Professional Documents

Culture Documents

Weed Control

Uploaded by

Aakash SheelvantCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weed Control

Uploaded by

Aakash SheelvantCopyright:

Available Formats

ISSN (Print) : 2320 3765

ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 10, October 2013

Advanced Agriculture Robotic Weed Control

System

Prof.V.A.Kulkarni1 ,Mr. Ajit G Deshmukh2

Asst. Prof, Dept. of E &TC, Jawaharlal Nehru Engineering College, Aurangabad, Maharashtra, India1

PG Student, Dept. of E &TC, Jawaharlal Nehru Engineering College, Aurangabad, Maharashtra, India2

ABSTRACT: This paper addresses a new system which can be implemented in agriculture processes. An electronic

system improves different agriculture processes like weed control, cultivation, harvesting, spraying by using autonomous

vehicle which increases speed, accuracy and life. We have developed a robotic vehicle having four wheels and steered by

dc motor and IR sensor arrangement. This vehicle will control the weeds in the farm by considering particular rows per

column at fixed distance depending on the crop and also detects the obstacles present in the path of vehicle. The whole

algorithm, calculation, processing, monitoring are designed with motors and sensors interfaced with microcontroller.

I.

INTRODUCTION

In modern globalization, many technologies are trying to update a new development based on automation which

works very rigidly, high effectively and within short period of time period. now the approach of this project is to develop

smart machine which do the right think at right place at right time with right amount in process of farming. The main goal

of this project is the development of the vehicle and the control unit, with possibility of using different sensor technologies.

We want to test the vehicle and control unit and show that the robot is capable of following a path under field conditions.

Today the environmental impact of agricultural production is very much in focus and the demands to the industry

is increasing. The production of agricultural products is growing and the competition is getting bigger, therefore the farmer

has to be very efficient to be able to compete. At the same time the demands, for less use of pesticides and fertilizers, from

the consumer and the legislation are increasing. Therefore the farmers have to use high technology in the fields for

weeding, spraying, etc., earlier weeding were done manually but today it is neither profitable or possible to get a sufficient

number of labor for this job. In this project, an autonomous agricultural vehicle, for test and development of sensors, tools

and information technology in the field, is going to be developed.

The goal of decreasing herbicide usage has so far focused on reducing the herbicide dosage or replace chemical

weed control by hoeing and harrowing. Environmental impact of agricultural production is very much in focus, while the

competition demands high efficiency. Some years ago, weeding was done manually without the use of pesticides. With the

development of an autonomous agricultural vehicle with sensors for weed detection, it will again be possible to avoid the

use of pesticide The conventional weed control strategy is to apply the same dose rate of herbicide or the same intensity of

physical treatments to the whole field.

To obtain efficient and accurate weed control systems they must be developed to target specific parts of the field.

A field in which the crop is established in rows can be divided into three weeding target areas: (i) the area between the rows

(inter-row area) (ii) the area between the crop seedlings within the rows (intra-row area), and (iii) the area close to and

around the crop seedlings (close-to-crop area). Now a day the most challenging problem is still to remove weeds within the

rows and close to crop plants. So far no commercial selective mechanical methods have been developed for the intra-row or

Copyright to IJAREEIE

www.ijareeie.com

5073

ISSN (Print) : 2320 3765

ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 10, October 2013

close-to-crop areas, thus, 10 % to 20 % of a field has to be controlled by band spraying or manual weeding. The main

obstacle for the progress of site specific weed control is the lack of automated detection and classification of crop and weed

plants. Optical sensors are able to discriminate between plant species by analyzing images and / or multi-spectral

information. These sensors and processing methods were developed intensively during the recent years. This result is still

not acceptable for most of the weed control requirement. An important element within robotic weeding is the requirement

to achieve highly accurate control especially in the close-to-crop area. Automatic controlled or autonomous vehicles are

therefore essential for the implementation of robotic weeding. The vision of the ongoing research project is to contribute to

the development of novel weeding technologies that can reduce manual efforts and herbicide.

II.

FARMING PROCEEELEMENTS OF THE ROBOTIC WEEDING SYSTEM

The following descriptions are organized as work packages within the robotic weeding project. Different cooperation

partners are responsible for achieving the specific package aims.

A.

Seed Geo-referencing

A map of geo-referenced seeds can be created by integrating a highly accurate positioning system with seed detection

sensors on each seeding unit of the machine. During the seeding operation, the positions of seeds dropped into the furrow

are logged and stored in a computer memory.

B.

Plant Recognition

The identification of the plant centre positions (ideally the position where the stems penetrate the soil) and the

identification of the positions of plant leaves is an important prerequisite for the robotic weeding operations. To physically

remove or treat the weeds with a minimum of crop damage it will be necessary to achieve accurate information about the

locations of crop and weed plants. The system integration includes the definitions of the weed control parameters and the

specifications of the technical framework. The focus target areas for the weeding system will be the intra-row and the closeto-crop area. By using automatic controlled platforms to carry out the weeding tasks, the well known and well developed

inter-row hoeing can additionally be included to achieve a complete system for targeting all three areas i) inter-row, ii)

intra-row and iii) close-to-crop area. The platform requirements for the weeding applications as for intra-row or close-tocrop weeding are different. Operations as seeding, intra-row tillage and mowing require tools of higher weights speed and

power needs whereas individual plant treatments as picking and micro-spraying will be carried out at lower speeds and with

lighter and smaller tools. The modules include interfaces to sensors, low-level and high-level controllers and more. , it has

been possible to develop a real-time control system a vehicle suitable for research under field conditions has been

developed. The vehicle has 4-WD, which makes it possible to test different steering strategies. The vehicle is specially

designed for in-row driving; this has been achieved with the use of in-wheel motors. The vehicle can drive in row crops wit

during the development of mechanics, electronics and software we have focused on making the vehicle flexible. The choice

of technology for the various functions has big impact on functionality, flexibility and performance. During the

development process we have had safety in the back of our minds and put an effort in eliminating or reducing the risks

concerning an autonomous vehicle.

The robot can be divided into four main modules:

1. A vehicle as a platform for carrying e.g. weeding tools for in row weeding. The vehicle could be equipped with the

control modules described below.

Copyright to IJAREEIE

www.ijareeie.com

5074

ISSN (Print) : 2320 3765

ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 10, October 2013

2. A control unit, with input from Vision, other necessary sensors is providing the vehicle and the tools with the necessary

control signals.

3. A vision system detecting the position of the crop relative to the vehicle position.

The development of the vision system is not a primary goal. Therefore, we want to make the vision system simple and it

should just be able to recognize spots on the ground with good contrast to the ground. It should be possible to replace this

simple module with more advanced modules for crop recognition in the field.

III.

METHODOLOGY

In this project, it is presenting that the farm weed control process in advanced agriculture system which is controlled by

microcontroller assembly. The technique of weed control based on row per column with fixed standard distance depending

upon type of crop or type of cultivation. The other main part of this technique is sensor part. The sensor perform the well

job of identifying weed present in between to crop lines as well as completion of farm and turn robotic vehicle to next row

per column and follow remaining part of the farm.

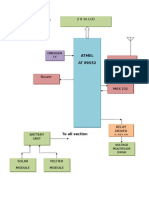

The hardware structure to control the robotic weed control vehicle as advanced agriculture system is as shown in figure

1. The system includes one color sensors, two DC motor, two servo motor and whole parts are controlled by

microcontroller assembly as designed in hardware. The operation of DC motor is based on simple electromagnetism, used

to give energy to the wheels of vehicle.

Figure 1: Hardware structure of Robotic system.

Depending upon the revolution per minute of DC motor axel, it drives vehicle at particular distance, the weed

cutting tool motor i.e. servo motor will be worked and controlled.

When DC motor would be started, vehicle moves along the particular columns between the two crop lines. The

color sensor is connected to the front edge of robot; other is at left side for controlling the movement of vehicle. The

process of weed control starts from sensing the color of the weed which is in front of robotic vehicle once the color is

sensed by color sensor then the controller work as per the information given from color sensor and given instruction to the

weed control tool which is present behind and that robotic vehicle, tool moves to down position. if color sensor do not

Copyright to IJAREEIE

www.ijareeie.com

5075

ISSN (Print) : 2320 3765

ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 10, October 2013

senses the color of the weed then that weed control tool is in up position and save the energy, means if there is weed present

in between that two lines of crop then color sensors senses the color and then only weed cutting tool is in down position

otherwise weed cutting tool is in up position. The mechanism of that process consists of one weed cutting tool.

The weed control tool is inserted vertically in the land at particular depth, corresponding IR sensor get interrupted

and it sends signal to microcontroller through analog to digital converter. In case weed control tool is not inserted in land,

microcontroller get understand. There are two cases to sense the sensor asCase I: weed is present:

If any weed is present color sensor gets triggered automatically and fetches such instruction towards

microcontroller to turn the weed control tool in downward direction (as explained in section IV (B)if there is no any weed

is present in between to lines of crop then again the color sensor fetches such instruction towards microcontroller to turn the

weed control tool in upward direction processed it further.

Case II: Completion of crop firm:

If there is no any signal from both the side sensors then controller can understand that crop land is completed, it will

moves up to last end of the column. At that position, it tries to move 270 but cannot succeed and microcontroller

understand to move next columns and in reverse direction. Now it again check for case (I) and move away further. And it

repeatedly follows these two cases. When vehicle moves towards row per column, depending upon driver section of DC

motor revolution, the servo motor terns shaft with up and down position mechanism which obeys the instruction of servo

motor. The different distance is required for different weed cutting process, controlled by servo motor driver section.

Case III: Obstacle is present:

If any obstacle is present like hard rock in the way of vehicle, the infrared sensor gets triggered automatically and

fetches such instruction towards microcontroller and stop the robotic vehicle and obstacle is removed by the inspecting

person on again robotic vehicle is start further.

IV.

ROBOTIC SYSTEM

A robot is a mechanical and artificial agent. It is usually an electromechanical system, conveys a sense that it has

agency of its own. It is a device that automatically complicated task, because of software programming.

1.

Design of robotic vehicle:

In this project, for developing the structure of robotic agriculture machine, simple technique is used. As shown on

figure 2, it shows the designing of vehicle.

Copyright to IJAREEIE

www.ijareeie.com

5076

ISSN (Print) : 2320 3765

ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 10, October 2013

Figure 2: Designing of vehicle

It has four wheels which are individually driven and steered. These wheels drive respectively with two dc motor,

provides direct drive without gearing. Also there are two sliding bearings, respectively connect to the front wheel and body,

so that the front wheel can rotate between +45 0 or -450 around bearing. All dc motors are energized by dc supply through

microcontroller circuit. Color sensor sets at the front edge of vehicle for sensing color of the weed in the way of vehicle,

provides instruction to microcontroller for controlling motion of weed cutting tool through a servo motor. The weed control

tool is fitted at back side of assembly, shown in figure 2. It is used to cut the weed present between two columns of the crop

controlled by servo motor. At weed cutting section, a servo motor and an infrared sensor is used to put the weed control

tool in ground and check whether the tool is placed in ground or not by infrared sensor. If any error is detected in this

process like weed cutting tool is not dropped in land, battery backup problem etc., then it stars buzzer and shows the fault

on display board.

2.

Path controlling:

In agriculture environment heavy or loaded vehicle cant move easily on the bumpy road, so small vehicle is designed,

operates on dc motor, in this project. For controlling path of vehicle, it should be predefined as shown in figure 3.

Previously, the vehicle drives in straight line to first column and after end of ploughed land, the vehicle rotate 1800 and

select second column and proceed further. to maintain the robotic vehicle position in between the two lines of crop there are

two sensors that are senses the distance between the crop line and the edge of robot if the distance towards one of the side is

decreases then distance towards the other side increases then the vehicle slightly moves towards the distance increasing side

up to maintain the near about same distance towards both the side and then robot move in forward direction .To determine

instantaneous values of all motors, the analysis of rigid body velocity is used. During the translational motion the

longitudinal direction of all front two wheels are oriented identically with respect to vehicle body and both wheels spin at

same rate around their drive axes.

Figure 3: Path control mechanism

Copyright to IJAREEIE

www.ijareeie.com

5077

ISSN (Print) : 2320 3765

ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 10, October 2013

And during rotational motion longitudinal axis of each wheel is oriented at +450 or -450 with respect to orientation of

vehicle body.

The MATLAB is used for controlling, modeling and analysis of DC motor with the help of two conditions as feed

forward and feedback system.

Figure 4: Block diagram of DC motor

The equation of transfer function for controlling of DC motor is obtained by using block diagram representation as shown

in figure 4. The control inputs for the steering and driving motors are computed using feedback control system laws as

Where,

Gv (s) -closed loop gain

w (s) - angular velocity

V (s) - input voltage

V.

ALGORITHM IMPLEMENTATION

The algorithm for operating the robotic agriculture vehicle and whole system is implemented as

1.

2.

3.

4.

5.

6.

7.

8.

Start the machine.

Select the vertical distance in meter.

Display the distance between two crop lines and robot on LCD display board.

Check the whether the color sensor is on or off.

If it is off, buzzer will on and DC motor will off. If it is on, start the DC motor.

Vehicle starts to move in forward direction according to distance between crop lines.

While processing it, if the distance one of the side decreases than other side then move the robot towards other side

slightly and maintain the distance between crop line and robot towards both sides of the robot. Microcontroller gives

instruction to vehicle, goes straight way.

If the color sensor senses the color of weed present between the crop lines after completion of ploughed line, the

vehicle moves back by rotating 1800 towards right side. Again it will go to step no. 8 up to end of ploughed land.

Copyright to IJAREEIE

www.ijareeie.com

5078

ISSN (Print) : 2320 3765

ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 10, October 2013

VI.

EXPERIMENTAL RESULTS

A series of automated robot guidance tests in rowed ground nuts, jawar, wheat etc were conducted to validate the

performance of the developed steering-based automated system. Ten rows of above crop were planted using a one-row

planter in similar pattern. We tested following results as

1.

Speed of vehicle depending upon moisture:

The speed of vehicle is only depends upon moisture level of soil. We have taken different results to the speed of

vehicle as shown in figure 5. The red column shows the standard level of moisture for those seeds. The red column defines

the good performance with characteristics as explained bellow.

Figure 5: Graph shows speed depends on moisture

2.

Speed torque characteristics of DC motor:

The D.C. motor is operated on 12V with 60 rpm. The graph shows torque speed characteristics of D.C. motor to full

load. It is obtained by increasing armature voltage from 1V to 12V linearly. It is plotted in figure 6.

Figure 6: Graph of speed torque characteristics of dc motors

3.

D.C. motor speed analysis with and without feedback :

The graph shows two techniques for reducing sensitivity of angular velocity () to load variation i.e. change in torque

opposed by the motor load. The plot compares the closed loop bode diagram with its simulation when back e.m.f. constant

(Eb=0.085). The simulation of feed forward and feedback is represented as shown in figure 7.

Copyright to IJAREEIE

www.ijareeie.com

5079

ISSN (Print) : 2320 3765

ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 10, October 2013

Figure 7: comparison between feedforward, feedback at E b =0.085.

4. Green color intensity sensor:

The output of green color sensor is obtained by considering different shades and its intensity as shown in figure 8,

which shows as percentage of green color increases out of sensor is also vary accordingly.

Figure 8: Green color shades

The following table clears that, different values are shown on LCD display.

Table 1: results of color sensor

Sr. no

1

2

3

4

5

6

7

8

9

Copyright to IJAREEIE

Color

shade

percent

20

30

40

50

60

70

80

90

100

in

Output on

display

8-10

13-15

22-24

30-33

38-42

48-52

57-61

65-68

73-77

www.ijareeie.com

LCD

5080

ISSN (Print) : 2320 3765

ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 10, October 2013

5. Current and battery discharge time with and no load.

Table 2 shows Current consumed by DC motor and Microcontroller, servo motor, color sensor, IR sensor and

from that we can calculate the discharging time for battery with load and without load. Formula to calculate to

time for no load is

Discharge Time =

mAH current of battery / Total current consumed by circuit in mA.

No Of

Battery

(12V)

Current

(mA)

No

load

Current

(mA)

With

load

Microcontroller

current(mA)

Battery discharge

time with no load

(Hr)

Battery discharge

Time with load

(Hr)

930

1250

100

1.29

0.96

930

1250

100

2.58

1.92

930

1250

100

3.87

2.88

930

1250

100

5.16

3.84

Table 2: shows current and battery discharge time with load and no load

VII.

FUTURE IMPLEMENTATION

The system can be advanced for checking the moisture of farming land by moisture sensor and adjust the particular

amount of water in soil (i.e. moisture of soil) according to seed and its requirement. It can automatically increase the

moisture of soil in land, when providing water supply to this system. The system can further be modified to measuring

various parameter in farming like crop growth, weed prevalence, its type etc. Also, one or many system can be monitored

through GSM system.

VIII.

CONCLUSION

The paper has presented that the requirements and progress made towards achieving a future precision autonomous

farming system. The assembly is developed for weed control system in ploughed land automatically i.e. no man power

required. The project has consists of two different mechanism. The first mechanism contains making an assembly of vehicle

and its motion, where as second mechanism is cutting the weed in between to crop lines. The microcontroller is used to

control and monitoring the process of system motion of vehicle. It is controlled with help of DC motor and servo motor.

This system also detect obstacle present in path of the vehicle by infrared sensor. It is also used for sensing turning position

of vehicle at the end of land. Because of no man power requirement and high speed of operation, it has scope for further

expansion.

REFERENCES

[1] Simon Blackmore, Bill Stout, Maohua Wang, Boris Runov , Robotic agriculture The future of agriculture mechanism, Agro Technology, the royal veterinary and

agriculture university.2005.

[2] H. Pota, R. Eaton, J. Katupitiya, S.D. Pathirana, Agricultural robotics: A streamlined approach to realization of autonomous farming, Second international conference on

industrial and information system, IEEE.2007.

[3] R. Eaton, R. Eaton, J. Katupitiya, S.D. Pathirana, Autonomous farming: Modeling and control of agricultural machinery in a unified framework, 15th international

conference on mechatronics and machine vision in practice, New Zealand.2008.

[4] Chengliang Liu, Mingjun Wang, and Jun Zhou, Coordinating control for an agricultural vehicle with individual wheel speeds and steering angles, IEEE control systems

magazine.2008.

Copyright to IJAREEIE

www.ijareeie.com

5081

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Automatic Brake Failure Indicator and Over Heating AlarmDocument11 pagesAutomatic Brake Failure Indicator and Over Heating AlarmAakash SheelvantNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Automated Rope Climbing RobotDocument10 pagesAutomated Rope Climbing RobotAakash SheelvantNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Autonomous Cleaning RobotDocument4 pagesAutonomous Cleaning RobotAakash SheelvantNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Design and Development of "Suraksha"-A Women SafetyDocument9 pagesDesign and Development of "Suraksha"-A Women SafetyAakash SheelvantNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- S124-Solar Based Mobile Charger For Rural AreasDocument4 pagesS124-Solar Based Mobile Charger For Rural AreasYellaturi Siva Kishore ReddyNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Multiuser Short Message Service Based Wireless Electronic Notice BoardDocument7 pagesMultiuser Short Message Service Based Wireless Electronic Notice BoardPavanJangidNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- ATM Security Using Fingerprint RecognitionDocument6 pagesATM Security Using Fingerprint RecognitionAakash SheelvantNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Autonomous Indoor Helicopter Flight Using A Single Onboard CameraDocument8 pagesAutonomous Indoor Helicopter Flight Using A Single Onboard CameraAakash SheelvantNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Safety Block DiagramDocument1 pageSafety Block DiagramAakash SheelvantNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Rotary Inverted PendulumDocument2 pagesRotary Inverted PendulumDuvanJahirBetancourtNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Circular Motion MCQ PDFDocument13 pagesCircular Motion MCQ PDFGiriprasad GunalanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Vectors and The Geometry of SpaceDocument81 pagesVectors and The Geometry of Spaceayesha noorNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- CentrifugationDocument21 pagesCentrifugationbrillyyudoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Revised Article-NiharikaDocument8 pagesRevised Article-NiharikaNiharika AgrNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Block Diagrams: Modeling and SimulationDocument48 pagesBlock Diagrams: Modeling and SimulationAbel CabaNo ratings yet

- The Feynman Lectures On Physics Vol. II CH PDFDocument14 pagesThe Feynman Lectures On Physics Vol. II CH PDFmanoj27081982No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Simple Harmonic Motion: Section ADocument53 pagesSimple Harmonic Motion: Section AAyush SrivastavNo ratings yet

- 1 - Design and Analysis of Impeller Blade For Axial Flow PumpsDocument31 pages1 - Design and Analysis of Impeller Blade For Axial Flow PumpsmghgolNo ratings yet

- 03 Gyroscopic CoupleDocument30 pages03 Gyroscopic CoupleSagar NeupaneNo ratings yet

- Technical Report (Manual) : FANUC Series 16i/18i-MA/TA Bidirectional Pitch Error Compensation FunctionDocument12 pagesTechnical Report (Manual) : FANUC Series 16i/18i-MA/TA Bidirectional Pitch Error Compensation Functionferjani ahmedNo ratings yet

- (Template) S5-2ND-TEST SERIES-2021-22-P.EDocument13 pages(Template) S5-2ND-TEST SERIES-2021-22-P.EcrazymindNo ratings yet

- Kinematics of Machinery (EME 202) CamsDocument25 pagesKinematics of Machinery (EME 202) Camshitaishi5599No ratings yet

- CircularMotion PCDocument18 pagesCircularMotion PCAaryan KeshanNo ratings yet

- Equations of Motion For A Single Degree-Of-Freedom SystemDocument42 pagesEquations of Motion For A Single Degree-Of-Freedom SystemFernanda LagoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Phenomena and Exploration Associated With The Solar SystemDocument25 pagesPhenomena and Exploration Associated With The Solar SystemDamithu DinlakaNo ratings yet

- Final General Awareness Capsule For SSC 2017 CGLDocument122 pagesFinal General Awareness Capsule For SSC 2017 CGLPupinder SinghNo ratings yet

- Axial FlowDocument13 pagesAxial FlowArivanandan Get GoingNo ratings yet

- Sub Code: ME8292 Sub Name: Engineering Mechanics Max - Marks:100 Duration: 3 Hrs Branch: Mechanical Engg. Year/Sem: I / II Answer All QuestionsDocument3 pagesSub Code: ME8292 Sub Name: Engineering Mechanics Max - Marks:100 Duration: 3 Hrs Branch: Mechanical Engg. Year/Sem: I / II Answer All QuestionssivashanmugamNo ratings yet

- TOMDocument21 pagesTOMHarikrishna ShenoyNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 005 Radex-N Rigiflex-N enDocument0 pages005 Radex-N Rigiflex-N enChevronelleNo ratings yet

- Operator Manual Hartrol M7200Document73 pagesOperator Manual Hartrol M7200Leonardo Borges100% (3)

- Reaction Wheel NoiseDocument17 pagesReaction Wheel NoisePedro JuradoNo ratings yet

- MotionManager Animation SolidworksDocument38 pagesMotionManager Animation SolidworksSudeep Rkp0% (1)

- Drag of A Disk Rotating in A Viscous FluidDocument50 pagesDrag of A Disk Rotating in A Viscous FluidBaptiste RéaudNo ratings yet

- Donald A. Neumann-Kinesiology of The Musculoskeletal SystemDocument607 pagesDonald A. Neumann-Kinesiology of The Musculoskeletal SystemLuciano Klapisch81% (16)

- CN PHY Vector (L) PDFDocument39 pagesCN PHY Vector (L) PDFPaathshala Education ITNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Math Ia PDFDocument12 pagesMath Ia PDFShreyasSNo ratings yet

- Investigations On Fluid Friction of Rotational Disks With Andwithout Modified Outlet Sections in Real Centrifugal Pump CasingsDocument9 pagesInvestigations On Fluid Friction of Rotational Disks With Andwithout Modified Outlet Sections in Real Centrifugal Pump CasingsAmanda KellyNo ratings yet

- Ballistic Target Flight Trajectory Simulation (A Matlab Program)Document14 pagesBallistic Target Flight Trajectory Simulation (A Matlab Program)Marcelo MartinezNo ratings yet