 2..weldingDocument7 pagesLab Report 2..weldingUsman Saeed Kiani100% (1)

- TLE - WEEK 2 - Creativity and Innovativeness in EnhancingDocument24 pagesTLE - WEEK 2 - Creativity and Innovativeness in EnhancingMarlene Tagavilla-Felipe DiculenNo ratings yet

- Jis-Astm SpecDocument1 pageJis-Astm SpecRizki AhmadNo ratings yet